Abstract

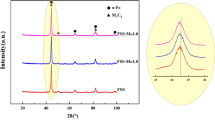

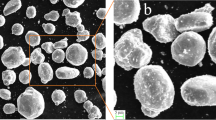

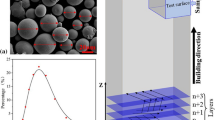

The study investigated novel wear and corrosion resistance of stainless steel and 316 stainless steel samples which were successfully prepared by laser melting deposition. Phase composition, microstructure, microhardness, wear resistance, and electrochemical corrosion resistance were studied. The experimental results showed that novel stainless steel was mainly composed of a-Fe and a few carbide phase (Cr, Fe)7C3. The microhardness of novel stainless steel was about 2.7 times greater than 316 stainless steel. Meanwhile, the specific wear rate of novel stainless steel and 316 stainless steel was 2.63 × 10-5 mm3/N m and 1.63 × 10-4 mm3/N m, respectively. The wear volume of 316 stainless steel was 6.19 times greater than novel stainless steel. The corrosion current and the corrosion potential of novel stainless steel and 316 stainless steel were 1.02 × 10-7 A/cm2 and 1.5 × 10-7 A/cm2, and -138.8 mV, -135.9 mV, respectively, in 3.5 wt% NaCl solution. Therefore, both microhardness and wear resistance of novel stainless steel were greatly improved, with high corrosion resistance.

Similar content being viewed by others

References

D.D. Gu, J. Ma, H.Y. Chen, K.J. Lin, and L.X. Xi: Laser additive manufactured WC reinforced Fe-based composites with gradient reinforcement/matrix interface and enhanced performance. Compos. Struct.192, 387 (2018).

L. Girelli, M. Giovagnoli, M. Tocci, A. Pola, A. Fortini, M. Merlin, and G. Marina La Vecchia: Evaluation of the impact behaviour of AlSi10Mg alloy produced using laser additive manufacturing. Mater. Sci. Eng., A748, 38 (2019).

E. Armelin, S. Moradi, S.G. Hatzikiriakos, and C. Aleman: Designing stainless steel surfaces with anti-pitting properties applying laser ablation and organofluorine coatings. Adv. Eng. Mater.20, 1 (2018).

M.S.F. de Lima and S. Sankaré: Microstructure and mechanical behavior of laser additive manufactured AISI 316 stainless steel stringers. Mater. Des.55, 526 (2014).

X.Z. Ran, D. Liu, A. Li, H.M. Wang, H.B. Tang, and X. Cheng: Microstructure characterization and mechanical behavior of laser additive manufactured ultrahigh-strength AerMet100 steel. Mater. Sci. Eng., A663, 69 (2016).

Y. Zhu, T. Peng, G.F. Jia, H. Zhang, S.M. Xu, and H.Y. Yang: Electrical energy consumption and mechanical properties of selective-laser-melting-produced 316L stainless steel samples using various processing parameters. J. Cleaner Prod.208, 77 (2019).

T. Pasang, A. Kirchner, U. Jehring, M. Aziziderouei, Y. Tao, C.P. Jiang, J.C. Wang, and I.S. Aisyah: Microstructure and mechanical properties of welded additively manufactured stainless steels SS316L. Met. Mater. Int.25, 1278 (2019).

Y.H. Zhao, J. Sun, J.F. Li, P.F. Wang, Z.C. Zheng, J.W. Chen, and Y.Q. Yan: The stress coupling mechanism of laser additive and milling subtractive for FeCr alloy made by additive-subtractive composite manufacturing. J. Alloys Compd.769, 898 (2018).

M. Oyesola, N. Mathe, K. Mpofu, and S. Fatoba: Sustainability of additive manufacturing for the South African aerospace industry: A business model for laser technology production, commercialization, and market prospects. Procedia CIRP72, 1530 (2018).

J. Bi, Z.L. Lei, X. Chen, P. Li, N.N. Lu, and Y.B. Chen: Microstructure and mechanical properties of TiB2-reinforced 7075 aluminum matrix composites fabricated by laser melting deposition. Ceram. Int.45, 5680 (2019).

M. Javaid and A. Haleem: Additive manufacturing applications in medical cases: A literature based review. Alexandria J. Med.54, 411 (2018).

Y. Zhang, C.J. Qiu, Y. Chen, J.S. Yu, J. Zhou, L.S. Li, and Z.C. Wang: Influence of high-frequency micro-forging on microstructure and properties of 304 stainless steel fabricated by laser rapid prototyping. Steel Res. Int.84, 870 (2013).

D.R. Manca, A.Y. Churyumov, A.V. Pozdniakov, A.S. Prosviryakov, D.K. Ryabov, A.Y. Krokhin, V.A. Korolev, and D.K. Daubarayt: Microstructure and properties of novel heat resistant Al–Ce–Cu alloy for additive manufacturing. Met. Mater. Int.25, 633 (2018).

H. Knoll, S. Ocylok, A. Weisheit, H. Springer, E. Jagle, and D. Raabe: Combinatorial alloy design by laser additive manufacturing. Steel Res. Int.88, 1 (2017).

R.D. Li, H. Chen, C. Chen, H.B. Zhu, M.B. Wang, T.C. Yuan, and B. Song: Selective laser melting of gas atomized Al–3.02Mg– 0.2Sc–0.1Zr alloy powder: Microstructure and mechanical properties. Adv. Eng. Mater.21, 1800650 (2019).

H.B. Wang, G.L. Song, and G.Y. Tang: Effect of electropulsing on surface mechanical properties and microstructure of AISI 304 stainless steel during ultrasonic surface rolling process. Mater. Sci. Eng., A662, 456 (2016).

Y. Byun, S. Lee, S.M. Seo, J. Yeom, S.E. Kim, N. Kang, and J. Hong: Effects of Cr and Fe addition on microstructure and tensile properties of Ti–6Al–4V prepared by direct energy deposition. Met. Mater. Int.24, 1213 (2018).

C. Wang, C.H. Zhang, S. Zhang, C.L. Wu, J.B. Zhang, Y. Liu, and X.X. Pu: Microstructure and wear resistance of in situ synthesized particle reinforced novel stainless steel by laser melting deposition. Mater. Res. Express6, 086561 (2019).

X. Cui, S. Zhang, C.H. Zhang, C.L. Wu, J.B. Zhang, Y. Liu, and A.O. Abdullah: The impact of powder oxygen content on formability of 12CrNi2 alloy steel fabricated by laser melting deposition. Powder Metall.62, 186 (2019).

S. Zhang, S. Wang, C.L. Wu, C.H. Zhang, M. Guan, and J.Z. Tan: Cavitation erosion and erosion-corrosion resistance of austenitic stainless steel by plasma transferred arc welding. Eng. Fail. Anal.76, 115 (2017).

C.L. Wu, S. Zhang, C.H. Zhang, H. Zhang, and S.Y. Dong: Phase evolution and cavitation erosion-corrosion behavior of FeCoCrAlNiTix high entropy alloy coatings on 304 stainless steel by laser surface alloying. J. Alloys Compd.698, 761 (2017).

X. Cui, S. Zhang, C. Wang, C.H. Zhang, J. Chen, and J.B. Zhang: Microstructure and fatigue behavior of a laser additive manufactured 12CrNi2 low alloy steel. Mater. Sci. Eng., A772, 138685 (2019).

B.W. Shen, B.R. Du, M.H. Wang, N. Xiao, Y.F. Xu, and S. Hao: Comparison on microstructure and properties of stainless steel layer formed by extreme high-speed and conventional laser melting deposition. Front. Mater.6, 248 (2019).

V. Contaldi, F. Del Re, B. Palumbo, A. Squillace, P. Corrado, and P. Di Petta: Mechanical characterization of stainless steel parts produced by direct metal laser sintering with virgin and reused powder. Int. J. Adv. Manuf. Technol.105, 3337 (2019).

J.D. Majumdar, A. Pinkerton, Z. Liu, I. Manna, and L. Li: Mechanical and electrochemical properties of multiple-layer diode laser cladding of 316L stainless steel. Appl. Surf. Sci.247, 373 (2005).

X. Xu, G.Y. Mi, Y.Q. Luo, P. Jiang, X.Y. Shao, and C.M. Wang: Morphologies, microstructures, and mechanical properties of samples produced using laser metal deposition with 316L stainless steel wire. Optic Laser. Eng.94, 1 (2017).

M. Zietala, T. Durejko, M. Polański, I. Kunce, T. Płociński, W. Zieliński, M. qazińska, W. Stepniowski, T. Czujko, K.J. Kurzydłowski, and Z. Bojar: The microstructure, mechanical properties, and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng., A677, 1 (2016).

H. Zhang, C.H. Zhang, Q. Wang, C.L. Wu, S. Zhang, J. Chen, and A.O. Abdullah: Effect of Ni content on stainless steel fabricated by laser melting deposition. Optic Laser. Technol.101, 363 (2018).

G. Huang, X.L. Wan, and K.M. Wu: Effect of Cr content on microstructure and impact toughness in the simulated coarsegrained heat-affected zone of high-strength low-alloy steels. Steel Res. Int.87, 1426 (2016).

A. Ayyagari, V. Hasannaeimi, H. Grewal, H. Arora, and S. Mukherjee: Corrosion, erosion and wear behavior of complex concentrated alloys: A review. Metals8, 603 (2018).

Q.L. Wu, W.G. Li, N. Zhong, and G.Q. Wang: Microstructure and properties of laser-clad Mo2NiB2 cermet coating on steel substrate. Steel Res. Int.86, 293 (2015).

M. Godec, C. Donik, A. Kocijan, B. Podgornik, and D.A. Skobir Balantič: Effect of post-treated low-temperature plasma nitriding on the wear and corrosion resistance of 316L stainless steel manufactured by laser powder-bed fusion. Addit. Manuf.32, 101000 (2020).

S. Azuma, T. Kudo, H. Miyuki, M. Yamashita, and H. Uchida: Effect of nickel alloying on crevice corrosion resistance of stainless steels. Corros. Sci.46, 2265 (2004).

J.C. Lippold and D.J. Kotecki:Welding Metallurgy and Weldability of Stainless Steels, Vol. 1 (John Wiley and Sons Inc, Hoboken, 2005); p. 376.

K.B. Li, D. Li, D.Y. Liu, G.Y. Pei, and L. Sun: Microstructure evolution and mechanical properties of multiple-layer laser cladding coating of 308L stainless steel. Appl. Surf. Sci.340, 143 (2015).

G. Mallaiah, A. Kumar, P.R. Reddy, and G.M. Reddy: Influence of grain refining elements on mechanical properties of AISI 430 ferritic stainless steel weldments—Taguchi approach. Mater. Des.36, 443 (2012).

B. Ghiban, C.A. Safta, M. Ion, C.E. Crângaşu, and M. Grecu: Structural aspects of silt erosion resistant materials used in hydraulic machines manufacturing. Energy Procedia112, 75 (2017).

L. Zhang and T. Kannengiesser: Austenite grain growth and microstructure control in simulated heat affected zones of microalloyed HSLA steel. Mater. Sci. Eng., A613, 326 (2014).

Y. Chen, Y.B. Guo, M.J. Xu, C.F. Ma, Q.L. Zhang, L. Wang, J.H. Yao, and Z.G. Li: Study on the element segregation and Laves phase formation in the laser metal deposited IN718 superalloy by flat top laser and Gaussian distribution laser. Mater. Sci. Eng., A754, 339 (2019).

X.Y. Yang, X. Peng, J. Chen, and F.H. Wang: Effect of a small increase in the Ni content on the properties of a laser surface clad Fe-based alloy. Appl. Surf. Sci.253, 4420 (2007).

N. Merakeb, A. Messai, and A.I. Ayesh: Investigation of phase transformation for ferrite–austenite structure in stainless steel thin films. Thin Solid Films606, 120 (2016).

R. Madec and L.P. Kubin: Dislocation strengthening in FCC metals and in BCC metals at high temperatures. Acta Mater.126, 166 (2017).

J.H. Dai:Technology and Properties of 17-4PH Stainless Steel by Laser Solid Solution and Alloying Hybrid Strengthening (Zhejiang University of Technology, Hangzhou, China, 2011).

H. Irrinki, S.D. Nath, M. Alhofors, J. Stitzel, O. Gulsoy, and S.V. Atre: Microstructures, properties, and applications of laser sintered 17-4PH stainless steel. J. Am. Ceram. Soc.102, 5679 (2019).

A. Dréano, S. Fouvry, and G. Guillonneau: A tribo-oxidation abrasive wear model to quantify the wear rate of a cobaltbased alloy subjected to fretting in low-to-medium temperature conditions. Tribol. Int.125, 128 (2018).

P. Xu, C.X. Lin, C.Y. Zhou, and X.P. Yi: Wear and corrosion resistance of laser cladding AISI 304 stainless steel/Al2O3 composite coatings. Surf. Coat. Technol.238, 9 (2014).

S. Wang, S. Zhang, C.H. Zhang, C.L. Wu, and J. Chen: Effect of Cr3C2 content on 316L stainless steel fabricated by laser melting deposition. Vacuum147, 92 (2018).

T.J. Lienert and J.C. Lippold: Improved weldability diagram for pulsed laser welded austenitic stainless steels. Sci. Technol. Weld. Join.8, 1 (2003).

M. Tanaka, K. Matsuo, N. Yoshimura, G. Shigesato, M. Hoshino, K. Ushioda, and K. Higashida: Effects of Ni and Mn on brittle-to-ductile transition in ultralow-carbon steels. Mater. Sci. Eng., A682, 370 (2017).

X.G. Feng, X.Y. Zhang, Y.W. Xu, R.L. Shi, X.Y. Lu, L.Y. Zhang, J. Zhang, and D. Chen: Corrosion behavior of deformed low-nickel stainless steel in groundwater solution. Eng. Fail. Anal.98, 49 (2019).

D.H. Wen, Q. Wang, B.B. Jiang, C. Zhang, X.N. Li, G.Q. Chen, R. Tang, R.Q. Zhang, C. Dong, and P.K. Liaw: Developing fuel cladding Fe–25Cr–22Ni stainless steels with high microstructural stabilities via Mo/Nb/Ti/Ta/W alloying. Mater. Sci. Eng., A719, 27 (2018).

X.C. Liu, H.L. Ming, Z.M. Zhang, J.Q. Wang, L.C. Tang, H. Qian, Y.C. Xie, and E.H. Han: Effects of temperature on fretting corrosion between alloy 690TT and 405 stainless steel in pure water. Acta Metall. Sin. (Engl. Lett.)32, 1437 (2019).

Acknowledgments

The authors gratefully acknowledge the financial support for this research from the National Key Research and Development Program of China (No. 2016YFB1100204), Key Research Project from the Science and Technology Commission of Liaoning Province (No. 2018106004), and Shenyang Science and Technology Funded Project (Nos. 19-109-1-03 and Z18-5-012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, Y., Zhang, C., Cui, X. et al. Microstructure and properties of a novel wear- and corrosion-resistant stainless steel fabricated by laser melting deposition. Journal of Materials Research 35, 2006–2015 (2020). https://doi.org/10.1557/jmr.2020.70

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.70