Abstract

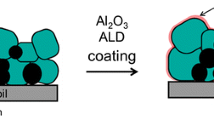

LiMnxCoyNi1−x−yO2 (LMCNO) has been broadly investigated and commercialized primarily as lithium ion battery (LIB) cathodes, owing to its high operating voltage, large energy density, and superior electronic conductivity. However, poor cycling stability induced by the rapid structure degradation limits their further development. Coating is regarded as a very effective strategy to address the problem of structure degradation. Regrettably, the coating layers obtained by traditional methods are usually thick, which is not appropriate for delivering of integrated performance. As an emerging coating technology, atomic layer deposition (ALD) demonstrates immeasurable advantages in deposition of ultrathin coating materials because of its atomic-level precision, and has been widely applied in construction of the coating layers on LMCNO substrate materials. Herein, we firstly outline the development and mechanism of ALD technology, and then systematically summarize intrinsic reasons for the enhanced electrochemical performance. Finally, we propose new insights toward designing and preparing the coating structure of LMCNO cathodes by controllable ALD for the next-generation LIBs.

Similar content being viewed by others

References

Y. Ding, Z.P. Cano, A. Yu, J. Lu, and Z. Chen: Automotive Li-ion batteries: Current status and future perspectives. Electrochem. Energy Rev. 2, 1–28 (2019).

R. Reinhardt: Towards sustainable business models for electric vehicle battery second use: A critical review. J. Environ. Manage. 245, 432–446 (2019).

L. Y. Q. Zhang, and J. Chen: Recent progress on lithium-ion batteries with high electrochemical performance. Sci. China Chem. 62, 533–548 (2019).

H. Maleki Kheimeh Sari and X. Li: Controllable cathode–electrolyte interface of Li[Ni0.8Co0.1Mn0.1]O2 for lithium ion batteries: A review. Adv. Energy Mater. 9, 1901597 (2019).

M.K. Shobana: Metal oxide coated cathode materials for Li ion batteries—A review. J. Alloys Compd. 802, 477–487 (2019).

H. Pinegar and Y.R. Smith: Recycling of end-of-life lithium ion batteries, Part I: Commercial processes. J. Sustainable Metall. 5, 402–416 (2019).

L. Li: The recycling of spent lithium-ion batteries: A review of current processes and technologies. Electrochem. Energy Rev. 1, 461–482 (2018).

X. Wu: Safety issues in lithium ion batteries: Materials and cell design. Front. Energy Res. 7, 65 (2019).

H. Zhang: Polymer electrolytes for high energy density ternary cathode material-based lithium batteries. Electrochem. Energy Rev. 2, 128–148 (2019).

S. Zhang: Identifying and addressing critical challenges of high-voltage layered ternary oxide cathode materials. Chem. Mater. 31, 6033–6065 (2019).

D. Becker: Surface modification of Ni-rich LiNi0.8Co0.1Mn0.1O2 cathode material by tungsten oxide coating for improved electrochemical performance in lithium-ion batteries. ACS Appl. Mater. Interfaces 11, 18404–18414 (2019).

S. Guo: Dual-component LixTiO2@silica functional coating in one layer for performance enhanced LiNi0.6Co0.2Mn0.2O2 cathode. Nano Energy 58, 673–679 (2019).

Y. Ding: Improved electrochemical performances of LiNi0.6Co0.2Mn0.2O2 cathode material by reducing lithium residues with the coating of Prussian blue. J. Alloys Compd. 774, 451–460 (2019).

J. Wu: Improvement of electrochemical performance of nickel rich LiNi0.8Co0.1Mn0.1O2 cathode by lithium aluminates surface modifications. Energy Technol. 7, 209–215 (2019).

J. Billaud: Li/Fe substitution in Li-rich Ni, Co, Mn oxides for enhanced electrochemical performance as cathode materials. J. Mater. Chem. A 7, 15215–15224 (2019).

S.J. Sim: Improving the electrochemical performances using a V-doped Ni-rich NCM cathode. Sci. Rep. 9, 8952 (2019).

C. Lv: 1D Nb-doped LiNi1/3Co1/3Mn1/3O2 nanostructures as excellent cathodes for Li-ion battery. Electrochim. Acta 297, 258–266 (2019).

L. Song: Effect of Zr doping and Li2O–2B2O3 layer on the structural electrochemical properties of LiNi0.5Co0.2Mn0.3O2 cathode material: Experiments and first-principle calculations. Ionics 25, 2017–2026 (2018).

S.J. Do: Al-doped Li[Ni0.78Co0.1Mn0.1Al0.02]O2 for high performance of lithium ion batteries. Ceram. Int. 45, 6972–6977 (2019).

X. Yao: Oxalate co-precipitation synthesis of LiNi0.6Co0.2Mn0.2O2 for low-cost and high-energy lithium-ion batteries. Mater. Today Commun. 19, 262–270 (2019).

D. Gu and F. Schuth: Synthesis of non-siliceous mesoporous oxides. Chem. Soc. Rev. 43, 313–344 (2014).

L. Cheng: General synthesis of carbon-coated nanostructure Li4Ti5O12 as a high rate electrode material for Li-ion intercalation. J. Mater. Chem. 20, 595–602 (2010).

D. Yang: Multiplexed gas sensor based on heterogeneous metal oxide nanomaterial array enabled by localized liquid-phase reaction. ACS Appl. Mater. Interfaces 7, 10152–10161 (2015).

R. Diao: CePO4 coated LiNi0.6Co0.2Mn0.2O2 as cathode material and its electrochemical performance. Int. J. Electrochem. Sci. 14, 8070–8079 (2019).

J. Liu: Improvement of high-voltage electrochemical performance of surface modified LiNi0.6Co0.2Mn0.2O2 cathode by La2O3 coating. Int. J. Electrochem. Sci., 13, 9816–9825 (2018).

S. Jurng: Minimized metal dissolution from high-energy nickel cobalt manganese oxide cathodes with Al2O3 coating and its effects on electrolyte decomposition on graphite anodes. J. Electrochem. Soc. 166, A2721–A2726 (2019).

X. Jiang: LiNi0.29Co0.33Mn0.38O2 polyhedrons with reduced cation mixing as a high-performance cathode material for Li-ion batteries synthesized via a combined co-precipitation and molten salt heating technique. J. Alloys Compd. 691, 206–214 (2017).

A. Sharifi Rad and M. Ghorbanzadeh: Structural, microstructural and electrochemical studies of TiO2–Ag double layer coated NCM cathode for lithium-ion batteries. Mater. Res. Express 6, 086471 (2019).

W. Liu: Significantly improving cycling performance of cathodes in lithium ion batteries: The effect of Al2O3 and LiAlO2 coatings on LiNi0.6Co0.2Mn0.2O2. Nano Energy 44, 111–120 (2018).

Z.M. Luo, Y.G. Sun, and H.Y. Liu: Electrochemical performance of a nano SnO2-modified LiNi1/3Co1/3Mn1/3O2 cathode material. Chin. Chem. Lett. 26, 1403–1408 (2015).

K. Park: Enhancement in the electrochemical performance of zirconium/phosphate bi-functional coatings on LiNi0.8Co0.15Mn0.05O2 by the removal of Li residuals. Phys. Chem. Chem. Phys. 18, 29076–29085 (2016).

Y. Jin: Electrochemically active MnO2 coated Li1.2Ni0.18Co0.04Mn0.58O2 cathode with highly improved initial coulombic efficiency. Appl. Surf. Sci. 384, 125–134 (2016).

H. Şahan: Improvement of cycling stability of LiMn2O4 cathode by Fe2O3 surface modification for Li-ion battery. Ionics 20, 323–333 (2013).

B. Xiao, P.b. Wang, B. Zhang, Z. He, Z. Yang, L. Tang, C-s. An, and J-c. zheng: Effect of MgO and TiO2 coating on electrochemical performance of Li rich cathode materials for lithium-ion batteries. Energy Technol. 7, 1800829 (2018).

D. Deng: Transition metal oxyfluorides for next-generation rechargeable batteries. ChemNanoMat 3, 146–159 (2017).

J. Zheng, P. Xu, M. Gu, J. Xiao, N.D. Browning, P. Yan, C. Wang, and J-G. Zhang: Structural and chemical evolution of Li- and Mn-rich layered cathode material. Chem. Mater. 27, 1381–1390 (2015).

Y. Sun, L. Zan, and Y. Zhang: Effects of Li3PO4 additive on the electrochemical properties of Li2FeSiO4 as cathode material for lithium-ion batteries. J. Mater. Sci.: Mater. Electron. 30, 15582–15591 (2019).

C. Qing: Enhanced cycling stability of LiMn2O4 cathode by amorphous FePO4 coating. Electrochim. Acta 56, 6612–6618 (2011).

J. Song: Investigation on the electrochemical properties and stabilized surface/interface of nano-AlPO4-coated Li1.15Ni0.17Co0.11Mn0.57O2 as the cathode for lithium-ion batteries. ACS Appl. Mater. Interfaces 10, 27326–27332 (2018).

K. Hu: Enhanced electrochemical performance of LiNi0.8Co0.1Mn0.1O2 cathode materials via Li4P2O7 surface modification for Li-ion batteries. Ceram. Int. 44, 14209–14216 (2018).

B. Shen: Improved electrochemical performance of NaAlO2-coated LiCoO2 for lithium-ion batteries. J. Solid State Electrochem. 21, 1195–1201 (2016).

L. Ku: Enhanced electrochemical performances of layered-spinel heterostructured lithium-rich Li1.2Ni0.13Co0.13Mn0.54O2 cathode materials. Chem. Eng. J. 370, 499–507 (2019).

P. Liu: Highly enhanced electrochemical performances of LiNi0.815Co0.15Al0.035O2 by coating via conductively LiTiO2 for lithium-ion batteries. Ceram. Int. 45, 18398–18405 (2019).

S. Hu: Li-rich layered oxides and their practical challenges: Recent progress and perspectives. Electrochem. Energy Rev. 2, 277–311 (2019).

M. Berdova: Protective coatings of hafnium dioxide by atomic layer deposition for microelectromechanical systems applications. Appl. Surf. Sci. 368, 470–476 (2016).

Z. Kan: Atomic-layer-deposited AZO outperforms ITO in high-efficiency polymer solar cells. J. Mater. Chem. A 6, 10176–10183 (2018).

B.E. Park: Atomic layer deposition of Y-stabilized ZrO2 for advanced DRAM capacitors. J. Alloys Compd. 722, 307–312 (2017).

P.O. Oviroh: New development of atomic layer deposition: Processes, methods and applications. Sci. Technol. Adv. Mater. 20, 465–496 (2019).

J.W. Kim: Surface chemistry of LiNi0.5Mn1.5O4 particles coated by Al2O3 using atomic layer deposition for lithium-ion batteries. J. Power Sources 274, 1254–1262 (2015).

J.A. Switzer: Chemistry. Atomic layer electrodeposition. Science 338, 1300–1 (2012).

R.L. Puurunen: A short history of Atomic layer deposition: Tuomo suntola’s Atomic layer epitaxy. Chem. Vap. Deposition 20, 332–344 (2014).

B.J. O’Neill: Catalyst design with atomic layer deposition. ACS Catal. 5, 1804–1825 (2015).

G.N. Parsons: History of atomic layer deposition and its relationship with the American Vacuum Society. J. Vac. Sci. Technol., A 31, 050818 (2013).

V. Aleskovsky and M. Koltcov: USSR Patent No. USSR422446, 1972.

B.C. Mallick: Review—On atomic layer deposition: Current progress and future challenges. ECS J. Solid State Sci. Technol. 8, N55–N78 (2019).

R.W. Johnson, A. Hultqvist, and S.F. Bent: A brief review of atomic layer deposition: From fundamentals to applications. Mater. Today 17, 236–246 (2014).

C. Detavernier: Tailoring nanoporous materials by atomic layer deposition. Chem. Soc. Rev. 40, 5242–5253 (2011).

L. Wen: Nanoengineering energy conversion and storage devices via atomic layer deposition. Adv. Energy Mater. 6, 1600468 (2016).

G. Cherkashinin: Electron spectroscopy study of Li[Ni,Co,Mn]O2/electrolyte interface: Electronic structure, interface composition, and device implications. Chem. Mater. 27, 2875–2887 (2015).

Y. You: Modified high-nickel cathodes with stable surface chemistry Against ambient air for lithium-ion batteries. Angew. Chem., Int. Ed. Engl. 57, 6480–6485 (2018).

P. Kalyani and N. Kalaiselvi: Various aspects of LiNiO2 chemistry: A review. Sci. Technol. Adv. Mater. 6, 689–703 (2016).

Y. Wu: Performance and stability improvement of layered NCM lithium-ion batteries at high voltage by a microporous Al2O3 sol–gel coating. ACS Omega 4, 13972–13980 (2019).

Y. Gao: Boosting the electrochemical performance of Li1.2Mn0.54Ni0.13Co0.13O2 by atomic layer-deposited CeO2 coating. ACS Omega 3, 906–916 (2018).

M.R. Laskar: Atomic layer deposition of Al2O3–Ga2O3 alloy coatings for Li[Ni0.5Mn0.3Co0.2]O2 cathode to improve rate performance in Li-ion battery. ACS Appl. Mater. Interfaces 8, 10572–10580 (2016).

J. Zhao and Y. Wang: Atomic layer deposition of epitaxial ZrO2 coating on LiMn2O4 nanoparticles for high-rate lithium ion batteries at elevated temperature. Nano Energy 2, 882–889 (2013).

R.L. Patel, S.A. Palaparty, and X. Liang: Ultrathin conductive CeO2 coating for significant improvement in electrochemical performance of LiMn1.5Ni0.5O4 cathode materials. J. Electrochem. Soc 164, A6236–A6243 (2016).

D. Mohanty: Modification of Ni-rich FCG NMC and NCA cathodes by atomic layer deposition: Preventing surface phase transitions for high-voltage lithium-ion batteries. Sci. Rep. 6, 26532 (2016).

J.Z. Kong: Ultrathin ZnO coating for improved electrochemical performance of LiNi0.5Co0.2Mn0.3O2 cathode material. J. Power Sources 266, 433–439 (2014).

R. Yu, Y. Lin, and Z. Huang: Investigation on the enhanced electrochemical performances of Li1.2Ni0.13Co0.13Mn0.54O2 by surface modification with ZnO. Electrochim. Acta 173, 515–522 (2015).

H. Yu, Y. Gao, and X. Liang: Slightly fluorination of Al2O3 ALD coating on Li1.2Mn0.54Co0.13Ni0.13O2 electrodes: Interface reaction to create stable solid permeable interphase layer. J. Electrochem. Soc. 166, A2021–A2027 (2019).

H.G. Song: Enhanced electrochemical properties of Li(Ni0.4Co0.3Mn0.3)O2 cathode by surface modification using Li3PO4-based materials. J. Power Sources 196, 6847–6855 (2011).

A. Hayashi, T. Konishi, K. Tadanaga, T. Minami, and M. Tatsumisago: All-solid-state rechargeable lithium batteries using Snx–P2X5 (X = S and O) amorphous negative electrodes. Chem. Intermed 32, 497–506 (2005).

Y. Sakurai: Preparation of amorphous Li4SiO4–Li3PO4 thin films by pulsed laser deposition for all-solid-state lithium secondary batteries. Solid State Ionics 182, 59–63 (2011).

B. Xiao: Unravelling the role of electrochemically active FePO4 coating by atomic layer deposition for increased high-voltage stability of LiNi0.5Mn1.5O4 cathode material. Adv. Sci. 2, 1500022 (2015).

D.H.K. Jackson: Optimizing AlF3 atomic layer deposition using trimethylaluminum and TaF5: Application to high voltage Li-ion battery cathodes. J. Vac. Sci. Technol., A 34, 031503 (2016).

J.Z. Kong: Enhanced electrochemical performance of LiNi0.5Co0.2Mn0.3O2 cathode material by ultrathin ZrO2 coating. J. Alloys Compd. 657, 593–600 (2016).

Y. Chen, K. Gerdes, and X. Song: Nanoionics and nanocatalysts: Conformal mesoporous surface scaffold for cathode of solid oxide fuel cells. Sci. Rep. 6, 32997 (2016).

M.R. Laskar: Atomic layer deposited MgO: A lower overpotential coating for Li[Ni0.5Mn0.3Co0.2]O2 cathode. ACS Appl. Mater. Interfaces 9, 11231–11239 (2017).

J. Ahn: Ultrathin ZrO2 on LiNi0.5Mn0.3Co0.2O2 electrode surface via atomic layer deposition for high-voltage operation in lithium-ion batteries. Appl. Surf. Sci. 484, 701–709 (2019).

S. Deng: New insight into atomic-scale engineering of electrode surface for long-life and safe high voltage lithium ion cathodes. Nano Energy 38, 19–27 (2017).

J.Z. Kong: Improved electrochemical performance of Li1.2Mn0.54Ni0.13Co0.13O2 cathode material coated with ultrathin ZnO. J. Alloys Compd. 694, 848–856 (2017).

W. Zhu: Ultrathin Al2O3 coating on LiNi0.8Co0.1Mn0.1O2 cathode material for enhanced cycleability at extended voltage ranges. Coatings 9, 92 (2019).

S. Sarkar: Unveiling the role of CeO2 Atomic layer deposition coatings on LiMn2O4 cathode materials: An experimental and theoretical study. ACS Appl. Mater. Interfaces 9, 30599–30607 (2017).

C. Qin: Improvement of electrochemical performance of nickel rich LiNi0.6Co0.2Mn0.2O2 cathode active material by ultrathin TiO2 coating. Dalton Trans. 45, 9669–9675 (2016).

D. Guan and Y. Wang: Ultrathin surface coatings to enhance cycling stability of LiMn2O4 cathode in lithium-ion batteries. Ionics 19, 1–8 (2012).

M. Ritala, K. Kukli, A. Rahtu, P. Leskela, T. Sajavaara, and J. Keinonen: Atomic layer deposition of oxide thin films with metal alkoxides as oxygen sources. Science 288, 319–321 (2000).

Y. Ma: Enhancement of the electrochemical performance of LiNi1/3Co1/3Mn1/3O2 cathode material by double-layer coating with graphene oxide and SnO2 for lithium-ion batteries. J. Nanomater. 2019, 1–10 (2019).

S. Huang: Rationally engineered amorphous TiOx/Si/TiOx nanomembrane as an anode material for high energy lithium ion battery. Energy Storage Mater. 12, 23–29 (2018).

C.C. Wang: Electrochemical and structural investigation on ultrathin ALD ZnO and TiO2 coated lithium-rich layered oxide cathodes. ACS Sustainable Chem. Eng. 6, 16941–16950 (2018).

G. Dai: Improved electrochemical performance of LiNi0.8Co0.15Al0.05O2 with ultrathin and thickness-controlled TiO2 shell via atomic layer deposition technology. RSC Adv. 6, 100841–100848 (2016).

B. Xiao: Nanoscale manipulation of spinel lithium nickel manganese oxide surface by multisite Ti occupation as high-performance cathode. Adv. Mater. 29, 1703764 (2017).

D. Ye: Ni-induced stepwise capacity increase in Ni-poor Li-rich cathode materials for high performance lithium ion batteries. Nano Res. 8, 808–820 (2014).

R.L. Patel: Employing synergetic effect of doping and thin film coating to boost the performance of lithium-ion battery cathode particles. Sci. Rep. 6, 25293 (2016).

X. Zhang: Structural and electrochemical study of Al2O3 and TiO2 coated Li1.2Ni0.13Mn0.54Co0.13O2 cathode material using ALD. Adv. Energy Mater. 3, 1299–1307 (2013).

N.A.M. Sven, C. Reitz, P. Hartmann, J. Janek, and T. Brezesinski: Effect of low-temperature Al2O3 ALD coating on Ni-rich layered oxide composite cathode on the long-term cycling performance of lithium-ion batteries. Sci. Rep. 9, 5328 (2019).

J.S. Park: Atomic layer deposition of Al–W-fluoride on LiCoO2 cathodes: Comparison of particle- and electrode-level coatings. ACS Omega 2, 3724–3729 (2017).

M. Xie: Synthesis of high-voltage (4.7 V) LiCoO2 cathode materials with Al doping and conformal Al2O3 coating by atomic layer deposition. RSC Adv. 6, 63250–63255 (2016).

Y. Shi: Ultrathin Al2O3 coatings for improved cycling performance and thermal stability of LiNi0.5Co0.2Mn0.3O2 cathode material. Electrochim. Acta 203, 154–161 (2016).

Y. Gao: Cooperating effects of conformal iron oxide (FeOx) ALD coating and post-annealing on Li-rich layered cathode materials. Electrochim. Acta 318, 513–524 (2019).

Y. Zhou: Coating solution for high-voltage cathode: AlF3 atomic layer deposition for freestanding LiCoO2 electrodes with high energy density and excellent flexibility. ACS Appl. Mater. Interfaces 9, 9614–9619 (2017).

M. Nanthagopal, P. Santhoshkumar, and N. Shaji: Nitrogen-doped carbon-coated Li[Ni0.8Co0.1Mn0.1]O2 cathode material for enhanced lithium-ion storage. Appl. Surf. Sci. 492, 871–878 (2019).

Acknowledgments

The authors gratefully acknowledge the financial support by Doctoral Scientific Research Startup Foundation of Xi’an University of Technology (101-451119016), the National Nature Science Foundation of China (51801153, 51672189 and 21975200), Natural science basic research plan in Shaanxi province of China (2019JLP-04) and Xi’an Science and Technology Project of China (201805037YD15CG21(20)).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, K., Li, W., Qin, J. et al. Controllable atomic layer deposition coatings to boost the performance of LiMnxCoyNi1−x−yO2 in lithium-ion batteries: A review. Journal of Materials Research 35, 762–774 (2020). https://doi.org/10.1557/jmr.2019.393

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.393