Abstract

This review covers recent advances on production techniques, unique properties and novel applications of nitrogen-doped graphene oxide (NGO). The focal point is placed on the evaluation of diverse methods of production for NGO and reduced nitrogen-doped graphene oxide (NrGO) nanosheets using GO and graphite as carbon precursors. Variation in chemical composition of GO with variable N content, C–N bonding configurations and chemical reactive functionalities of NGO allow tuneable properties that render NGO a suitable material for various applications such as lithium-ion batteries, biosensors, supercapacitors and adsorption processes. NGO and NrGO exhibit significantly different performances compared to GO even with small amounts of N-doping. The type of C–N bonding and surface chemistries on the NGO are responsible for their unique electrical, mechanical, adsorption, chemical reactivity, photocatalytic activity, and optical properties. Various investigative techniques used to study NGO nanomaterials are also reviewed. Finally, future perspectives of NGO in this rapidly developing area are discussed.

Graphical abstract

Methods of synthesis of N-doped graphene oxide nanosheets and their advantages and disadvantages.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Graphene oxide (GO), the most popular derivative of graphene, has attracted tremendous attention due to its reputable properties such as excellent electrical, catalytic and thermal properties, high conductivity and chemical stability, as well as large surface area [1, 2]. As a result, GO is utilized in a wide variety of applications including electronics, optics, energy storage, water treatment, biosensors, supercapacitors, biomedical, drug delivery and catalytic oxidation [3,4,5,6,7]. The presence of the defects on its lattice and the oxygen functionalities (i.e. carboxyl, hydroxyl, and carbonyl and epoxy groups) makes it possible for GO to undergo chemical modification with metal oxide nanoparticles, polymeric species and organic molecules and also allows for facile doping with heteroatoms such as nitrogen (N), boron (B), phosphorus (P) and sulphur (S). It is these modification strategies (chemical functionalization and doping) that tailor the physicochemical properties of GO for use in desired applications [8,9,10,11,12,13].

Heteroatom-doping of GO is one of the key processes usually employed to improve various properties of the GO framework by activating its defective sites. Previously, heteroatoms such as N, P, S and B have been used to effectively dope the GO network [8, 14,15,16]. Amongst these, N atoms are found to be the most suitable dopants for GO due to their compatible atomic sizes (0.56 Å) with C atoms (0.67 Å). In addition, these remarkable properties of GO make it a promising starting material for developing few or single interconnected nitrogen-doped graphene oxide (NGO) layers, which are sometimes referred to as reduced nitrogen-doped graphene oxide (NrGO). To be specific, N-doping substantially induces structural, and electronic disorders and significantly increases active sites on the GO framework consequently leading to modifications in its surface, structural and electronic properties [17,18,19]. N-doping of GO therefore stimulates the delocalized electron state within the NGO structure, improves the band gap, shifts up the Fermi level, and enhances thermal stability, ultrahigh electron mobility and electrical conductivity of the nanosheets. These properties can further be improved by altering the type of N configuration and N content on the GO lattice. In this way, the physicochemical properties of NGO can be modulated for a desired performance.

Numerous efficient approaches have been employed for the fabrication of GO nanomaterials with various forms, configurations and contents of N [9, 10, 20,21,22]. The content and type of N in NGO strongly depends on the process chosen, N-precursors and synthesis conditions. Doping of N atoms into the graphene lattice occurs in four forms of N or bonding configurations namely, pyridinic-N, pyrrolic-N, graphitic-N (also known as quaternary-N) and oxidized pyridinic-N as demonstrated in Fig. 1. The formation of pyridinic-N and pyrrolic-N into the GO lattice is easily achievable, however, graphitic-N and oxidized pyridinic-N are often challenging to form. This is attributed to the fact that graphitic-N species are formed through the transformation of pyrrolic-N, which usually occurs at high temperatures. In particular, graphitic-N is often either present in low quantities or even not present at all in graphene structures [23,24,25].

Bonding configurations for nitrogen atoms in N-doped graphene oxide [25].

Previously, researchers have developed numerous methods to alter the properties of graphenes via doping with N atoms [19, 26, 27]. The differences in the surface reactivity of graphene and GO has caused the N-doping of graphene to be difficult in comparison to the doping of GO due to the oxygen-rich edges found in GO. Graphene surface reactivity is loaded with strong covalent bonding of sp2 hybrid between carbon atoms, which require high energy to interrupt [19]. On the other hand, the presence of oxygen functional groups in the GO lattice makes the edge sites of GO more reactive to chemical bonding with various chemical moieties such as hydrogen, oxygen and other electronegative atoms [15, 28].

Consequently, GO offers a basic framework for the development of NGO with high N content and enhanced properties. Meanwhile, several researchers have found that it is difficult to formulate NGO with uniform, high-content N-doping and controllable N-types [29,30,31]. Therefore, it is of great interest to develop novel routes to produce N-doped graphene-like materials with uniform and enhanced N concentration with various N-forms in the graphene framework for desirable applications.

Previously, a handful of reviews have focussed on the synthetic pathways of GO, graphene structures and graphene-based adsorbents in terms of their adsorption affinity and mechanism, as well as regeneration for wastewater treatment [1, 32, 33]. Other reviews have discussed the application of NGO and carbon nanotubes (CNTs) in oxygen reduction reactions, energy storage and catalytic applications [18, 34]. Recently, Xu et al., reviewed the synthesis, characterization of NGO and its applications in energy [20]. While this review provides comprehensive analysis of the existing data in this field, they do not fully explore the use of GO as a carbon precursor for the production of NGO or NrGO nanosheets. Moreover, preparation of NGO using different methods and the mechanism of N-doping are not fully addressed. There is no attempt on establishing the effect of introducing N atoms on the GO lattice in terms of “structure–property–application” relationships for various applications, especially in the field of water treatment. Therefore, in this review, we summarize the recent advances in this niche area with focus placed on the synthesis of NGO with new and interesting properties geared towards application in energy storage, sensors and water treatment. We discuss new developments in NGO preparation methods, effect of the type of N, its concentration, as well as the number of sheets layers. The review also covers the latest NGO developments, doping mechanisms, characterizations and properties when different parameters including synthesis routes, conditions, N-precursors and reaction times are used. Their applications in diverse fields such water treatment, supercapacitors, sensors, lithium batteries and oxygen reduction reaction applications are explored. In latter sections, the larger scale production of these materials and their commercial viability as well as potential applications in diverse fields is explored.

Methods of synthesis for N-doped graphene oxide

A variety of methods for the production of NGO nanomaterials with single-, few- and multi-layered nanosheets exist [23]. As shown in Fig. 2, the methods for the synthesis of NGO can be broadly categorized into two major classes; namely post-treatment or ex-situ approaches and direct doping or in-situ methods.

Post-treatment methods

The post-treatment method involves two steps namely;

-

(i)

Preparation of GO via chemical oxidation processes such as Hummer, Staudenmaier and Hofmann methods (which involves the oxidation of graphite with strong oxidizing agents) as shown in Fig. 3, and

-

(ii)

Exposing the prepared GO to N-precursors in the vapour form, which further react with GO to produce NGO nanosheets using approaches such as chemical vapour deposition (CVD), arc discharge plasma and thermal annealing process [9].

Typical processes involved in the synthesis of GO with single or few nanosheets from oxidation of raw graphite [35].

However, the above-mentioned methods use severe reaction conditions (i.e. high temperatures and in the presence of toxic gases) and often need the use of complicated and expensive equipment. In addition, they provide little control over the number and size of nanosheet layers, and the N-doping level attained. Moreover, during synthesis, gaseous pollutants are emitted which makes these techniques unsuitable for large-scale production of NGO materials.

Various post-treatment methods, which provide various N- loading, depending on applied reaction conditions are given in Table 1.

In a study by Park et al., a GO suspension was first reacted with various organic molecules with amine moiety (ethylene diamine (N1), diethylene triamine (N2), triethylene tetramine (N3), tetraethylene pentamine (N4), and pentaethylene hexamine (N5)), in order to produce an amine-functionalized reduced graphene oxide (NrGO). The produced NrGO suspensions were thermally annealed at 800 °C under Ar atmosphere to yield NGO nanosheets exhibiting various amounts of N ranging from 0.72 to 4.3 at.% and exhibiting diverse N configurations within the graphitic framework [21]. In another study, heating or annealing of GO at temperature between 700 and 1000 °C in the presence of melamine was found to produce NGO with a N content of 10.1 at.% which mainly comprised of pyridinic-N type [37]. Li et al. [36] reported that by annealing GO at 500 °C under an NH3 atmosphere a NGO sheets with 5 at.% N-doping level are obtained [36].

Li et al. [26] prepared NGO nanosheets under thermal annealing of GO with ammonia at 900 °C. The results showed that the produced NGO consisted of pyridinic-N, pyrrolic-N and quaternary-N and a total N content of 3.97 at.%. Lin and co-workers [38] obtained NGO by the pyrolysis of GO and polyaniline at a temperature of 1000 °C. The resulting NGO contained 2.4 at.% N, of which about 1.2 at.% was quaternary-N [38]. Shao et al. and Jeong et al. [39] reported NGO produced from plasma treatment of GO in the presence of N2 plasma [9, 29]. Other workers synthesized NGO via thermal treatment, however they started with GO preparation using the Hummers method and employed cyanamide as an N-source. The NGO were produced under two temperature conditions i.e. 400 and 900 °C which are named NGO-400 and NGO-900, respectively. NGO-900 °C exhibited a high surface area, high pore volume and highly crumpled morphology, which showed remarkably improved performance as electrodes for supercapacitors. Moreover, these NGO sheets demonstrated a distinct crumpled structure compared to GO and NGO prepared at lower temperatures [39].

Wang et al. reported on the synthesis of NGO via the thermal exfoliation route using different chemical oxidation methods (Staudenmaier, Hofmann and Hummers methods) where graphite powder was used as a starting material [42]. The GO prepared was then thermally annealed in an ammonia atmosphere for 12 min at 600, 800 and 1000 °C to form NGO materials. It was observed that the amount of N atoms incorporated within the GO prepared using different methods was different due to the differences in oxygen functional groups present in the structures of GO produced. NGO produced through GO synthesised using Hummers method had the highest amount of N (7.2 at.%) which is higher than NGO made using GO prepared from Staudenmaier and Hofman methods (0.94 at.%).

In-situ synthesis methods

The in-situ approaches include hydrothermal, solvothermal and chemical exfoliation (also known as chemical oxidation) routes and are the most effective and most frequently used techniques for the synthesis of NGO nanomaterials compared to post-treatment methods [46]. The former involves the direct incorporation of N atoms onto the GO lattice during the preparation process. The processes are therefore achieved in a one-pot synthesis route, where N-precursors (such as NH3 or melamine) are added into the GO suspension to form the desired NGO nanosheets. Furthermore, these methods are capable of producing NGO at low temperatures with controlled N content and number of nanosheets and are capable of producing NGO in large quantities [10, 47]. Table 2 presents NGO sheets prepared via in-situ methods using different N-precursors, conditions of synthesis and their applications. As already highlighted in earlier sections, NGO is achieved via GO which is prepared by oxidation of graphite powder to form GO followed by the addition of N containing sources at controlled conditions to produce NGO nanosheets. Hydrothermal treatment, also known as the solvothermal method, is usually carried out in a Teflon-line autoclave or a batch reactor at typical temperatures of 100 to 400 °C [48]. Farzaneh et al., used the hydrothermal process for the synthesis of 3D mesoporous NrGO with different N contents that ranged from 1.0 to 4.7%. This was achieved through variation of relative amount of the GO and melamine that was used as a N-source [49]. The method has also been used by Balaji et al. in a reactor using urea as a N-source with the aid of nitric acid to yield NGO with 7.25–9.35 at.% N contents. This resulted in NGO with an enhanced electrochemical performance for supercapacitors [17]. Similarly, Du et al. [50] used the same technique to synthesise NGO nanosheets as anode material for lithium-ion batteries [50].

Zou et al. [51] successfully fabricated NGO for superior capacitive energy storage using hexamethylenetetramine (HAMT) via the hydrothermal process in two ways. First, NGO was prepared without the thermal expansion step. The second method involved pre-treatment of GO first by thermal expansion followed by N-doping using HAMT to produce N-doped thermal expanded GO (NtGO). It was found that the NGO produced via thermal expansion has a higher surface area, but low N levels (237 m2.g−1 and 5.8 at.%, respectively) than NGO prepared without the thermal expansion step (141 m2 g−1 and 9.67 at.%, respectively) [51]. Sun et al. [52] also employed a similar approach to produce NGO with N content of 10.13 at.% N and a large surface area (of 593 m2.g−1) which was further used in supercapacitors [52].

Chemical oxidation methods, on the other hand, are generally facile and considered as green approaches and thus are known to be environmentally benign [53, 54]. This is because the synthesis takes place at low temperatures without involving controlled gaseous atmosphere (thus leading to emission of less or no gaseous pollutants during the reaction). These methods are therefore applicable in the economical production of NGO at a large scale. The production of NGO using chemical oxidation methods is carried out in a one-pot route [42]. Generally, graphite is first oxidized using strong oxidants, followed by the addition of a N-source and finally exfoliation takes place to form NGO with few layer nanosheets or a single nanosheet. The chemical oxidation modification methods produce GO with plenty of oxygen-containing functional groups which offer the potential to further produce large scale NGO nanomaterials at a low cost.

The main goal of producing NGO via the chemical oxidation methods is to;

-

(i)

Solve the restacking problem of the nanosheets which is due to π-π interactions,

-

(ii)

Enhance accessibility of reactants to the active sites, and

-

(iii)

Prolong the distinctive properties of NGO. Additionally, selection of a suitable N-precursor has great impact on the N amount and N-form on the GO surface.

Researchers have employed numerous N-sources that are easy to handle, such as urea, melamine, ammonia, and organic amines (ethylene diamine, tetraethylene pentaamine (TEPA), triethylene tetramine, and diethylene triamine) utilizing different processes, as demonstrated by other studies [42,43,44]. Long et al. reported a combination of chemical and hydrothermal doping method for the production of NGO nanosheets by using NH3 as a N dopant [55]. The NGO sheets produced at relatively lower temperatures had slightly wrinkled and folded features and higher N content up to 5 at.%. Meanwhile, NGO sheets produced at elevated temperatures had more wrinkled and folded structures and lower N levels with more pyridinic-N incorporation [55]. Recently, NGO with the N level as high as 8.0 at.% was achieved via a simple chemical oxidation reaction of GO with hydrazine [54].

Ball milling

The ball milling method is one of the methods used for the preparation of NGO. The ball milling mechanism for the production of NGO is different from in-situ and post-treatment approaches [69, 70]. Figure 4(a) shows the principle of ball milling method, which involves both mechanical and chemical processes. The milling process generates the mechanical energy, which also referred to as the activation energy of reactions in ball milling. The created activation energy of reactions is the one that facilitates the synthesis reaction between the GO precursors and nitrogen precursors in the ball milling method [69, 71]. The ball milling synthesis process for NGO follows these steps: First, GO nanosheets and N-source are mixed together in deionized water. The suspension solution is then heated to dissolve the nitrogen source in the solution. The suspension solution is then cooled to room temperature and ultrasonicated to produce a well-dispersed suspension solution. The precursor solution is transferred to a stainless-steel grinding jar and inserted into the ball mill for further synthesis to produce NGO.

(a) Principle of ball milling method and (b) schematic representation of high-energy wet ball milling approach for the synthesis of nitrogen-doped graphene oxide sheets [71].

For example, Zhuang et al. [71] prepared NGO using wet ball milling route by grinding GO and melamine as N-precursor in a high-speed rotating jar with some grinding media. During the synthesis process, the solid particles of GO and melamine are destroyed to small particles and activated by collision from the grinding media, hence the nitrogen atoms from the N source can be doped on activated GO nanosheets to form NGO [Fig. 4(b)] [71]. The produced NGO shown to possess an N content as high as 23.2 at.% as well as good catalytic properties. It is worth mentioning that the entire synthesis process in wet ball milling can be performed at room temperature and the heat generated by grinding is much less than using chemical approaches. Consequently, it has problems of high-temperatures requirement, use of gaseous-N sources and high-temperature safety do not exist in the wet ball milling approach.

Characterization tools for N-doped graphene oxide

NGO has been extensively characterized to determine surface and structural morphology as well as the doping level and nature or configuration of the dopant substituted in the carbon–oxygen framework. Raman spectroscopy, for example, is used to study the degree of graphitization on the structural of the carbon materials. X-ray diffraction (XRD) spectroscopy is used to study the crystallinity and to determine the overall doping degree of heteroatoms on the structure of GO. The pore structure and surface area of the NGO ordered mesoporous carbons are commonly characterized by N2 adsorption–desorption using the Brunauer–Emmett–Teller (BET) technique. X-ray photoelectron spectroscopy (XPS) can be used to determine the elemental compositions and N bonding configuration in NGO nanomaterial. Microscopic techniques such as transmission electron microscopy (TEM) and scanning electron microscopy (SEM) are used to probe the surface and microstructure of NGO nanomaterials.

Microscopic and spectroscopic characterization of NGO nanosheets

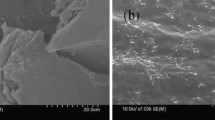

Microscopic techniques such as TEM, SEM, scanning tunneling microscopy (STM) and atomic force microscopy (AFM) are the most widely used techniques to provide useful information about surface morphology, microstructure, and number of layers of NGO nanosheets. According to published research, produced NGO resulted in crumpled sheet-like microstructures that are typical of graphene (Fig. 5) [72]. This was due to the removal of many oxy-functional groups (e.g. carboxylic and hydroxyl groups) from their structure. The production of NGO films using urea as a N-precursor also displayed relatively transparent flat surfaces that were mechanically flexible. Furthermore, HRTEM images showed that the NGO were composed of about eight layers. The authors observed that the thickness of the two selected NGO sheets were in a nm range, and this was verified by AFM measurements as shown in Fig. 5(d). STM is used to understand the local structure in the vicinity of an N dopant into NGO structure and N distribution, concentration and density of states by using the spectroscopic imaging of NGO nanosheets [48,49,50,51,52]. It also displays the NGO surface roughness and gives more information on whether clustering of dopants occurs during NGO synthesis, as well as calculating all the N–N distances for NGO materials. The STM image for NGO, generally displays bright objects which are associated with N dopants. The bright features are usually not present in pristine GO nanosheets. To estimate the N-doping concentration per carbon atom, the number of the bright features associating N atoms are counted.

Structural characterization of NGO nanosheets is normally carried out by powder XRD and Raman spectroscopy. Raman spectroscopy is used to determine the crystallinity, defects and degree of disorder from the microstructure of NGO materials. As shown in Fig. 6(a), the typical features in the Raman spectra obtained from NGO materials are the sharp peaks at 1350 cm−1 and 1590 cm−1, which are associated with the D-band and G-band, respectively. The D-band is associated with the degree of disorder or amount of defects in the NGO structure, while the G-band represents the first-order scattering of the E2g mode of sp2 carbon domains. The broad and weak 2D-band peak which is the D-band overtone peak is also observed around 2650 cm−1 and is used to estimate the number of layers present on the prepared NGO materials [73, 74]. The intensity ratio of D-band and G-band (ID/IG) is usually used as an indicator of the defect levels of carbon. A higher ID/IG value indicates the presence of large degree of defects or disorder including boundaries, bonding disorders, vacancies and heteroatoms in the NGO structure. Normally, after N-doping GO, the ID/IG ratio becomes larger because of the generation of more defects on the surface of GO during N-doping [Fig. 6(a)] [73].

XRD is used to provide an insight into the structural properties of NGO, which elucidates how the incorporation of N atoms affect the GO interlayer spacing [Fig. 6(b)]. The XRD pattern of GO show a broad peak at 2θ = 11.6°, indicating a significant increase in the GO layer spacing. On other hand, after doping the peak of GO sample disappears and exhibits a new broad diffraction peak around 26°, which is similar to that usually observed in the XRD peak of N-doped graphene [50]. Small angle X-ray scattering (SAXS) measurements are used to confirm the structure of the NGO materials. The scattering pattern of the NGO is shown in Fig. 6(c) and it demonstrates that the NGO consists of plate- or sheet-like morphology [75].

X-ray photoelectron spectroscopy (XPS) is usually used to determine and quantify elemental composition within the NGO. An example of XPS spectra for NGO is shown in Fig. 7. Here it is shown that NGO consists of different C–N bond types, including pyridinic, pyrrolic-N and graphitic-N and these bond types have profound effects on the NGO properties and applications. The N level and N species could be controlled by tuning the experimental parameters such as mass ratio between dopant and GO source, reaction time and hydrothermal temperature [76, 77]. In addition, the N content and N types with different amount can depend greatly on the amount and type of oxygen functionalities present on the GO surface. For example, GO modified with more carboxyl groups (GO-OOH) had high N content compared to GO modified with −OH and −C=O functionalities under similar conditions due to the reduction in epoxy groups as the carboxyl groups introduced increases (Fig. 7) [76]. Therefore, an increase in the carboxyl groups enhances the surface activity of GO. As a result, it introduces N atoms into the GO active sites, and hence increases the N content on NGO materials.

XPS spectra of NGO produces from GO with different oxygenic groups (a GO, (b) GO-OH, (c) GO=O (d) GO–OOH and (e) GO-avg. Schematic illustration of nitrogen functional groups in the GO lattice (f) [76].

Mou et al. [77], demonstrated that certain oxygen functional groups in GO are responsible for the incorporation of N atoms within the GO structure to form C–N bonds. This presumption was made due to the absence of N observed in the elemental analysis when GO was annealed with urea at 700 °C. Additionally, Mou et al. [77] and Chen et al. [76], stated that carboxyl groups which provide active sites on the GO are the main oxygen functionalities responsible for the reaction with N atoms. Chen et al. also added that at high-temperature and alkaline conditions the carbonyl groups are transformed into carboxyl groups, which reacted with NH3 and favoured N-doping. This finding may give a broad understanding of the reason why GO with low number of or without carboxyl groups, produces NGO with maximum N amount after hydrothermal reduction. However, hydroxyl groups partially participate in the reaction due to the stable structure formed between phenolic hydroxyls and the benzene ring due to π-π conjugation. Thus, more carboxyl groups on the GO surface are of importance to help produce NGO with high N levels.

Other characterization techniques

Other characterization techniques for studying NGO are thermo-gravimetric analysis (TGA), Fourier transform infra-red (FT-IR) spectroscopy, energy dispersive X-ray spectroscopy (EDS), Brunauer–Emmett–Teller (BET) surface area analysis, ultraviolet–visible (UV–Vis) spectrophotometry, energy electron loss spectroscopy (EELS) and zeta potential. These techniques have been employed successfully to probe the chemical composition, surface area, surface charge, thermal stability and structure of the layers of GO-based materials [75].

The FT-IR spectroscopy is used to determine the presence of functional groups such as oxygen-containing and nitrogen-containing chemical groups present in the NGO materials [48]. EDS is one of the techniques used to analyze the surface elemental content of NGO and is normally modulated to SEM. BET helps to evaluate the surface area and pore and volume of NGO materials [78]. While UV–Vis spectroscopy is utilized to investigate the inference of the composition, content and structure of the NGO [55]. The UV–Vis spectra of GO normally displays two peaks at around 220 nm and 270 nm which are related to π–π* electron transitions of aromatic C–C bonds and n–π* transitions of C=O bonds present on the GO structure, respectively. After doping one peak around 260 nm is observed, which is an indication of restoration of electronic conjugation of GO. Researchers employ TGA to quantify the degree of functionalization and thermal decomposition within the NGO structure [78]. The degree of functionalization is determined by the mass loss measurement of functional moieties removed from the NGO during the thermal heating in an inert environment. Zeta potential is performed in order to confirm the surface chemistries of the NGO in aqueous media [79], i.e. evaluate the surface charges and determine the point of zero charge on NGO surface. EELS is also useful to elucidate the surface composition of the N-doped graphene materials (amount of N, nitrogen density and C–N configuration) [80].

Mechanism for the formation of NGO nanosheets

Researchers have described mechanistic models for the N-doping of GO with three different N types species when various N-containing organic [48, 76, 77]. It is found that different N-precursors have distinct effects on the N concentration and N species introduced in the GO framework are influenced by characteristics of the dopant, oxygen functionalities on GO and synthesis temperatures, source of GO, source of N and nature of atmosphere. The possible formation mechanisms of doping GO nanosheets with N atoms are well demonstrated in Schemes (a) and (b) [48, 76]. These models describe the various mechanistic scenarios that lead to the formation of diverse configurations of N species on the graphene network and have been widely adopted. Typically, the N species present on the N-source (e.g. HMTA, ammonia and melamine) reacts with oxygen atoms on the defects and vacancies, and/or replaces the carbon atoms in the lattice of GO. For example, during the doping process, a N dopant such as ammonia or urea molecule starts to decompose and hydrolyze to form H2O molecules accompanied by the release of NH3 species in a sustained manner. The released NH3 then reacts with the oxygen functional groups of the GO mainly the –COOH groups [48]. This is followed by a reaction between –COOH and NH3 to generate amidated GO, imide GO, as well as lactam. This process then initiates a series of reactions with tautomeric transformations, leading to the formation of N-doped GO nanosheets. In addition, it also results in the removal of small molecules such as H2O, CO2 and CO [Scheme (a)]. The produced NGO results in N atoms appearing at four corners of the NGO structure which are covalently bonded with carbon atoms [52]. The N atoms are bonded with the carbon in 5 member-ring structures which indicates the formation of pyrrolic-N. Pyrrolic-N is formed from the dehydrolysis between the neighbour carboxyl and amide groups. In the pyridinic-N, N atoms are bonded to the second C nearest neighbours. In graphitic-N, N atoms are bonded to the 3 neighbouring C atoms. The fourth N type that forms is pyridinic-N oxide where the N is bonded to O. The contribution of various oxygenic groups (−COOH, −OH and C–O–C) for the formation of the N type can be therefore explained as follows (See Scheme 1):

NH3 reactions with (1) carboxyl group forming amide, (2) carboxyl group forming pyrrolic N, (3) carboxyl group forming imides and pyridinic-N, (4) epoxy group forming aromatic amine, and (5) hydroxyl group forming aromatic amine (Scheme a) [48].

-

1.

The participation of hydroxyl groups for N introduction is initiated by the original–OH and–OH generated from C–O–C [Scheme b (c, e and g)] [76].

-

2.

As for carboxyl groups, the –C = O groups are transformed into phenols from the quinone structure, which then participate in the nitrogen-doping process [Scheme b) (f)] [48, 76].

-

3.

The participation of carboxyl groups for production of NGO are demonstrated in Scheme b (2, 3 and 4). The –COOH groups which is adjacent to –OH in the GO structure react with the NH3 species and form aminated GO. During the process the amide groups interact with the–OH groups to generate pyridone-N (N-5(1) and pyrrolic-N (N-5(2) during removal of H2O and CO. Meanwhile, the reaction of anime groups with –COOH adjacent to –COOH and H atoms [Scheme a (3) and b (2 and 4)] generate the formation of pyridine-N (N-6).

-

4.

The amine groups react with the epoxy groups, which open-up its ring and form hydrazino alcohol (Scheme a (4) and b(5)).

-

5.

The contribution of various oxygenic groups (–COOH, –OH and C–O–C) results in the formation of the N-Q type via dehydration and re-composition of the ring [Scheme b (6 and 7)] [48, 76].

Properties of N-doped graphene oxide

Doping of the GO with N atoms has been reported to result in the band gap of GO between the conduction band and the valence band being opened with N-doping which tailors its electronic, conductivity, chemical stability, mechanical strength, magnetic, chemical activity, transport features and optical properties [70, 81,82,83]. Thus, the NGO greatly broadens the spectrum of possible applications including energy storage, fuel cells, supercapacitors and electronic devices [14, 21, 30, 84,85,86]. However, the NGO performance towards these technologies is governed by the amount of N and C–N bond type configurations within the NGO lattice (e.g. pyrrolic, pyridinic and graphitic). This is because the electronic and conductivity features (closed or open electron shell arrangement) of NGO is determined by the amount of N and C–N bond type introduced on the GO lattice. Moreover, doping GO with nitrogen also improve the wettability and provide additional surface sites, chemistry and surface charge distribution. On the other hand, it has a substantial impact on the thickness, roughness, mesoporous structure of the GO sheets and surface areas, making NGO be the suitable candidate for adsorption processes.

It was found that oxygen- and nitrogen-containing groups on NGO provide better interaction of NGO surface with gaseous molecules and heavy metals, organic and inorganic molecules for gas storage and water treatment application, respectively [48, 56, 87]. Most importantly, the chemical moieties on the NGO surface can serve as chemical handles for further modification with functional groups and metal oxide nanoparticle through covalent bonding. In the next section we explore how these unique properties permit NGO use in a variety of applications.

Applications of N-doped graphene oxide nanomaterials

Graphene oxide doped with N atoms has recently become a highly attractive material for different applications such energy storage, electrochemical application, fuel cells, sensors and water treatment due to its unique features such as excellent electronic properties, electrocatalytic activity, high conductivity, and large surface area [23, 26, 28]. N-doping processes do not only enhance the surface, morphological, thermal, and electrical properties of NGO, but also effectively enhance the formation of active site for chemical reaction with other materials to occur [15, 29].

Energy storage and electrochemical applications

Supercapacitors

NGO has attracted great attention in new energy storage devices such as supercapacitors (SCs) [88,89,90,91]. This is because of their inherent properties such as high power density, excellent cycling stability and fast charge or discharge capability [91, 92]. SCs have been used in many applications including electric vehicles, portable electronic devices, and sustainable energy generation devices. SCs can be broadly categorized into two classes based on their energy storage mechanism and these are electrical double-layer capacitors (EDLCs) and pseudocapacitors. EDLCs mainly use carbon-based materials such as activated carbon, carbon nanotubes and graphene as electrode while pseudocapacitors use electrodes that are made from electroactive materials such as transition metal oxides and conducting polymers [39, 51, 92]. Previous studies have used graphene as electrodes in EDLCs, as a result of its high surface area and conductivity [93]. However, intensive studies have been attempted to improve the electrochemical properties of graphene oxide into EDLCs. This was done by introducing N atoms into the GO lattice [26, 47, 94].

Recently, NGO has received attention in SCs due to the improvement of its properties and it offers the key to success in this area [17, 26, 54, 95]. The NGO exhibits significant improvement in various performance parameters of supercapacitors (i.e. capacity, reaction rate and recyclability) due to structural defects during doping (wrinkled structures, high pore volume, pores and active sites), increase in surface area and improved electrical conductivity. Previous research studies investigated the effect of N content and N bonding types of NGO on supercapacitor performance (Table 4) [26, 39, 51, 92]. The studies reported that N-doping enhances the storage capacity of NGO networks as well as the surface wettability with electrolytes as it induces surface functionalities, which accommodate different pseudo-capacitive materials. Furthermore, it enhances its electrical conductivities and improves the free charge-carrier density, thus resulting in NGO nanomaterials with high pseudo-capacitance effect, and consequently enhancing its energy density.

The presence of quaternary-N type into the NGO structure plays an important role in the improvement of the wettability between the electrolyte and the electrode in the process improving the pseudo-capacitance effect of the material. The micropore or mesopore holes formed on the surface of GO during the N-doping process increase the charge accommodation and provide the electrode material with high energy density. In addition, quaternary-N and oxidized pyridinic-N helps maintain a stable capacity during fast charging and discharging [17, 26, 54]. Moreover, N-doping of GO improves the specific capacitance of NGO and maintains high power densities of the NGO-based supercapacitors. For example, Huang et al. [88] prepared NGO via the hydrothermal process using urea as a N-source. The prepared NGO exhibited high specific capacitance of 223 F.g−1 at 0.29 A.g−1 with high rate capacity performance with the capacitance maintained at 184 F.g−1 at a high rate of 35.7 A.g−1. NGO also attain good cycling stability after 3000 cycles, with the specific capacitance of about 206 F.g−1 [88]. Balaji et al. [17] prepared NGO nanosheets by hydrothermal treatment using urea as a N source with the aid of nitric acid (NA-NGO). NA-NGO attained a specific capacitance of 261 F.g−1 at a current density of 0.5 A.g−1 which was greater than that of untreated NGO (ca. 150 F.g−1 at 0.5 A.g−1) [17]. Moreover, it demonstrated high stability of up to 3000 cycles at a current density of 5 A.g−1 and 126% capacitance retention after 1000 cycles.

Li et al. [26] prepared NGO using thermal treatment that had a specific capacitance of 246.4 F.g−1 at a current density of 1 A.g−1. In addition, the NGO showed high cycle stability that was 2 times higher than that of undoped GO [26]. Haque et al. [94] produced NGO with excellent charge–discharge stability after 5000 cycles with a high capacity retention of 90% and a specific capacitance of 210 F.g−1 at a current density of 1 A.g−1. Furthermore, the specific capacitance of NGO was greater than the values attained by graphene and a GO electrode by factors of about two and six, respectively [94]. Zou et al. [51] prepared NGO with specific capacitance of 270 F.g−1 at 1 A.g−1 which was much higher than NGO and the capacitance retention was 97% after 2000 cycles at this density [51]. It was also reported that the NGO with high N content (a ratio of C to N of 15.97) had more crumpled structures which helped to achieve the aspects of high capacity, excellent rate capability and cycle performance. Recently, Wen and co-workers reported an activated microwave-expanded graphite oxide for application in supercapacitors. The NGO prepared at 900 °C resulted in a capacitance of 302 F.g−1 at a current density of up to 1 F.g−1. In addition, the specific capacity of NGO-900 was maintained around 96.1% of its corresponding initial specific capacity [39]. In another study Sun et al. [52] synthesized NGO with enhanced capacitive behaviours of about 326 F.g−1 at a current density of 0.2 A.g−1 with superior cycling stability and coulombic efficiency of up to 99.6% after 2000 cycles [52]. Elsewhere, NGO exhibited a high-rate performance and high specific capacitance of up to 484 F.g−1 at a high current density of 100 A.g−1 [96].

Restacking-inhibited mesoporous NGO with surface area as high as 698 m2.g−1 and up to 6.83 at.% N content, exhibited a specific capacity of about 25.8 F.g−1 at a current density of 5 A.g−1, energy density of 21.8 kW.kg−1 and long cycle stability with an 85% retention in specific capacitance after 5000 cycles [43]. Sliwak, et al. [63] prepared NGO nanomaterials with N level ranging from 10.9 to 13.4 at.%, using the hydrothermal method and amitrole as an N-precursor. This amount is the highest reported for this NGO type of materials prepared using the hydrothermal method. Pyridinic-N was found to be the most predominant N species followed by amine groups, pyrrolic-N and quaternary-N. The NGO with the highest amount of N was found to have an excellent specific capacitance of 244 F.g−1 at a high scan rate of 100 mVs−1 and an excellent rate capability of 98% [63].

In another study, mesoporous NGO produced from amidated GO using 2,6-diaminopyridine (DAP) and pyridine-2,6-dicarboxylic acid (PDA) as N-sources was used a material for supercapacitors. It is found that the mesoporous NGO with the highest N concentration (9.25%) exhibits a significant capacitance of 408 F.g−1 at a current density of 1 A.g−1, high-rate capability and excellent cyclic stability [97]. Recently, Singh et al. [64] reported on the porous NGO as a solid-state supercapacitor. The fabricated supercapacitor exhibited a specific capacitance of 230 F.g−1 at current density 1 A.g−1 and up to ∼88% capacitance retention after 10,000 cycles at 5 A.g−1 [64]. The N-doping effect on the GO structure creates defects, vacancies, porosity and the improved surface area is believed to be the essential principle for the enhanced charge storage ability within the NGO capacitor. Wang et al. [61] reported the use of NGO synthesized using glycine as a N-precursor. The produced NGO was used as a supercapacitor electrode and exhibited a maximum specific capacitance of 270 F.g−1 at a current density of 0.5 A.g−1 with capacitance retention of 90% after 10,000 cycles at 10 A.g−1 current density [61]. Synthesis of NGO using hydrazine hydrate via the hydrothermal route yielded NGO with a specific capacitance as high as 206 F.g−1 at 1 A.g−1 current density, which is 70% much greater than that of the rGO electrode (207 F.g−1). Furthermore, the NGO was found to have energy density of 55 Wh.kg−1 at a high power density of 1800 W.kg−1 [62]. Table 3 summarizes these and other examples of the use of NGO in supercapacitors.

There are several factors that contribute to the outstanding electrochemical performance of the NGO electrode. A large surface area is one of the critical reasons why NGO electrode exhibits high specific capacitance. This is because a large area allows for efficient ion adsorption/or desorption. N-doping also increases the surface reactive site within the NGO structure and as a result provide high-density active sites within NGO that promotes great capacitance performance. Finally, during doping the formation of defects, vacancies and pores onto NGO lattice provide effective pathway and channels for charge transport.

Lithium and sodium ion batteries

Several strategies have been developed to produce NGO via thermal, hydrothermal treatment and chemical exfoliation of graphite for potential use in lithium-ion batteries (LIB) and sodium ion battery applications (Table 4) [40, 50, 100]. NGO-based nanomaterials have been used as LIB anodes. For example, Du et al. [50] used hydrothermal treatment to produce NGO material endowed with excellent reversible capacity of 600 mAh.g−1 at a current density of 372 mA.g−1 after 60 cycles, superior to that of pristine-RGO (350 mAh.g−1 at a current density of 372 mA.g−1). Wang et al. [40] successfully produced NGO through thermal treatment of graphite oxide under an ammonia atmosphere at 800 °C with a N-doping level of ca. 2 at.%. The NGO nanosheets exhibited a high reversible capacity of 900 mAh.g−1 at 42 mA.g−1 [40]. Wu et al. produced NGO with 3 at.% N which had a high reversible capacity (> 1040 mAh.g−1) at a low rate of 50 mA.g−1 in the first cycle. In addition, NGO showed an improved capacity of up to 872 mAh.g−1after 30 cycles at a low current rate of 50 mA.g−1, which was higher than that of the undoped graphene (638 mAh.g−1) [101]. The initial discharge and charge specific capacities are up to 1420 mAh.g−1. The discharge capacity of the second cycle decreases to 960 mAh.g−1. The discharge/charge cycling performance of the NGO electrode at 100 mA.g−1 after the fifth cycle was stable and maintained above 600 mAh.g−1, indicating high capacity retention of the electrode. NGO exhibited high reversible capacity, superior rate capability as well as long-term cycling stability [102]. Zhang et al. [103] synthesized high-performance NGO aerogels with 2.64 at.% N using thermal treatment for sodium ion batteries. The produced NGO aerogels showed reversible capacity of 287.9 mAh.g−1 at a current rate of 100 mA.g−1, which was higher than that of the pristine graphene (209.2 mAh.g−1) [103]. In another study, NGO was used as the anode for sodium ion batteries, which attained a high reversible capacity of 405.2 mAh.g−1 at 0.05 A.g−1 and maintained 100% capacity retention up to 3700 cycles at 2 A.g−1 [44].

N-doped GO nanomaterials catalyst for ORR

Oxygen reduction reaction (ORR) is an important reaction that take place in energy conversion systems such as fuel cells and metal–air batteries, which convert oxygen as an energy source and therefore determining the electrochemical performance of the devices [105,106,107,108]. Conventionally, platinum-based catalysts have been employed as ORR catalysts because of their excellent catalytic efficiency, low over potential and high current density. Even though that is the case, Pt-based catalysts still suffer from serious limitations, which hinder their application in ORR applications [105, 109]. These limiting factors include poor stabilization efficiency and poor dispersion and distribution of the metal catalyst particles since the particle distribution of the catalyst mainly depend on the catalyst support. In addition, their high costs limit their practical use in large-scale applications.

In order, to overcome the challenges presented by Pt-based catalysts, several supports have been used to enhance it conductivity and catalytic performance. NGO materials have recently rose as the most promising and intriguing catalyst supports for fuel cells and battery applications because of their large specific surface area, wide pore structures and high electrical conductivity. NGO has demonstrated to exhibit outstanding electrical, chemical, and mechanical properties, which are favourable in the harsh ORR environment [38, 49, 107].

A few studies have been reported on the application of hydrothermally and thermally derived NGO towards ORR applications [21, 49, 106]. N-precursors such as ammonia, urea, melamine, organic amines, hydrazine, pyrrole, hexamethylenetetramine and dicyandiamide have been used for the fabrication of NGO materials in one-pot treatment processes (Table 5). These processes are reported to produce NGO with mostly pyrrolic-N as the dominant N form. Farzaneh et al. [49] reported that NGO produced using hydrothermal method stimulates ORR performance at lower potentials regardless of the bonding configurations, due to activation and strengthening of π-electrons of the NGO framework. Furthermore, pyridinic-N has shown to have a significant role in ORR at higher potentials, because of activation of their lone pair of electrons [49]. In addition, Ma et al. and Lin and co-workers [110, 111] further reported that pyridinic-N has higher reversible capacity in a lithium-ion battery. Park et al. [21] prepared NGO nanosheets through thermal treatment and covalent functionalization of GO using various N-precursors (melamine, urea and polyaniline). The produced NGO nanosheets exhibited NGO with various content and configurations of nitrogen atoms within the graphitic framework of GO depending on the type of N-precursors used [105,106,107]. NGO nanosheets with a high content of pyridinic-N type, showed the desired one-step, quasi-four-electron transfer pathway during ORR, which is similar to that of commercial Pt/C [21].

NGO with high quaternary-N has been touted as the most beneficial functionality for enhancing the capacitance of NGO in supercapacitors [38]. This type of NGO has excellent catalytic activity toward ORR and oxygen evolution reactions (OER), meaning that it has a potential to be used as a bi-functional catalyst for both ORR and OER [38]. In a separate study, NGO was synthesised via a two-step hydrothermal reaction using urea as a N source. The NGO was used to produce a 3D NGO/reduced CNT-OH composite aerogel, which was used as a flexible counter electrode (CE) for dye-sensitized solar cells (DSSCs) to replace the conventional high-cost Pt-based CE [106]. The prepared NGO/CNT-OH paper CE was found to exhibit high electrocatalytic activity, outstanding carrier (electron/ion) transport ability and remarkable mechanical flexibility, concurrently. Additionally, DSSCs with NGO/20%CNT-OH CE demonstrated the greatest efficiency of 6.36%, which is better than that of Pt-based DSSCs (5.74%).

Li and co-workers prepared 3D-NGO nanosheets with N content ranging from 3.13 to 9.69 at.% for ORR applications. It was found that the increase in N content on GO does not necessarily result in increased electrocatalytic activity. Rather, NGO with the highest amount of graphitic-N and pyridinic-N (69.2%) offered the most excellent activity towards ORR [112]. On the another hand, NGO with 3.5 at.% of N content prepared using CVD method demonstrated high reaction onset potential of 0.78 V versus RHE towards the ORR in alkaline electrolytes [45]. Tao et al. reported the production of NGO at 5 °C using ammonia as a N-source [113]. The resulting NGO with 2.78 at.% N showed a high activity towards the ORR. Several research groups have reported that both pyridinic-N and quaternary-N species are more responsible for the enhancement of the ORR activity of NGO [112, 113]. Therefore, it is very important to achieve high percentage of desirable N type functionalities to optimize the NGO material performance in ORR applications. The studies described above therefore demonstrated that NGO-based materials with controllable N species ca be used as catalyst in the ORR application.

Water treatment and electrochemical sensor applications

Due to its unique properties presented in earlier sections NGO can also be used in many other fields such as wastewater treatment, photoelectron chemical H2 generation and electrochemical sensors (see Table 6) [87, 114,115,116,117,118]. NGO has the potential to be employed as an adsorbents or filter materials due to its high surface area, pore volumes and abundant adsorption sites. Hence, NGO nanomaterials have been used for removing toxic species such as organic pollutants, dyes and heavy metal ions from wastewater [56, 119]. Moreover, N-doping offers more active sites and enhances the interaction between the active sites and organic or ionic species, thus improving the adsorption capacity and removal efficiency of these pollutants. Chen et al., for example, investigated the effect of N content, structural properties of NGO nanosheets in the adsorption of boron in seawater. A maximum adsorption capacity of 58.7 mg.g−1 was obtained [56]. Figure 8 shows the removal mechanism of boron using NGO nanosheets as an adsorbent. As shown in Fig. 8, there are two mechanisms in which boron ions can be removed using NGO, namely; physisorption and chemical bonding. Boron atoms exist in the form of negatively charged B(OH)4− ions and boric acid in aqueous solution and NGO has a positively charged surface due to the presence of nitrogen atoms. Therefore, boron ions B(OH)4− are electrostatically attracted to the positively changed surface of NGO and thus results in a high adsorption capacity of boron ions. The other possible adsorption mechanism for the removal of boron is through the formation of complexes between the –OH groups attached to carbon atoms adjacent to nitrogen-doped sites of the NGO and –OH groups from the boron ions [56]. Recently, Liang et al. developed novel NGO aerogels with a high adsorption capacity of about 408.48 mg.g−1 for Cr(VI) at pH of 2.0 [58].

(a) Schematic representation of the boron removal by the filtration process, (b) schematic diagrams for removing boron by NGO material [56].

Other studies used NGO in the degradation and adsorption of phenolic compounds from wastewater and a significantly improved performance was achieved [84, 119, 120]. Wang et al. reported NrGO with a degradation rate constant of 0.71 min−1 for bisphenol in the presence of 0.6 mmol.L−1 persulfate, which was 700 times greater than that of undoped rGO (0.001 min−1) [84]. In another study, Liu et al. fabricated NGO incorporated filter membranes possessing high physical adsorption, enhanced mass transfer rates and good catalytic oxidation for phenols removal [120]. Maqbool et al., used NGO as an adsorbent and a mediator or catalyst in the degradation behaviour of natural organic matter (NOM)) from wastewater. The N-doped GO materials were reported to exhibit a high potential for PS activation. The NOM removal by NGO was found to increase with the increase in the addition of NGO for both oxidative and non-oxidative systems. The NOM removal was found to be 86.9%, 59.9%, and 60.3% on the bases of SUVA values of Suwannee River NOM, Suwannee River humic acid, and Suwannee River fulvic acid, respectively [59].

In a similar study by Wang, NGO prepared by the hydrothermal method was used for the removal of bisphenol A (BPA) from aqueous solution. The NGO materials showed excellent performance for BPA adsorption. More than 95% of BPA (88 mg.L−1) was removed within 10 min due to pre-adsorption and after 7 min it was completely removed as a result of oxidative degradation [60]. Rahmani et al., obtained NGO aerogels with specific surface area of 340 m2.g−1 and 4.16% N amount, which exhibited excellent adsorption capacity of 210 g.g−1 towards the removal of crude oil was reported [121]. Xing and co-workers reported on synthesis of 3D NGO aerogels by using melamine and NH3 as dopant in a chemical oxidation process, which was used as adsorbents for removal of heavy metals. The prepared NGO aerogels exhibit high adsorption capacities toward Pb2+ (205 mg.g−1), Cu2+ (175 mg.g−1) and Cd2+ (155 mg.g−1) [122].

NGO has also been used as a supporting material of CdS nanoparticles to enhance its photocatalytic hydrogen evolution efficiency from water [41]. The CdS modified with NGO (2 wt.%) nanocomposites exhibited significantly enhanced H2 evolution rate compared to graphene/CdS and GO/CdS nanocomposites. In a study by Chekin and coworkers, NGO sensors were utilized for the detection and quantification of cardiac troponin I (cTnI) in serum. The NGO sensors demonstrated high selectivity performance towards cTnI and showed that it can detect serum levels of cTnI as low as 1 pg.mL−1 in human serum [65]. Recently, Wiench et al., reported on the detection of dopamine (DA) using NGO as active electrode materials. The developed NGO DA sensor was able to detect DA in the range of 0.5–150.0 µM with a limit of detection of 410 nM [66].

Megawati and co-workers produced NGO materials using four different GO precursors and using ammonia as an N source for the detection of the six biomolecules (dopamine, ascorbic acid, uric acid, cytosine free bases, nicotinamide adenine nucleotide (NADH) and adenine). The produced NGO materials exhibited an improved sensitivity for ascorbic acid, uric acid, and dopamine compared to the bare glassy carbon surface. While the NGO nanomaterials showed lower sensitivity than the bare GC towards NADH, adenine and cytosine free bases [106]. In another study NGO was also developed and used as a biosensor for the determination of hypoxanthine (HX) and xanthine (X) in fish meat. The NGO used as a biosensor was operated at–0.35 V vs. Ag/AgCl which achieved sensitivity for HX and X of about 1.6 and 1.3 mA cm−2 mM−1, respectively [123]. In other studies, NrGO was produced hydrothermally and then used to the removal of anthracene (ANT) and 2-methylanthraquinone (2-MAQ). The maximum adsorption capacity of the obtained NrGO adsorbent for ANT was 5.77 mg/g and for 2-MAQ was 9.29 mg/g [124].

Conclusion and future perspectives

Doping of GO with N atoms is an effective technique to tailor and control the critical properties of GO including surface area, functional sites, surface chemistry, surface defects, shape, size, electronic and microstructure. These unique properties of NGO offer a potential opportunity for the use of NGO in an assortment of applications including among others catalysis, energy storage, biosensor, adsorption separation and water treatment. The N content and type of C–N bonding incorporated into the GO framework can be controlled to yield NGO with desirable properties. In the field of energy storage, NGO nanosheets are found to exhibit a good electrocatalytic activity and superior stability and these properties are better than currently used commercial Pt/C catalysts. In ORR applications the incorporation of N atoms into the GO lattice has been shown to greatly enhance the ORR performance. Electrochemical studies show that NGO possesses superior electrochemical performances (i.e. highest capacitance at slow sweep rate) compared to GO materials.

The N-doping of GO leads to the adsorption of different organic pollutants and heavy metals for water treatment and good detection (high selectivity and sensitivity) of particular biological molecules in the field of biosensors. This is due to the presence of nitrogen and oxygen-containing negative groups on the GO surface, which facilitate the interaction with biomolecules such as vitamins, amino acids, and glucose through π-π or hydrophobic interactions, hydrogen bonding and electrostatic interactions. Few studies have reported on the use of NGO in water treatment to determine its potential ability for the removal of different contaminants. It is now clear that N-doping of GO creates defects to formulate pores within the GO structure in the process increasing its surface area. These properties are important for their use as nanoadsorbents in water treatment applications.

To date, numerous work has been done to determine the potential of GO prepared in various conditions (reaction time, source of N, amount of the N-source and temperatures) using different synthesis methods to produce NGO materials with different properties. Future research is essential to understand the potential of different NGO materials in the water treatment area. Most adsorption studies are performed using batch adsorption methods and hence future research on the use of column studies and prototypes is recommended. Researches should carry out toxicity studies since these NGO materials will end-up into the environment. The evaluation of toxicity and safety of NGO materials is of importance; hence they could be used in the field of bioimaging and drug delivery to fight back some of the fatal diseases for which therapeutic treatment have not been fully explored.

Although much progress has been achieved in the area of NGO production using GO as the starting material in large scale using post-synthesis approaches (i.e. CVD and thermal treatment) and direct approaches, there is still a need for more work to be covered. Thus, future research on finding optimistic chemical oxidation approaches for production of GO with controlled oxygen functional groups should be established in order to be able to produce NGO with controlled N level and C–N bonding configurations as well as desirable number of sheet layers. This is because the amount and types of oxygen-containing groups present on the GO lattice play an important role in the C–N bonding types and N content for broad applications. In our opinion, the scope of development of new novel NGO and NGO-based for different applications such as photo-electronic devices, battery, supercapacitors, hydrogen storage, drug delivery and other new electrochemical energy storage devices, seems to be still evolving. It is very important to address the manufacturing and application of NGO and NGO-based material in bulk or industrial scale at low cost.

References

N. Hashim, Z. Muda, M.Z. Hussein, I.M. Isa, A. Mohamed, A. Kamari, S.A. Bakar, M. Mamat, A.M. Jaafar, A brief review on recent graphene oxide-based material nanocomposites: Synthesis and applications. J. Mater. Environ. Sci. 7, 3225–3243 (2016)

D.J. Joshi, J.R. Koduru, N.I. Malek, C.M. Hussain, S.K. Kailasa, Surface modifications and analytical applications of graphene oxide: a review. Trends Anal. Chem. 144, 116448 (2021)

Y. Liu, Application of graphene oxide in water treatment. IOP Conf. Ser. 94, 012060 (2017)

J. Lee, J. Kim, S. Kim, D.H. Min, Biosensors based on graphene oxide and its biomedical application. Adv. Drug Deliv. Rev. 105, 275–287 (2016)

R. Eivazzadeh-Keihan, F. Alimirzaloo, H. Aghamirza Moghim Aliabadi, E. Bahojboruzi, A.R. Akbarzadeh, A. Maleki, H. Madanchi, M. Mahdavi, Functionalized graphene oxide nanosheets with folic acid and silk fibroin as a novel nanobiocomposite for biomedical applications. Sci. Rep. 12, 1–12 (2022)

P. Paik, Graphene oxide for biomedical applications. J. Nanomed. Res. 5, 1–6 (2017)

H. Sachdeva, Recent advances in the catalytic applications of GO/rGO for green organic synthesis. Green Process. Synth. 9, 515–537 (2020)

K. Gopalsamy, J. Balamurugan, T.D. Thanh, N.H. Kim, J.H. Lee, Fabrication of nitrogen and sulfur co-doped graphene nanoribbons with porous architecture for high-performance supercapacitors. Chem. Eng. J. 312, 180–190 (2017)

H.M. Jeong, J.W. Lee, W.H. Shin, Y.J. Choi, H.J. Shin, J.K. Kang, J.W. Choi, Nitrogen-doped graphene for high-performance ultracapacitors and the importance of nitrogen-doped sites at basal planes. Nano Lett. 11, 2472–2477 (2011)

R.I. Jafri, N. Rajalakshmi, K.S. Dhathathreyan, S. Ramaprabhu, Nitrogen doped graphene prepared by hydrothermal and thermal solid state methods as catalyst supports for fuel cell. Int. J. Hydrog. Energy. 40, 4337–4348 (2015)

A.D. Ambaye, K.K. Kefeni, T.G. Kebede, B. Ntsendwana, S.B. Mishra, E.N. Nxumalo, Cu-MOF/N-doped GO nanocomposites modified screen-printed carbon electrode towards detection of 4-nitrophenol. J. Electroanal. Chem. 919, 116542 (2022)

B. Ntsendwana, B.B. Mamba, S. Sampath, O.A. Arotiba, Electrochemical detection of bisphenol a using graphene-modified glassy carbon electrode. Int. J. Electrochem. Sci 7, 3501–3512 (2012)

M. Coros, C. Varodi, F. Pogacean, E. Gal, S.M. Pruneanu, Nitrogen-doped graphene: The influence of doping level on the charge-transfer resistance and apparent heterogeneous electron transfer rate. Sensors. 20, 1815 (2020)

J. Porwal, N. Karanwal, S. Kaul, S.L. Jain, Carbocatalysis: N-doped reduced graphene oxide catalyzed esterification of fatty acids with long chain alcohols. New J. Chem. 40, 1547–1553 (2016)

M. Chen, L.L. Shao, Y.X. Guo, X.Q. Cao, Nitrogen and phosphorus co-doped carbon nanosheets as efficient counter electrodes of dye-sensitized solar cells. Chem. Eng. J. 304, 303–312 (2016)

J.P. Paraknowitsch, A. Thomas, Doping carbons beyond nitrogen: an overview of advanced heteroatom doped carbons with boron, sulphur and phosphorus for energy applications. Energy Environ. Sci. 6, 2839–2855 (2013)

S.S. Balaji, M. Sathish, Supercritical fluid processing of nitric acid treated nitrogen doped graphene with enhanced electrochemical supercapacitance. RSC Adv. 4, 52256–52262 (2014)

W.J. Lee, U.N. Maiti, J.M. Lee, J. Lim, T.H. Han, S.O. Kim, Nitrogen-doped carbon nanotubes and graphene composite structures for energy and catalytic applications. Chem. Commun. 50, 6818–6830 (2014)

C. Bie, H. Yu, B. Cheng, W. Ho, J. Fan, J. Yu, Design, fabrication, and mechanism of nitrogen-doped graphene-based photocatalyst. Adv. Mater. 3, 2003521 (2021)

H. Xu, L. Ma, Z. Jin, Nitrogen-doped graphene: Synthesis, characterizations and energy applications. J. Energy Chem. 27, 146–160 (2018)

M. Park, T. Lee, B.-S. Kim, Covalent functionalization-based heteroatom doped graphene nanosheet as a metal-free electrocatalyst for oxygen reduction reaction. Nanoscale 5, 12255–12260 (2013)

P. Mandal, J. Debbarma, M. Saha, One step synthesis of N-containing graphene oxide from 3-Aminophenol. Cryst. Res. Technol. 55, 1900158 (2020)

N. Daems, X. Sheng, I.F.J. Vankelecom, P.P. Pescarmona, Metal-free doped carbon materials as electrocatalysts for the oxygen reduction reaction. J. Mater. Chem. A. 2, 4085–4110 (2014)

S. Sarma, S.C. Ray, A.M. Strydom, Electronic and magnetic properties of nitrogen functionalized graphene-oxide. Diam. Relat. Mater. 79, 1–6 (2017)

J. Zhang, Z. Xia, L. Dai, Carbon-based electrocatalysts for advanced energy conversion and storage. Sci Adv. 1, 1500564 (2015)

D. Li, C. Yu, M. Wang, Y. Zhang, C. Pan, Synthesis of nitrogen doped graphene from graphene oxide within an ammonia flame for high performance supercapacitors. RSC Adv. 4, 55394–55399 (2014)

S.H. Park, J. Chae, M.-H. Cho, J.W.J.H. Kim, K.-H. Yoo, S.W. Cho, T.G. Kim, J.W.J.H. Kim, High concentration of nitrogen doped into graphene using N2 plasma with an aluminum oxide buffer layer. J. Mater. Chem. C. 2, 933–939 (2014)

E. Jayabal, A. Natarajan, V. Rengarajan, One-pot hydrothermal synthesis of nitrogen-doped reduced graphene oxide for the highly sensitive and simultaneous determination of dihydroxy benzene isomers. J. Appl. Electrochem. 51, 1189–1205 (2021)

Y. Shao, S. Zhang, M.H. Engelhard, G. Li, G. Shao, Y. Wang, J. Liu, I.A. Aksay, Y. Lin, Nitrogen-doped graphene and its electrochemical applications. J. Mater. Chem. 20, 7491–7496 (2010)

B. Guo, Q. Liu, E. Chen, H. Zhu, L. Fang, J.R. Gong, Controllable N-doping of graphene. Nano Lett. 10, 4975–4980 (2010)

A.A. Koós, A.T. Murdock, P. Nemes-Incze, R.J. Nicholls, A.J. Pollard, S.J. Spencer, A.G. Shard, D. Roy, L.P. Biró, N. Grobert, Effects of temperature and ammonia flow rate on the chemical vapour deposition growth of nitrogen-doped graphene. Phys. Chem. Chem. Phys. 16, 19446–19452 (2014)

B.Y.Z. Hiew, L.Y. Lee, X.J. Lee, S. Thangalazhy-Gopakumar, S. Gan, S.S. Lim, G.T. Pan, T.C.K. Yang, W.S. Chiu, P.S. Khiew, Review on synthesis of 3D graphene-based configurations and their adsorption performance for hazardous water pollutants. Process Saf. Environ. Prot. 116, 262–286 (2018)

O.J. Ajala, J.O. Tijani, M.T. Bankole, A.S. Abdulkareem, A critical review on graphene oxide nanostructured material: properties, synthesis, characterization and application in water and wastewater treatment. Environ. Nanotechnol. Monit. Manag. 18, 100673 (2022)

Q. Wei, X. Tong, G. Zhang, J. Qiao, Q. Gong, S. Sun, Nitrogen-Doped Carbon Nanotube and Graphene Materials for Oxygen Reduction Reactions. Catalysts 5, 1574–1602 (2015)

A.Y.S. Eng, C.K. Chua, M. Pumera, Refinements to the structure of graphite oxide: Absolute quantification of functional groups via selective labelling. Nanoscale 7, 20256–20266 (2015)

X. Li, H. Wang, J.T. Robinson, H. Sanchez, G. Diankov, Simultaneous nitrogen doping and reduction of graphene oxide. J Am Chem Soc. 131, 15939–15944 (2009)

Z. Sheng, L. Shao, J. Chen, W. Bao, F. Wang, X. Xia, Catalyst-free synthesis of nitrogen- doped graphene via thermal annealing graphite oxide with melamine and its excellent electrocatalysis. ACS Nano 5, 4350–4358 (2011)

Z. Lin, G.H. Waller, Y. Liu, M. Liu, C.P. Wong, Simple preparation of nanoporous few-layer nitrogen-doped graphene for use as an efficient electrocatalyst for oxygen reduction and oxygen evolution reactions. Carbon 53, 130–136 (2013)

Z. Wen, X. Wang, S. Mao, Z. Bo, H. Kim, S. Cui, G. Lu, X. Feng, J. Chen, Crumpled nitrogen-doped graphene nanosheets with ultrahigh pore volume for high-performance supercapacitor. Adv. Mater. 24, 5610–5616 (2012)

H. Wang, C. Zhang, Z. Liu, L. Wang, P. Han, H. Xu, K. Zhang, S. Dong, J. Yao, G. Cui, Nitrogen-doped graphene nanosheets with excellent lithium storage properties. J. Mater. Chem. 21, 5430–5434 (2011)

L. Jia, D.-H. Wang, Y.-X. Huang, A.-W. Xu, H.-Q. Yu, Highly durable N-doped graphene/CdS Nanocomposites with enhanced photocatalytic hydrogen evolution from water under visible light irradiation. J. Phys. Chem. C. 115, 11466–11473 (2011)

L. Wang, Z. Sofer, J. Luxa, M. Pumera, Nitrogen doped graphene: Influence of precursors and conditions of the synthesis. J. Mater. Chem. C. 2, 2887–2893 (2014)

M. Kota, H.S. Park, Restacking-inhibited nitrogen-incorporated mesoporous reduced graphene oxides for high energy supercapacitors. Ceram. Int. 44, 3195–3200 (2018)

Z. Lin, X. Xiong, J. Zheng, G. Wang, C. Yang, Three-dimensional N-doped graphene as anode material with superior cycle stability for sodium ion batteries. Mater. Lett. 202, 123–126 (2017)

S. Kumar, S. Gonen, A. Friedman, L. Elbaz, G.D. Nessim, Doping and reduction of graphene oxide using chitosan-derived volatile N-heterocyclic compounds for metal-free oxygen reduction reaction. Carbon 120, 419–426 (2017)

W. Du, M. Wu, M. Zhang, G. Xu, T. Gao, L. Qian, X. Yu, F. Chi, C. Li, G. Shi, High-quality graphene films and nitrogen-doped organogels prepared from the organic dispersions of graphene oxide. Carbon 129, 15–20 (2018)

N. Xiao, H. Tan, J. Zhu, L. Tan, X. Rui, X. Dong, Q. Yan, High-performance supercapacitor electrodes based on graphene achieved by thermal treatment with the aid of nitric acid. ACS Appl. Mater. Interfaces 5, 9656–9662 (2013)

F.H. Baldovino, A.T. Quitain, N.P. Dugos, S.A. Roces, M. Koinuma, M. Yuasa, T. Kida, Synthesis and characterization of nitrogen-functionalized graphene oxide in high-temperature and high-pressure ammonia. RSC Adv. 6, 113924–113932 (2016)

A. Farzaneh, N. Saghatoleslami, E.K. Goharshadi, H. Gharibi, H. Ahmadzadeh, 3-D mesoporous nitrogen-doped reduced graphene oxide as an efficient metal-free electrocatalyst for oxygen reduction reaction in alkaline fuel cells: Role of π and lone pair electrons. Electrochim. Acta. 222, 608–618 (2016)

M. Du, J. Sun, J. Chang, F. Yang, L. Shi, L. Gao, Synthesis of nitrogen-doped reduced graphene oxide directly from nitrogen-doped graphene oxide as a high-performance lithium ion battery anode. RSC Adv. 4, 42412–42417 (2014)

Y. Zou, I.A. Kinloch, R.A.W. Dryfe, Nitrogen-doped and crumpled graphene sheets with improved supercapacitance. J. Mater. Chem. A. 2, 19495–19499 (2014)

L. Sun, L. Wang, C. Tian, T. Tan, Y. Xie, K. Shi, M. Li, H. Fu, Nitrogen-doped graphene with high nitrogen level via a one-step hydrothermal reaction of graphene oxide with urea for superior capacitive energy storage. RSC Adv. 2, 4498–4506 (2012)

Z. Yang, Q. Lan, J. Li, J. Wu, Y. Tang, X. Hu, Efficient streptavidin-functionalized nitrogen-doped graphene for the development of highly sensitive electrochemical immunosensor. Biosens. Bioelectron. 89, 312–318 (2016)

B. Xie, Y. Chen, M. Yu, X. Shen, H. Lei, T. Xie, Y. Zhang, Y. Wu, Carboxyl-assisted synthesis of nitrogen- doped graphene sheets for supercapacitor applications. Nanoscale Res. Lett. 10, 1–11 (2015)

D. Long, W. Li, L. Ling, J. Miyawaki, I. Mochida, S.H. Yoon, Preparation of nitrogen-doped graphene sheets by a combined chemical and hydrothermal reduction of graphene oxide. Langmuir 26, 16096–16102 (2010)

F. Chen, L. Guo, X. Zhang, Z.Y. Leong, S. Yang, H.Y. Yang, Nitrogen-doped graphene oxide for effectively removing boron ions from seawater. Nanoscale 9, 326–333 (2017)

K. Yokwana, S.C. Ray, M. Khenfouch, A.T. Kuvarega, B.B. Mamba, S.D. Mhlanga, E.N. Nxumalo, Facile synthesis of nitrogen doped graphene oxide from graphite flakes and powders: A comparison of their surface chemistry. J. Nanosci. Nanotechnol. 18, 5470–5484 (2018)

Q. Liang, H. Luo, J. Geng, J. Chen, Facile one-pot preparation of nitrogen-doped ultra-light graphene oxide aerogel and its prominent adsorption performance of Cr(VI). Chem. Eng. J. 338, 62–71 (2018)

T. Maqbool, S. Bae, J. Hur, Exploring the complex removal behavior of natural organic matter upon N-doped reduced graphene oxide-activated persulfate via excitation-emission matrix combined with parallel factor analysis and size exclusion chromatography Chem. Eng. J. 347, 252–262 (2018)

X. Wang, P. Tang, C. Ding, X. Cao, S. Yuan, X. Zuo, X. Deng, Simultaneous enhancement of adsorption and peroxymonosulfate activation of nitrogen-doped reduced graphene oxide for bisphenol a removal. J. Environ. Chem. Eng. 5, 4291–4297 (2017)

S. Suresh Balaji, M. Karnan, M. Sathish, Supercritical fluid processing of N-doped graphene and its application in high energy symmetric supercapacitor. Int. J. Hydrogen Energy. 43, 4044–4057 (2018)

S. Dai, Z. Liu, B. Zhao, J. Zeng, H. Hu, Q. Zhang, D. Chen, C. Qu, D. Dang, M. Liu, A high-performance supercapacitor electrode based on N-doped porous graphene. J. Power Sources 387, 43–48 (2018)

A. Śliwak, B. Grzyb, N. Díez, G. Gryglewicz, Nitrogen-doped reduced graphene oxide as electrode material for high rate supercapacitors. Appl. Surf. Sci. 399, 265–271 (2017)

S.K. Singh, V.M. Dhavale, R. Boukherroub, S. Kurungot, S. Szunerits, N-doped porous reduced graphene oxide as an efficient electrode material for high performance flexible solid-state supercapacitor. Appl. Mater. Today. 8, 141–149 (2017)

F. Chekin, A. Vasilescu, R. Jijie, S.K. Singh, S. Kurungot, M. Iancu, G. Badea, R. Boukherroub, S. Szunerits, Sensitive electrochemical detection of cardiac troponin I in serum and saliva by nitrogen-doped porous reduced graphene oxide electrode. Sens. Actuators, B Chem. 262, 180–187 (2018)

P. Wiench, Z. González, R. Menéndez, B. Grzyb, G. Gryglewicz, Beneficial impact of oxygen on the electrochemical performance of dopamine sensors based on N-doped reduced graphene oxides. Sensors Actuators, B Chem. 257, 143–153 (2018)

N.S. Tehrani, M. Masoumi, F. Chekin, M.S. Baei, Nitrogen doped porous reduced graphene oxide hybrid as a nanocarrier of imatinib anticancer drug. Russ. J. Appl. Chem. 93, 1221–1228 (2020)

N.S. Tehrani, M. Masoumi, F. Chekin, M.S. Baei, Hybrid interface based on carboxymethyl cellulose/N-doped porous reduced graphene oxide for on-demand electrochemical release of imatinib. Russ. J. Appl. Chem. 57, 885–891 (2021)

T. Xing, J. Sunarso, W. Yang, Y. Yin, A.M. Glushenkov, L.H. Li, P.C. Howlett, Y. Chen, Ball milling: A green mechanochemical approach for synthesis of nitrogen doped carbon nanoparticles. Nanoscale 5, 7970–7976 (2013)

Y. Xue, H. Chen, J. Qu, L. Dai, Nitrogen-doped graphene by ball-milling graphite with melamine for energy conversion and storage. 2D Mater 2, 44001 (2015)

S. Zhuang, E.S. Lee, L. Lei, B.B. Nunna, L. Kuang, W. Zhang, Synthesis of nitrogen-doped graphene catalyst by high- energy wet ball milling for electrochemical systems. Int. J. Energy Res. 40, 2136–2149 (2016)

T.N. Huan, T. Van Khai, Y. Kang, K.B. Shim, Hoeil Chung, Enhancement of quaternary nitrogen doping of graphene oxide via chemical reduction prior to thermal annealing and an investigation of its electrochemical properties. J. Mater. Chem. 22, 14756–14762 (2012)

J. Yang, M.R. Jo, M. Kang, Y.S. Huh, H. Jung, Y.-M. Kang, Rapid and controllable synthesis of nitrogen doped reduced graphene oxide using microwave-assisted hydrothermal reaction for high power-density supercapacitors. Carbon 73, 106–113 (2014)

A. Giménez-Pérez, S.K. Bikkarolla, J. Benson, C. Bengoa, F. Stüber, A. Fortuny, A. Fabregat, J. Font, P. Papakonstantinou, Synthesis of N-doped and non-doped partially oxidised graphene membranes supported over ceramic materials. J. Mater. Sci. 51, 8346–8360 (2016)

G.I. Titelman, V. Gelman, S. Bron, R.L. Khalfin, Y. Cohen, Characteristics and microstructure of aqueous colloidal dispersions of graphite oxide. Carbon 43, 641–649 (2005)

Y. Chen, B. Xie, Y. Ren, M. Yu, Y. Qu, T. Xie, Y. Zhang, Y. Wu, Designed nitrogen doping of few-layer graphene functionalized by selective oxygenic groups. Nanoscale Res. Lett. 9, 1–8 (2014)

Z. Mou, X. Chen, Y. Du, X. Wang, P. Yang, S. Wang, Forming mechanism of nitrogen doped graphene prepared by thermal solid-state reaction of graphite oxide and urea. Appl. Surf. Sci. 258, 1704–1710 (2011)

H.R. Naderi, P. Norouzi, M.R. Ganjali, H. Gholipour-Ranjbar, Synthesis of a novel magnetite/nitrogen-doped reduced graphene oxide nanocomposite as high performance supercapacitor. Powder Technol. 302, 298–308 (2016)

R. Imani, S. Hojjati, Shahab Faghihi, Nano-graphene oxide carboxylation for efficient bioconjugation applications: a quantitative optimization approach. J. Nanoparticle Res. 17, 1–15 (2015)

M.H. Yeh, Y.A. Leu, W.H. Chiang, Y.S. Li, G.L. Chen, T.J. Li, L.Y. Chang, L.Y. Lin, J.J. Lin, K.C. Ho, Boron-doped carbon nanotubes as metal-free electrocatalyst for dye-sensitized solar cells: Heteroatom doping level effect on tri-iodide reduction reaction. J. Power Sources 375, 29–36 (2018)

C. Yu, H. Fang, Z. Liu, H. Hu, X. Meng, J. Qiu, Chemically grafting graphene oxide to B, N co-doped graphene via ionic liquid and their superior performance for triiodide reduction. Nano Energy 25, 184–192 (2016)

R. Yadav, C.K. Dixit, Synthesis, characterization and prospective applications of nitrogen-doped graphene: a short review. J. Sci. Adv. Mater. Devices. 2, 141–149 (2017)

Z.E. Gorji, A.A. Khodadadi, S. Riahi, T. Repo, Y. Mortazavi, M. Kemell, Functionalization of nitrogen-doped graphene quantum dot: a sustainable carbon-based catalyst for the production of cyclic carbonate from epoxide and CO2. J. Environ. Sci. 126, 408–422 (2023)

X. Wang, Y. Qin, L. Zhu, H. Tang, Nitrogen-doped reduced graphene oxide as a bifunctional material for removing bisphenols: synergistic effect between adsorption and catalysis. Environ. Sci. Technol. 49, 855–6864 (2015)

L.T. Soo, K.S. Loh, A.B. Mohamad, W.R.W. Daud, W.Y. Wong, Effect of nitrogen precursors on the electrochemical performance of nitrogen-doped reduced graphene oxide towards oxygen reduction reaction. J. Alloys Compd. 677, 112–120 (2016)

N. Mahmood, C. Zhang, H. Yin, Y. Hou, Graphene-based nanocomposites for energy storage and conversion in lithium batteries, supercapacitors and fuel cells. J. Mater. Chem. A. 2, 15–32 (2014)