Abstract

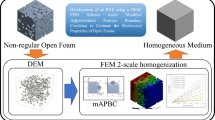

Foamed concretes are highly porous materials with excellent insulation properties. Their thermal conductivity is strongly dependent on the pore structure, characterized by the porosity as well as the shape and size distribution of pores. To define the representative volume element (RVE) of foamed concretes with high fidelity, we develop NRGene, an automatic generator of cubic samples with spherical air inclusions whose number and size obey a given distribution. We compute the effective thermal conductivity tensor for a given RVE using finite-element-based computational homogenization. The hi-fi RVE of foamed concretes may contain hundreds of millions of finite elements, making it better suited for benchmarking than for everyday engineering applications. Then, having the hi-fi model as benchmark, we propose a simplified model consisting of the hi-fi model called with a truncated histogram as input, which is largely cheaper while keeping a satisfactory accuracy. We model 21 different foamed concretes with a wide range of porosities and different compositions of the cement paste. Further, we demonstrate that it is the volume of all the pores of a given size, and not its quantity, what affects the effective thermal conductivity of foamed concretes.

Similar content being viewed by others

References

Aldridge D (2005) Introduction to foamed concrete: What, why, how? In Ravindra K. Dhir, Moray D. Newlands, and Aikaterini McCarthy, editors, Proceedings of the international conference on the use of foamed concrete in construction. University of Dundee, Scotland, UK, Institution of Civil Engineers (ICE), Jul https://doi.org/10.1680/uofcic.34068.0001. pp 1–14

Bindiganavile V, Hoseini M (2019) Foamed concrete. Developments in the formulation and reinforcement of concrete, 2nd edn. Elsevier, pp 365–390

ACI Committee 523 (1996) ACI 523.2R-96: Guide for precast cellular concrete floor, roof, and wall units. American Concrete Institute (ACI)

ACI Committee 523 (2006) ACI 523.1R-06: Guide for cast-in-place low-density cellular concrete. American Concrete Institute (ACI)

Batool F, Bindiganavile V (2017) Air-void size distribution of cement based foam and its effect on thermal conductivity. Constr Build Mater 149:17–28. https://doi.org/10.1016/j.conbuildmat.2017.05.114

Jones MR, McCarthy A (2005) Behaviour and assessment of foamed concrete for construction applications. In Ravindra K. Dhir, Moray D. Newlands, and Aikaterini McCarthy (eds) Proceedings of the international conference on the use of foamed concrete in construction. University of Dundee, Scotland, UK, Institution of Civil Engineers (ICE), July. https://doi.org/10.1680/uofcic.34068.0008. pp 61–88

Kearsley EP, Mostert HF (2005) Opportunities for expanding the use of foamed concrete in the construction industry. In: Ravindra K. Dhir, Moray D. Newlands, and Aikaterini McCarthy (eds) Proceedings of the international conference on the use of foamed concrete in construction. University of Dundee, Scotland, UK, Institution of Civil Engineers (ICE), July https://doi.org/10.1680/uofcic.34068.0015. pp 143–154

European Commission. Integrated porous cementitious nanocomposites in non-residential building envelopes for green active/passive energy STORAGE, grant agreement 870114. URL https://cordis.europa.eu/project/id/870114

Koenders E, Mankel C, Caggiano A (2022) Hybridwerkstoff für Wärmedämmung, Deutsches Patent- und Markenamt, DE102020134308A1

Gołaszewski J, Klemczak B, Smolana A, Gołaszewska M, Cygan G, Mankel C, Peralta I, Röser F, Koenders EAB (2022) Effect of foaming agent, binder and density on the compressive strength and thermal conductivity of ultra-light foam concrete. Buildings 12(8):1176. https://doi.org/10.3390/buildings12081176

Gilka-Bötzow A, Röser F, Koenders EAB (2015) Mineral foam in energy active buildings. In International conference on the regeneration and conservation of concrete structures, Nagasaki, Japan, Japan Concrete Institute. https://doi.org/10.13140/RG.2.1.4871.6966

Pisello AL, Cotana F, Nicolini A, Buratti C (2014) Effect of dynamic characteristics of building envelope on thermal-energy performance in winter conditions: In field experiment. Energy Build 80:218–230. https://doi.org/10.1016/j.enbuild.2014.05.017

Maxwell JC (1873) A treatise on electricity and magnetism. Clarendon Press

Fang X-Q (2009) Scattering of thermal waves and non-steady effective thermal conductivity of composites with coated particles. Appl Therm Eng 29(5–6):925–931. https://doi.org/10.1016/j.applthermaleng.2008.04.020

Singh R (2008) Thermal conduction through porous systems. Wiley-VCH, Weinheim, pp 199–238

Kunhanandan Nambiar EK, Ramamurthy K (2007) Air-void characterisation of foam concrete. Cem Concr Res 37(2):221–230. https://doi.org/10.1016/j.cemconres.2006.10.009

Batool F (2015) Effect of microstructure on thermal conductivity of cement-based foam. PhD thesis, Department of Civil and Environmental Engineering, University of Alberta (Canada)

Kearsley E, Visagie M (2002) Properties of foamed concrete as influenced by air-void parameters. Concr Beton 101:9–12

Wei S, Yiqiang C, Yunsheng Z, Jones MR (2013) Characterization and simulation of microstructure and thermal properties of foamed concrete. Constr Build Mater 47:1278–1291. https://doi.org/10.1016/j.conbuildmat.2013.06.027

Aligizaki KK (2006) Pore structure of cement-based materials. CRC Press, Boco Raton

Bruggeman DAG (1935) Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann Phys 416(7):636–664. https://doi.org/10.1002/andp.19354160705

Lewis TB, Nielsen LE (1968) Viscosity of dispersed and aggregated suspensions of spheres. Trans Soc Rheol 12(3):421–443. https://doi.org/10.1122/1.549114

Nielsen LE (1974) The thermal and electrical conductivity of two-phase systems. Indus Eng Chem Fundam 13(1):17–20. https://doi.org/10.1021/i160049a004

Miled K, Limam O (2016) Effective thermal conductivity of foam concretes: Homogenization schemes vs experimental data and FEM simulations. Mech Res Commun 76:96–100. https://doi.org/10.1016/j.mechrescom.2016.07.004

Keskin RSO, Hover KC, Grigoriu M (2011) Size effects in modeling diffusivity of hardened mortar. Comput Struct 89(9–10):713–723. https://doi.org/10.1016/j.compstruc.2011.02.018

Caggiano A, Said Schicchi D, Mankel C, Ukrainczyk N, Koenders EAB (2018) A mesoscale approach for modeling capillary water absorption and transport phenomena in cementitious materials. Comput Struct 200:1–10. https://doi.org/10.1016/j.compstruc.2018.01.013

Xu WX, Chen HS (2013) Numerical investigation of effect of particle shape and particle size distribution on fresh cement paste microstructure via random sequential packing of dodecahedral cement particles. Comput Struct 114–115:35–45. https://doi.org/10.1016/j.compstruc.2012.10.009

Liu L, Shen D, Chen H, Xu W (2014) Aggregate shape effect on the diffusivity of mortar: a 3D numerical investigation by random packing models of ellipsoidal particles and of convex polyhedral particles. Comput Struct 144:40–51. https://doi.org/10.1016/j.compstruc.2014.07.022

Bailakanavar M, Liu Y, Fish J, Zheng Y (2012) Automated modeling of random inclusion composites. Eng Comput 30(4):609–625. https://doi.org/10.1007/s00366-012-0310-x

Schneider K, Klusemann B, Bargmann S (2016) Automatic three-dimensional geometry and mesh generation of periodic representative volume elements for matrix-inclusion composites. Adv Eng Softw 99:177–188. https://doi.org/10.1016/j.advengsoft.2016.06.001

Schneider K, Klusemann B, Bargmann S (2017) Fully periodic RVEs for technological relevant composites: Not worth the effort! J Mech Mater Struct 12(4):471–484. https://doi.org/10.2140/jomms.2017.12.471

Yvonnet J (2019) Computational homogenization of heterogeneous materials with finite elements. Springer, Cham

Matlab Statistics and Machine Learning Toolbox - User’s guide. The MathWorks, Inc., Natick, MA, USA, R2022B edition, (2022a)

Bentley JL (1975) Multidimensional binary search trees used for associative searching. Commun ACM 18(9):509–517. https://doi.org/10.1145/361002.361007

Batool F, Bindiganavile V (2018) Quantification of factors influencing the thermal conductivity of cement-based foam. Cement Concr Compos 91:76–86. https://doi.org/10.1016/j.cemconcomp.2018.04.015

Othuman Mydin MA, Wang YC (2011) Elevated-temperature thermal properties of lightweight foamed concrete. Constr Build Mater 25(2):705–716. https://doi.org/10.1016/j.conbuildmat.2010.07.016

Othuman Mydin MA, Wang YC (2012) Thermal and mechanical properties of lightweight foamed concrete at elevated temperatures. Mag Concr Res 64(3):213–224. https://doi.org/10.1680/macr.10.00162

Loeb AL (1954) Thermal conductivity: VIII, a theory of thermal conductivity of porous materials. J Am Ceram Soc 37(2):96–99. https://doi.org/10.1111/j.1551-2916.1954.tb20107.x

Kelley CT (1995) Iterative methods for linear and nonlinear equations. Soc Indus Appl Math. https://doi.org/10.1137/1.9781611970944

Mathematics Matlab (2022) The MathWorks Inc, R2022B edn. Natick, MA, USA

Toro S, Sánchez PJ, Huespe AE, Giusti SM, Blanco PJ, Feijóo RA (2014) A two-scale failure model for heterogeneous materials: Numerical implementation based on the finite element method. Int J Numer Meth Eng 97(5):313–351. https://doi.org/10.1002/nme.4576

Cebeci ÖZ (1981) Pore structure of air-entrained hardened cement paste. Cem Concr Res 11(2):257–265. https://doi.org/10.1016/0008-8846(81)90067-3

Grafarend EW (2006) Linear and nonlinear models. Walter de Gruyter, Berlin

Kamseu E, Nait-Ali B, Bignozzi MC, Leonelli C, Rossignol S, Smith DS (2012) Bulk composition and microstructure dependence of effective thermal conductivity of porous inorganic polymer cements. J Eur Ceram Soc 32(8):1593–1603. https://doi.org/10.1016/j.jeurceramsoc.2011.12.030

Kamseu E, Ngouloure Zénabou NM, Benoît Nait Ali S, Melo Zekeng UC, Rossignol S, Leonelli C (2015) Cumulative pore volume, pore size distribution and phases percolation in porous inorganic polymer composites: Relation microstructure and effective thermal conductivity. Energy Build 88:45–56. https://doi.org/10.1016/j.enbuild.2014.11.066

Wang M, Pan N (2008) Modeling and prediction of the effective thermal conductivity of random open-cell porous foams. Int J Heat Mass Transf 51(5–6):1325–1331. https://doi.org/10.1016/j.ijheatmasstransfer.2007.11.031

Pathan MV, Tagarielli VL, Patsias S, Baiz-Villafranca PM (2017) A new algorithm to generate representative volume elements of composites with cylindrical or spherical fillers. Compos B Eng 110:267–278. https://doi.org/10.1016/j.compositesb.2016.10.078

Wyrwal J, Marynowicz A, Swirska J (2008) Effective thermal conductivity of porous building materials—analysis and verification. Bauphysik 30(6):431–433. https://doi.org/10.1002/bapi.200810056

Han K, Clark SM (2021) Review of calculating the electrical conductivity of mineral aggregates from constituent conductivities. Solid Earth Sci. https://doi.org/10.1016/j.sesci.2021.02.003

Eucken A (1940) Allgemeine Gesetzmäßigkeiten für das Wärmeleitvermögen verschiedener Stoffarten und Aggregatzustände. Forschung auf dem Gebiete des Ingenieurwesens 11(1):6–20. https://doi.org/10.1007/bf02584103

Collishaw PG, Evans JRG (1994) An assessment of expressions for the apparent thermal conductivity of cellular materials. J Mater Sci 29(2):486–498. https://doi.org/10.1007/bf01162512

Pal R (2008) On the Lewis-Nielsen model for thermal/electrical conductivity of composites. Compos A Appl Sci Manuf 39(5):718–726. https://doi.org/10.1016/j.compositesa.2008.02.008

Hashin Z, Shtrikman S (1962) A variational approach to the theory of the effective magnetic permeability of multiphase materials. J Appl Phys 33(10):3125–3131. https://doi.org/10.1063/1.1728579

Landauer R (1952) The electrical resistance of binary metallic mixtures. J Appl Phys 23(7):779–784. https://doi.org/10.1063/1.1702301

Pietrak K, Wiśniewski T (2015) A review of models for effective thermal conductivity of composite materials. J Power Technol 95(1):14–24

Lewis TB, Nielsen LE (1970) Dynamic mechanical properties of particulate-filled composites. J Appl Polym Sci 14(6):1449–1471. https://doi.org/10.1002/app.1970.070140604

Acknowledgements

The authors gratefully acknowledge the financial support from: the European Commission through the project “NRG-STORAGE: Integrated porous cementitious Nanocomposites in non-Residential building envelopes for Green active/passive energy STORAGE” (grant agreement 870114) [8], the National Agency for the Promotion of Research, Technological Development and Innovation (AGENCIA) of Argentina through the projects “Computational design of metamaterials applied to the development of thermal diodes for building envelopes” (PICT 2020 Serie A 03765) and “Optimization of the thermal performance of building envelopes” (PICT 2020 Serie A 01032), the National Scientific and Technical Research Council (CONICET) of Argentina through the project “Computational design of functional thermal metamaterials in transient regime taking advantage of phase changes” (PIP 2021-23-GI), the National Technological University (UTN) of Argentina through the project “Computational design of metamaterials” (PID MAUTNFE0007745), the National University of the Littoral (UNL) of Argentina through the project “Computational design and optimization of envelopes to improve the energy efficiency of buildings in the Littoral region” (CAI+D 2020 50620190100141LI).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix I: Scheme of the mesh generation algorithm

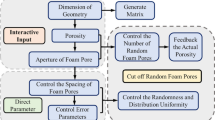

To generate the voxelized RVE of a foamed concrete, NRGene takes the histogram \(H=\{D_1,n_1,\dots ,D_Q,n_Q\}\) (with \(D_q<D_{q+1}\)) and the porosity p as input data. The user-defined mesh generation setup includes the initial guess \(V_\text {\tiny {RVE}}^{(0)}\) for the RVE volume, the porosity tolerance \(\varepsilon _\text {por}\), the refinement parameter \(n_\text {ref}\) (ratio between the minimum pore size \(D_1\) and the maximum voxel size \(h_\text {max}\)), free or forced periodicity (\(\text {PER}=0\) or \(\text {PER}=1\), respectively), and to free or control the pore volume loss (\(\text {PVL}=0\) or \(\text {PVL}=1\), respectively). In case \(\text {PVL}=1\), the tolerance \(\varepsilon _\text {\tiny {PVL}}\) and the maximum number of tries \(n_\text {\tiny {PVL}}\) are also needed; note that \(\text {PVL}=0\) is implied by adopting \(\varepsilon _\text {\tiny {PVL}}=\infty \).

The full procedure is summarized below.

Appendix II: Static condensation

Following Toro et al. [41], we use the static condensation technique to convert the semi-definite system (26) into an equivalent but positive definite system. To this end, let us firt identify all the couples \(({\textbf{x}}_\alpha ,{\textbf{x}}_\beta )\) of opposite boundary nodes in the finite element mesh of the RVE. Then, let us order the indices \(\alpha \) and \(\beta \) in the sets \({\mathcal {M}}\) and \({\mathcal {S}}\) of indices of the “master” and “slave” boundary nodes, respectively. Either \({\mathcal {M}}\) or \({\mathcal {S}}\) or both have repeated indices, but one can manage to order the indices in such a way that one of these sets has no repeated indices; let \({\mathcal {M}}\) be such set. Being \({\mathcal {M}}\cup {\mathcal {S}}\) the set of indices of the boundary nodes, let \({\mathcal {I}}\) be the set of \(N_\text {int}\) indices of those nodes strictly inside the RVE. Further, master and interior nodes are the “free” nodes, whose indices are grouped in the set \({\mathcal {F}}\) with dimension \(N_\text {free}=N_\text {int}+N_\text {con}\).

Then, the semi-definite linear algebraic system (26), that is

is rewritten as

where \({\textbf{K}}_{{\mathcal {F}}{\mathcal {F}}}\) is the \(N_\text {free}\times N_\text {free}\)-matrix whose ij component is \(K_{{\mathcal {F}}_i {\mathcal {F}}_j}\), \({\textbf{K}}_{{\mathcal {F}}{\mathcal {S}}}\) is the \(N_\text {free}\times N_\text {con}\)-matrix whose ij component is \(K_{{\mathcal {F}}_i {\mathcal {S}}_j}\), \({\textbf{K}}_{{\mathcal {S}}{\mathcal {S}}}\) is the \(N_\text {con}\times N_\text {con}\)-matrix whose ij component is \(K_{{\mathcal {S}}_i {\mathcal {S}}_j}\), \({\textbf{T}}_{\mathcal {F}}\) is the unknown \(N_\text {free}\times 1\)-vector with components \(T_{{\mathcal {F}}_i}\), and \({\textbf{T}}_{\mathcal {S}}\) is the \(N_\text {con}\times 1\)-vector with components \(T_{{\mathcal {S}}_i}\), \({\mathcal {F}}_i\) and \({\mathcal {S}}_i\) denoting the i-th entry of the sets \({\mathcal {F}}\) and \({\mathcal {S}}\), respectively. The vector \({\textbf{T}}_{\mathcal {S}}\) is defined by the linear equality constraints (23) as

where \({\textbf{C}}_{{\mathcal {S}}{\mathcal {F}}}\) is the highly sparse \(N_\text {con}\times N_\text {free}\)-matrix with components

With \({\textbf{T}}_{\mathcal {S}}\) defined by the Eq. (37), the FEM heat conduction Eqs. (35) and (36) take the form

Finally, premultiplying both sides of the last Eq. by \({\textbf{C}}_{{\mathcal {S}}{\mathcal {F}}}^T\) and summing the resulting equation to Eq. (39), we arrive to the statically condensed version of the localization problem:

with

Now, \({\textbf{K}}^*\) exhibits the valuable properties of symmetry and positive definiteness.

Once determined \({\textbf{T}}_{\mathcal {F}}\) after solving Eq. (41) and \({\textbf{T}}_{\mathcal {S}}\) by Eq. (37), and knowing the respective sets of indices \({\mathcal {F}}\) and \({\mathcal {S}}\), it is straightforward to build the original nodal vector \({\textbf{T}}\).

Appendix III: Material data for the modeled foamed concretes

All the foamed concretes modeled in this work were produced by Batool in the framework of her PhD thesis [17]. The reference foamed concrete Ref-\(\rho \) (with \(\rho =\) 400, 600 or 800 referring to the cast density in kg/m\(^3\)) was prepared by adding a pre-formed foam produced by a synthetic foaming agent to a slurry made of HE-type Portland cement with 0.69 water-to-cement ratio. The foamed concretes labeled FA10-\(\rho \), SF10-\(\rho \), and MK10-\(\rho \) were prepared in a similar way as Ref-\(\rho \) except for the use of fly ash (FA), silica fume (SF) or metakaolin (MK) to replace 10% in mass fraction of Portland cement; this fraction increases to 20% for FA20-\(\rho \), SF20-\(\rho \), and MK20-\(\rho \).

For each one of these foams, the thermal conductivity of the solid phase is assumed to be equal to that of the corresponding hardened cement paste at the hydration age of 300 days, listed in Table 1.

Finally, Figs. 14, 15, 16 and 17 show the porosity and pore size distribution for all the modeled concrete foams.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fachinotti, V.D., Peralta, I., Toro, S. et al. Automatic generation of high-fidelity representative volume elements and computational homogenization for the determination of thermal conductivity in foamed concretes. Mater Struct 56, 179 (2023). https://doi.org/10.1617/s11527-023-02253-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-023-02253-2