Abstract

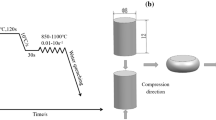

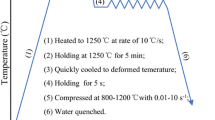

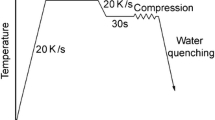

The constitutive equation was established based on the consideration of strain compensation to describe the hot deformation behavior of low carbon reduced activation ferritic/martensitic (RAFM) steels at the temperatures of 850–1050 °C and the strain rates of 0.01–10 s−1. The result indicates that the flow stress is increased with the increase of strain rate but decreased with increase of deformation temperature. During the hot deformation process, the increase of temperature is beneficial to attain the complete dynamic recrystallization (DRX). However, excessively high temperature leads to grow up of dynamic recrystallized grain. Higher strain rate leads to finer recrystallized grains. The material constants (α, n, A) and deformation activation energy (Q) are calculated by the regression analysis. The increase of strain caused the decrease of Q, indicating the DRX occurred more easily. In addition, the developed constitutive equation could accurately predict the hot deformation behavior of the low carbon RAFM steel.

Similar content being viewed by others

References

J. Knaster, A. Moeslang, and T. Muroga: Materials research for fusion. Nat. Phys. 12, 426–434 (2016).

S.J. Zinkle, A. Moeslang, T. Muroga, and H. Tanigawa: Multimodal options for materials research to advance the basis for fusion energy in the ITER era. Nucl. Fusion 53, 1–13 (2013).

K. Ehrlich, W. Cierjacks, S. Kelzenberg, and A. Moeslang: The development of structural materials for reduced long-term activation. In 17th International Symposium on Effects of Radiation on Materials, Vol. 1270, D.Gelles, R. Nanstad and A. Kumar, eds. (ASTM STP, West Conshocken, 1996); pp. 1109–1122.

M.R. Gilbert and R.A. Forrest: Comprehensive handbook of activation data calculated using EASY-2003. Fusion Eng. Des. 81, 1511–1516 (2006).

K. Ehrlich: Materials research towards a fusion reactor. Fusion Eng. Des. 56, 71–82 (2001).

R.L. Klueh, D.J. Alexander, and M. Rieth: The effect of tantalum on the mechanical properties of a 9Cr–2W–0.25V–0.07Ta–0.1C steel. J. Nucl. Mater. 273, 146–154 (1999).

Q. Huang, N. Baluc, Y. Dai, S. Jitsukawa, A. Kimura, J. Konys, R.J. Kurtz, R. Lindau, T. Muroga, G.R. Odette, B. Raj, R.E. Stoller, L. Tan, H. Tanigawa, A-A.F. Tavassoli, T. Yamamoto, F. Wan, and Y. Wu: Recent progress of R&D activities on reduced activation ferritic/martensitic steels. J. Nucl. Mater. 442, S2–S8 (2013).

M. Taneike, K. Sawada, and F. Abe: Effect carbon concentration on precipitation behavior of M23C6 carbides and MX carbonitrides in martensitic 9Cr steel during heat treatment. Metall. Mater. Trans. A 35, 1255–1262 (2004).

M. Taneike, F. Abe, and K. Sawada: Creep-strengthening of steel at high temperature using nano-sized carbonitrides dispersions. Nature 424, 294–296 (2003).

A.S. Taylor and P.D. Hodgson: Dynamic behaviour of 304 stainless steel during high Z deformation. Mater. Sci. Eng., A 528, 3310–3320 (2011).

Z. Akbari, H. Mirzadeh, and J.M. Cabrera: A simple constitutive model for predicting flow stress of medium carbon microalloyed steel during hot deformation. Mater. Des. 77, 126–131 (2015).

S.K. Badjena: Dynamic recrystallization behavior of vanadium micro-alloyed forging medium carbon steel. ISIJ Int. 54, 650–656 (2014).

C. Zhang, L. Zhang, W. Shen, C. Liu, Y. Xia, and R. Li: Study on constitutive modeling and processing maps for hot deformation of medium carbon Cr–Ni–Mo alloyed steel. Mater. Des. 90, 804–814 (2016).

Y. Zhou, Y. Liu, X. Zhou, C. Liu, L. Yu, and C. Li: Processing maps and microstructural evolution of the type 347H austenitic heat-resistant stainless steel. J. Mater. Res. 30, 2090–2100 (2015).

W.T. Wang, X.Z. Guo, B. Huang, J. Tao, H.G. Li, and W.J. Pei: The flow behaviors of CLAM steel at high temperature. Mater. Sci. Eng., A 599, 134–140 (2014).

Z.B. Zhang, O.V. Mishin, N.R. Tao, and W. Pantleon: Microstructure and annealing behavior of a modified 9Cr–1Mo steel after dynamic plastic deformation to different strains. J. Nucl. Mater. 458, 64–69 (2015).

Z. Zhang, Y. Zhang, O.V. Mishin, N. Tao, W. Pantleon, and D.J. Jensen: Microstructural analysis of orientation-dependent recovery and recrystallization in a modified 9Cr–1Mo steel deformed by compression at high strain rate. Metall. Mater. Trans. A 47, 4682–4693 (2016).

Y. de Carlan, A. Alamo, M.H. Mathon, G. Geoffroy, and A. Castaing: Effect of thermal aging on the microstructure and mechanical properties of 7–11CrW steels. J. Nucl. Mater. 283, 672–676 (2000).

Z.X. Xia, C. Zhang, N.Q. Fan, Y.F. Zhao, F. Xue, and S.J. Liu: Improve creep properties of reduced activation steels by controlling precipitation behaviors. Mater. Sci. Eng., A 545, 91–96 (2012).

W.B. Liu, C. Zhang, Z.X. Xia, and Z.G. Yang: Improving high temperature creep resistance of reduced activation steels by addition of nitrogen and intermediate heat treatment. J. Nucl. Mater. 455, 402–406 (2014).

S. Banerjee, P.S. Robi, A. Srinivasan, and L.P. Kumar: High temperature deformation behavior of Al–Cu–Mg alloys micro-alloyed with Sn. Mater. Sci. Eng., A 527, 2498–2503 (2010).

M.R. Rokni, A. Zarie-Hanzaki, A.A. Roostaei, and A. Abolhasani: Constitutive base analysis of a 7075 aluminum alloy during hot compression testing. Mater. Des. 32, 4955–4960 (2011).

H. Mirzadeh, J.M. Cabrera, J.M. Prado, and A. Najafizadeh: Hot deformation behavior of a medium carbon microalloyed steel. Mater. Sci. Eng., A 528, 3876–3882 (2011).

Y.C. Lin, Y.C. Xia, X.M. Chen, and M.S. Chen: Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain rate. Comput. Mater. Sci. 50, 227–233 (2010).

H.Y. Li, D.D. Wei, J.D. Hu, Y.H. Li, and S.L. Chen: Constitutive modeling for hot deformation behavior of T24 ferritic steel. Comput. Mater. Sci. 53, 425–430 (2012).

Y.C. Lin, M.S. Chen, and J. Zhong: Prediction of 42CrMo steel flow stress at high temperature and strain rate. Mech. Res. Commun. 35, 142–150 (2008).

Q-s. Wu, S-h. Zheng, Q-y. Huang, S-j. Liu, and Y-y. Han: Continuous cooling transformation behaviors of CLAM steel. J. Nucl. Mater. 442, S67–S70 (2013).

Y.C. Lin, M.S. Chen, and J. Zhong: Microstructure evolution in 42CrMo steel during compression at elevated temperatures. Mater. Lett. 62, 2132–2135 (2008).

C.M. Sellars and W.J. McTegart: On the mechanism of hot deformation. Acta Metall. 14, 1136–1138 (1966).

S. Srinivasulu and A. Jain: A comparative analysis of training methods for artificial neural network rainfall-runoff modes. Appl. Soft. Comput. 6, 295–306 (2006).

ACKNOWLEDGMENTS

The authors are grateful to the China National Funds for Distinguished Young Scientists (granted No. 51325401), the National Natural Science Foundation of China (granted No. 51501126), the National Magnetic Confinement Fusion Energy Research Program (granted No. 2015GB119001), and the Key Project of Natural Science Foundation of Tianjin (granted No. 14JCZDJC38700) for grant and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Liu, Y., Liu, C. et al. Study on microstructural evolution and constitutive modeling for hot deformation behavior of a low-carbon RAFM steel. Journal of Materials Research 32, 1376–1385 (2017). https://doi.org/10.1557/jmr.2017.77

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.77