Abstract

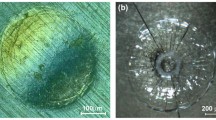

A combination of varying hole and splat morphologies and arrangements were used to construct Morse-Code architectures of dot and dash features in single edge notch bend specimens of PMMA. The crack tip driving force was determined in terms of the normalized energy release rate (G) for these features by finite element simulations. Selected architectures were laser micro-machined and tested. The fracture resistance measured in terms of initiation work of fracture and total work of fracture per unit area from experimental load (P)–crack opening displacement (COD) curves shows that the right combination of these features can provide 20–24 times higher fracture resistance than the bulk solid. While hole-like features led to crack tip blunting, the splat-like feature led to crack deflection. The enhanced damage tolerance in materials containing combination of such features can guide design of architectures in intrinsically porous structures produced by additive or subtractive routes.

Graphical abstract

Similar content being viewed by others

References

H. Herman, S. Sampath, R. McCune, Thermal spray: current status and future trends. MRS Bull. 25, 17–25 (2000). https://doi.org/10.1557/mrs2000.119

L. JyothishKumar, P.M. Pandey, D.I. Wimpenny, 3D Printing and Additive Manufacturing Technologies (Springer Singapore, Singapore, 2018). https://doi.org/10.1007/978-981-13-0305-0

A. Vackel, T. Nakamura, S. Sampath, Mechanical behavior of spray-coated metallic laminates. J. Therm. Spray Technol. (2016). https://doi.org/10.1007/s11666-016-0404-x

J.R. Davis (ed.), Handbook of Thermal Spray Technology (ASM International, 2004)

A. du Plessis, I. Yadroitsava, I. Yadroitsev, Effects of defects on mechanical properties in metal additive manufacturing: a review focusing on X-ray tomography insights. Mater. Des. 187, 108385 (2020). https://doi.org/10.1016/j.matdes.2019.108385

G. Dwivedi, K. Flynn, M. Resnick, S. Sampath, A. Gouldstone, Bioinspired hybrid materials from spray-formed ceramic templates. Adv. Mater. 27, 3073–3078 (2015). https://doi.org/10.1002/adma.201500303

G.K.L. Ng, A.E.W. Jarfors, G. Bi, H.Y. Zheng, Porosity formation and gas bubble retention in laser metal deposition. Appl. Phys. A 97, 641–649 (2009). https://doi.org/10.1007/s00339-009-5266-3

A. Saboori, M. Toushekhah, A. Aversa, M. Lai, M. Lombardi, S. Biamino, P. Fino, Critical features in the microstructural analysis of AISI 316L produced by metal additive manufacturing. Metallogr. Microstruct. Anal. 9, 92–96 (2020). https://doi.org/10.1007/s13632-019-00604-6

G. Dwivedi, V. Viswanathan, S. Sampath, A. Shyam, E. Lara-Curzio, Fracture toughness of plasma-sprayed thermal barrier ceramics: influence of processing, microstructure, and thermal aging. J. Am. Ceram. Soc. 97, 2736–2744 (2014). https://doi.org/10.1111/jace.13021

D. Lal, P. Kumar, R. Bathe, S. Sampath, V. Jayaram, Effect of microstructure on fracture behavior of freestanding plasma sprayed 7 wt.% Y2O3 stabilized ZrO2. J. Eur. Ceram. Soc. 41, 4294–4301 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.02.038

K.M. Conway, C. Kunka, B.C. White, G.J. Pataky, B.L. Boyce, Increasing fracture toughness via architected porosity. Mater. Des. 205, 109696 (2021). https://doi.org/10.1016/j.matdes.2021.109696

Y. Liu, L. St-Pierre, N.A. Fleck, V.S. Deshpande, A. Srivastava, High fracture toughness micro-architectured materials. J. Mech. Phys. Solids 143, 104060 (2020). https://doi.org/10.1016/j.jmps.2020.104060

G. Bullegas, J. Benoliel, P.L. Fenelli, S.T. Pinho, S. Pimenta, Towards quasi isotropic laminates with engineered fracture behaviour for industrial applications. Compos. Sci. Technol. 165, 290–306 (2018). https://doi.org/10.1016/j.compscitech.2018.07.004

M. Benedetti, V. Fontanari, M. Bandini, F. Zanini, S. Carmignato, Low- and high-cycle fatigue resistance of Ti-6Al-4V ELI additively manufactured via selective laser melting: mean stress and defect sensitivity. Int. J. Fatigue 107, 96–109 (2018). https://doi.org/10.1016/j.ijfatigue.2017.10.021

B. Fotovvati, N. Namdari, A. Dehghanghadikolaei, Fatigue performance of selective laser melted Ti6Al4V components: state of the art. Mater. Res. Express (2019). https://doi.org/10.1088/2053-1591/aae10e

P. Edwards, M. Ramulu, Fatigue performance evaluation of selective laser melted Ti-6Al-4V. Mater. Sci. Eng. A 598, 327–337 (2014). https://doi.org/10.1016/j.msea.2014.01.041

T.S. Chaudhari, N.G. Mathews, A.K. Mishra, H.P. Sahasrabuddhe, B.N. Jaya, Energy release rate formulations for non-conventional fracture test geometries. JOM 73, 1597–1606 (2021). https://doi.org/10.1007/s11837-021-04637-7

L.B. Freund, S. Suresh, Stress, Defect Formation and Surface Evolution (Cambridge University Press, Cambridge, 2003), pp. 1–820

H.D. Espinosa, J.E. Rim, F. Barthelat, M.J. Buehler, Merger of structure and material in nacre and bone—perspectives on de novo biomimetic materials. Prog. Mater. Sci. 54, 1059–1100 (2009). https://doi.org/10.1016/j.pmatsci.2009.05.001

G. Bullegas, S.T. Pinho, S. Pimenta, Engineering the translaminar fracture behaviour of thin-ply composites. Compos. Sci. Technol. 131, 110–122 (2016). https://doi.org/10.1016/j.compscitech.2016.06.002

F. Narducci, S.T. Pinho, Exploiting nacre-inspired crack deflection mechanisms in CFRP via micro-structural design. Compos. Sci. Technol. 153, 178–189 (2017). https://doi.org/10.1016/j.compscitech.2017.08.023

F. Narducci, S.T. Pinho, Interaction between nacre-like CFRP mesolayers and long-fibre interlayers. Compos. Struct. 200, 921–928 (2018). https://doi.org/10.1016/j.compstruct.2018.05.103

F. Narducci, K.Y. Lee, S.T. Pinho, Realising damage-tolerant nacre-inspired CFRP. J. Mech. Phys. Solids 116, 391–402 (2018). https://doi.org/10.1016/j.jmps.2018.04.004

L. Mencattelli, J. Tang, Y. Swolfs, L. Gorbatikh, S.T. Pinho, Bio-inspired design for enhanced damage tolerance of self-reinforced polypropylene/carbon fibre polypropylene hybrid composites. Compos. A 121, 341–352 (2019). https://doi.org/10.1016/j.compositesa.2019.03.028

F. Barthelat, Nacre from mollusk shells: a model for high-performance structural materials. Bioinspir. Biomimet. 5, 1–8 (2010). https://doi.org/10.1088/1748-3182/5/3/035001

A. Shafiei, J.W. Pro, F. Barthelat, Bioinspired buckling of scaled skins. Bioinspir. Biomimet. (2021). https://doi.org/10.1088/1748-3190/abfd7e

C.F. Shih, B. Moran, T. Nakamura, Energy release rate along a three-dimensional crack front in a thermally stressed body. Int. J. Fract. 30, 79–102 (1986). https://doi.org/10.1007/BF00034019

Acknowledgments

The authors are grateful to Max-Planck Society (17MAX001) for financial support. The authors would like to acknowledge SINE IIT Bombay for providing laser machining facilities to cut PMMA samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yadav, D., More, T. & Jaya, B.N. Morse-Code inspired architectures for tunable damage tolerance in brittle material systems. Journal of Materials Research 37, 1201–1215 (2022). https://doi.org/10.1557/s43578-022-00520-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00520-6