Abstract

TiO2 nanoparticles obtained by microwave-assisted hydrothermal synthesis were subjected to facile post-processing based on vacuum annealing. The resulting defective (TiO2-x) material showed extended light absorption in the visible range, enhancing sunlight compatibility. Structural and optical characterization point to the arising of an Urbach tail as the main reason. TiO2-x was then employed as photocatalyst for the inactivation of ciprofloxacin, an emerging environmental threat and source of antimicrobial resistance, under sunlight. TiO2-x performed significantly better than its parent compound and mechanistic analysis of the degradation pathway indicates that this material is a promising candidate for solar treatment of fluoroquinolones residues in water.

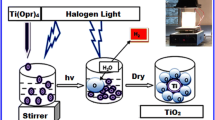

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Titanium dioxide is a benchmark material for heterogeneous photocatalysis, owing to a combination of good catalytic performance with remarkable chemical stability in a wide range of experimental conditions.[1] However, decades of research notwithstanding, actual applications to solar photocatalysis of this material are still limited because of poor, owing to a band structure only allowing absorption of the UV fraction of the spectrum.[2] A variety of methods have been developed over time to address this issue, including tweaking the electronic structure by doping,[3,4] sensitization by coupling with molecular or plasmonic absorbers,[5,6] and the fabrication of composites.[7,8] Another approach relies on inducing surface defects in the material which result in a smaller optical band gap and/or the rising of an Urbach tail.[9,10] To this scope, oxygen vacancies and Ti3+ have been shown to be particularly effective for photocatalysis purpose.[11,12] A different approach to the issue of low compatibility between TiO2 absorption and sunlight spectrum is that of working not on the material but on the illumination source, for example, by manipulating solar radiation using concentrating collectors.[13] In this case, the increasing availability of economically viable concentrator-based processes is an important progress towards applications.[14] The equipment to make an effective use of the UV fraction of sunlight remains significantly complex though, requiring for example especially designed mirrors based on anodized aluminum.[15] Thus, improving the optical matching between TiO2 and sunlight would be greatly beneficial also in this context.

In this work, we investigated a facile modification of a TiO2 nanomaterial, resulting in extended light absorption in the visible range. A microwave-assisted hydrothermal synthesis was employed to obtain TiO2 nanopowders, which were then annealed in vacuum. The resulting material (TiO2-x) shows a color change to light-brown, a decreased, albeit modestly optical band gap, but especially the arising of an absorption tail in the visible range. Optical and structural properties were investigated by UV–Vis and micro-Raman spectroscopy, electron microscopy both in scanning (SEM) and transmission (TEM) mode, and selected area electron diffraction (SAED). To verify the suitability of this material for solar photocatalysis, the degradation of Ciprofloxacin (CIP) under direct sunlight was studied and a reaction mechanism investigated by determining intermediates with High-Performance Liquid Chromatography (HPLC) methods. CIP, a fluoroquinolone antibiotic used in both medicine and veterinary medicine, was selected as the target pollutant for several reasons: (a) it is one of the most used fluoroquinolones worldwide, employed in massive quantities; (b) current wastewater treatment processes are only marginally effective at removing CIP, and consequently, it has been detected in surface waters worldwide; (c) as such, it can heavily contribute to the rise of antimicrobial resistance (AMR), a top threat to public health.[16] In this framework, solar photocatalysis is a promising approach for a potentially cost-effective, sunlight-driven pollutant degradation process with high efficiency. Also, it is worth considering that while the ultimate goal of solar photocatalysis treatments is generally considered as the total removal of pollutants via mineralization, AMR reduction in principle only requires the inactivation of antibiotic residues in water. This is, at least on paper, a less demanding goal.[17]

Materials and methods

Reagents

TiO2 nanopowders were synthesized using titanium butoxide (Ti(C4H9O)4 purum, ≥ 97.0% gravimetric, Sigma-Aldrich) as precursor and 2-butanol (C4H10O, purity ≥ 99.5% gravimetric, Sigma-Aldrich) as solvent. Ciprofloxacin (C17H18FN3O3, MW: 385.82 g/mol, Standard PHR1044-1G, Sigma-Aldrich). All reagents and chemicals were used as received.

Synthesis

TiO2 nanopowders were produced employing a microwave-assisted protocol adapted from the literature:[18] 16 ml of titanium butoxide was mixed with 100 ml of 2-butanol and 5 ml of deionized water (DI) was then added in droplets. The resulting suspension was stirred under cooling (ice bath) for 30 min, followed by overnight stirring at room temperature and then transferred to a 35 ml CEM microwave vessel. TiO2 was then obtained via microwave-assisted hydrothermal treatment of the suspension at 180°C for 1 h (3°C/min) using a CEM Discover S-Class microwave system set to a power of 220 watts and 2455 MHz frequency. The resulting powder was washed with water and ethanol, dried at 60°C, crushed, and calcined in a muffle furnace at 400°C for 4 h with a heating rate of 9°C/min. To obtain the TiO2-x material, the protocol was followed by overnight thermal annealing in a custom-built vacuum oven (10–8 mBar, 400°C, at 5°C/min) equipped with a drag-stage turbomolecular pump and a membrane pump for pre-vacuum.

Characterization

Raman measurements were performed on a Horiba LabAramis setup equipped with a HeNe 633 nm laser as source and a confocal microscope (100 × objective) coupled to a 460 mm focal length CCD-based spectrograph equipped with a four interchangeable gratings turret. Wavenumber accuracy was 1 cm−1 with an 1800 L/mm grating. A field emission scanning electron microscope (FESEM, JSM 7001 F, JEOL) equipped with energy-dispersive X-Ray spectroscopy analysis (EDXS, Oxford INCA PentaFET- × 3) was used to investigate particle morphology and composition. Further structural analysis was performed with TEM and high-resolution-TEM (HRTEM) imaging, as well as SAED patterns obtained with a Thermo Scientific™ Talos™ F200S scanning/transmission electron microscope (S/TEM) set to 200 kV accelerating voltage. UV–Vis reflectance was measured using a VARIAN Cary 5000 UV–Vis-NIR spectrophotometer over a wavelength range of 200 to 800 nm. Both the Kubelka–Munk function and the Tauc equation were used to evaluate the indirect bandgap of the synthesized nanomaterials. In Eq. 1, the Kubelka–Munk function F(R) is defined as follows:

where R is the reflectance of the sample.

The Tauc equation for indirect electronic transitions is

where α is the optical absorption coefficient, which can be replaced in the Tauc equation by F(R) calculated from the Kubelka–Munk function; hν is the incident photon energy in eV; A is the material-dependent absorption constant; and Eg is the nanomaterial’s bandgap energy.

Photocatalysis experiments were carried out in a pyrex vessel containing 50 ml of 10 ppm CIP solution, and samples were kept in the dark for 30 min to achieve adsorption–desorption equilibrium and afterwards exposed to direct sunlight for 180 min., in the period of November and December 2022 in Trento (Italy, coordinates 46.066408° N, 11.150723° E) between 10:30 and 14:00 local time. The spectrum of incident sunlight was measured with a portable mini-spectrometer (Hamamatsu C10082CA) and is reported in supplementary Figure S1, while solar irradiation measurements were performed using a Kipp & Zonnen CHP1 pyrheliometer with monitored readings between 720 and 750 W/m2. Blank experiments were performed to test for the effects of direct photolysis of CIP by either sunlight, artificial 365 nm UV light (Actinic Philips BL TL-D 15W/10 1SL/25, luminous flux of 130 lumens, positioned at 40 cm above the solution) or thermolysis at 50°C. Where the catalysts are present, a loading of 0.5 g/l was adopted. Mixing and catalyst dispersion were ensured by means of a Hielscher UP400s probe sonicator at 1 cycle, 50% amplitude. Except where otherwise noted, samples were taken at − 30 (ref), 0, 15, 30, 45, 60, 90, 120, 150, and 180 min. The degradation of CIP was monitored by acquiring the absorption spectra using a VARIAN Cary 5000 UV–Vis–NIR spectrophotometer over a wavelength range of 200 to 400 nm. 1 ml of solution was filtered over a 0.2 µm cellulose acetate membrane syringe filter (VWR) to avoid excessive scattering by the photocatalyst.

The degradation of CIP was calculated using the following equation:

where Co is the initial molar concentration of CIP obtained from Ao (the initial absorbance at λmax = 272 nm) and C is the molar concentration of CIP after each sampling interval obtained from the absorbance A (the absorbance of CIP at λmax after each sampling interval). A verification of the Lambert–Beer law indicating a linear correlation between CIP Abs and concentration in the explored range is provided in figure S10.

Analysis of the products related to CIP photocatalytic degradation was conducted by liquid chromatography (Model 1100 Series, HP) coupled to photodiode-array detector (Model Agilent, 1100 Series, PDA), and to mass spectrometer (Bruker Esquire-LC quadrupole ion trap) in positive-ion-mode Electrospray ionization source (ESI +). Chromatographic separation was carried out on a C18 column at 303 K (Eclipse XDB-C18, Agilent Technologies, 3.5µ 150 × 4.6 mm; flow 1.0 ml/min; T = 30°C; injected volume = 10 ul). The mobile phase consisted of solvent 1 (water 20% + trifluoroacetic acid 0.1%) and solvent 2 (MeOH 80% + trifluoroacetic acid 0.1%) at a flow of 1 mL/min. The DataAnalysis 3.0 software was used to integrate the collected ion chromatograms from the positive-ion full scan mode (50–500 Da) for the structural assignment of species (Bruker Daltonik, Bremen, Germany). A working curve of the available standard of CIP was built by recording UV (λ = 280 nm) peak areas for several solution of CIP obtained by sequential dilution of a 10 mg/L mother solution. The rate constant of disappearance (degradation) was calculated assuming a pseudo-first-order kinetics:

where Co and C are, respectively, the initial and the actual molar concentration of CIP at λ = 278 nm at a given timepoint of the CIP degradation and kobs is the total observed kinetic constant. A qualitative determination of CO2 evolution along the degradation experiment was measured to detect eventual mineralization, using a sensor (5% model GSS COZIR, Gaslab software monitor) with an acquisition every 30 s with the device placed 3 cm above the reactor. This measurement provides a qualitative data of the variation in the atmospheric level of CO2 at the experiment immediate surroundings.

Results and discussion

Micro-Raman spectroscopy was used to identify the crystal phases in TiO2 and TiO2-x nanopowders, and related spectra are reported in Figure S2. Both materials show the characteristic peaks of both anatase and brookite phases: the high-intensity sharp shape peak at 143 cm−1 is consistent to Eg and A1g modes of, respectively, anatase and brookite phases. The peaks at 196 (Eg), 398 (B1g), 516 (A1g), and 638 (Eg) reveal the presence of anatase while the characteristic peaks of brookite appear with low intensities at 245 (A1g), 320 (B1g), and 367 cm−1 (B2g).[19] The similarity between TiO2 and TiO2-x nanomaterials reveals that no significant change in the crystallinity of TiO2-x is observed after annealing under vacuum. Morphology and size of both synthesized materials were investigated by using SEM and HRTEM techniques. SEM images shown in Fig. S3 indicate both TiO2 (a) and TiO2-x (b) consisting of agglomerated small particles in the range from 10 to 20 nm, mostly spherical in shape. This indicates that morphology is not significantly affected by the vacuum annealing. This observation is confirmed by TEM images (Fig. 1), where the size and shape of TiO2 (a, b) and TiO2-x (d, e) nanoparticles are very similar. In both cases, small (10–20 nm) and spherical nanoparticles have been observed. Their corresponding SAED pattern (c, f) indicates the crystalline nature of nanoparticles, mainly of anatase phase (101) with a d-spacing d = 0.35 nm [magnified images Fig. 1(b, e)].

Further analysis of the SAED data confirms this initial observation. Starting from the diffraction ring patterns, the integral intensities were calculated as function of the scattering angles, thus, obtaining the diffraction data reported in Figure S4. The intensities of the concentric rings were averaged as a function of the radius, and the final results are compatible with anatase as the main phase, while the two main peaks of brookite can also be detected in both TiO2 and TiO2-x.[20,21,22] Conclusively, we can say that annealing under vacuum does not have a significant detectable effect on the crystalline phase of the material.

UV–visible spectroscopy data are shown in Fig. 2 below. While structural characterization did not show appreciable differences in the two synthesized materials, their optical properties are remarkably different. After vacuum annealing, the powders show a clear change in color from white to light-brown, arising from an absorption tail in the spectrum of TiO2-x (Fig. 2, top) extending into the visible range. Tauc plots (Fig. 2, bottom) are compatible with an indirect optical band gap of 3.18 eV for TiO2, slightly narrowed to 3.11 eV for TiO2-x. From these data, the change in color is primarily due to the absorption tail into the visible range. This is compatible with an Urbach model, where point surface defects are responsible for localized color centers, generally involving oxygen vacancies and showing a wide range of excitation energies altering the electronic structure of TiO2.[23] The improved absorption due to the slightly lower band gap in defective TiO2-x than TiO2 could be related to the presence of localized defects states in the band gap of TiO2-x. These localized defects could produce an absorption tail extending into forbidden gap.[24,25] Therefore, in case of TiO2-x, the high Urbach energy is expected due to the presence of more oxygen vacancies and surface defects. Further, a qualitatively higher brightness of SAED for TiO2-x can be observed when compared to TiO2 [Fig. 1(c, f)] which, according to the literature Refs. 24,25, is related to changes on the surface defects states, as the crystalline phases are the same in both samples. In fact, in-depth XPS analysis in the literature for materials obtained in similar conditions, frequently shows the features of undervalent Ti(III).[26,27] This hypothesis is also supported by the characterization for TiO2 and TiO2-x, where both morphology and crystal phase are very similar, more compatible with the low density, surface-localized point defects of the Urbach model than with the presence of bulk defects and/or an high density of point defects extending into the bulk.

Given that the optical properties of TiO2-x suggest an increased compatibility with the sunlight spectrum than for TiO2, CIP photodegradation experiments where performed to investigate a possible application of this material for solar wastewater remediation. Blank experiments to evaluate the effect of CIP thermolysis, photolysis under UV 365 nm light, and under sunlight, are reported in the Supplementary Figure S5. In the experimental conditions and time scale explored (180 min treatments), CIP is shown to be substantially stable, with a maximum of about 10% degradation under sunlight at the end of irradiation, while no thermolysis was detected. Significant degradation is instead observed when TiO2 and TiO2-x were present, as reported in Fig. 3 below.

In these experiments, TiO2-x showed both better adsorption capability, likely due to the presence of surface defects as previously reported in the literature,[28] and increased rate constant with respect to TiO2, resulting in earlier (90 min) significant disappearance of the CIP absorption. CIP degradation products of the experiment performed with TiO2-x were investigated by LC-UV-MS measurements. The chromatogram is reported in Supplementary Figure S6, with the main signals (labeled from 1 to 10), as detected by PDA at λ 278 nm after 60 min of treatment, attributed to ciprofloxacin derivatives since none of these peaks were detected in the CIP standard before treatment. The structures were tentatively assigned by analyzing their LC–MS spectra and by comparison with MS data previously reported in the literature.[29] The degradation products shown in Fig. 4 and their corresponding UV absorption peaks (Supplementary Fig. S7) mainly derive from the partial ·OH radicals attack towards the cleavage of the piperazynilic ring of the ciprofloxacin molecule, leading to 8 fragmented subproducts with masses of m/z values 332.14. 334.16, 348.14, 362.11, 306.12, 165.06, 263.08, and 291.11.[30,31] In agreement with Ohko et al.[32] and Zhang et al.[33], the pathway for CIP degradation is here based on the photo-hole (h+) oxidation and hydroxylation given by the TiO2-x photocatalyst. In the first step, the fluorine atom electronegativity subjects the piperazynilic ring to angle stresses which likely lead to a partial release of ethylene groups and formation of desethylene. In CIP, defluorination and decarboxylation are the main events given the existence of two powerful electron extracting substituents (carboxylic and fluorine groups). The concomitance of the degradation of both piperazynilic and defluorination is observed and leads to lower molecular weight compounds.[34] Finally, it is observed that the central quinolone and cyclopropyl structures remain along all the observed subproducts as confirmed by the literature.[35]

The LC–MS degradation kinetics constant kobs, obtained by recording UV (λ = 280 nm) peak areas for the CIP solution and resulting from the sum of all the degradation processes, was 3 × 10–2 in accordance (Supplementary S8) with the value obtained by spectrophotometry analysis. The CO2 evolution measurement was also run during the experiment with TiO2-x. The resulting data (Supplementary Fig. S9) show a significant increase in CO2 above ambient levels, indicating that also a degree of mineralization occurs. Overall, these results point to a degradation pathway leading to significant modification of CIP, with the potential for application to solar inactivation of CIP in wastewaters.

Conclusions

In this work, a simple vacuum annealing on TiO2 nanopowders proved to be an effective method to induce optical properties change, extending absorption into the visible range. Structural and optical characterization of the resulting material point to the arising of an Urbach tail as the main reason for this behavior. When tested for photocatalysis of CIP under sunlight, such TiO2-x material proved to be more performing than its TiO2 counterpart, showing that the modification is effective at enhancing photoactivity. Analysis of the CIP degradation pathway and products indicates that this material is a promising candidate for solar photocatalytic treatments aimed at fluoroquinolones inactivation. The results reported here are a decisive step forward in this direction.

Data availability

Raw data or datasets not included here are available from the authors on request.

References

H. Xu, S. Ouyang, L. Liu, P. Reunchan, N. Umezawa, J. Ye, Recent advances in TiO2-based photocatalysis. J. Mater. Chem. A. 2, 12642–12661 (2014). https://doi.org/10.1039/C4TA00941J

R.V. Nair, V.S. Gummaluri, M.V. Matham, C. Vijayan, A review on optical bandgap engineering in TiO2 nanostructures via doping and intrinsic vacancy modulation towards visible light applications. J. Phys. D. Appl. Phys. 55, 313003 (2022). https://doi.org/10.1088/1361-6463/ac6135

Z. El Koura, M. Cazzanelli, N. Bazzanella, N. Patel, R. Fernandes, G.E. Arnaoutakis, A. Gakamsky, A. Dick, A. Quaranta, A. Miotello, Synthesis and characterization of Cu and N codoped RF-sputtered TiO2 films: photoluminescence dynamics of charge carriers relevant for water splitting. J. Phys. Chem. C. 120, 12042–12050 (2016). https://doi.org/10.1021/acs.jpcc.6b03058

X. Zhu, J. Wang, D. Yang, J. Liu, L. He, M. Tang, W. Feng, X. Wu, Fabrication, characterization and high photocatalytic activity of Ag–ZnO heterojunctions under UV-visible light. RSC Adv. 11, 27257–27266 (2021). https://doi.org/10.1039/D1RA05060E

W. Hou, S.B. Cronin, A review of surface plasmon resonance-enhanced photocatalysis. Adv. Funct. Mater. 23, 1612–1619 (2013). https://doi.org/10.1002/adfm.201202148

G. Pozzi, S. Quici, M.C. Raffo, C.A. Bignozzi, S. Caramori, M. Orlandi, Fluorous molecules for dye-sensitized solar cells: synthesis and photoelectrochemistry of unsymmetrical zinc phthalocyanine sensitizers with bulky fluorophilic donor groups. J. Phys. Chem. C. 115, 3777–3788 (2011). https://doi.org/10.1021/jp109846k

A. Rey, P. García-Muñoz, M.D. Hernández-Alonso, E. Mena, S. García-Rodríguez, F.J. Beltrán, WO3–TiO2 based catalysts for the simulated solar radiation assisted photocatalytic ozonation of emerging contaminants in a municipal wastewater treatment plant effluent. Appl. Catal. B Environ. 154–155, 274–284 (2014). https://doi.org/10.1016/j.apcatb.2014.02.035

M. Yadav, A. Yadav, R. Fernandes, Y. Popat, M. Orlandi, A. Dashora, D.C. Kothari, A. Miotello, B.L. Ahuja, N. Patel, Tungsten-doped TiO2/reduced graphene oxide nano-composite photocatalyst for degradation of phenol: a system to reduce surface and bulk electron-hole recombination. J. Environ. Manage. 203, 364–374 (2017). https://doi.org/10.1016/j.jenvman.2017.08.010

E. Jimenez-Relinque, I. Llorente, M. Castellote, TiO2 cement-based materials: Understanding optical properties and electronic band structure of complex matrices. Catal. Today. 287, 203–209 (2017). https://doi.org/10.1016/j.cattod.2016.11.015

L. Andronic, D. Ghica, M. Stefan, C.G. Mihalcea, A.-M. Vlaicu, S. Karazhanov, Visible-light-active black TiO2 nanoparticles with efficient photocatalytic performance for degradation of pharmaceuticals. Nanomaterials 12, 2563 (2022). https://doi.org/10.3390/nano12152563

Z. Pei, L. Ding, W. Feng, S. Weng, P. Liu, Defect self-doped TiO2 for visible light activity and direct noble metal anchoring. Phys. Chem. Chem. Phys. 16, 21876–21881 (2014). https://doi.org/10.1039/C4CP02286F

K. Zhang, J.H. Park, Surface localization of defects in black TiO2: enhancing photoactivity or reactivity. J. Phys. Chem. Lett. 8, 199–207 (2017). https://doi.org/10.1021/acs.jpclett.6b02289

D. Spasiano, R. Marotta, S. Malato, P. Fernandez-Ibañez, I. Di Somma, Solar photocatalysis: materials, reactors, some commercial, and pre-industrialized applications. A comprehensive approach. Appl. Catal. B Environ. 170–171, 90–123 (2015). https://doi.org/10.1016/j.apcatb.2014.12.050

A. El Golli, M. Fendrich, N. Bazzanella, C. Dridi, A. Miotello, M. Orlandi, Wastewater remediation with ZnO photocatalysts: Green synthesis and solar concentration as an economically and environmentally viable route to application. J. Environ. Manage. 286, 112226 (2021). https://doi.org/10.1016/j.jenvman.2021.112226

A. Ustaoglu, C. Kandilli, M. Cakmak, H. Torlaklı, Experimental and economical performance investigation of V-trough concentrator with different reflectance characteristic in photovoltaic applications. J. Clean. Prod. 272, 123072 (2020). https://doi.org/10.1016/j.jclepro.2020.123072

T. aus der Beek, F.-A. Weber, A. Bergmann, S. Hickmann, I. Ebert, A. Hein, A. Küster, Pharmaceuticals in the environment—global occurrences and perspectives. Environ. Toxicol. Chem. 35, 823–835 (2016). https://doi.org/10.1002/etc.3339

A.R. Ribeiro, O.C. Nunes, M.F.R. Pereira, A.M.T. Silva, An overview on the advanced oxidation processes applied for the treatment of water pollutants defined in the recently launched directive 2013/39/EU. Environ. Int. 75, 33–51 (2015). https://doi.org/10.1016/j.envint.2014.10.027

A.J. Moreira, L.O. Campos, C.P. Maldi, J.A. Dias, E.C. Paris, T.R. Giraldi, G.P.G. Freschi, Photocatalytic degradation of Prozac® mediated by TiO2 nanoparticles obtained via three synthesis methods: sonochemical, microwave hydrothermal, and polymeric precursor. Environ. Sci. Pollut. Res. 27, 27032–27047 (2020). https://doi.org/10.1007/s11356-020-08798-x

L.A. García-Contreras, J.O. Flores-Flores, J.Á. Arenas-Alatorre, J.Á. Chávez-Carvayar, Synthesis, characterization and study of the structural change of nanobelts of TiO2 (H2Ti3O7) to nanobelts with anatase, brookite and rutile phases. J. Alloys Compd. 923, 166236 (2022). https://doi.org/10.1016/j.jallcom.2022.166236

S. Bakardjieva, V. Stengl, L. Szatmary, J. Subrt, J. Lukac, N. Murafa, D. Niznansky, K. Cizek, J. Jirkovsky, N. Petrova, Transformation of brookite-type TiO2 nanocrystals to rutile: correlation between microstructure and photoactivity. J. Mater. Chem. 16, 1709–1716 (2006). https://doi.org/10.1039/B514632A

S.N. Hosseini, X. Chen, P.J. Baesjou, A. Imhof, A. van Blaaderen, Synthesis and characterization of anatase TiO2 nanorods: insights from nanorods’ formation and self-assembly. Appl. Sci. (2022). https://doi.org/10.3390/app12031614

M. Abushad, S. Naseem, M. Arshad, A. Shafi, M.Z. Khan, A. Ansari, V.K. Chakradhary, F. Singh, S. Husain, W. Khan, Physical properties and photocatalytic activity of Cr doped TiO2 nanoparticles. J. Microsc. (2023). https://doi.org/10.1111/jmi.13211

B. Choudhury, A. Choudhury, Oxygen defect dependent variation of band gap, Urbach energy and luminescence property of anatase, anatase–rutile mixed phase and of rutile phases of TiO2 nanoparticles. Phys. E Low-Dimens. Syst. Nanostruct. 56, 364–371 (2014). https://doi.org/10.1016/j.physe.2013.10.014

R. Vettumperumal, S. Kalyanaraman, B. Santoshkumar, R. Thangavel, Estimation of electron-phonon coupling and Urbach energy in group-I elements doped ZnO nanoparticles and thin films by sol-gel method. Mater. Res. Bull. 77, 101–110 (2016). https://doi.org/10.1016/j.materresbull.2016.01.015

G. GitongaRiungu, S. WaweruMugo, J. MbiyuNgaruiya, G. Mbae John, N. Mugambi, Optical band energy, urbach energy and associated band tails of nano crystalline TiO<sub>2</sub> films at different annealing rates. Am. J. Nanosci. 7, 28 (2021). https://doi.org/10.11648/j.ajn.20210701.15

M. Hantusch, V. Bessergenev, M.C. Mateus, M. Knupfer, E. Burkel, Electronic properties of photocatalytic improved Degussa P25 titanium dioxide powder. Catal. Today. 307, 111–118 (2018). https://doi.org/10.1016/j.cattod.2017.11.005

A. Busiakiewicz, A. Kisielewska, I. Piwoński, D. Batory, K. Pabianek, Formation of gold and platinum nanostructures on rutile TiO2(001) by thermal treatment of thin films in vacuum. Vacuum 163, 248–254 (2019). https://doi.org/10.1016/j.vacuum.2019.02.026

S. Liu, L. Lu, C. Zhu, Q. Fang, S. Song, Y. Zheng, Y. Shen, The role of dual vacancies in TiO2 for enhanced photocatalytic hydrogen generation and pollutants removal. ChemCatChem 14, e202201107 (2022). https://doi.org/10.1002/cctc.202201107

S. Rehm, K.M. Rentsch, LC-MS/MS method for nine different antibiotics. Clin. Chim. Acta. 511, 360–367 (2020). https://doi.org/10.1016/j.cca.2020.11.001

T. An, H. Yang, G. Li, W. Song, W.J. Cooper, X. Nie, Kinetics and mechanism of advanced oxidation processes (AOPs) in degradation of ciprofloxacin in water. Appl. Catal. B Environ. 94, 288–294 (2010). https://doi.org/10.1016/j.apcatb.2009.12.002

A.J. Moreira, J.O.D. Malafatti, T.R. Giraldi, E.C. Paris, E.C. Pereira, V.R. de Mendonça, V.R. Mastelaro, G.P.G. Freschi, Prozac® photodegradation mediated by Mn-doped TiO2 nanoparticles: evaluation of by-products and mechanisms proposal. J. Environ. Chem. Eng. (2020). https://doi.org/10.1016/j.jece.2020.104543

Y. Ohko, K. Iuchi, C. Niwa, T. Tatsuma, T. Nakashima, T. Iguchi, Y. Kubota, A. Fujishima, 17β-Estradiol degradation by TiO2 photocatalysis as a means of reducing estrogenic activity. Environ. Sci. Technol. 36, 4175–4181 (2002). https://doi.org/10.1021/es011500a

X. Zhang, F. Wu, X. Wu, P. Chen, N. Deng, Photodegradation of acetaminophen in TiO2 suspended solution. J. Hazard. Mater. 157, 300–307 (2008). https://doi.org/10.1016/j.jhazmat.2007.12.098

X. Zhang, R. Li, M. Jia, S. Wang, Y. Huang, C. Chen, Degradation of ciprofloxacin in aqueous bismuth oxybromide (BiOBr) suspensions under visible light irradiation: a direct hole oxidation pathway. Chem. Eng. J. 274, 290–297 (2015). https://doi.org/10.1016/j.cej.2015.03.077

A. Gupta, A. Garg, Degradation of ciprofloxacin using Fenton’s oxidation: effect of operating parameters, identification of oxidized by-products and toxicity assessment. Chemosphere 193, 1181–1188 (2018). https://doi.org/10.1016/j.chemosphere.2017.11.046

Acknowledgments

The authors would like to acknowledge Gloria Ischia for TEM analysis and Adriano Sterni for the LC-MS measurements. This work was supported by project ERICSOL funded by the University of Trento, Italy.

Funding

Open access funding provided by Università degli Studi di Trento within the CRUI-CARE Agreement. Università degli Studi di Trento, ERICSOL.

Author information

Authors and Affiliations

Contributions

Conceptualization: MF. Formal analysis: MF, NB, OPB, GG. Investigation: MF, NB, OPB, GG. Writing—original draft preparation: MO, MF. Writing—review and editing: MO, AM, GG. Supervision: MO, AM. Funding acquisition: MO, AM. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

No approval was needed to carry out any of the experiments reported in this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

43579_2023_440_MOESM1_ESM.docx

Supplementary file1 (DOCX 2014 KB) The solar spectrum at the irradiation site, blank experiments, additional HPLC-UV and LC-MS data along with qualitative CO2 evolution data are available as supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bazzanella, N., Bajpai, O.P., Fendrich, M. et al. Ciprofloxacin degradation with a defective TiO2-x nanomaterial under sunlight. MRS Communications 13, 1252–1259 (2023). https://doi.org/10.1557/s43579-023-00440-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-023-00440-4