Abstract

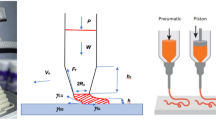

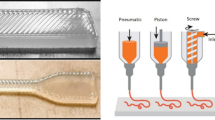

Direct ink writing (DIW) is an ambient temperature additive manufacturing (AM) method that accommodates many possible ink materials. Here, we demonstrate using a moisture-curable commercially available polyurethane (PU) sealant as an alternative ink for DIW. We discussed the fundamentals of PU chemistry and determined the best 3D printing parameters. Studies on rheological, thermogravimetric, spectroscopic characterization, and initial finite element analyses (FEA) showed properties expected from a performance sealant with high elongation and low modulus of a 3D-printed object. This affirms the flexibility of the DIW technique as an accessible AM method amenable for future materials development from commercial model formulations.

Graphical abstract

Similar content being viewed by others

References

T.D. Ngo, A. Kashani, G. Imbalzano, K.T.Q. Nguyen, D. Hui, Additive manufacturing (3D printing): a review of materials, methods, applications, and challenges. Composites B 143, 172–196 (2018)

G.M. Elahee, L.-H. Rong, C. Breting, J. Bonilla-Cruz, T.E. Ceniceros, Z.J. Smith, J. Ge, X. Cheng, M. Xu, M. Yang, E.L. Ribeiro, E.B. Caldona, R.C. Advincula, Acrylic sealants as practicable direct ink writing (DIW) 3D-printable materials. MRS Commun. 13, 299–305 (2023)

P. Chung, J.A. Heller, M. Etemadi, P.E. Ottoson, J.A. Liu, L. Rand, S. Roy, Rapid and low-cost prototyping of medical devices using 3D printed molds for liquid injection molding. J. Vis. Exp. 88, e51745 (2014). https://doi.org/10.3791/51745

M. Moczadlo, Q. Chen, X. Cheng et al., On the 3D printing of polypropylene and post-processing optimization of thermomechanical properties. MRS Commun. 13, 169–176 (2023)

R.C. Advincula, J.R.C. Dizon, E.B. Caldona, R.A. Viers, F.D.C. Siacor, R.D. Maalihan, A.H. Espera Jr., On the progress of 3D-printed hydrogels for tissue engineering. MRS Commun. 11, 539 (2021)

D.B. Gutierrez, E.B. Caldona, R.D. Espiritu, R.C. Advincula, The potential of additively manufactured membranes for selective separation and capture of CO2. MRS Commun. 11, 391 (2021)

R.C. Advincula, J.R.C. Dizon, Q. Chen, I. Niu, J. Chung, L. Kilpatrick, R. New-man, Additive manufacturing for COVID-19: devices, materials, prospects, and challenges. MRS Commun. 10(3), 413 (2020)

E.B. Caldona, J.R.C. Dizon, R.A. Viers, V.J. Garcia, Z.J. Smith, R.C. Advincula, Additively manufactured high-performance polymeric materials and their potential use in the oil and gas industry. MRS Commun. 11, 701 (2021)

A.D. Valino, J.R.C. Dizon, A.H. Espera Jr., Q. Chen, J. Messman, R.C. Advincula, Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 98, 101162 (2019)

Z.J. Smith, D.R. Barsoum, Z.L. Arwood, D. Penumadu, R.C. Advincula, Characterization of micro-sandwich structures via direct ink writing epoxy based cores. J. Sandw. Struct. Mater. 25(1), 112–127 (2022)

J.A. Lewis, J.E. Smay, J. Stuecker, J. Cesarano, Direct ink writing of three-dimensional ceramic structures. J. Am. Ceram. Soc. 89, 3599–3609 (2006). https://doi.org/10.1111/j.1551-2916.2006.01382.x

J.A. Lewis, Direct ink writing of 3D functional materials. Adv. Funct. Mater. 16(17), 2193–2204 (2006)

H.-W. Engels, H.-G. Pirkl, R. Albers, R.W. Albach, J. Krause, A. Hoffmann, H. Casselmann, J. Dormish, Polyurethanes: versatile materials and sustainable problem solvers for today’s challenges. Angew. Chem. Int. Ed. 52(36), 9422–9441 (2013)

T.M. Crescentini et al., Mass spectrometry of polyurethanes. Polymer 181, 121624 (2019). https://doi.org/10.1016/j.polymer.2019.121624

A.L. Daniel da Silva, J.M. Martín-Martínez, J.C. Bordado, Influence of the free isocyanate content in the adhesive properties of reactive trifunctional polyether urethane quasi-prepolymers. Int. J. Adhes. Adhes. 26(5), 355–362 (2006). https://doi.org/10.1016/j.ijadhadh.2005.06.001

Zafar, F., Chapter 1 polyurethane. In: Polyurethane: An Introduction (IntechOpen, London, 2012). https://doi.org/10.5772/51663

J.N. Hahladakis et al., An overview of chemical additives present in plastics: migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 344, 179–199 (2018). https://doi.org/10.1016/j.jhazmat.2017.10.014

LOCTITE® PL Concrete, Non-sag Polyurethane Sealant Page 1 of 4 Technical Data Sheet. https://dm.henkel-dam.com/is/content/henkel/tds-us-loctite-loc-pl-concrete-non-sag-polyurethane-sealant-2020-09-01. Accessed 22 March 2023

M.T. Espino, B.J. Tuazon, A.H. Espera et al., Statistical methods for design and testing of 3D-printed polymers. MRS Commun. (2023). https://doi.org/10.1557/s43579-023-00332-7

Admin (no date) Engine SR—standard resolution 3D printer, Hyrel 3D. http://www.hyrel3d.com/portfolio/engine-sr-standard-resolution/. Accessed 27 Jan 2023

A.H. Espera, J.R.C. Dizon, A.D. Valino et al., On the 3D printability of silicone-based adhesives via viscous paste extrusion. MRS Commun. 13, 102–110 (2023)

X.-D. Chen, N.-Q. Zhou, H. Zhang, Preparation and properties of cast polyurethane elastomers with molecularly uniform hard segments based on 2, 4-toluene diisocyanate and 3, 5-dimethyl thio toluene diamine. J. Biomed. Sci. Eng. 2, 245–253 (2009)

G. Lligadas, J.C. Ronda, M. Galià, U. Biermann, J.O. Metzger, Synthesis and characterization of polyurethanes from epoxidized methyl oleate based polyether polyols as renewable resources. J. Polym. Sci. A 44, 634–645 (2006)

X. Feng, S. Yusheng, H. Shuhuai, Synthesis and performance of transparent casting polyurethane resin. J. Wuhan Univ. Technol. Mater. Sci. Ed. 20, 24–28 (2005)

J.R. Saunders, The reactions of isocyanates and isocyanate derivatives at elevated temperatures. Rubber Chem. Technol. 32, 337 (1959)

C.L. Cao, J. Cheng, X.D. Liu, R. Wang, J.Y. Zhang, J. Qu, U. Jaeger, Study of properties of one-component moisture-curable polyurethane and silane modified polyurethane adhesives. J. Adhes. Sci. Technol. 26(10–11), 1395–1405 (2012)

X. Wei, T. Luo, Chain length effect on thermal transport in amorphous polymers and a structure–thermal conductivity relation. Phys. Chem. Chem. Phys. 21(28), 15523–15530 (2019). https://doi.org/10.1039/C9CP02397F

D. Yang, M. Tian, Y. Dong, H. Liu, Y. Yu, L. Zhang, Disclosed dielectric and electromechanical properties of hydrogenated nitrile–butadiene dielectric elastomer. Smart Mater. Struct. 21(3), 035017 (2012). https://doi.org/10.1088/0964-1726/21/3/035017

C.S. Miron-Borzan, E. Sabau, M. Mera, P. Berce, Research regarding the manufacturing through AM technologies of an implant for cervical disc replacement. MATEC Web Conf. 137, 02008 (2017)

D.G. Puttaraju, H.G. Hanumantharaju, Finite element analysis and validation of tensile properties of carbon fiber reinforced polymer matrix composites. Mater. Today: Proc. 62, 2800–2807 (2022)

Acknowledgements

We acknowledge technical support from Frontier Laboratories and Quantum Analytics. This work (or part of this work) was conducted in Oak Ridge National Laboratory Center for Nanophase Materials Sciences by R.C. Adivncula, a US Department of Energy Office of Science User Facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rigoberto Advincula was an editor of this journal during the review and decision stage. For the MRS Communications policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editormanuscripts/.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nocheseda, C.J.C., Fazley Elahee, G.M., Santos, M.F.A. et al. On the 3D printability of one-part moisture-curable polyurethanes via direct ink writing (DIW). MRS Communications 13, 647–656 (2023). https://doi.org/10.1557/s43579-023-00407-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-023-00407-5