Abstract

The development of liquid cells for transmission electron microscopy has enabled breakthroughs in our ability to follow nanoscale structural, morphological, or chemical changes during materials growth and applications. Time-resolved high-resolution imaging and chemical analysis through liquids opened the opportunity to capture nanoscale dynamic processes of materials, including reaction intermediates and the transformation pathways. In this article, a series of work is highlighted with topics ranging from liquid cell developments to in situ studies of nanocrystal growth and transformations, dendrite formation, and suppression of lithium dendrites through in situ characterization of the solid–electrolyte interphase chemistry. The understanding garnered is expected to accelerate the discovery of novel materials for applications in energy storage, catalysis, sensors, and other functional devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

A fundamental understanding of materials transformations is critical to designing novel materials and the applications of materials in functional devices. Materials often experience structural, morphological, or chemical transformations in response to an external stimulus. Presently, it remains challenging to make useful predictions on the transformation pathways of nanomaterials using statistical theories. Nanoscale systems and their transformations can be dominated by inhomogeneity and fluctuations. Direct measurement of individual events using in situ high-resolution imaging often becomes necessary for achieving a basic understanding of the underlying processes and governing factors. While challenges remain in reliable, real-time imaging of materials transformations in liquids at small length and time scales, progress has been made, as highlighted in this article.

Liquid cell TEM (also called liquid phase TEM) has attracted broad interests in recent years.1 Recent developments have extended earlier liquid cell techniques to incorporate a wide range of capabilities, including high spatial resolution, real-time chemical analysis using energy-dispersive x-ray spectroscopy (EDS), and electron energy-loss spectroscopy (EELS). These advances enabled us to resolve some of the issues critical to an understanding of nanoscale transformation mechanisms. Examples include the studies of defect evolution in nanometer-sized crystals and of multicomponent material systems2,3,4,5 where chemical analysis is essential. Recent liquid cell development6,7 enabled unprecedented spatial resolution (~2 Å) in comparison to earlier techniques (1 to 5 nm).8,9 Additionally, direct EDS through liquid cell samples opened a range of opportunities. Central to this development is the use of thin membranes. The subsequent work on liquid cells with thin membranes enabled spatial resolutions down to the atomic scale10,11,12,13,14 and high-resolution imaging of biological samples.15 The new design also allows for the study of electrochemistry in liquid cells with various electrode configurations.4,16,17 Today, the high-resolution liquid cells are compatible with EELS, EDS, and atomic-resolution scanning TEM (STEM) analysis. In addition, thermal heating of a liquid cell for in situ TEM was accomplished, which is important for studying thermally induced nucleation and growth of nanoparticles (rather than electron-beam-induced processes).18 Our advanced liquid cell TEM studies benefit from the recent advances in TEM, including aberration-corrected electron optics, fast electron detectors, and advanced image analysis. For example, the early access to the fast electron detector through collaborating with industrial partners has led to a series of scientific discoveries.13,19,20

The liquid cell TEM is a powerful platform to tackle many challenging problems. It facilitated a series of discoveries through detailed studies of nucleation, growth, and self-assembly of nanoparticles, electrode–electrolyte interfaces, catalysis, and beyond. Other areas of study include nanoscale chemical reactions, solid–liquid–gas interfaces, catalysis, and biological samples.

This article highlights the liquid cell development and its associated work with a focus on nonspherical nanoscale materials, including the growth and transformations of PtFe nanowires,2 facet development of Pt nanocubes,13,21 two-dimensional (2D) nanosheet formation with three-dimensional (3D) nanoparticles as the intermediates,14 reversible giant deformation of PbSe nanocrystals during superlattice transformations,11 and Li dendrites formation.4,22 Not only do these material systems have unique anisotropic properties,23,24 they are also ideal systems for exploring nonequilibrium behaviors at the nanoscale, in which a small perturbation can drive them out of equilibrium. To this end, direct observations with high spatial and temporal resolution are necessary for yielding critical insights to a range of related questions. These include how a system responds to perturbations, and what are the governing rules for a system to evolve away from its initial thermodynamic equilibrium. Coupled with theoretical calculations, these fundamental studies foster the discovery of novel materials and promote their real-world applications in functional devices.

This article is adapted and extended from the presentation I gave at the MRS Medal Award session of the 2019 MRS Fall Meeting. It is my hope that researchers from materials science to physics, chemistry, and engineering, find the materials presented informative and useful.

Development of liquid cells allowing high-resolution imaging and chemical analysis

The challenges of liquid phase TEM imaging arise largely from the liquid cell being too thick to achieve high resolution. Previously, nitrocellulose thin films,25 aluminum thin films,26 and thick SiNx membranes more than 50 nm in thickness were typically used; liquid cell fabrication features the stacking or gluing two chips together. Making ultrathin freestanding membranes and controlling the liquid thickness are some of the key attributes to recent developments. These were achieved by using low-stress silicon nitride, SiNx (x < 4/3), 25 nm in thickness on a thinner silicon wafer (100-μm-thick, as compared to the standard 500-μm-thick standard wafer). Even thinner SiNx membranes have been developed and used more recently. A unique problem associated with the use of thin wafers is that they are too fragile to be processed using standard nanofabrication processes. To overcome this problem, one solution is to first bond a thin wafer to a standard 500-μm wafer with photoresist, thus batch fabrication of liquid cells with automated lithography patterning can be accomplished (Figure 1a). To control the liquid thickness inside the cell, a thin In spacer (70–100 nm) may be deposited by thermal evaporation on the bottom chip of the cell and bottom chip can be bonded with the top chip. The thin wafer design minimizes the attenuation of x-ray signals in EDS (Figure 2). The self-contained liquid cells (Figure 1c) with dimensions typically of 2.6 mm × 2.6 mm and 200 μm in thickness fit well into a standard TEM holder.6,7

The development of self-contained liquid cells allowing high resolution and chemical analysis capabilities. (a) A thin Si wafer with a thickness of 100 μm was bonded to a standard wafer with the thickness of 500 μm, thus programed lithographical patterning for batch fabrication can be achieved. (b) A photolithography mask for batch fabrication of the liquid cells. (c) A photograph of regular liquid cells. (d) A photograph of electrochemical liquid cells. (e) A schematic illustration showing that electrodes were made on the bottom chip, liquid reservoirs, and Sn spacer (blue) were made on the top chip of a liquid cell. Adapted with permission from Reference 3. © 2015 American Chemical Society. (f) Transmission electron microscope holder with electrical biasing capability for the electrochemical cells in (d). (g) Thin carbon film liquid cells enabling controlled reactions in PbSe superlattice transformations. Adapted with permission from Reference 11. © 2019 AAAS. (h) In a MoS2 liquid cell, MoS2 2D film serves as a functional substrate as well as the supporting membrane. Adapted with permission from Reference 12. © 2019 American Chemical Society. (i) Lipid nanoreactors were developed. Adapted with permission from Reference 28. © 2020 Royal Society of Chemistry.

The initial work on high-resolution imaging and chemical analysis of liquid cell samples. (a) High-resolution images of Au nanoparticles in a liquid cell. Adapted with permission from Reference 6. © 2009 American Chemical Society. (b) Pt nanocrystals with homogeneous particle size distributions were synthesized in a liquid cell. (c) High-resolution image of a Pt nanocrystal from (b). (d) Energy-dispersive x-ray spectroscopy spectra of a liquid cell sample corresponding to (b). (b–d) Adapted with permission from Reference 7. © 2009 AAAS. (e) Electron energy-loss spectroscopy spectra showing the liquid thickness in a liquid cell can be measured. Reprinted with permission from Reference 14. © 2019 Springer Nature.

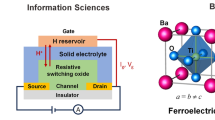

Electrochemical liquid cells may be fabricated by incorporating patterned electrodes (Figure 1e–f). Various metals (e.g., Au, Ti, and Pt) may be used as the electrode materials,3,16,22,27 and they may be electrically connected to the electric pads on the TEM holder with Au or Al wires. Here, the TEM holder must be specially designed to enable electrochemical biasing. EDS chemical analysis is possible with these thin electrochemical liquid cells. For most of the studies on deposition of alkali metals on the electrode, high-resolution imaging is possible, but low-dose imaging is often necessary to avoid electron-beam damage, as will be elaborated later.

Superior high-resolution imaging has been accomplished with a range of newer membranes and 2D materials ranging from carbon films10,11 to MoS2 combined with graphene12 (Figure 1g–h); lipid nanoreactors28 (Figure 1i), on the other hand, offer unique opportunities for study of controlled nanochemistry and nanoscale chemical reactions.

In situ high-resolution tracking of colloidal nanoparticle growth and transformations

The ability to directly monitor colloidal nanoparticle transformations with high resolution opens the opportunities to uncover their growth and transformation mechanisms. Many nanoparticles show no distinct facets (Figure 2a–c). A group of nanoparticles with certain shape and facets, such as nanowires, nanosheets, and nanocubes, has attracted significant interests due to their shape-dependent properties. Synthesis of nanoparticles with controlled shapes has been achieved recently.29 However, our understanding of the shape-control mechanisms remains limited in many nanoparticle systems.

The conventional way of investigating nanocrystal growth is by ex situ measurements (e.g., by periodically taking out nanoparticles from the solution during synthesis, drying them and examining them under TEM). The drawbacks of ex situ measurements are the possible structural changes during sample preparation and the need to infer crystal growth between the examining points. Direct imaging during synthesis resolves this problem, as we can track the trajectories of individual nanoparticle growth and capture the intermediate states on the fly.

Liquid cell imaging can provide valuable insights into the growth mechanisms of 1D nanowires from quantum-dots as the building blocks. Figure 3a shows the sequential images of the growth of a single PtFe nanorod from a molecular precursor solution. Nanoparticles were formed initially. They subsequently attached together to form a nanowire, followed by atomic-level structural rearrangement between the nanoparticles eventually leading to the formation of a single-crystal Pt3Fe nanowire.2 The role of ligands in the nanoparticle shape evolution is revealed through theoretical simulation coupled with a series of control experiments.2,21,30 With advanced image analysis, it is possible to capture the interaction energetics during nanoparticle self-assembly.30

In situ liquid phase transmission electron microscopy study of nonspherical nanocrystal growth and transformations. (a) Sequential images showing the growth of a PtFe nanowire by the attachment of PtFe nanoparticles formed from a molecular precursor solution. (b) High-resolution imaging of a single-crystal Pt3Fe nanowire. (a, b) Reprinted with permission from Reference 2. © 2012 AAAS. (c) With increased concentration of surfactant ligands, PtFe nanoparticles were maintained without attachment and the interaction forces and interaction energetics were calculated. Adapted with permission from Reference 30. © 2017 American Chemical Society. (d) Sequential images showing the growth of a Pt nanocube. The simulated images (in gray) highlight the shape evolution. (e) Tracking the growth of different facets. (f) Density functional theory calculation by considering ligand mobility and other factors. (d–f) Reprinted with permission from Reference 13. © 2014 AAAS. (g–i) The study of 2D cobalt oxide nanosheet formed with 3D nanoparticles as intermediates. (g) A schematic illustration showing the formation of 3D cobalt oxide nanoparticles and subsequent transition into 2D nanosheet. (h) High-resolution images from an in situ movie showing the growth of a 2D nanosheet. (i) Theoretical calculations of the energy evolution by including a shape factor in the classical nucleation and growth theory. Reprinted with permission from Reference 14. © 2019 Springer Nature.

Pt nanocube formation has been studied using liquid cell TEM (Figure 3d–f).13 For the shape evolution of nanocrystals, Wulff construction31,32 is often used to explain their growth. For instance, high-energy facets grow faster than the low-energy facets. In other words, the fast growing facets are eventually replaced by low-energy facets.29,33 Surfactant ligands, however, modify the facet energy, thus influencing the relative growth rate of different facets and altering the final shape of a nanocrystal.34,35An in situ study of Pt nanocube growth demonstrated that the facet development can deviate from the Wulff construction. As shown in Figure 3e, the growth rates of all low-energy index facets, {100}, {110}, and {111}, are similar until the {100} facets stop growing at about 2.5 nm (dc). The {110} facets continue to grow until an edge is formed, whereas the growth of {111} facets fills the corners of the nanocube. Density functional theory (DFT) calculation revealed that the different mobilities of the ligands on the different facets play an important role here. Specifically, the mobility of ligands is several orders of magnitude lower on the {100} than the {111} facets, thus retarding the growth of the {100} facets. A selective facet-arrested shape-control mechanism, mediated by the ligand mobility on different facets, is thus proposed from the complementary theoretical calculations and experiments. Interestingly, the growth of nanocrystals was found to be largely stochastic when they are smaller than a critical size (dc = 2.5 nm), below which no obvious differences in the growth rate could be observed.

Drastic shape evolution was also observed in the growth of cobalt oxide or cobalt nickel oxide nanoparticles (Figure 3g–i). Nanoparticles are formed first from a precursor solution and they transform into nanosheets after they reach a critical size. Different from the previously reported 2D nanosheet formation through oriented attachment of primary 3D nanocrystals36,37 or the “soft template”-assisted growth of 2D nanostructures,38,39,40 the 3D-to-2D transformation involves thinning down at the edges of the nanoparticles first followed by the formation of a uniform single-crystal nanosheet.

Individual PbSe nanocrystals were observed to experience shape changes during superlattice transformations.11 When oleate ligands were removed from the nanoparticle surface by ethylene glycol (EG), negligible changes of individual nanocrystals were observed. In contrast, a small amount of ethylenediamine (EDA) with EDA:EG = 1:1000 in the ligand exchange solution induced large shape changes (up to 40%) as the PbSe nanoparticle interacting with neighboring particles. The deformation of individual PbSe nanocrystals introduces defects in the final superlattice, for example, lower degree of connectivity and higher degree of misorientation in the superlattice formed by ligand exchange with EDA than that formed with pure EG (Figure 4c–d). Further in situ study resolved the necking formation mechanism at the atomic level and revealed the origin of defects in PbSe superlattice transformations.41

Liquid phase transmission electron microscope (TEM) study of PbSe nanocrystal deformation during superlattice transitions. (a) Reversible large deformation of PbSe nanocrystals (No. 11). Scale bar = 5 nm. (b) Quantification of the deformation. (c) Low- and high-magnification TEM images showing that nearly perfect PbSe superlattice was achieved with ethylene glycol (EG) as the ligand exchange solution. Scale bars = 20 nm (left) and 5 nm (right). (d) Comparing to (c), defects were observed with ethylenediamine (EDA) in the ligand exchange solution. Scale bars = 20 nm (left) and 5 nm (right). Reprinted with permission from Reference 11. © 2019 AAAS.

In situ study of dendrite formation at the nanoscale

Understanding nanodendrite pattern formation

Dendritic materials are widely found both in nature and through laboratory synthesis.42 Their formation mechanisms have been explored theoretically.43,44,45,46,47,48,49 Using liquid cell TEM with fine control of the growth conditions and advanced data collection and image analysis, the growth mechanism of iron oxide nanodendrites has been studied with a focus on validating the applicability of available theories for nanoscale systems (Figure 5a–b). Tracking the trajectories of their morphology development reveals the relationship between the tip curvature and growth rate, tip splitting relative to instabilities, and the effects of precursor diffusion and depletion on the morphology evolution. Interestingly, the dendritic morphology evolution observed during the growth of iron oxide nanodendrites was remarkably consistent with existing theoretical predictions, despite occurring at the nanoscale.50,51

In situ study of dendrite growth allowing fundamental understanding of the dendrite formation at the nanoscale and controlling of dendrite growth in functional devices (i.e., Li-ion batteries). (a) Iron oxide dendrite formed in a liquid cell overlapping with the contour map from computer tracing of the dendrite evolution. (b) Large data analysis revealed tip split arising from instabilities. Adapted with permission from Reference 50. © 2018 American Chemical Society. (c) Electrodeposition and dissolution of Pb dendrites in an electrochemical liquid cell. Reprinted with permission from Reference 16. © 2013 Nature Publishing Group. (d) Electrodeposition and dissolution of Li dendrites in an electrochemical liquid cell. Adapted with permission from Reference 22. © 2018 American Chemical Society. (e–h) Suppressing Li dendrite formation with a cationic polymer film (PDDA) coated on the electrodes inside the liquid cell. (e) Li nanogranular growth was achieved on the electrode coated with PDDA. (f) Li dendrite growth was achieved on a bare electrode without polymer coating. (g) Energy-dispersive x-ray spectroscopy (EDS) chemical mapping of a Li nanograin with SEI on the surface. (h) EDS line scan profile showing the solid–electrolyte interphase (SEI) chemistry. (e–h) Reprinted with permission from Reference 4. © 2020 Royal Society of Chemistry.

Interests in metal dendrites stem from the fact that their growth is a primary cause for short-circuit failures in rechargeable batteries and other electronic devices. In a study of the crystallization and morphology evolution of lead dendrites,16 we observed dendrite growth through tip splitting and dissolution of dendrites with mass loss when electric biasing was reversed (Figure 5c). The electrochemically reduced lead atoms form nanograins on the electrode. They subsequently aggregate into clusters and eventually form a dendritic structure. In situ study of Li dendritic growth with liquid phase TEM was challenging because of the use of air/moisture-sensitive electrolyte, and alkali metals being electron-beam sensitive.22 Nevertheless, the deposition and dissolution of Li dendrites were observed in situ for the first time using a commercial electrolyte for Li-ion batteries (Figure 5d–f). More discussion is provided in this article.

Understanding and controlling of Li dendrite growth through in situ chemical analysis

Alkali metal (e.g., Li and Na) plating and stripping have been studied using liquid cell TEM3,17,22 with an emphasis on analysis of the role of solid–electrolyte interphase (SEI).3,4 As a passivation interfacial film formed from the reduction of the electrolyte, SEI plays an important role in the cycle stability of Li-ion batteries. Previous efforts on the study of SEI were primarily through ex situ FTIR, Raman spectroscopy, atomic force microscopy, x-ray photoelectron spectroscopy, and scanning tunneling microscopy.52,53 In situ characterization has been attempted using x-ray scattering,54 and neutron reflectometry55 avoiding complications due to sample exposure to air and moisture. In situ electron microscopy imaging with nanoscale chemical analysis complements these studies.56 Liquid phase TEM observations and nanobeam diffraction of SEI on the electrode revealed that the SEI layer contained LiF nanocrystals distributed in an amorphous matrix,3,4 in contract to the previous understanding of a denser layer of inorganic components adhering to the electrode with a porous organic outer layer exposing to electrolyte.57,58,59 Since the Ti electrode is not reactive with the LiPF6/EC/DEC electrolyte, the formation of SEI should be stepwise from preferential reduction of certain electrolyte components.3 In the contrary, the Li metal electrode reacts with the electrolyte directly, leading to instantaneous SEI formation. For this reason, the reduction of electrolyte components should be indiscriminate to all species.3

Further advances of in situ study of electrochemical liquid cells allowed the mapping of spatially resolved SEI chemistry on individual lithium nanograins.4 The observation revealed that Li dendrites can be suppressed by a cationic polymer coating on the electrode (Figure 5e–h), thus uncovering a potential path to Li dendrite suppression.

Electron-beam effects

The high-energy electron beam is known to interact with liquids, causing molecular dissociation, ionization, and other chemical reactions. Concerns about sample damage due to electron-beam exposure have been discussed throughout the history of electron microscopy development.60 Recently, there have been an increased number of studies on this problem especially for beam-sensitive materials in liquids.61 There have also been reports about simulation of radiolysis-induced damages of water62 and organic molecules.63 Real-time time-dependent density functional theory (rt-TDDFT) calculations revealed the strong competition among different dissociation paths in C2H6O2 radiolysis.63 Obviously, blocking the dissociation paths during electron microscopy imaging may reduce the electron-beam damage, even though radiolysis damage to a liquid solution can be rather complex. Many factors must be considered, including the electron-beam energy, molecules being studied, and their competing chemical reactions.

While no universal solution exists, lowering the electron-beam current density reduces the electron-beam effects. For example, low-dose imaging has been applied to electrochemical studies3,4,16,17,22 and no discernible reactions should be observed before applying an electric bias. In the study of nanocrystal growth and transformations, strong electron-beam intensity was often needed, in which case, control experiments would become critical to observing and isolating the beam damage effects.64

Understanding of materials transformations accelerates materials discovery

With the fundamental understanding of nanoscale materials growth and transformations garnered from in situ studies, materials may be designed for achieving special functions. For example, a series of functional materials was prepared through laser synthesis involving nonequilibrium phonon-induced reactions.65,66,67 Nanoporous metal–organic composites were designed and prepared recently, showing nearly 100% selective of CO production over H2 generation from CO2 reduction reaction. Tandem catalysts prepared by incorporating Rh or Ag nanoparticles into the metal–organic composites, on the other hand, produced formic and acetic acids. Remarkably, laser synthesis significantly shortens the growth processes, from 24+ h with the conventional solvothermal method to 30 min–2 h.

Conclusions

With the development of in situ liquid cell TEM, unprecedented advances in high-resolution imaging and chemical analysis have been made for a wide range of problems involving nanoscale materials growth and transformations. These advances opened many opportunities to resolve dynamic processes of nanoscale materials that were unreachable previously. This article highlights some examples of liquid phase TEM studies of nanoscale materials, from one-dimensional nanocrystals to faceted nanocrystals, 2D nanosheets, and superlattice transformations. Other applications discussed include nanodendrite formation and Li dendrite suppression by resolving nanoscale structure and chemistry of SEI. Clearly, the advances in liquid cell electron microscopy accelerate materials discovery.

There are tremendous future opportunities in liquid phase TEM as the liquid cell development is tuned for specific experiments with better control of reactions under various stimuli. And, as advanced imaging with fast data collection has become widely available, large data processing and data interpretation are highly integral components of the studies. Liquid phase TEM will continue to attract great interest in various research fields from materials science to chemistry, physics, and biology.

Data availability

Data are available in the online version of this paper. Data that support the findings of this study are available from the author upon reasonable request.

References

U. Mirsaidov, J.P. Patterson, H. Zheng, Liquid phase transmission electron microscopy for imaging of nanoscale processes in solution. MRS Bull. 45, 704 (2020)

H.-G. Liao, L. Cui, S. Whitelam, H. Zheng, Real-time imaging of Pt3Fe nanorod growth in solution. Science 336, 1011 (2012)

Z. Zeng, X. Zhang, K. Bustillo, K. Niu, C. Gammer, J. Xu, H. Zheng, In situ study of lithiation and delithiation of MoS2 nanosheets using electrochemical liquid cell transmission electron microscopy. Nano Lett. 15, 5214 (2015)

S.-Y. Lee, J. Shangguan, J. Alvarado, S. Betzler, S.J. Harris, M.M. Doeff, H. Zheng, Unveiling the mechanisms of lithium dendrite suppression by cationic polymer film induced solid–electrolyte interphase modification. Energy Environ. Sci. 13, 1832 (2020)

K.-Y. Niu, M. Liu, K.A. Persson, Y. Han, H. Zheng, Strain-mediated interfacial dynamics during Au–PbS core–shell nanostructure formation. ACS Nano 10, 6235 (2016)

H. Zheng, S.A. Claridge, A.M. Minor, A.P. Alivisatos, U. Dahmen, Nanocrystal diffusion in a liquid thin film observed by in situ transmission electron microscopy. Nano Lett. 9, 2460 (2009)

H. Zheng, R.K. Smith, Y.-w. Jun, C. Kisielowski, U. Dahmen, A.P. Alivisatos, Observation of single colloidal platinum nanocrystal growth trajectories. Science 324, 1309 (2009)

M. Williamson, R. Tromp, P. Vereecken, R. Hull, F. Ross, Dynamic microscopy of nanoscale cluster growth at the solid–liquid interface. Nat. Mater. 2, 532 (2003)

N. De Jonge, D.B. Peckys, G. Kremers, D. Piston, Electron microscopy of whole cells in liquid with nanometer resolution. Proc. Natl. Acad. Sci. 106, 2159 (2009)

C. Zhu, S. Liang, E. Song, Y. Zhou, W. Wang, F. Shan, Y. Shi, C. Hao, K. Yin, T. Zhang, J. Liu, H. Zheng, L. Sun, In-situ liquid cell transmission electron microscopy investigation on oriented attachment of gold nanoparticles. Nat. Commun. 9, 421 (2018)

Y. Wang, X. Peng, A. Abelson, P. Xiao, C. Qian, L. Yu, C. Ophus, P. Ercius, L.-W. Wang, M. Law, Dynamic deformability of individual PbSe nanocrystals during superlattice phase transitions. Sci. Adv. 5, eaaw5623 (2019)

J. Yang, M.K. Choi, Y. Sheng, J. Jung, K. Bustillo, T. Chen, S.-W. Lee, P. Ercius, J.H. Kim, J.H. Warner, MoS2 liquid cell electron microscopy through clean and fast polymer-free MoS2 transfer. Nano Lett. 19, 1788 (2019)

H.-G. Liao, D. Zherebetskyy, H. Xin, C. Czarnik, P. Ercius, H. Elmlund, M. Pan, L.-W. Wang, H. Zheng, Facet development during platinum nanocube growth. Science 345, 916 (2014)

J. Yang, Z. Zeng, J. Kang, S. Betzler, C. Czarnik, X. Zhang, C. Ophus, C. Yu, K. Bustillo, M. Pan, Formation of two-dimensional transition metal oxide nanosheets with nanoparticles as intermediates. Nat. Mater. 18, 970 (2019)

U.M. Mirsaidov, H. Zheng, Y. Casana, P. Matsudaira, Imaging protein structure in water at 2.7 nm resolution by transmission electron microscopy. Biophys. J. 102, L15 (2012)

M. Sun, H.-G. Liao, K. Niu, H. Zheng, Structural and morphological evolution of lead dendrites during electrochemical migration. Sci. Rep. 3, 3227 (2013)

Z. Zeng, P. Barai, S.-Y. Lee, J. Yang, X. Zhang, W. Zheng, Y.-S. Liu, K.C. Bustillo, P. Ercius, J. Guo, Electrode roughness dependent electrodeposition of sodium at the nanoscale. Nano Energy 72, 104721 (2020)

H.L. Xin, H. Zheng, In situ observation of oscillatory growth of bismuth nanoparticles. Nano Lett. 12, 1470 (2012)

W.-I. Liang, X. Zhang, K. Bustillo, C.-H. Chiu, W.-W. Wu, J. Xu, Y.-H. Chu, H. Zheng, In situ study of spinel ferrite nanocrystal growth using liquid cell transmission electron microscopy. Chem. Mater. 27, 8146 (2015)

W.-I. Liang, X. Zhang, Y. Zan, M. Pan, C. Czarnik, K. Bustillo, J. Xu, Y.-H. Chu, H. Zheng, In situ study of Fe3Pt–Fe2O3 core–shell nanoparticle formation. J. Am. Chem. Soc. 137, 14850 (2015)

H.-G. Liao, H. Zheng, Liquid cell transmission electron microscopy study of platinum iron nanocrystal growth and shape evolution. J. Am. Chem. Soc. 135, 5038 (2013)

Z. Zeng, W.-I. Liang, H.-G. Liao, H.L. Xin, Y.-H. Chu, H. Zheng, Visualization of electrode–electrolyte interfaces in LiPF6/EC/DEC electrolyte for lithium ion batteries via in situ TEM. Nano Lett. 14, 1745 (2014)

A.K. Pearce, T.R. Wilks, M.C. Arno, R.K. O’Reilly, Synthesis and applications of anisotropic nanoparticles with precisely defined dimensions. Nat. Rev. Chem. 21 (2020)

T.K. Sau, A.L. Rogach, F. Jäckel, T.A. Klar, J. Feldmann, Properties and applications of colloidal nonspherical noble metal nanoparticles. Adv. Mater. 22, 1805 (2010)

I. Abrams, J. McBain, A closed cell for electron microscopy. J. Appl. Phys. 15, 607 (1944)

L. Marton, Electron microscopy of biological objects. Phys. Rev. 46, 527 (1934)

R.M. Arán-Ais, R. Rizo, P. Grosse, G. Algara-Siller, K. Dembélé, M. Plodinec, T. Lunkenbein, S.W. Chee, B.R. Cuenya, Imaging electrochemically synthesized Cu2O cubes and their morphological evolution under conditions relevant to CO2 electroreduction. Nat. Commun. 11, 3489 (2020)

S.B. Alam, J. Yang, K.C. Bustillo, C. Ophus, P. Ercius, H. Zheng, E.M. Chan, Hybrid nanocapsules for in situ TEM imaging of gas evolution reactions in confined liquids. Nanoscale 12, 18606 (2020)

Y. Xia, Y. Xiong, B. Lim, S.E. Skrabalak, Shape-controlled synthesis of metal nanocrystals: Simple chemistry meets complex physics? Angew. Chem. Int. Ed. 48, 60 (2009)

A.S. Powers, H.-G. Liao, S.N. Raja, N.D. Bronstein, A.P. Alivisatos, H. Zheng, Tracking nanoparticle diffusion and interaction during self-assembly in a liquid cell. Nano Lett. 17, 15 (2017)

J.W. Gibbs, H.A. Bumstead, R.G. Van Name, W.R. Longley, The collected works of J. Willard Gibbs (Longmans, Green and Co., New York, 1902)

G. Wulff, On the question of speed of growth and dissolution of crystal surfaces. Z. Fur Krystall. Mineral. 34, 449 (1901)

N. Tian, Z.-Y. Zhou, S.-G. Sun, Y. Ding, Z.L. Wang, Synthesis of tetrahexahedral platinum nanocrystals with high-index facets and high electro-oxidation activity. Science 316, 732 (2007)

C.R. Bealing, W.J. Baumgardner, J.J. Choi, T. Hanrath, R.G. Hennig, Predicting nanocrystal shape through consideration of surface-ligand interactions. ACS Nano 6, 2118 (2012)

E. Ringe, R.P. Van Duyne, L.D. Marks, Wulff construction for alloy nanoparticles. Nano Lett. 11, 3399 (2011)

C. Schliehe, B.H. Juarez, M. Pelletier, S. Jander, D. Greshnykh, M. Nagel, A. Meyer, S. Foerster, A. Kornowski, C. Klinke, Ultrathin PbS sheets by two-dimensional oriented attachment. Science 329, 550 (2010)

S. Gao, Y. Sun, F. Lei, L. Liang, J. Liu, W. Bi, B. Pan, Y. Xie, Ultrahigh energy density realized by a single‐layer β‐Co(OH)2 all‐solid‐state asymmetric supercapacitor. Angew. Chem. Int. Ed. 53, 12789 (2014)

J.S. Son, X.D. Wen, J. Joo, J. Chae, S.i. Baek, K. Park, J.H. Kim, K. An, J.H. Yu, S.G. Kwon, Large‐scale soft colloidal template synthesis of 1.4 nm thick CdSe nanosheets. Angew. Chem. 121, 6993 (2009)

S. Sun, H. Zeng, D.B. Robinson, S. Raoux, P.M. Rice, S.X. Wang, G. Li, Monodisperse MFe2O4 (M = Fe, Co, Mn) nanoparticles. J. Am. Chem. Soc. 126, 273 (2004)

J.S. Son, J.H. Yu, S.G. Kwon, J. Lee, J. Joo, T. Hyeon, Colloidal synthesis of ultrathin two‐dimensional semiconductor nanocrystals. Adv. Mater. 23(28), 3214

Y. Wang, X. Peng, A. Abelson, B.-K. Zhang, C. Qian, P. Ercius, L.-W. Wang, M. Law, H. Zheng, In situ TEM observation of neck formation during oriented attachment of PbSe nanocrystals. Nano Res. 12, 2549 (2019)

P. Meakin, Fractals, Scaling and Growth Far from Equilibrium (Cambridge University Press, Cambridge, UK, 1998)

W.W. Mullins, R. Sekerka, Stability of a planar interface during solidification of a dilute binary alloy. J. Appl. Phys. 35, 444 (1964)

W.W. Mullins, R.F. Sekerka, Morphological stability of a particle growing by diffusion or heat flow. J. Appl. Phys. 34, 323 (1963)

J.S. Langer, Instabilities and pattern formation in crystal growth. Rev. Mod. Phys. 52, 1 (1980)

J.S. Langer, "Lectures in the Theory of Pattern Formation," in Chance and Matter, J. Souletie, J. Vannimenus, R. Stora, Eds. (North Holland Publishing, New York, 1987), pp. 629–711

D.A. Kessler, J. Koplik, H. Levine, Pattern selection in fingered growth phenomena. Adv. Phys. 37, 255 (1988)

M.B. Amar, E. Brener, Theory of pattern selection in three-dimensional nonaxisymmetric dendritic growth. Phys. Rev. Lett. 71, 589 (1993)

A. Barbieri, J. Langer, Predictions of dendritic growth rates in the linearized solvability theory. Phys. Rev. A 39, 5314 (1989)

M.R. Hauwiller, X. Zhang, W.-I. Liang, C.-H. Chiu, Q. Zhang, W. Zheng, C. Ophus, E.M. Chan, C. Czarnik, M. Pan, Dynamics of nanoscale dendrite formation in solution growth revealed through in situ liquid cell electron microscopy. Nano Lett. 18, 6427 (2018)

W. Zheng, M.R. Hauwiller, W.-I. Liang, C. Ophus, P. Ercius, E.M. Chan, Y.-H. Chu, M. Asta, X. Du, A.P. Alivisatos, Real time imaging of two-dimensional iron oxide spherulite nanostructure formation. Nano Res. 12, 2889 (2019)

K. Xu, Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303 (2004)

P. Verma, P. Maire, P. Novák, A review of the features and analyses of the solid electrolyte interphase in Li-ion batteries. Electrochim. Acta 55, 6332 (2010)

D. Stevens, J. Dahn, The mechanisms of lithium and sodium insertion in carbon materials. J. Electrochem. Soc. 148, A803 (2001)

J.E. Owejan, J.P. Owejan, S.C. DeCaluwe, J.A. Dura, Solid electrolyte interphase in Li-ion batteries: Evolving structures measured in situ by neutron reflectometry. Chem. Mater. 24, 2133 (2012)

Y.A. Wu, Z. Yin, M. Farmand, Y.-S. Yu, D.A. Shapiro, H.-G. Liao, W.-I. Liang, Y.-H. Chu, H. Zheng, In-situ multimodal imaging and spectroscopy of Mg electrodeposition at electrode–electrolyte interfaces. Sci. Rep. 7, 42527 (2017)

J. Christensen, J. Newman, A mathematical model for the lithium-ion negative electrode solid electrolyte interphase. J. Electrochem. Soc. 151, A1977 (2004)

D. Aurbach, Y. Ein‐Ely, A. Zaban, The surface chemistry of lithium electrodes in alkyl carbonate solutions. J. Electrochem. Soc. 141, L1 (1994)

D. Bar‐Tow, E. Peled, L. Burstein, A study of highly oriented pyrolytic graphite as a model for the graphite anode in Li‐Ion batteries. J. Electrochem. Soc. 146, 824 (1999)

S.M. Seltzer, M.J. Berger, Evaluation of the collision stopping power of elements and compounds for electrons and positrons. Int. J. Appl. Radiat. Isot. 33, 1189 (1982)

P. Abellan, T. Woehl, L. Parent, N. Browning, J. Evans, I. Arslan, Factors influencing quantitative liquid (scanning) transmission electron microscopy. Chem. Commun. 50, 4873 (2014)

N.M. Schneider, M.M. Norton, B.J. Mendel, J.M. Grogan, F.M. Ross, H.H. Bau, Electron–water interactions and implications for liquid cell electron microscopy. J. Phys. Chem. C 118, 22373 (2014)

Z. Cai, S. Chen, L.-W. Wang, Dissociation path competition of radiolysis ionization-induced molecule damage under electron beam illumination. Chem. Sci. 10, 10706 (2019)

X. Peng, A. Abelson, Y. Wang, C. Qian, J. Shangguan, Q. Zhang, L. Yu, Z.-W. Yin, W. Zheng, K.C. Bustillo, In situ TEM study of the degradation of PbSe nanocrystals in air. Chem. Mater. 31, 190 (2018)

K.-Y. Niu, F. Lin, S. Jung, L. Fang, D. Nordlund, C.C. McCrory, T.-C. Weng, P. Ercius, M.M. Doeff, H. Zheng, Tuning complex transition metal hydroxide nanostructures as active catalysts for water oxidation by a laser–chemical route. Nano Lett. 15, 2498 (2015

K.Y. Niu, L. Fang, R. Ye, D. Nordlund, M.M. Doeff, F. Lin, H. Zheng, Tailoring transition‐metal hydroxides and oxides by photon‐induced reactions. Angew. Chem. 128, 14484 (2016)

K. Niu, Y. Xu, H. Wang, R. Ye, H.L. Xin, F. Lin, C. Tian, Y. Lum, K.C. Bustillo, M.M. Doeff, A spongy nickel-organic CO2 reduction photocatalyst for nearly 100% selective CO production. Sci. Adv. 3, e1700921 (2017)

Acknowledgments

I would like to thank the current and previous members of my research group for their dedication and effort in research. I would especially like to thank my graduate students, J. Shangguan and D. Lee, for their assistance in preparing references and figures, and Y. Wang for proofreading of this article. This work was supported by the US Department of Energy (DOE), Office of Science, Office of Basic Energy Sciences (BES), Materials Sciences and Engineering Division under Contract No. DE-AC02-05-CH11231 within the KC22ZH program. Work at the Molecular Foundry of Lawrence Berkeley National Laboratory (LBNL) was supported by the Office of Science, Office of Basic Energy Sciences, of the US Department of Energy under Contract No. DE-AC02-05CH11231.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing financial interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zheng, H. Imaging, understanding, and control of nanoscale materials transformations. MRS Bulletin 46, 443–450 (2021). https://doi.org/10.1557/s43577-021-00113-4

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-021-00113-4