Abstract

The sorption of superabsorbent polymers (SAP) and kinetics of the process can differ significantly depending on SAP composition and grading as well as on properties of sorbed fluid. Several performance-oriented testing methods of SAP have been proposed in the literature to determine the individual sorption of polymers and to link them with their effects when embedded in cementitious materials as a multifunctional admixture. This recommendation focuses on the two main sorption capacity testing methods of free sorption assessment, the tea-bag and filtration methods. It includes experimental prescriptions to obtain consistent results and to draw conclusions as to whether or not a particular SAP is suitable for a cementitious material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 General provisions

1.1 Scope of this recommendation

This recommendation focuses on the testing of superabsorbent polymers (SAP) for their free sorption capacity and kinetics when exposed to ionic liquids relevant to cement-based construction materials, i.e., their pore solutions. They function as pre-tests in screening SAP samples for their potential use as multifunctional admixtures in such binder systems.

1.2 Definition of terms

Superabsorbent polymers (SAP) are cross-linked polyelectrolytes which swell upon contact with water or aqueous solutions, so resulting in formation of a hydrogel.

Free sorption describes the inherent ability of a SAP to absorb a liquid (by forming a hydrogel) and potentially desorb it (in part or in full). While sorption kinetics describe the progressive evolution of ad-, ab- and de-sorption, the sorption capacity represents the long-term equilibrium amount of absorbed liquid. Free sorption occurs without external forces, including spatial confinement, applied pressure, or marked varying of ionic composition. Both the sorption kinetics and the sorption capacity of a SAP (or hydrogel, respectively) are influenced by surrounding conditions. Hence, absorbency under pressure or sorption inside a cement-based matrix may differ from free sorption behaviour by absolute times or storage ability. Free sorption test results disclose qualitative trends among a group of SAP samples but cannot mirror the exact characteristics of each individual chemical substance absolutely.

Cement filtrate solution is the mixture of cement with water subsequently filtered after a given amount of time. The filtrate is used as a test fluid. Another possibility is the use of a synthetic pore solution, where the cement pore liquid is simulated, especially in terms of ionic concentrations and composition.

Tea-bag method is a method using a saturated tea-bag filled with SAP and immersed in a certain pre-described fluid. At regular time intervals, the tea-bag is weighed. In this way the kinetics and sorption capacity in the respective liquid is determined gravimetrically.

Filtration method is a method to determine the sorption kinetics and sorption capacity after filtration of a cup filled with a certain amount of initially dry and freely swellable SAP particles and a certain mass of fluid. By aligning the results of filtration setups at different sorption times, the swelling kinetics and capacity of the SAP sample in the respective fluid is obtained.

1.3 Sorption capacity of superabsorbent polymers: background and motivation

Significant interest in superabsorbent polymers (SAP) as a class of chemical admixtures for concrete has arisen due to their multiple functionalities [1]. Applications of SAP include modifying the rheology [2], mitigation of plastic and autogenous shrinkage [1, 3], improvement of freeze/thaw resistance [4], self-sealing [5], and self-healing of cement-based construction materials [6, 7]. The sorption kinetics as well as the short- and long-term storage capacities of a SAP are of crucial importance as an indication of its effect on cementitious material. Full-scale concrete tests are not necessary at first to establish whether a SAP is potentially useful as a multipurpose admixture in a cement-based construction material. Although non-invasive imaging methods (X-ray or neutron imaging [8]) or polished sections microscopy [9] can provide exact data on absorption and/or desorption behaviour, these techniques are time consuming and require specialised experimental setups as well as highly qualified personnel. Accordingly, practical, simple pre-tests have been developed to assess the principal suitability of SAP. The purpose of this document is to summarise two highly important pre-tests to obtain an initial indication of their features and individual behaviours.

This recommendation is written to further SAP technology by showing practitioners and researchers which and how simple pre-tests on SAP samples can disclose fundamental hints towards their effects and performance in the cement-based construction materials. Statements independent of a particular choice of raw materials, laboratory equipment and local staff can be obtained. This was demonstrated by a round-robin test performed by RILEM TC 260-RSC [10].

2 Main tests to characterize the sorption capacity of SAP

2.1 General rules

Two main tests for SAP to be used in cement-based materials are discussed in the following sections. The absolute sorption values determined by free sorption tests should not be directly implemented in concrete mix design. Their progressive development, desorption after primary sorption or long-term storage, however, gives a qualitative, matching indication of their actual sorption kinetics in the cement matrix and their resulting efficiency for the intended applications.

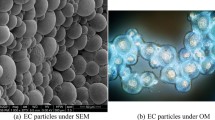

Several types of SAP are currently available. They differ with respect to each other in their chemical composition, their production, and in their particle size, shape, and absorption/desorption properties. The particles’ sizes in dry state should be measured by means of optical microscopy or laser light diffraction-based methods. Alternatively, sieving can be applied using metal-mesh sieves. Thereby it is of uttermost importance to pay attention to the absence of any trace of water to allow smooth processing. Cleaning of the sieves should avoid water as well, and an air jet stream is recommended to insure the absence of water.

The SAP samples should at all times be stored in sealed containers or bags to minimize contact with moisture. They should not be placed in direct sunlight since UV-light may change their properties. Before placing them in containers, they should be acclimatised at < 60% RH and (20 ± 2) °C until their mass remains constant. The test itself is conducted at the standard laboratory conditions, whereby the relative humidity should be < 60% RH as the SAP may absorb a noteworthy quantity of moisture at RH > 60% [11]. A temperature in the range of 10–30 °C has practically no effect on the sorption capacity. Short-term, quick sorption up to a few minutes can be delayed at lower temperatures, but the long-term sorption capacity is practically not influenced by temperature in the given range [12].

Several experimental methods to determine the sorption kinetics and sorption capacity, including gravimetric and volumetric approaches, have been documented in the literature. For a concise summary, cf. [13].

For example, fundamental prescriptions or guidelines have been issued by The European Disposables and Nonwovens Association denominated as “EDANA Recommended Test Procedures” [14].

As well, two Japanese standards are available on testing the water absorbency [15] and water sorption rate of SAP [16]. These standards use deionised water and 0.9 wt% sodium chloride dissolved in deionised water. The principal methodology accords with the tea-bag method described in the present document, but the Japanese standard is valuable for particles with the smallest size being 60 µm. JIS K 7223 [15] prescribes a tea-bag made of non-woven nylon with openings of 57 µm. As immersion times JIS K 7223 [15] specifies 3 and 24 h for deionised water and 1, 3 and 24 h for the saline solution. Tea-bags taken from the solution should be hung freely in laboratory air for 10 min to let liquid drop off, after which time they should be weighed. This prescription, however, cannot be recommended for cement filtrate or other highly alkaline test liquids due to the liquid’s uncontrolled carbonation, which may in turn affect the SAP absorption or desorption.

On the other hand, JIS K 7224 [16] determines the time required for a SAP sample to absorb as much fluid as to make a stirred liquid which has a stable vortex such that the stirrer chip becomes covered with test liquid. It is highlighted that dyeing the test liquid eases detection of the endpoint and the corresponding time reading. As a result, the water sorption rate expressed as unit mass of absorbed test liquid per unit mass of dry SAP and unit time can be obtained. In both methods, five replicates should be tested.

Depending on the envisaged application, different studies can be performed: a time-dependent study or a swelling capacity at a certain moment. In the latter case time of measurement should be carefully decided upon due to the potential de-swelling or dissolution of the polymer network.

As general rules, any moisture evaporation from the solutions must be prevented and good laboratory practice observed, especially with respect to the highly alkaline solutions. The fluids must be covered as tightly and as quickly as possible to reduce the risks of evaporation and carbonation in the case of pore fluid use. When conducting these tests, the ambient relative humidity and temperature must be recorded.

The operator should be careful during SAP handling due to the possible electrostatic forces’ acting on the polymer particles after being stored or transported in synthetic bags or containers. They can lead to certain losses of mass during weighing process or to the particles’ adhering to the beaker’s wall during preparation of the SAP solution in the filtration method.

Prior to quantitative testing it is recommended to check qualitatively the suitability of the tea-bag and the filter. Neither dry nor soaked and sorbed SAP particles are to be allowed to escape through the interstices or meshes of either the tea-bag or the filter.

2.2 Test solutions/fluids

Sorption performance depends on the absorbed fluid. Depending on the aim of the test, different fluids should be tested, e.g.:

-

1.

DI water: De-ionized by any common method, e.g., ion exchange or distillation; apart from serving as the basis for comparability with other sorption results and quality control, this is relevant to the assessment of the actual or potential self-sealing of SAP incorporated in a cement-based matrix after cracking due to the expectedly low ionic loading of freshly added water from the outside surroundings, e.g., rain water;

-

2.

Filtrate of cement slurry: A slurry of the respective cement in locally available, typical mixing water for concrete should be used to estimate SAP sorption kinetics and sorption capacity qualitatively for the SAP’s intended purpose as an admixture to mitigate plastic and/or autogenous shrinkage or freeze-thaw resistance. As practical parameters for generating sufficient amounts of this kind of characteristic ionic solution a W/C on an order of magnitude of 5 (wt/wt) and an immersion time of 24 h with continuous automated stirring, followed by filtration or decantation of the liquid, can be recommended.

2.3 Tea-bag method

In qualitative pre-tests it should be insured that neither the dry SAP particles nor the long-term immersed hydrogel moieties can escape through the interstices or meshes of the tea-bag or similar permeable sachet. A typical tea-bag would have a size of several centimetres in height and width, e.g. 7 × 12 [cm2]. When using a tea-bag of such size, a SAP amount of 0.2–0.3 g in its dry state is usually appropriate. The amount of SAP should not be too high, thus expanding the tea-bag during sorption test, because such filling might give rise to restraints that would hinder free sorption. For each weighing, a mass scale with a precision of at least 0.001 g, but preferably 0.0001 g, should be used.

The average mass of fluid absorbed by an empty tea-bag should first be assessed using at least ten individual tea-bags. The reason behind this is to account for the typical wet load of each tea-bag in the further procedure. The tester should be aware that this handling prescription represents a modification of previously described processes [14, 17]. It is based on multiple, consolidated experiences with attempts to insert dry SAP into a pre-wetted tea-bag. Each of the minimum ten tea-bags should be weighed in its dry state (mass mA). After briefly (couple seconds) soaking in the intended liquid, the tea-bag should be placed on a dry cloth and gently wiped with another dry cloth for a short time, approximately 30 s, to remove surplus and weakly bound liquid and, following that, its mass determined (mass mB). Averaging the results according to Eq. 1 gives the mass of the fluid absorbed by an empty tea-bag (m0) to be regarded for purposes of the remaining procedure; cf. Figure 1 and Eq. 2. At least ten individuals within one batch of tea-bags and test liquid yields a statistically sound value. Upon drying to a point where their masses remain constant, the tea-bags may be used for the main procedure.

Figure 1 sketches the two-step procedure of the tea-bag method. Equation 2 provides the formula to calculate the sorption capacity (SC).

A dry tea-bag should be weighed (mass m1). Dry SAP particles should be inserted and the tea-bag containing the SAP be weighed (mass m2). This filled tea-bag should be hung in a beaker filled with the test fluid (about 200 mL). The beaker should be quickly and tightly covered with a self-adhesive plastic stretch film to avoid carbonation and evaporation. It should only be removed briefly for each weighing. After 1, 5, 10, 30, 60 min, 3 and 24 h after the SAP/liquid contact time, the tea-bag with the hydrogel inside should be removed and weighed (mass m3). Drip-drying is performed in the same manner as for the determination of m0. In order not to disturb the degree of sorption, the sample should neither be squeezed nor come into contact with the cloths for any abnormally long time. After weighing, the tea-bag containing the hydrogel should be returned into the test fluid until the end of the next time interval for recording mass. Each required time of non-contact with solution (i.e. drip-drying and weighing procedures) should not be excluded from the time-line, but the time-line should be counted continuously from the initial SAP/liquid contact time onwards.

where m0 is the average wet dead load of the tea-bags to be inserted for purposes of Eq. 2 in calculating the sorption capacity SC, where n is the number of tea-bags used, being n ≥ 10, and mBi and mAi are the individual wet and dry masses of each tea-bag, respectively.

where m1 is the mass of the dry tea-bag, m2 is the mass of the dry hydrogel-containing tea-bag and m3 is the mass of the hydrogel-containing tea-bag at a specific time of soaking.

To insure reliability of the results, three individual tea-bags should be prepared for each SAP sample. In one beaker, three to six tea-bags may be inserted at the same time. Spatial confinement of the freely sorbing SAP samples as well as changes of the ionic composition as the consequence of the ab- and desorption do not have significant effect on the test results. However, a fresh test liquid should be used for each long-term test sequence, and the liquids should not be re-used.

2.4 Filtration method

The amount of dry SAP particulate is dependent on the actual sorption capacity; there should be an excess of test liquid for the polymers to swell freely to their full extent. It is recommended to perform a dummy test to estimate the amount needed to take up approximately 40–50 mL in every fluid studied. This amount of dry SAP added should be used in further testing. The amount of SAP, typically in the range of tenths of grams, should be recorded using a mass scale with a precision of at least 0.001 g (mass m1).

The specific amount of dry SAP should be placed in a 100 mL beaker and approximately 100 g (exact mass to be recorded; m2) of the test fluid should be added. During storage, the beakers should be tightly sealed to prevent carbonation. After 1, 5, 10, 30, 60 min, 3 and 24 h after the SAP/liquid contact time, the whole solution should be filtered. To ensure that there is no influence of the filter paper (12–15 µm mesh size), the latter is saturated with the test fluid prior to filtration. As the polymers settle during sorption, one can first carefully pour the major part of the free solution into the filter, followed by the saturated SAP and the rest of the free solution. This will decrease any possible clogging effects and avoid slowing the percolation. To guarantee optimal filtration, the filter paper should be folded in such a way that the filter paper is hovering above the funnel; see Fig. 2. In that way, there is less contact with the funnel, leaving a greater surface area available for filtration. The use of a ribbed funnel could serve the same purpose. During measurement, a lid should be put on top of the filter to ensure no evaporation during that time. By using a lid, care should be taken that no vacuum is created which could potentially slow/stop the flow of liquid through the filter/funnel assembly. For all different times, different containers need to be filled as the sorption capacity can be measured only once per sample. All measurements should be performed in triplicate (n = 3) for reasons of statistical significance. Neither the filtered solution nor the separated SAP/hydrogel should be re-used. The amount of filtered fluid is recorded in determining the mass (m3). Subsequent drops should occur within 1 min of each other. If the overall filtration takes longer than a quarter of an hour, which can be the case when using small SAP, the measurements at early ages should be studied with care since percolation and clogging may have occurred.

One other way to study time-dependent swelling behaviour is to determine the level head of the particles when they settle [18]. This can give a rough estimation of swelling time, but the method is based on many assumptions and the swollen particles should not be buoyant.

The overall end value by means of filtration is the correct one, and filtration should proceed until no drops are visible any more. At the end, the mass of the filtered fluid is determined. The different steps are shown in Fig. 2.

The mass increase of the SAP is measured as the difference between the added water and the filtered water. This mass increase is a measure of the total sorption; the value obtained is divided by the dry mass of the SAP particles under study. Equation 3 provides the formula to calculate the sorption capacity SC.

where m1 is the mass of the dry SAP, m2 is the mass of added test fluid and m3 is the mass of filtered fluid at a specific time.

2.5 Statistical evaluation

Any well known, contemporary mode of statistical evaluation can be applied to evaluate the measurement results obtained. They can include averaging the results per SAP per time per liquid, standard deviation, T test, or any other indication of statistical significance or uncertainty of the measurements. Other calculation schemes described in the literature may be considered as well, but they are not an explicit part of the present recommendation.

References

Mechtcherine V, Reinhardt HW (Eds) (2012) Application of super absorbent polymers (SAP) in concrete construction. State-of-the-Art Report Prepared by Technical Committee 225-SAP. Springer

Mechtcherine V, Secrieru E, Schröfl C (2015) Effect of superabsorbent polymers (SAPs) on rheological properties of fresh cement-based mortars—development of yield stress and plastic viscosity over time. Cem Concr Res 67:52–65. https://doi.org/10.1016/j.cemconres.2014.07.003

Mechtcherine V, Gorges M, Schröfl C, Assmann A, Brameshuber W, Bettencourt Ribeiro V, Cusson D, Custódio J, Fonseca da Silva E, Ichimiya K, Igarashi S, Klemm A, Kovler K, Lopes A, Lura P, Nguyen VT, Reinhardt HWTF, Weiss RDJ, Wyrzykowski M, Ye G, Zhutovsky S (2014) Effect of internal curing by using superabsorbent polymers (SAP) on autogenous shrinkage and other properties of a high-performance fine-grained concrete: results of a RILEM round-robin test, TC 225-SAP. Mater Struct 47(3):541–562

Mechtcherine V, Schröfl C, Wyrzykowski M, Gorges M, Cusson D, Margeson J, De Belie N, Snoeck D, Ichimiya K, Igarashi S-I, Falikman V, Friedrich S, Bokern J, Kara P, Lura P, Marciniak A, Reinhardt H-W, Sippel S, Ribeiro AB, Custódio J, Ye G, Dong H, Weiss J (2017) Effect of superabsorbent polymers (SAP) on the freeze-thaw resistance of concrete: results of a RILEM interlaboratory test. Mater Struct 50(14):1–19. https://doi.org/10.1617/s11527-016-0868-7

Snoeck D, Steuperaert S, Van Tittelboom K, Dubruel P, De Belie N (2012) Visualization of water penetration in cementitious materials with superabsorbent polymers by means of neutron radiography. Cem Concr Res 42(8):1113–1121. https://doi.org/10.1016/j.cemconres.2012.05.005

Snoeck D, De Belie N (2015) Repeated autogenous healing in strain-hardening cementitious composites by using superabsorbent polymers. J Mater Civ Eng 04015086:1–11. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001360

Snoeck D, Van Tittelboom K, Steuperaert S, Dubruel P, De Belie N (2014) Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers. J Intel Mat Syst Str 25(1):13–24. https://doi.org/10.1177/1045389X12438623

Schröfl C, Mechtcherine V, Vontobel P, Hovind J, Lehmann E (2015) Sorption kinetics of superabsorbent polymers (SAPs) in fresh Portland cement-based pastes visualized and quantified by neutron radiography and correlated to the progress of cement hydration. Cem Concr Res 75:1–13. https://doi.org/10.1016/j.cemconres.2015.05.001

Justs J, Wyrzykowski M, Bajare D, Lura P (2015) Internal curing by superabsorbent polymers in ultra-high performance concrete. Cem Concr Res 76:82–90. https://doi.org/10.1016/j.cemconres.2015.05.005

Mechtcherine V, Snoeck D, Schröfl C, De Belie N, Klemm AJ, Ichimiya K, Moon J, Wyrzykowski M, Lura P, Toropovs N, Assmann A, Igarashi S, De La Varga I, Almeida FCR, Erk KA, Ribeiro AB, Custódio J, Reinhardt HW, Falikman V (2018) Testing superabsorbent polymer (SAP) sorption properties prior to implementation in concrete: results of a RILEM round-robin test. Mater Struct. https://doi.org/10.1617/s11527-018-1149-4

Snoeck D, Velasco LF, Mignon A, Van Vlierberghe S, Dubruel P, Lodewyckx P, De Belie N (2015) The effects of superabsorbent polymers on the microstructure of cementitious materials studied by means of sorption experiments. Cem Concr Res 77:26–35

Secrieru E, Mechtcherine V, Schröfl C, Borin D (2016) Rheological characterisation and prediction of pumpability of strain-hardening cement-based composites (SHCC) with and without addition of superabsorbent polymers (SAP) at various temperatures. Constr Build Mater 112:581–594

Schröfl C, Snoeck D, Mechtcherine V (2017) A review of characterisation methods for superabsorbent polymer (SAP) samples to be used in cement-based construction materials—report of the RILEM TC 260-RSC. Mater Struct 50(197):1–19. https://doi.org/10.1917/s11527-017-1060-4

EDANA (2002) EDANA recommended test methods. European Disposables and Nonwovens Association, Brussels

JIS JIS (1996) Testing method for water absorption capacity of super absorbent polymers. JIS K 7223

JIS JIS (1996) Testing method for water absorption rate of super absorbent polymers. JIS K 7224

Schröfl C, Mechtcherine V, Gorges M (2012) Relation between the molecular structure and the efficiency of superabsorbent polymers (SAP) as concrete admixture to mitigate autogenous shrinkage. Cem Concr Res 42(6):865–873. https://doi.org/10.1016/j.cemconres.2012.03.011

Jensen OM (2011) Water absorption of superabsorbent polymers in a cementitious environment. In: Leung CKY, Wan KT (eds) International RILEM conference on advances in construction materials through science and engineering, Hong Kong SAR, 2011. RILEM Publications S.A.R.L, pp 22–35

Acknowledgements

The contributions of all TC members in discussion during the drafting of this recommendation are gratefully acknowledged. The authors extend their thanks to industrial partners for the proofreading and valuable comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

This recommendation has been prepared by members of Work Group 1 “Testing SAP”: Didier Snoeck, Christof Schröfl and Viktor Mechtcherine acting within the RILEM TC 260-RSC “Recommendations for use of superabsorbent polymers in concrete construction” and has been reviewed and approved by all members of the TC 260-RSC.

RILEM TC 260-RSC membership

Chair: Viktor Mechtcherine.

Deputy Chair: Mateusz Wyrzykowski.

Members: Fernando C.R. Almeida, Alexander Assmann, Billy Boshoff, Daniel Cusson, João Custódio, Nele De Belie, Igor De la Varga, Kendra Erk, Vyatcheslav Falikman, Stefan Friedrich, Kazuo Ichimiya, Shin-Ichi Igarashi, Agnieszka J. Klemm, Pietro Lura, Juhyuk Moon, Michaela Reichardt, Hans W. Reinhardt, António Bettencourt Ribeiro, Christof Schroefl, Didier Snoeck, Nikolajs Toropovs, Chiara Villani.

Rights and permissions

About this article

Cite this article

Snoeck, D., Schröfl, C. & Mechtcherine, V. Recommendation of RILEM TC 260-RSC: testing sorption by superabsorbent polymers (SAP) prior to implementation in cement-based materials. Mater Struct 51, 116 (2018). https://doi.org/10.1617/s11527-018-1242-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-018-1242-8