Abstract

Although metal–organic (MO) precursors are widely used in technologically relevant deposition techniques, reports on their temperature-dependent evaporation and decomposition behaviors are scarce. Here, MO precursors of the metals Ti, V, Al, Hf, Zr, Ge, Ta, and Pt were subjected to thermogravimetric analysis to experimentally determine their vapor pressure curves and to gain insight into their temperature-dependent decomposition kinetics. Benzoic acid was used as a calibration standard and vapor pressure curves were extracted from thermogravimetric measurements using the Langmuir equation. The obtained data is used to discuss the suitability of these MO precursors in chemical vapor deposition-based thin film growth approaches in general, and hybrid molecular beam epitaxy in particular. All MOs, except for Ta- and one Ti-based MOs, were deemed suitable for gas inlet systems. The Ta-based MO demonstrated suitability for an effusion cell, while all MOs showed compatibility with cracker usage.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Crystalline thin films have impacted many areas of research such as electronics [1], optics [2], energy generation [3], and energy storage [4]. The phenomenal rise in the development of thin films is likely to continue as they have become the key elements of technological advancements [5]. Thin film growth processes can be broadly classified into three different approaches. These encompass chemical vapor deposition (CVD) techniques, including metal–organic chemical vapor deposition (MOCVD), metal–organic vapor phase epitaxy (MOVPE), metal–organic molecular beam epitaxy (MOMBE) or chemical beam epitaxy (CBE), and atomic layer deposition (ALD). Additionally, physical vapor deposition (PVD) methods play a significant role, such as sputtering, pulsed laser deposition (PLD), thermal evaporation, and molecular beam epitaxy (MBE). Combinatorial approaches such as hybrid MBE (hMBE), where the advantages of CVD and PVD are ideally combined, have recently been developed as well [6, 7], e.g., for the growth of complex oxide thin films. All of these approaches share the common feature that the thin film material is supplied to the film growth front in the gas form.

Among these deposition techniques, MBE offers the highest degree of control over the film thickness and provides the most controlled deposition environment by supplying ultra-pure atomic or molecular beams of elements to a heated crystalline substrate under ultra-high vacuum (UHV) conditions [8, 9]. However, thin films consisting of elements with low vapor pressures present a technological challenge for MBE that severely limits growth rates and renders thermal evaporation virtually impossible for some elements, requiring very high temperatures that cannot be reached with thermal Knudsen effusion cells [10, 11]. An alternative to supplying low vapor pressure elements is using an electron beam (e-beam) evaporator. However, these proved to provide less stable fluxes, requiring continuous flux monitoring and integrated feedback control loops [12]. Furthermore, e-beam evaporators expose the substrate to an unintentional heat load during operation and their electromagnetic stray fields can distract electron beams used by in situ growth monitoring techniques, like reflection high energy electron diffraction (RHEED), which can have a detrimental impact on control over the overall film deposition process [13].

A second alternative for the supply of low vapor pressure elements in an MBE reactor is hMBE. Here, higher vapor pressure metal–organic (MO) precursors are used instead of thermally evaporating the low vapor pressure elements. This approach entails two benefits. First, it reduces the necessary cell temperatures for the MO source material, which makes it easier to evaporate, reduces costs, and leads to faster growth rates. [14]. Typically, the required evaporation temperature can be lowered by a few hundred to 1000 K [14] by supplying constituents in MO form instead of elemental form. Second, it has been transformative to the field of oxide thin film growth as it demonstrated superior control over cation stoichiometry for compound oxides by enabling access to self-regulated growth kinetics [7, 14]. Particularly, Jalan et al. [7] have shown the growth of stoichiometric SrTiO3 using a simple Knudsen effusion cell for Sr, a plasma source for oxygen, and the MO precursor titanium(IV) tetraisopropoxide (TTIP) supplied by a gas inlet system for Ti, which enabled self-regulated cation stoichiometry control, scalable growth rates and produced films of outstanding structural quality due to favorable growth kinetics of the volatile MO during the growth process. Following the work of Jalan et al., various studies have been conducted to widen the scope of utilizing MO precursors in hMBE. Zhang et al. [15] reported on the heteroepitaxial growth of SrTiO3 on Si(001) by hMBE using a co-supply of elemental Sr and TTIP in the absence of additional oxygen, demonstrating that the MO precursor acts simultaneously as a Ti as well as an oxygen source. Later, Zhang et al. [16] have grown LaVO3 thin films on SrTiO3 (001) using another volatile MO precursor, vanadium(V) oxytriisopropoxide (VTIP). By varying the VTIP flux and keeping the La flux fixed, stoichiometric LaVO3 films were obtained for a range of cation flux ratios, suggesting a self-regulated growth window. The ever-expanding list of oxide materials successfully grown by hMBE today includes SrVO3 (111) with residual resistivity ratios exceeding 20 showing high-quality metallic behavior with lower defect concentration and ultra-clean thin films [17], and BaTiO3 with optical constants showing bulk-like behavior in the spectral range of (375–1690) nm [18].

The remarkable success of oxide hMBE and the ongoing quest for synthesizing innovative oxide materials drive the exploration of new MO precursor chemistries and their suitability in terms of decomposition and evaporation properties for hMBE. In this regard, favorable ligand separation is essential where all carbon-based volatile by-products are pumped away to avoid unintentional carbon contamination of the films, ultimately allowing the incorporation of the element(s) of interest into the film. Thus, MOs containing ligands with fewer carbon atoms might be preferred over the ones with bulky ligands to reduce the number of possible by-products and to limit the total carbon exposure to the growing film. However, there are a few exceptions to this situation where a MO substance (triethylgallium), despite having a higher carbon atom content, was found to induce less carbon contamination than its lower carbon-containing counterpart (trimethylgallium). This disparity can be attributed to variations in the decomposition kinetics between these two substances [19]. Additionally, while in CVD, MOCVD, and ALD, MO precursors are universally supplied using carrier gases through a gas injector source [20], the suitable evaporation source for different MO precursors in hMBE will vary depending on their vaporization enthalpies (the energy required to transform a substance from its liquid into its gas phase) and vapor pressure curves. This raises the importance of MO precursor vapor pressure studies and their implications for use in hMBE.

Several methods exist to determine the vapor pressure curves for different substances. A direct way is to measure the vapor pressures using a manometer [21]. This method requires cleaning of the vapor pressure measurement setup every time a new MO is measured based on cleaning recipes of each MO which is not a time and cost-efficient route. Interestingly, a simplistic thermogravimetric analysis (TGA) technique relating weight loss rate to vapor pressure as a function of temperature was shown to indirectly, but accurately determine vapor pressure curves of pharmaceutical compounds by Elder and Xie [22, 23]. Here, the weight loss rate from TGA was linked to the vapor pressure of the compound using established vapor pressure curves of known materials as comparison standards [22, 23]. Further research in the field on many different chemical substances has confirmed that TGA is a valid, reproducible, and accurate method to determine vapor pressures through the application of the Langmuir equation relating weight loss rates to vapor pressures [21, 24,25,26,27,28,29]. Due to its high versatility as well as the broad and easy accessibility of TGA setups, it provides a very effective means to determine temperature-dependent vapor pressures when compared with the aforementioned method.

In this work, we performed TGA experiments on various MO precursors containing high-interest refractory elements and derived their temperature-dependent vapor pressure curves, specifically the MO precursors titanium(IV) isopropoxide (TTIP), vanadium(V) oxytriisopropoxide (VTIP), dimethylaluminum isopropoxide (DMAi), hafnium(IV) tert-butoxide (HTB), zirconium(IV) tert-butoxide (ZTB), germanium(IV) ethoxide (GeE), tantalum(V) n-butoxide (TaNB), titanium(IV) diisopropoxidebis(2,2,6,6-tetramethyl-3,5-heptanedionate) (TDIP), and trimethyl(methylcyclopentadienyl) platinum(IV) (TMCP), which could potentially serve as Ti, V, Al, Hf, Zr, Ge, Ta, Ti, and Pt sources, respectively. Benzoic acid was used as a calibration standard. This work presents temperature-dependent vapor pressure curves for all nine substances. Although vapor pressures of some of these MO precursors have been presented before, previously reported curves were in parts extrapolations based on very limited data sets, which were found in safety data sheets of MO chemicals. Here, vapor pressures were derived with high accuracy directly from TGA measurements. The suitability of these precursors for hMBE is also discussed with respect to their tendency to generate non-volatile residues along with their ability to generate stable fluxes.

Materials and methods

The weight loss data per unit time was gathered using a NETZSCH STA 449 F3 Jupiter® instrument, operating with a heating rate of 10 K/min. The choice of this heating rate, 10 K/min, is determined by the need to strike a balance and is motivated by many other TGA studies focusing on vapor pressure estimation [25, 29,30,31]. On one hand, it is crucial to prevent the oxidation of MOs, which can occur at low heating rates. On the other hand, it is essential to capture the critical decomposition kinetics without using excessively high heating rates which may result in some important reactions remain undetected [32]. Our validation via a direct vapor pressure measurement (VPM) method (SuppInfo Fig. 1) reaffirms that a heating rate of 10 K/min was an ideal compromise. The measurements were conducted in a dry nitrogen (99.99% purity) atmosphere with a flow rate of 50 ml/min to prevent combustion and account for the moisture sensitivity of the majority of the MOs examined in this study. Sample pans made from Pt/Rh having an outer bottom diameter of 6.8 mm (85 µl) were purchased from NETZSCH. Benzoic acid (Sigma-Aldrich, ≥ 99.5%), TTIP (Sigma-Aldrich, 99.999% trace metals basis), VTIP (Sigma-Aldrich, 99%), DMAi (Strem Chemicals, Inc., ≥ 99.99%), HTB (Strem Chemicals, Inc., 99.9%-Hf, < 1.5%-Zr), ZTB (Strem Chemicals, Inc., 99.99%-Zr), GeE (Strem Chemicals, Inc. ≥ 99.99%), TaNB (Strem Chemicals, Inc., ≥ 99.99%), TDIP (Sigma-Aldrich, ≥ 99.99%), and TMCP (Strem Chemicals, Inc., ≥ 99%) were used as received without further purification or modification. Depending on the amount of each chemical required to cover the surface of the pan as a thin layer, (10–20) mg of substance were placed in the pans. Since TDIP and TCMP were solids at room temperature they were spread evenly in the pan to achieve a smooth coverage of the pan with a well-defined surface. All other MOs investigated were liquid at room temperature and even though a meniscus formation was expected to occur, such surface area variation was neglected. Benzoic acid was used as a chemical substance to establish a calibration standard for the TGA equipment, which is an ideal choice due to its thermal stability and well-known pressures in the temperature window of interest, i.e., 300 K to 500 K. The Antoine equation (Eq. 1) [33]

with p: vapor pressure (Pa), T: temperature (K), and \(A\):, \(B\):, and, \(C\): Antoine’s parameters is a semi-empirical equation that was used to calculate the benzoic acid vapor pressure as a function of temperature. Table 1 summarizes Antoine’s parameters, which were used for benzoic acid in this work [29, 30]. It is noted that even though the SI system recommends using Pascals, the parameters of Antoine's equation are typically given in Torr. The parameters used in this study were taken from the NIST online chemistry webbook [34].

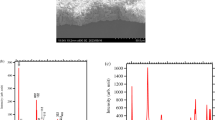

(a) Weight (%) and relative weight loss (%/min) profiles of benzoic acid obtained from thermogravimetric analysis in the temperature range of 300 K to 570 K. The solid line (thermogravimetric (TG) data) represents the weight percentage, while the dotted line represents the relative weight loss (differential thermogravimetric (DTG) data). (b) A plot of calculated vapor pressure versus measured \(v\) for benzoic acid. The calibration constant k is the slope and was determined by linear regression as 6.2 × 106 J0.5/K0.5mol0.5 with an R2 value of 0.99.

The Langmuir equation [Eq. 2 with \(F\): area of the TGA pan bottom (m2), \(p\): vapor pressure (Pa), \(M\): relative molecular weight of the analyte (kg/mol); \(T\): absolute temperature (K); \(R\): gas constant (8.314 J/{K mol}), and \(\alpha \): vaporization coefficient, which is typically assumed to be unity] was used to calculate vapor pressures from the TGA recorded weight loss data as \(dm/dt\)(kg/s), i.e., the weight loss at known time intervals during evaporation in a controlled environment as part of the measurement process [17, 36].

Rearranging the Langmuir equation as:

with \(k=\sqrt{2\pi R}/\alpha \) in units of J0.5/K0.5mol0.5 and \(v=-(1/F)(dm/dt)\sqrt{T/M}\) in units of kg0.5K0.5mol0.5/m2s1 allows plotting \(p\) versus \(v\) as a linear curve from the TGA data. Here, \(v\) is independent of the instrument and is only dependent on the analyte, while the so-called calibration constant \(k\) is solely dependent on the TGA instrument [25, 37]. TGA, therefore, requires a calibration standard with well-known properties to determine the instrument-specific value of \(k\). Plotting the vapor pressure \(p\) of benzoic acid calculated from tabulated Antoine’s parameters in a given temperature range taken from Table 1 versus \(v\) obtained from the TGA measurements of benzoic acid allowed to determine \(k\) from a linear fit of \(p\) versus \(v\), which made it possible to link temperature-dependent weight loss rates to vapor pressure curves. The vaporization enthalpy—i.e., the heat of vaporization or heat of evaporation—can be determined directly from the vapor pressure–temperature curves using the Clausius–Clapeyron equation:

For comparison of the TGA method and the determination of its accuracy, a vapor pressure measurement (VPM) setup (SuppInfo Fig. 1) was used to rule out systematic errors from the determination of the calibration constant, summarized in the Supporting Information. The performance of the VPM setup itself was evaluated by measuring the vapor pressure curve of water, which was in excellent agreement with published data. The combined TGA and Langmuir method was subsequently compared to the results directly obtained from VPM using TTIP. Within the error bars of the respective methods, the data obtained from both approaches were in very good agreement, see SuppInfo Fig. 2(a) and (b), confirming that the indirect method of experimental vapor pressure curve determination from TGA provides reliable results [21,22,23,24,25,26,27,28,29].

Results and discussion

The values of the TGA measurement [thermogravimetric data (TG): the analyte weight in the TGA pan relative to the loading weight in %, and differential thermogravimetric (DTG) data: first derivative of TG in %/min] as a function of temperature are shown in Fig. 1(a) for benzoic acid. Its molecular structure is sketched in the inset of Fig. 1(a). After heating benzoic acid from room temperature to 570 K, it was completely evaporated, and the residual weight was 0%. The DTG curve revealed two peaks. The dominant one between (400–480) K was attributed to the evaporation of benzoic acid, while the very subtle peak at 395 K was attributed to the melting of benzoic acid. These two DTG features were in perfect agreement with the literature values for benzoic acid [34]. Figure 1(b) shows the vapor pressures of benzoic acid calculated by the Antoine equation using the Antoine parameters from the literature [34] shown in Tab. 1 in the investigated temperature range of (369–522.4) K over the experimentally determined \(v\) values calculated from DTG data shown in Fig. 1(a) as gray dots. A linear regression of \(p\) versus \(v\) shown in Fig. 1(b) was used to extract the TGA instrument-specific constant \(k\). The slope was found to be k = 6.2 × 106 J0.5/K0.5mol0.5 with an R2 value of 0.99.

In this section, MOs for each figure were categorized into groups based on their shared ligand chemistries. The TG (weight relative to the loading weight) and DTG (relative weight loss) curves of TTIP are shown in Fig. 2(a). TTIP is an odorless and colorless to light yellow liquid at room temperature which has a molecular weight of 284.22 g/mol. Its molecular structure consists of four isopropoxide ligands [− OCH(CH3)2] attached to the central Ti atom as sketched in the inset of Fig. 2(a). The TG curve shows that the significant mass loss event from 100% weight at room temperature down to about 25% weight occurred at 450 K, accompanied by the highest DTG peak. This first mass loss event was attributed to the initial evaporation of TTIP molecules. After this evaporation step, a second DTG peak occurred at 490 K attributed to the onset of TTIP’s thermal decomposition. The third peak at 550 K was similarly assigned to additional weight loss from thermal decomposition and evaporation. From this temperature on, the weight loss gradually increased by a small amount reflecting most likely the decomposition and evaporation of the remaining Ti-based compounds until no residual TTIP was left in the pan. The residue-free evaporation process renders TTIP an ideally suited candidate since it will not need a thorough cleaning procedure, as it can be fully evaporated, emptied, and cleaned with a simple temperature cycle of 550 K. The vapor pressure versus temperature curve for TTIP in Fig. 2(b) was calculated using the Langmuir equation and the instrument-specific calibration constant \(k\). The data is shown on a semilog scale versus 1/T in the inset of Fig. 2(b). Symbols represent the calculated data points in both plots, while the line reflects a linear fit through the data with an R2 value of 0.97. The experimental values for TTIP follow the logarithmic fit very well, except for a few outliers at low temperatures, which were attributed to temperature fluctuations during the ramp-up process. As discussed in the Supporting Information, a VPM system was built to access the vapor pressure curve for TTIP directly. The comparison is given in SuppInfo Fig. 2(b) and yielded excellent agreement with the data calculated from TGA, ruling out systematic errors in the determination of the calibration constant k. Notably, for all the investigated MOs, no weight gain was observed. This outcome can be attributed to the use of an inert and non-reactive dry nitrogen atmosphere, which effectively prevents any unexpected combination or synthesis reactions from occurring.

(a, c, e) Weight and relative weight loss, and (b, d, f) extracted temperature-dependent vapor pressure of TTIP, VTIP, and DMAi with insets containing a semi-log plot vs inverse temperature. Vapor pressure curves were estimated from the shaded section of the relative weight loss data. Molecular structures for TTIP, VTIP, and DMAi are depicted in (a, c, e).

Following this methodology, Figs. 2(c) and (d) show the TG/DTG and derived vapor pressure curve for VTIP, respectively. VTIP is an odorless yellow liquid at room temperature with a molecular weight of 244.20 g/mol. The structure of the VTIP molecule is similar to that of TTIP, consisting of three isopropoxide ligands [− OCH(CH3)2] and one oxygen atom which is double bonded to the central V atom, see the sketch in Fig. 2(c). Similar to TTIP, VTIP showed a pronounced DTG peak arising from the onset of a sizeable evaporation rate already at low temperatures (300—420) K. The second peak at 465 K was assigned to the dissociation of the ligand structure producing vanadium oxides of VTIP. No further weight loss events were observed and a total residual weight of about 30% was present at the end of the measurement. These non-volatile residues will remain in gas inlet systems. Figure 2(d) shows the corresponding vapor pressure plot for VTIP. The experimental deviations from the logarithmic fit (R2 = 0.95) at low temperatures were due to fluctuations in the temperature ramp-up process, a general behavior observed in TTIP, VTIP, and many of the analytes below.

The TG and DTG curves of another MO precursor, DMAi, are shown in Fig. 2(e). DMAi is an odorless colorless liquid at room temperature which has a molecular weight of 116.14 g/mol. DMAi molecule is structured with two methyl groups (–CH3) represented by two lines and one isopropoxide ligand [− OCH(CH3)2] that are all attached to the central Al atom as depicted in the inset of Fig. 2(e). The first and largest DTG peak was attributed to the evaporation process of DMAi around (300—400) K. The second, third, and fourth peaks were attributed to the pyrolysis of the molecule and the loss of the methyl and the isopropoxide ligands, as suggested by an experimental study that investigated the decomposition of DMAi [38]. A white solid residue making up around 25% of the total weight was observed, which seemed to be made up of aluminum oxides. Figure 2(f) shows the corresponding vapor pressure plot for DMAi and the linear fit of the pressure versus 1/T data with an R2 value of 0.96.

HTB is a liquid that appears colorless or pale yellow at room temperature and has a molecular weight of 470.94 g/mol. TG and DTG data are plotted in Fig. 3(a). The molecular structure of HTB consists of the central Hf atom and four bulky tert-butoxide ligands [− OC(CH3)3] as shown in the inset of Fig. 3(a). The largest peak of the DTG curve was attributed to the thermal evaporation of HTB around (300–440) K. The reason behind the secondary DTG peak around 380 K, attributed to HTB's instability in that temperature range and similar to what was previously reported for the HTB MO precursor [39], remains unclear in terms of its actual cause. It is noteworthy that no phase change from solid to liquid occurred within that temperature range where this peak was observed, further adding to the uncertainty. The small peak at 540 K was attributed to a decomposition reaction between C and O atoms of the MO substance leaving Hf oxides in the sample pan. A black residue of about 35% of the total initial weight remained in the pan at the end of the experiment suggesting that carbon-based ligands did not completely break off and non-volatile carbon-based compounds were formed during evaporation. Figure 3(b) shows the corresponding vapor pressure plot for HTB, where fit and experimental values were not consistent throughout the entire temperature range (R2 = 0.92) unlike the other MOs studied.

(a, c, e) Weight and relative weight loss, and (b, d, f) extracted temperature-dependent vapor pressure of HTB, ZTB, and GeE with insets containing a semi-log plot vs inverse temperature. Vapor pressure curves were estimated from the shaded section of the relative weight loss data. Molecular structures for HTB, ZTB, and GeE are depicted in (a, c, e).

Having very similar chemistries with HTB; the ZTB molecule has four tert-butoxide ligands [− OC(CH3)3] as shown in the inset of Fig. 3(c). It is a light yellow liquid at room temperature with a molecular weight of 383.68 g/mol and shows almost the same TG and DTG patterns as HTB in Fig. 3(c). The similarities between HTB and ZTB are evident, particularly in their DTG data, which exhibit three peaks for both compounds. Remarkably, both compounds display a pattern of a low-intensity peak, followed by a high-intensity peak, and then a subsequent lower-intensity peak. This observation can be attributed to the similar ligand chemistries present in HTB and ZTB. Only the first peak at 420 K was attributed to the ZTB evaporation, all other peaks were assumed to originate from the decomposition reactions of the substance producing ZrO2 [30]. Again, a black residue of about 15% of the total initial weight remained in the pan at the end of the experiment indicating that the decomposed ligands were not fully evaporated, but similar to HTB also turned into carbon-based non-volatile residues. The corresponding vapor pressure curve for ZTB is shown in Fig. 3(d), experimental values and fit are in very good agreement throughout the entire investigated temperature range with an R2 value of 0.99.

GeE is a colorless liquid at room temperature. This MO has a molecular weight of 252.88 g/mol. The molecular structure of GeE consists of four ethoxide ligands (–OCH2CH3) as depicted in the inset of Fig. 3(e). GeE shows very smooth TG and DTG curves as displayed in Fig. 3(e) with just one DTG peak at 390 K corresponding to the evaporation of the precursor. A large amount of non-volatile residue amounting to 50% of the total weight remained in the TGA pan at the end of the experiment. Figure 3(f) shows the corresponding vapor pressure curve for GeE. The agreement of experimental values and fit is excellent showing an R2 value of 0.99.

Figure 4(a) shows the TG and DTG curves of TaNB, a very viscous transparent liquid at room temperature with a molecular weight of 546.52 g/mol. Its molecules are made up of five alkoxide chains that are composed of one oxygen and four carbon atoms (–OCH2CH2CH2CH3), sketched in the inset of Fig. 4(a). The evaporation temperature was 570 K-indicated by the first peak on the DTG plot. This was the highest evaporation temperature among all precursors investigated. The second peak at 640 K was attributed to the first thermal decomposition step of TaNB, where one of the five n-butoxide ligands was broken off and evaporated. A non-volatile opaque white residue of about 25% of the total weight remained in the sample pan at the end of the experiment that was most likely composed of n-butoxide ligands and oxides of tantalum. Figure 4(b) shows the corresponding vapor pressure plot for TaNB. Deviations from the logarithmic fit at low temperatures are similar to VTIP, but much more pronounced in the experimental data, which resulted from the variations in the temperature during the ramp-up process and possibly a process where the viscous MO became more fluid (R2 = 0.64).

(a, c, e) Weight and relative weight loss, and (b, d, f) extracted temperature-dependent vapor pressure of TaNB, TDIP, and TMCP with insets containing a semi-log plot vs inverse temperature. Vapor pressure curves were estimated from the shaded section of the relative weight loss data. Molecular structures for TaNB, TDIP, and TMCP are depicted in (a, c, e).

TDIP, which is a white solid powder at room temperature with a molecular weight of 532.58 g/mol and the one with the most complex molecule in this study, was measured as an oxygen-rich alternative to TTIP. The TDIP molecule consists of two isopropoxide [–OCH(CH3)2] and two very bulky 2,2,6,6-tetramethyl-3,5-heptanedionate groups as ligands as shown in the inset of Fig. 4(c). The TG and DTG curves of TDIP are shown in Fig. 4(c). The largest and first DTG peak was attributed to the thermal evaporation of the precursor at 500 K. The second peak at 600 K was attributed to a decomposition reaction. No reports were found on the potential pathways of decomposition for this MO. A non-volatile white residue of about 10% of the total weight remained in the TGA pan at the end of the experiment. Figure 4(d) shows the corresponding vapor pressure curve obtained for TDIP. TDIP had very low vapor pressure values compared to most of the other MO substances measured in this study and has deviations in the low-temperature range due to the physical state change from solid to liquid with an R2 value of 0.93. Both TaNB and TDIP exhibit significant fluctuations just above room temperature. However, when these fluctuations are removed, both TaNB and TDIP demonstrate R2 values of 0.99, confirming the excellent performance of these MOs at these temperatures.

Finally, TMCP, a gel-like MO at room temperature which has a molecular weight of 319.30 g/mol and a white to yellow color was measured to investigate its suitability as a high-pressure Pt source. The TMCP molecule has three methyl (–CH3) groups directly bonded to the Pt atom and one bulky 5-membered ring with another methyl (–C5H4CH3) attached to it as shown in the inset of Fig. 4(e). The TG and DTG curves of TMCP are shown in Fig. 4(e). The largest, and first DTG peak was attributed to the MO evaporation at 430 K. The small peaks were observed in the temperature range of (460–500) K. A previous study in which possible decomposition pathways of TMCP were studied in detail reports that methyl (–CH3) groups are possible by-products of the decomposition reactions [40]. Based on this previous study and due to the low molecular weight of methyl (–CH3) molecule thus smaller peaks on the relative weight loss curve, it was assumed that those small peaks resulted from the breaking off and evaporation of methyl (–CH3) groups. A non-volatile white residue of about 30% remained in the TGA pan at the end of the experiment. Figure 4(f) shows the corresponding vapor pressure curve obtained for TMCP. Similar to TaNB, a gel-like MO, TMCP, showed deviations in the low-temperature range due to the physical state change from gel to a more fluid form with an R2 value of 0.96.

All obtained vapor pressure curves are plotted in Fig. 5 for direct comparison. The fit parameters X and Y as per the equation in Fig. 5 are summarized in Table 2 for all investigated substances. The ideal MO window was determined based on the typical temperatures [(300–400) K] and pressures [(1–10) Torr] at which gas inlets of hMBE systems are generally operated [14]. The complex behavior and deviation of experimentally found values from the logarithmic fit seen for some MOs right above room temperature were attributed to the rearrangements of molecules before evaporation and small fluctuations in the temperature ramp-up process as discussed before. As shown in Fig. 5, those fluctuations occurred outside of the applicable temperature range for MO evaporation [outside of the ideal MO window of [(300–400) K and (1–10) Torr] and can therefore be neglected. Data points with large deviations from linearity were thus truncated for clarity in Fig. 5 for TaNB and TDIP at low temperatures [(300–450) K for TaNB and (300–380) K for TDIP]. Overall, the vapor pressure curves for most of the studied MOs were very close to one another except for TaNB and TDIP. The very viscous liquid TaNB and solid TDIP had much-reduced vapor pressures compared to TTIP, VTIP, DMAi, HTB, ZTB, GeE, and TMCP. Vaporization enthalpies ΔH calculated from the lnp versus 1/T data (Equation in Fig. 5) were found to be between (47.35–115.01) kJ/mol as listed in Table 2 for all investigated MO precursors. In addition to the fitting constants, X and Y, and the vaporization enthalpy, Table 2 also includes the amount of residual weight left in the TGA pans after each measurement, vapor pressures at room temperature, as well as temperatures where vapor pressures values of (100, 1 × 10–6, and 1 × 10–9) Torr were reached. These temperatures provide guidance on what type of evaporation source would be required in hMBE systems, i.e., gas inlet source, cracker cell, or conventional Knudsen effusion cell design. Evaluating the data presented in Table 2, seven MOs, namely TTIP, VTIP, DMAi, HTB, ZTB, GeE, and TMCP were found to be suited for gas inlet systems as they fall into the ideal MO window in Fig. 5. TaNB and TDIP cannot be supplied via gas inlet systems because they require higher temperatures than a typical gas inlet system design can provide to reach the (1–10) Torr pressure range. The utilization of GeE in a gas inlet system appears to be highly inefficient, as evidenced by the significant residual weight of more than 50% observed in this study following the heating process. TTIP, VTIP, DMAi, HTB, ZTB, GeE, TDIP, and TMCP have too high vapor pressures at room temperature [(1 × 10–2–1) Torr] to be supplied from an effusion cell. From the experimentally gained values, it is difficult to comment on the suitability of TaNB and TDIP for effusion cells using the raw TGA data, as their vapor pressures at room temperature were not accessible due to molecular rearrangements and fluctuations around room temperature. Extrapolations of the fit to room temperature and below, however, gave the following results. The vapor pressures of TaNB and TDIP at room temperature were (1.2 × 10–8 and 1.4 × 10–4) Torr, respectively, meaning TaNB could possibly be placed in an effusion cell without compromising the vacuum level in an MBE system too much. The four orders of magnitude higher vapor pressure of TDIP renders it unsuitable for evaporation from a conventional Knudsen effusion cell. The temperatures at which the pressures of TaNB and TDIP reach (1 × 10–6 and 1 × 10–9) Torr offer valuable information regarding their suitability for use in effusion cells. This data sheds light on the potential exploration of alternative sources for these MO precursors, such as ultra-low temperature effusion cells, which could serve as viable alternatives in the quest for more efficient supply methods. Here, based on the measured and extrapolated vapor pressures, TaNB (p = 10–9 Torr at 283 K) was determined to be compatible with ultra-low temperature effusion cells within a temperature range of (283–550) K, making it a suitable choice for UHV systems. Commercially available options are accessible for implementing this MO precursor. TDIP would require idle temperatures around 210 K, which touches upon the lowest temperature bound for up-to-date available effusion cells. However, a respective effusion cell for TDIP would also be required to reach operation temperatures up to 500 K. Therefore, a cracker cell design might be more suitable for TDIP as it readily evaporates thermally in the (300–1000) K temperature range. It has been determined that TDIP is not suitable for use in gas inlet systems due to its relatively low vapor pressures at typical temperatures found in such systems. Additionally, it is not suitable for effusion cells due to its high vapor pressures (1.4 × 10–4 Torr) at room temperature, which are incompatible with UHV requirements. However, the use of a cracker cell shows promise for TDIP and all other MOs, as it can potentially enhance the decomposition process by removing the carbon-based ligands and releasing the desired elements during thin film during growth.

A semi-log plot of vapor pressure (Torr) versus inverse temperature [1/T (K)] for all metal–organic precursors investigated. The equation given describes the fit of the presented data. The ideal MO window was outlined based on the typical temperatures and pressures used in gas inlet systems [(300–400) K and (1–10) Torr].

In conclusion, the vapor pressure curves of nine MO substances for highly sought-after transition and post-transition metals in oxides, such as Ti, V, Al, Hf, Zr, Ge, Ta, and Pt were calculated from measured TGA data and compared to the direct measurement using a VPM system (Supporting information) in the case of TTIP. The results obtained from TGA and VPM for TTIP were in excellent agreement, confirming the established practice of TGA as a reliable, fast, affordable, and accurate method for determining vapor pressures. X and Y constants of the vapor pressure equation lnp = X + (Y/T), were listed and the suitability of the MOs was assessed based on the pressures achieved at various temperatures and the non-volatile residual weight observed at the conclusion of the TGA measurements. MOs such as TTIP, VTIP, DMAi, HTB, ZTB, GeE, and TMCP, which exhibit vapor pressures (1–10) Torr at typical gas inlet operation temperatures (300–400) K, were assessed for their potential use in the gas inlets of hMBE systems. These MOs were found to provide an adequate flux during thin film growth, making them suitable candidates for gas inlet applications. These MOs also have relatively low vaporization enthalpies [ΔH = (47.35–72.34) kJ/mol] compared with others. However, despite GeE having a relatively low vaporization enthalpy (ΔH = 53.82 kJ/mol), it was observed to leave a significant amount of residue, up to 50% of its initial weight, after the TGA measurement. GeE thus might not be a very cost-effective choice. TaNB (ΔH = 115.01 kJ/mol) and TDIP (ΔH = 70.36 kJ/mol) do not provide high enough vapor pressures for gas inlet operation [(300–400) K] and were thus found not suitable for the external gas inlet supply. However, less commonly used sources like ultra-low temperature effusion cells offer a potential alternative for TaNB use in the UHV environment of hMBE. TDIP was determined to require a cracker cell, as it is not compatible with either gas inlet systems or effusion cells. A cracker source can also be used for all other MOs to enhance the decomposition. Similar studies on an abundance of MO precursors and alternative chemistries for the supply of low vapor pressure elements with high technological relevance are needed. Their impact is not limited to hMBE but benefits the large field of bottom-up growth approaches relying on MO precursors and with that advances a vastly broad range of applications.

Data availability

The data generated and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

K. Nomura, H. Ohta, K. Ueda, T. Kamiya, M. Hirano, H. Hosono, Thin-film transistor fabricated in single-crystalline transparent oxide semiconductor. Science 300, 1269–1272 (2003). https://doi.org/10.1126/science.1083212

K. Pfeiffer, S. Shestaeva, A. Bingel, P. Munzert, L. Ghazaryan, C. van Helvoirt et al., Comparative study of ALD SiO_2 thin films for optical applications. Opt. Mater. Express 6, 660 (2016). https://doi.org/10.1364/ome.6.000660

S. Trolier-Mckinstry, P. Muralt, Thin film piezoelectrics for MEMS. J. Electroceram. 12, 7–17 (2004). https://doi.org/10.1023/B:JECR.0000033998.72845.51

M.C. Rao, M.S. Shekhawat, A brief survey on basic properties of thin films for device application. Int. J. Mod. Phys. Conf. Ser. 22, 576–582 (2013). https://doi.org/10.1142/s2010194513010696

M. Ohring, Materials Science of Thin Films, 2nd edn. (Academic Press, New York, 2001)

B. Jalan, P. Moetakef, S. Stemmer, Molecular beam epitaxy of SrTiO3 with a growth window. Appl. Phys. Lett. (2009). https://doi.org/10.1063/1.3184767

B. Jalan, R. Engel-Herbert, N.J. Wright, S. Stemmer, Growth of high-quality SrTiO3 films using a hybrid molecular beam epitaxy approach. J. Vac. Sci. Technol. A 27, 461–464 (2009). https://doi.org/10.1116/1.3106610

A.Y. Cho, J.R. Arthur, Molecular beam epitaxy. Prog. Solid-State Chem 10, 157–191 (1975)

S. Franchi, Molecular beam epitaxy: fundamentals, historical background and future prospects. Elsevier (2013). https://doi.org/10.1016/B978-0-12-387839-7.00001-4

C.D. Theis, D.G. Schlom, Cheap and stable titanium source for use in oxide molecular beam epitaxy systems. J. Vac. Sci. Technol. A 14, 2677–2679 (1996). https://doi.org/10.1116/1.580185

S.A. Chambers, Epitaxial growth and properties of thin film oxides. Surf. Sci. Rep. 39, 105–180 (2000). https://doi.org/10.1016/S0167-5729(00)00005-4

M. Naito, H. Yamamoto, H. Sato, Reflection high-energy electron diffraction and atomic force microscopy studies on homoepitaxial growth of SrTiO 001. Phys C 305, 233–250 (1998)

J.L. Hughes, Scale-up problems in electron-beam evaporation and sputtering. J. Vac. Sci. Technol. 15, 1572–1579 (1978). https://doi.org/10.1116/1.569813

M. Brahlek, A. Gupta, J. Lapano, J. Roth, H.T. Zhang, L. Zhang et al., frontiers in the growth of complex oxide thin films: past, present, and future of hybrid MBE. Adv. Funct. Mater. 28, 1–41 (2018). https://doi.org/10.1002/adfm.201702772

L. Zhang, R. Engel-Herbert, Growth of SrTiO3 on Si(001) by hybrid molecular beam epitaxy. Phys. Status Solidi 8, 917–923 (2014). https://doi.org/10.1002/pssr.201409383

H.T. Zhang, L.R. Dedon, L.W. Martin, R. Engel-Herbert, Self-regulated growth of LaVO3 thin films by hybrid molecular beam epitaxy. Appl. Phys. Lett. (2015). https://doi.org/10.1063/1.4922213

J. Roth, T. Kuznetsova, L. Miao, A. Pogrebnyakov, N. Alem, R. Engel-Herbert, Self-regulated growth of [111]-oriented perovskite oxide films using hybrid molecular beam epitaxy. APL Mater. (2021). https://doi.org/10.1063/5.0040047

B. Fazlioglu-Yalcin, A.C. Suceava, T. Kuznetsova, K. Wang, V. Gopalan, R. Engel-Herbert, Stoichiometric control and optical properties of BaTiO3 thin films grown by hybrid MBE. Adv. Mater. Interfaces (2023). https://doi.org/10.1002/admi.202300018

D.M. Speckman, J.P. Wendt, Alternatives to arsine: the atmospheric pressure organometallic chemical vapor deposition growth of GaAs using triethylarsenic. Appl. Phys. Lett. 50, 676–678 (1987). https://doi.org/10.1063/1.98063

K.L. Siefering, G.L. Griffin, Growth kinetics of CVD TiO2: influence of carrier gas. J. Electrochem. Soc. 137, 1206–1208 (1990). https://doi.org/10.1149/1.2086632

V. Ruz, M.M. González, D. Winant, Z. Rodríguez, G. Van Den Mooter, Characterization of the sublimation and vapor pressure of 2-(2-Nitrovinyl) furan (G-0) using thermogravimetric analysis: effects of complexation with cyclodextrins. Molecules 20, 15175–15191 (2015). https://doi.org/10.3390/molecules200815175

J.P. Elder, Sublimation measurements of pharmaceutical compounds by isothermal thermogravimetry. J. Therm. Anal. 49, 897–905 (1997). https://doi.org/10.1007/bf01996775

M. Xie, T.M. Ziemba, M.B. Maurin, Sublimation characterization and vapor pressure estimation of an HIV nonnucleoside reverse transcriptase inhibitor using thermogravimetric analysis. AAPS PharmSciTech 4, 1–10 (2003). https://doi.org/10.1208/pt040223

D.M. Price, Vapor pressure determination by thermogravimetry. Thermochim. Acta 367–368, 253–262 (2001). https://doi.org/10.1016/S0040-6031(00)00676-6

C. Wang, S. Yang, Y. Chen, Determination of the vapour pressure curves and vaporization enthalpies of hafnium alkoxides using thermogravimetric analysis. R Soc Open Sci (2019). https://doi.org/10.1098/rsos.181193

C. Karakaya, S. Ricote, D. Albin, E. Sánchez-Cortezón, B. Linares-Zea, R.J. Kee, Thermogravimetric analysis of InCl3 sublimation at atmospheric pressure. Thermochim. Acta 622, 55–63 (2015). https://doi.org/10.1016/j.tca.2015.07.018

S. Giani, R. Riesen, J.E.K. Schawe, An indirect method for vapor pressure and phase change enthalpy determination by thermogravimetry. Int. J. Thermophys. 39, 1–12 (2018). https://doi.org/10.1007/s10765-018-2407-y

M.F. Cuddy, A.R. Poda, M.A. Chappell, Estimations of vapor pressures by thermogravimetric analysis of the insensitive munitions IMX-101, IMX-104, and individual components. Propel. Explos. Pyrotech. 39, 236–242 (2014). https://doi.org/10.1002/prep.201300069

J.E. Brady, J.L. Smith, C.E. Hart, J. Oxley, Estimating ambient vapor pressures of low volatility explosives by rising-temperature thermogravimetry. Propel. Explos. Pyrotech. 37, 215–222 (2012). https://doi.org/10.1002/prep.201100077

G.I. Spijksma, G.A. Seisenbaeva, H.J.M. Bouwmeester, D.H.A. Blank, V.G. Kessler, Zirconium and hafnium tert-butoxides and tert-butoxo-β-diketonate complexes-Isolation, structural characterization and application in the one-step synthesis of 3D metal oxide nanostructures. Polyhedron 53, 150–156 (2013). https://doi.org/10.1016/j.poly.2013.01.046

K.M. Ahmadi, Thermal probe of vapor–liquid thermodynamic equilibrium. J. Therm. Anal. Calorim. 147, 6015–6034 (2022). https://doi.org/10.1007/s10973-021-10972-3

P. Gabbott, Principles and Applications of Thermal Analysis (Blackwell, New York, 2008)

R.C. Rodgers, G.E. Hill, Equations for vapour pressure versus temperature: derivation and use of the Antoine equation on a hand-held programmable calculator. Br. J. Anaesth. 50, 415–424 (1978). https://doi.org/10.1093/bja/50.5.415

Sheet SD. Benzoic Acid 2019;108:1–8. https://webbook.nist.gov/cgi/cbook.cgi?ID=C65850&Mask=4#ref-15.

D.R. Stull, Vapor pressure of pure substances. Organic and inorganic compounds. Ind. Eng. Chem. 39, 517–540 (1947). https://doi.org/10.1021/ie50448a022

I. Langmuir, The vapor pressure of metallic tungsten. Phys. Rev. II, 329–342 (1913)

D. Menon, D. Dollimore, K.S. Alexander, A TG-DTA study of the sublimation of nicotinic acid. Thermochim. Acta 392–393, 237–241 (2002). https://doi.org/10.1016/s0040-6031(02)00106-5

S.Y. Lee, B. Luo, Y. Sun, J.M. White, Y. Kim, Thermal decomposition of dimethylaluminum isopropoxide on Si(1 0 0). Appl. Surf. Sci. 222, 234–242 (2004). https://doi.org/10.1016/j.apsusc.2003.08.016

Process for preparing hafnium oxide thin films by metal organic chemical vapor deposition - KR 100592793B1, 2006.

S. Engmann, M. Stano, Š Matejčík, O. Ingólfsson, Gas phase low energy electron induced decomposition of the focused electron beam induced deposition (FEBID) precursor trimethyl (methylcyclopentadienyl) platinum(iv) (MeCpPtMe3). Phys. Chem. Chem. Phys. 14, 14611–14618 (2012). https://doi.org/10.1039/c2cp42637d

Haynes WM. Handbook of Chemistry and Physics (95th edition). CRD Press; 1942.

W. Nunn, T.K. Truttmann, B. Jalan, A review of molecular-beam epitaxy of wide bandgap complex oxide semiconductors. J. Mater. Res. 36, 4846–4864 (2021). https://doi.org/10.1557/s43578-021-00377-1

Acknowledgments

The authors express their gratitude to the Materials Characterization (MCL) staff, Ekaterina Bazilevskaya and Gino Tambourine, for their assistance with TGA measurements. B. F.-Y. and R. E.-H. would also like to thank the National Science Foundation for data acquisition through DMR-1905861, as well as Simon Munyan for his contribution to the assembly of the vapor pressure measurement system. M. H. acknowledges funding through the NSF Cooperative Agreement No. DMR-2039351 for the Two-Dimensional Crystal Consortium, a Materials Innovation Platform.

Funding

Open Access funding enabled and organized by Projekt DEAL. National Science Foundation through DMR-1905861. NSF Cooperative Agreement No. DMR-2039351 for the Two-Dimensional Crystal Consortium, a Materials Innovation Platform.

Author information

Authors and Affiliations

Contributions

BF-Y and RE-H jointly conceptualized and designed the experimental framework. BF-Y executed the experiments and took the lead in writing the manuscript. MH made substantial contributions to the result interpretation and offered insights for the composition and structure of the manuscript. All authors played pivotal roles by providing input, thus significantly influencing the research process, data analysis, and final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fazlioglu-Yalcin, B., Hilse, M. & Engel-Herbert, R. Thermogravimetric study of metal–organic precursors and their suitability for hybrid molecular beam epitaxy. Journal of Materials Research 39, 436–448 (2024). https://doi.org/10.1557/s43578-023-01237-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-01237-w