Abstract

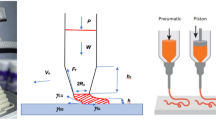

Direct Ink Writing (DIW) utilizes a wide range of ink formulations to produce desirable 3D-printed structures and properties. Styrene-butadiene rubber (SBR) is an attractive candidate for 3D printing owing to its commercial availability, rheology, excellent mechanical properties, good impact resilience, and chemical stability. The SBR-based sealant was 3D printed in a DIW process, even in an ambient environment. The rheological behavior was assessed and correlated with optimized printing parameters. Important physico-chemical properties of the 3D-printed material were reported showing excellent properties as an elastomer. This work should expand the potential applications of existing rubber-based materials in additive manufacturing.

Graphical abstract

Similar content being viewed by others

Data availability

All data for the work are either included in this manuscript or are part of the Electronic Supplementary Information file.

References

T. McCue, Wohlers Report 2018: 3D Printer industry tops $7 billion, 2018. Available at: https://www.forbes.com/sites/tjmccue/2018/06/04/wohlers-report-2018-3d-printer-industry-rises-21-percent-to-over-7-billion/#577ed47a2d1a. Accessed 15 Oct 2022

E.-H. Ramírez-Soria, J. Bonilla-Cruz, M.G. Flores-Amaro, V.J. Garcia, T.E. Lara-Ceniceros, F.E. Longoria-Rodríguez, P. Elizondo, R.C. Advincula, On the effect of ultralow loading of microwave-assisted bifunctionalized graphene oxide in stereolithographic 3D-printed nanocomposites. ACS Appl. Mater. Interfaces. 12(43), 49061–49072 (2020). https://doi.org/10.1021/acsami.0c13702

E.B. Caldona, J.R.C. Dizon, R.A. Viers, V.J. Garcia, Z.J. Smith, R.C. Advincula, Additively manufactured high-performance polymeric materials and their potential use in the oil and gas industry. MRS Commun. 11(6), 701–715 (2021). https://doi.org/10.1557/s43579-021-00134-9

I. Gibson, D.W. Rosen, B. Strucker, Additive manufacturing technologies: rapid prototyping to direct digital manufacturing, 2nd edn. (Springer Science+Business Media, LLC, New York, 2010)

J.A. Lewis, Direct ink writing of 3D functional materials. Adv. Funct. Mater. 16(17), 2193–2204 (2006). https://doi.org/10.1002/adfm.200600434

R.J. Dhanorkar, S. Mohanty, V.K. Gupta, Synthesis of functionalized styrene butadiene rubber and its applications in SBR-silica composites for high-performance tire applications. Ind. Eng. Chem. Res. 60(12), 4517–4535 (2021). https://doi.org/10.1021/acs.iecr.1c00013

S. Thomas, R. Stephen, Rubber nanocomposites: preparation, properties and applications (John Wiley & Sons (Asia) Pte. Ltd., Singapore, 2010)

M. Hirsch, Discover the flexibility of caulks and sealants, 2019. Available at: https://knowledge.ulprospector.com/9377/pc-discover-the-flexibility-of-caulks-and-sealants/. Accessed 01 Feb 2023

Con-Spec Industries, Lexel is better than silicone, 2013. Available at: https://www.conspecindustries.com/wp-content/uploads/2013/03/lexel.pdf. Accessed 20 Feb 2023

Sashco, Lexel technical data sheet (2022), https://sashcoinc.app.box.com/s/unh5zcyega0uimu3c70q6ipizz4m26xa. Accessed 20 Feb 2023

Z.J. Smith, D.R. Barsoum, Z.L. Arwood, D. Penumadu, R.C. Advincula, Characterization of micro-sandwich structures via direct ink writing epoxy based cores. J. Sandw. Struct. Mater. 25(1), 112–127 (2023). https://doi.org/10.1177/10996362221118329

D.B. Gutierrez, E.B. Caldona, Z. Yang, X. Suo, X. Cheng, S. Dai, R.D. Espiritu, R.C. Advincula, 3D-printed PDMS-based membranes for CO2 separation applications. MRS Commun. 12(6), 1174–1182 (2022). https://doi.org/10.1557/s43579-022-00287-1

M.J. Castaldi, E. Kwon, Thermo-gravimetric analysis (TGA) of combustion and gasification of styrene-butadiene copolymer (SBR). Proceedings of the 13th annual North American waste-to-energy conference. Am. Soc. Mech. Eng. (2005). https://doi.org/10.1115/NAWTEC13-3149

S.R. Shield, G.N. Ghebremeskel, C. Hendrix, Pyrolysis−GC/MS and TGA as tools for characterizing blends of SBR and NBR. Rubber Chem. Technol. 74(5), 803–813 (2001). https://doi.org/10.5254/1.3547654

A. Nandiyanto, R. Oktiani, R. Ragadhita, How to read and interpret FTIR spectroscope of organic material. Indones. J. Sci. Technol. 4(1), 97–118 (2019). https://doi.org/10.17509/ijost.v4i1.15806

S.S. Kamath, J.W. Choi, 3D printing of synthetic rubber ink via the direct ink writing process. Rubber World 11, 40–45 (2021)

G.M.F. Elahee, L. Rong, C. Breting, J. Bonilla-Cruz, T.E. Lara-Ceniceros, Z.J. Smith, J. Ge, X. Cheng, M. Xu, M. Yang, E.L. Ribeiro, E.B. Caldona, R.C. Advincula, Acrylic sealants as practicable direct ink writing (DIW) 3D-printable materials. MRS Commun. (2023). https://doi.org/10.1557/s43579-023-00343-4

A. Espera, J. Dizon, A. Valino, Q. Chen, I. Silva, S. Nguyen, L. Rong, R. Advincula, On the 3D printability of silicone-based adhesives via viscous paste extrusion. MRS Commun. 13, 102–110 (2023). https://doi.org/10.1557/s43579-022-00318-x

D.J. Bergman, The dielectric constant of a composite material—a problem in classical physics. Phys. Rep. 43(9), 377–407 (1978). https://doi.org/10.1016/0370-1573(78)90009-1

J. Bicerano, Prediction of polymer properties, 3rd edn. (Marcel Dekker, Inc., New York, 2002)

Paul Martin, Dissipation factor of plastic materials explained, 2022. Available at: https://passive-components.eu/dissipation-factor-of-plastic-materials-explained/#:~:text=Dissipation%20Factor%20is%20a%20dimensionless,radar%20equipment%20or%20microwave%20parts. Accessed 04 March 2023

P. Barber, S. Balasubramanian, Y. Anguchamy, S. Gong, A. Wibowo, H. Gao, H.J. Ploehn, H.-C. Zur Loye, Polymer composite and nanocomposite dielectric materials for pulse power energy storage. Materials 2(4), 1697–1733 (2009). https://doi.org/10.3390/ma2041697

J. Artbauer, Electric strength of polymers. J. Phys. D: Appl. Phys. 29(2), 446–456 (1996). https://doi.org/10.1088/0022-3727/29/2/024

ASTM D257-14, Standard test methods for DC resistance or conductance of insulating materials, ASTM International, West Conshohocken, PA. (2021). https://doi.org/10.1520/D0257-14R21E01

M. Lisowski, Issues of volume resistivity measurement of flat dielectric specimens and evaluation on uncertainty of the measurement results by approximate method at confidence level of 0.95. Metrol. Meas. Syst. 16(2), 233–248 (2009)

S.M. Aharoni, Electrical resistivity of a composite of conducting particles in an insulating matrix. J. Appl. Phys. 43(5), 2463–2465 (1972). https://doi.org/10.1063/1.1661529

W.D. Callister Jr., D.G. Rethwisch, Materials science and engineering, 9th edn. (John Wiley & Sons, Inc., USA, 2014)

A. Abdel-Hakim, S.A. El-Mogy, A.I. Abou-Kandil, Novel modification of styrene butadiene rubber/acrylic rubber blends to improve mechanical, dynamic mechanical, and swelling behavior for oil sealing applications. Polym. Polym. Compos. 29(9), S959–S968 (2021). https://doi.org/10.1177/09673911211031351

J. Liu, X. Li, L. Xu, P. Zhang, Investigation of aging behavior and mechanism of nitrile-butadiene rubber (NBR) in the accelerated thermal aging environment. Polym. Test. 54, 59–66 (2016). https://doi.org/10.1016/j.polymertesting.2016.06.010

M. Dridi, S. Hachemi, A.A. Belkadi, Influence of styrene-butadiene rubber and pretreated hemp fibers on the properties of cement-based repair mortars. Eur. J. Environ. Civ. Eng. 27, 538–557 (2023). https://doi.org/10.1080/19648189.2022.2052968

C. Kasprzak, J. Brown, K. Feller, P. Scott, V. Meenakshisundaram, C. Williams, T. Long, Vat photopolymerization of reinforced styrene-butadiene elastomers: a degradable scaffold approach. ACS Appl. Mater. Interfaces 14(16), 18965–18973 (2022)

P. Scott, V. Meenakshisundaram, M. Hegde, C. Kasprzak, C. Winkler, K. Feller, C. Williams, T. Long, 3D printing latex: a route to complex geometries of high molecular weight polymers. ACS Appl. Mater. Interfaces 12(9), 10918–10928 (2020)

Acknowledgments

We acknowledge technical support from Frontier Laboratories and Quantum Analytics for technical support. This work (or part of this work) was conducted in Oak Ridge National Laboratory Center for Nanophase Materials Sciences by Rigoberto C. Advincula, a US Department of Energy Office of Science User Facility.

Funding

This study was funded by U.S. Department of Energy.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no known conflict of interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rigoberto Advincula was an editor of this journal during the review and decision stage. For the MRS Communications policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editormanuscripts/.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Garcia, V.J., Fazley Elahee, G.M., Collera, A.K. et al. On the direct ink write (DIW) 3D printing of styrene-butadiene rubber (SBR)-based adhesive sealant. MRS Communications 13, 1266–1274 (2023). https://doi.org/10.1557/s43579-023-00436-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-023-00436-0