Abstract

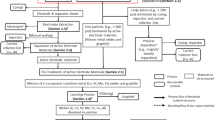

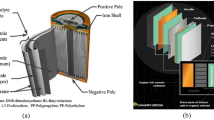

Lithium ion batteries (LIBs) are an essential energy-storage device for a majority of advanced electronics used in our everyday lives, from cell phones and laptops, to medical devices and electric vehicles. Despite their continued widespread adoption, methods to recycle and reuse end-of-life (EOL) LIB materials are still under active development. In the first part of this two-part review on LIB recycling, we review current commercial scale processes in practice for recycling or reusing EOL LIB components. Future waste projections estimate 4 million tons of cumulative EOL EV battery modules by 2030, which is above the current global recycling capacity. All of the processes in use today utilize a combination of pyrometallurgical and hydrometallurgical or mechanical and hydrometallurgical processing to recover mainly cobalt and nickel and copper, while other components are disposed as waste unless further processed. In this review, we highlight the need for recycling LIB material components based on resource availability and the current processes in practice to recover and recycle LIBs.

Similar content being viewed by others

References

Blomgren GE (2017) The development and future of lithium ion batteries. J Electrochem Soc 164:5019–5025. https://doi.org/10.1149/2.0251701jes

Mizushima K, Jones PC, Wiseman PJ, Goodenough JB (1981) 2-LixCoO2 (0). Solid State Ionics 3–4:171–174. https://doi.org/10.1016/0167-2738(81)90077-1

Yoshino A, Sanechika K, Nakajima T (1987) Secondary battery. Asahi Kasei Corp. U.S. Patent 4,668,595

Yoshino A (2012) The birth of the lithium-ion battery. Angew Chemie Int Ed 51:5798–5800. https://doi.org/10.1002/anie.201105006

Nitta N, Wu F, Lee JT, Yushin G (2015) Li-ion battery materials: present and future. Mater Today 18:252–264. https://doi.org/10.1016/j.mattod.2014.10.040

Molenda J, Mole M (2011) Composite cathode material for Li-ion batteries based on LiFePO4 system. In: Metal, ceramic and polymeric composites for various uses. InTech, Rijeka

Deng D (2015) Li-ion batteries: basics, progress, and challenges. Energy Sci Eng 3:385–418. https://doi.org/10.1002/ese3.95

Bryner M, Clarke GM, Jansen AM, et al (2013) Lithium-ion batteries. Chem Eng Prog 35–64

Perdu F (2016) Overview of existing and innovative batteries. In: Science and energy seminar. e-EPS, Les Houches

Bloomberg New Energy Finance (2017) Electric vehicle outlook 2017

Curry C (2017) Lithium-ion battery costs and market. Bloomberg New Energy Finance. https://data.bloomberglp.com/bnef/sites/14/2017/07/BNEF-Lithium-ion-batterycosts-and-market.pdf. Accessed 12 July 2019

Pillot C (2017) The rechargeable battery market and main trends 2016–2025. In: International battery seminar & exhibit, March 20th. https://www.avicenne.com/pdf/Fort_Lauderdale_Tutorial_C_Pillot_March2015.pdf. Accessed 30 May 2019

Song C, Wang W, Peng H, et al (2018) Improving the electrochemical performance of LiNi0.80Co0.15Al0.05O2 in lithium ion batteries by LiAlO2 surface modification. Appl Sci 8:378. https://doi.org/10.3390/app8030378

Sverdrup HU, Ragnarsdottir KV, Koca D (2017) An assessment of metal supply sustainability as an input to policy: security of supply extraction rates, stocks-in-use, recycling, and risk of scarcity. J Clean Prod 140:359–372. https://doi.org/10.1016/j.jclepro.2015.06.085

Lee Bray E (2018) Bauxite and alumina. US Geol Surv Miner Commod Summ, pp 30–31

Shedd K (2018) Cobalt. US Geol Surv Miner Commod Summ, pp 50–51

Flanagan D (2018) Copper. US Geol Surv Miner Commod Summ, pp 52–53

Tuck C (2018) Iron ore. US Geol Surv Miner Commod Summ, pp 88–89

Jaskula B (2018) Lithium. US Geol Surv Miner Commod Summ, pp 98–99. https://doi.org/10.3133/70194932

Corathers L (2018) Manganese. US Geol Surv Miner Commod Summ, pp 104–105. https://doi.org/10.3133/70194932

Olson D (2018) Graphite (Natural). US Geol Surv Miner Commod Summ, pp 72–73

McRae M (2018) Nickel. US Geol Surv Miner Commod Summ, pp 112–113

Jasinski S (2018) Phosphate rock. US Geol Surv Miner Commod Summ, pp 122–123

Schnebele E (2018) Silicon. US Geol Surv Miner Commod Summ, pp 148–149

Schuyler Anderson C (2018) Tin. US Geol Surv Miner Commod Summ, pp 172–173

Bedinger G (2018) Titanium mineral concentrates. US Geol Surv Miner Commod Summ, pp 176–177. https://doi.org/10.3133/70194932

Martin G, Rentsch L, Höck M, Bertau M (2017) Lithium market research—global supply, future demand and price development. Energy Storage Mater 6:171–179. https://doi.org/10.1016/j.ensm.2016.11.004

Helbig C, Bradshaw AM, Wietschel L et al (2018) Supply risks associated with lithium-ion battery materials. J Clean Prod 172:274–286. https://doi.org/10.1016/j.jclepro.2017.10.122

Chohan UW (2018) Blockchain and the extractive industries: cobalt case study. Available at SSRN: https://ssrn.com/abstract=3138271. Accessed 12 July 2019

Moradi B, Botte GG (2016) Recycling of graphite anodes for the next generation of lithium ion batteries. J Appl Electrochem 46:123–148. https://doi.org/10.1007/s10800-015-0914-0

Yang Q, Geng Y, Dong H et al (2017) Effect of environmental regulations on China’s graphite export. J Clean Prod 161:327–334. https://doi.org/10.1016/j.jclepro.2017.05.131

Jara AD, Betemariam A, Woldetinsae G, Kim JY (2019) Purification, application and current market trend of natural graphite: a review. Int J Min Sci Technol. https://doi.org/10.1016/j.ijmst.2019.04.003

Klemola K (2016) Life-cycle impacts of tesla model S 85 and volkswagen passat. Online Report: http://kimmoklemola.fi/data/documents/SF-comparison-USA-20160110.pdf. Accessed 12 July 2019

ELIBAMA project (2014) Li-ion batteries recycling. In: Electrodes and cells manufacturing white paper. ELIBAMA project, pp 239–264

Foster M, Isely P, Standridge CR, Hasan MM (2014) Feasibility assessment of remanufacturing, repurposing, and recycling of end of vehicle application lithium-ion batteries. J Ind Eng Manag 7:698–715. https://doi.org/10.3926/jiem.939

Tedjar F, Foudraz J-C (2010) Method for the mixed recycling of lithium-based anode batteries and cells. U.S. Patent No. US 7,820,317

Kang DHP, Chen M, Ogunseitan OA (2013) Potential environmental and human health impacts of rechargeable lithium batteries in electronic waste. Environ Sci Technol 47:5495–5503. https://doi.org/10.1021/es400614y

Zeng X, Li J, Singh N (2014) Recycling of spent lithium-ion battery: a critical review. Crit Rev Environ Sci Technol 44:1129–1165. https://doi.org/10.1080/10643389.2013.763578

Larsson F, Andersson P, Blomqvist P, Mellander BE (2017) Toxic fluoride gas emissions from lithium-ion battery fires. Sci Rep 7:1–13. https://doi.org/10.1038/s41598-017-09784-z

Dunn JB, Gaines L, Barnes M, Sullivan J, Wang M (2014) Material and energy flows in the materials production, assembly, and end-of-life stages of the automotive lithium-ion battery life cycle (No. ANL/ESD/12-3 Rev.). Argonne National Laboratory (ANL), Argonne

Romare M, Dahllöf L (2017) The life cycle energy consumption and greenhouse gas emissions from lithium-ion batteries: a study with focus on current technology and batteries for light-duty vehicles. IVL Swedish Environmental Research Institute, Stockholm

Notter DA, Gauch M, Widmer R et al (2010) Contribution of Li-ion batteries to the environmental impact of electric vehicles. Environ Sci Technol 44:6550–6556. https://doi.org/10.1021/es903729a

Dewulf J, Van der Vorst G, Denturck K et al (2010) Recycling rechargeable lithium ion batteries: critical analysis of natural resource savings. Resour Conserv Recycl 54:229–234. https://doi.org/10.1016/j.resconrec.2009.08.004

Heelan J, Gratz E, Zheng Z et al (2016) Current and prospective Li-ion battery recycling and recovery processes. Jom 68:2632–2638. https://doi.org/10.1007/s11837-016-1994-y

Gu F, Guo J, Yao X et al (2017) An investigation of the current status of recycling spent lithium-ion batteries from consumer electronics in China. J Clean Prod 161:765–780. https://doi.org/10.1016/j.jclepro.2017.05.181

Nowak S, Winter M (2017) The role of sub- and supercritical CO2 as “processing solvent” for the recycling and sample preparation of lithium ion battery electrolytes. Molecules 22:403. https://doi.org/10.3390/molecules22030403

Ellis T, Mirza A (2015) Battery recycling: defining the market and identifying the technology required to keep high value materials in the economy and out of the waste dump. https://www.researchgate.net. Accessed 30 May 2019

Saloojee F, Lloyd J (2015) Lithium battery recycling process. Department of Environmental affairs Development Bank of South Africa (Project No. DB-074 (RW1/1016))

Zeng X, Li J, Liu L (2015) Solving spent lithium-ion battery problems in China: opportunities and challenges. Renew Sustain Energy Rev 52:1759–1767. https://doi.org/10.1016/j.rser.2015.08.014

De-Leon S (2018) Lithium ion battery recycling market 2018. Shumuel De-Leon Energy Ltd, Hod-Hasharon

Yazicioglu B, Tytgat J (2011) Life cycle assessments involving umicore’s battery recycling process. In: DG Environment–Stakeholder Meeting, Umicore

Cheret D, Santen S (2007) Battery recycling. U.S. Patent No. 7,169,206

Gaines L (2014) The future of automotive lithium-ion battery recycling: charting a sustainable course. Sustain Mater Technol 1:2–7. https://doi.org/10.1016/j.susmat.2014.10.001

Sonoc A, Jeswiet J, Soo VK (2015) Opportunities to improve recycling of automotive lithium ion batteries. Procedia CIRP 29:752–757. https://doi.org/10.1016/j.procir.2015.02.039

Georgi-Maschler T, Friedrich B, Weyhe R et al (2012) Development of a recycling process for Li-ion batteries. J Power Sources 207:173–182. https://doi.org/10.1016/j.jpowsour.2012.01.152

Weyhe R. International Energy Agency Photovoltaic Power System Programme, Accurec Recycling Gmbh. http://ieapvps.org/fileadmin/dam/public/workshop/10_Reiner_Thomas_WEYHE.pdf. Accessed 12 July 2019

McLaughlin W, Adams TS (1999) Li reclamation process. U.S. Patent No. 5,888,463

Zenger T, Krebs A, van Deutekom HJH (2010) Method of and apparatus for dismantling and storage of objects comprising alkali metals, such as alkali metal containing batteries. U.S. Patent No. 7,833,646

Sloop, Steven E, Parker R (2011) System and method for processing and end-of-life or reduced performance energy storage and/or conversion device using a supercritical fluid. U.S. Patent No. 8,067,107

Diekmann J, Hanisch C, Frob L et al (2017) Ecological recycling of lithium-ion batteries from electric vehicles with focus on mechanical processes. J Electrochem Soc 164:6184–6191. https://doi.org/10.1149/2.0271701jes

Gaines L (2018) Lithium-ion battery recycling processes: research towards a sustainable course. Sustain Mater Technol 17:e00068. https://doi.org/10.1016/j.susmat.2018.e00068

Julien CM, Mauger A, Zaghib K, Groult H (2014) Comparative issues of cathode materials for Li-ion batteries. Inorganics 2:132–154. https://doi.org/10.3390/inorganics2020132

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Brajendra Mishra.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pinegar, H., Smith, Y.R. Recycling of End-of-Life Lithium Ion Batteries, Part I: Commercial Processes. J. Sustain. Metall. 5, 402–416 (2019). https://doi.org/10.1007/s40831-019-00235-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-019-00235-9