Abstract

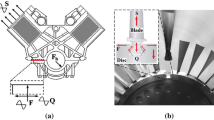

This paper presents the effects of surface finish and treatment on the high cycle fatigue behaviour of vibrating cylinder block of a new two-stroke free piston engine at complex variable amplitude loading conditions using frequency response approach. Finite element modelling and frequency response analysis was conducted using finite element analysis software Package MSC.PATRAN/MSC.NASTRAN and fatigue life prediction was carried out using MSC.FATIGUE software. Based on the finite element results, different frequency response approach was applied to predict the cylinder block fatigue life. Results for different load histories and material combinations are also discussed. Results indicated great effects for all surface finish and treatment. It is concluded that polished and cast surface finish conditions give the highest and lowest cylinder block lives, respectively; and that Nitrided treatment leads to longest cylinder block life. The results were used to draw contour plots of fatigue life and damage in the worst or most damaging case.

Similar content being viewed by others

References

Altenberger, I., Scholtes, B., Martin, U., Oettel, H., 1999. Cyclic deformation and near surface microstructures of shot peened or deep rolled austenitic stainless steel AISI 304. Materials Science and Engineering, A264:1–16.

Anthes, R.J., 1997. Modified rainflow counting keeping the load sequences. Int. J. Fatigue, 19(7):529–35. [doi: 10.1016/S0142-1123(97)00078-9]

Bannantine, S.A., Comer, J.J., Handrock, J.L., 1990. Fundamentals of Metal Fatigue Analysis. Prentice-Hall, New Jersey, USA.

Bell, T., Mao, K., Sun, Y., 1998. Surface engineering design: modelling surface engineering systems for improved tribological performance. Surface and Coatings Technology, 108–109(1–3):360–368. [doi: 10.1016/S0257-8972(98)00623-9]

Bendat, J.S., 1964. Probability Functions for Random Responses. NASA Report on Contract NASA-5-4590.

Bishop, N.W.M., 1988. The Use of Frequency Domain Parameters to Predict Structural Fatigue. Ph.D Thesis, Warwick University, UK.

Bishop, N.W.M., Sherratt, F., 1989. Fatigue life prediction from power spectral density data. Part-1, Traditional approaches and part-2 recent developments. Environmental Engineering, 2:11–19.

Bishop, N.W.M., Hu, Z.H., 1991. The Fatigue Analysis of Wind Turbine Blades Using Frequency Domain Techniques. European Wind Energy Conference (EWEC’91), Amsterdam, p.246–250.

Bishop, N.W.M., Sherratt, F., 2000. Finite Element Based Fatigue Calculations. NAFEMS Ltd., UK.

Chaudhury, G.K., Dover, W.D., 1985. Fatigue analysis of offshore platforms subject to sea wave loading. Int. J. Fatigue, 7(1):13–19. [doi: 10.1016/0142-1123(85)90003-9]

Dirlik, T., 1985. Application of Computers in Fatigue Analysis. Ph.D Thesis, University of Warwick, UK.

Harada, Y., Mon, K., 2005. Effect of processing temperature on warm shot peening of spring steel. Journal of Materials Processing Technology, 162–163:498–503. [doi: 10.1016/j.jmatprotec.2005.02.095]

Hassan, A.M., Momani, A.M.S., 2000. Further improvements in some properties of shot peened components using the burnishing process. Int. J. Machine Tools and Manufacture, 40(12):1775–1786. [doi: 10.1016/S0890-6955(00)00018-3]

Juvinall, R.C., Marshek, K.M., 1991. Fundamentals of Machine Component Design. John Willey and Sons, New York, USA.

Kam, J.C.P., Dover, W.D., 1988. Fast Fatigue Assessment Procedure for Offshore Structures under Random Stress History. Proc. Institute of Civil Engineers, Part 2, 85:689–700.

Khosrovaneh, A.K., Downing, N.E., 1990. Fatigue loading history reconstruction based on rainflow technique. Int. J. Fatigue, 12(2):99–106. [doi: 10.1016/0142-1123(90)90679-9]

Koster, W.P., Field, M., 1973. Effects of Machining Variables on the Surface and Structural Integrity of Titanium. Proceedings of the North American Manufacturing Research Conference, SME, 2:67–87.

Lipson, C., Juvinall, R.C., 1963. Handbook of Stress and Strength—Design and Material Applications. Macmillan & Co., New York, USA.

Martin, U., Altenberger, I., Scholtes, B., Kremmer, K., Oettel, H., 1998. Cyclic deformation and near microstructures of normalized shot peened steel SAE 1045. Materials Science and Engineering, A246:69–80.

MSC, 2004. MSC/FATIGUE User’s Guide. MSC Software Corporation, USA.

Novovic, D., Dewes, R.C., Aspinwall, D.K., Voice, W., Bowen, P., 2004. The effect of machined topology and integrity on fatigue life. Int. J. Machine Tools & Manufacture, 44(2–3):125–134. [doi: 10.1016/j.ijmachtools.2003.10.018]

Rahman, M.M., Ariffin, A.K., Jamaluddin, N., Haron, C.H.C., 2005. Vibration Fatigue Analysis of Linear Generator Engine Using Frequency Response Approach. Proc. of the National Seminar on Advances in Malaysian Noise, Vibration and Comfort 2005 (NVC-2005), ESSET, Bangi, Malaysia, p.277–286.

Reemsnyder, H.S., 1985. Simplified Stress-life Model. Bethleham Steel Corporation Report, Bethleham, PA.

Rice, S.O., 1954. Mathematical Analysis of Random Noise. Selected Papers on Noise and Stochastic Processes. Dover, New York.

Rodopoulos, C.A., Curtis, S.A., de Los Rios, E.R., SolisRomero, J., 2004. Optimisation of the fatigue resistance of 2024-T351 aluminum alloys by controlled shot peening—Methodology, results and analysis. Int. J. Fatigue, 26(8):849–856. [doi: 10.1016/j.ijfatigue.2004.01.003]

Schaeffer, H.G., 2001. MSC NASTRAN Primer for Linear Analysis. MSC Software Corporation, USA.

Sidhom, N., Laamouri, A., Fathallah, R., Lieurade, H.P., 2005. Fatigue strength improvement of 5083 H 11 Al-alloy T-weld joints by shot peening: experimental characterization and predictive approach. Int. J. Fatigue, 27(7):729–745. [doi: 10.1016/j.ijfatigue.2005.02.001]

Stephens, R.I., Fatemi, A., Stephens, R.R., Fuchs, H.O., 2001. Metal Fatigue in Engineering. John Wiley and Sons, Inc., USA.

Torres, M.A.S., Voorwald, H.J.C., 2002. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue, 24(8):877–886. [doi: 10.1016/S0142-1123(01)00205-5]

Tunna, J.M., 1986. Fatigue life prediction for Gaussian random loads at the design stage. Fatigue Fracture Engineering, Mat. Structure, 9(3):169–184.

Wirsching, P.H., Light, M.C., 1980. Fatigue under wide band random loading. Journal of Structural Div., ASCE, 106(7):1593–1607.

Author information

Authors and Affiliations

Additional information

Project (No. 03-02-02-0056 PR0025/04-03) supported by Ministry of Science, Technology and Innovation, Malaysia

Rights and permissions

About this article

Cite this article

Rahman, M.M., Ariffin, A.K. Effects of surface finish and treatment on the fatigue behaviour of vibrating cylinder block using frequency response approach. J. Zhejiang Univ. - Sci. A 7, 352–360 (2006). https://doi.org/10.1631/jzus.2006.A0352

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.2006.A0352