Abstract

The effects of pre-treatments on the precipitate microstructures of an Al-Zn-Mg-Cu alloy are investigated. Meanwhile, the creep-rupture behavior of the under-aged and peak-aged alloys are comparatively analyzed. Additionally, the effects of pre-treatment on the fracture mechanisms are discussed. It is found that the precipitate microstructures are sensitive to pre-treatments. The intragranular precipitates of the peak-aged alloy are larger than those of the under-aged. The precipitate free zone of the peak-aged alloy is wider than that of the under-aged. Some large intergranular precipitates appear on the grain boundaries of the under-aged alloy, and induce the nucleation of microvoids. Eventually, the creep fracture of the under-aged alloy is accelerated. Therefore, the differences in microstructures lead to the shorter creep-rupture life of the under-aged alloy, compared to the peak-aged alloy.

Similar content being viewed by others

References

Y.C. Lin, L.T. Li, Y.C. Xia, and Y.Q. Jiang: Hot deformation and processing map of a typical Al–Zn–Mg–Cu alloy. J. Alloys Compd., 550, 438 (2013).

M.H. Shaeri, M.T. Salehi, S.H. Seyyedein, M.R. Abutalebi, and J.K. Park: Microstructure and mechanical properties of Al-7075 alloy processed by equal channel angular pressing combined with aging treatment. Mater. Des., 57, 250 (2014).

C.J. Shi, J. Lai, and X.G. Chen: Microstructural evolution and dynamic softening mechanisms of Al–Zn–Mg–Cu alloy during hot compressive deformation. Materials, 7, 244 (2014).

M.R. Rokni, A. Zarei-Hanzaki, C.A. Widener, and P. Changizian: The strain-compensated constitutive equation for high temperature flow behavior of an Al–Zn–Mg–Cu alloy. J. Mater. Eng. Perform. 23, 4002 (2014).

Y.C. Lin and X.M. Chen: A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 32, 1733 (2011).

K. Elkhodary, W. Lee, L.P. Sun, D.W. Brenner, and M.A. Zikry: Deformation mechanisms of an Ω precipitate in a high-strength aluminum alloy subjected to high strain rates. J. Mater. Res. 26, 487 (2011).

T.S.B. Naser and G. Krallics: Mechanical behavior of multiple-forged Al 7075 aluminum alloy. Acta Polytech. Hung. 11, 103 (2014).

N. Haghdadi, A. Zarei-Hanzaki, H.R. Abedi, and O. Sabokpa: The effect of thermomechanical parameters on the eutectic silicon characteristics in a non-modified cast A356 aluminum alloy. Mater. Sci. Eng., A. 549, 93 (2012).

W.T. Huo, L.G. Hou, H. Cui, L.Z. Zhuang, and J.S. Zhang: Fine-grained AA 7075 processed by different thermo-mechanical processing. Mater. Sci. Eng., A. 618, 244 (2014).

M.H. Shaeri, M.T. Salehi, S.H. Seyyedein, M.R. Abutalebi, and J.K. Park: Characterization of microstructure and deformation texture during equal channel Angular pressing of Al–Zn–Mg–Cu alloy. J. Alloys Compd. 576, 350 (2013).

P. Shaterani, A. Zarei-Hanzaki, S.M. Fatemi-Varzaneh, and S.B. Hassas-Irani: The second phase particles and mechanical properties of 2124 aluminum alloy processed by accumulative back extrusion. Mater. Des. 58, 535 (2014).

J.K. Park and A.J. Ardell: Microchemical analysis of precipitate free zones in 7075-A1 in the T6, T7 and RRA tempers. Acta Mater. 39, 591 (1991).

K.K. Sankaran, R. Perez, and K.V. Jata: Effects of pitting corrosion on the fatigue behavior of aluminum alloy 7075-T6: Modeling and experimental studies. Mater. Sci. Eng., A. 297, 223 (2001).

Y.J. Shi, Q.L. Pan, M.J. Li, X. Huang, and B. Li: Effect of Sc and Zr additions on corrosion behaviour of Al–Zn–Mg–Cu alloys. J. Alloys Compd. 612, 42 (2014).

A.S. El-Amoush: Investigation of corrosion behaviour of hydrogenated 7075-T6 aluminum alloy. J. Alloys Compd. 443, 171 (2007).

A.S. El-Amoush: Intergranular corrosion behavior of the 7075-T6 aluminum alloy under different annealing conditions. Mater. Chem. Phys. 126, 607 (2011).

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, and B. Baroux: Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al–Zn–Mg–Cu alloy. Acta Mater. 58, 4814, (2010).

W.C. Yang, S.X. Ji, Q. Zhang, and M.P. Wang: Investigation of mechanical and corrosion properties of an Al-Zn-Mg-Cu alloy under various ageing conditions and interface analysis of η’ precipitate. Mater. Des. 85, 752 (2015).

J.F. Li, N. Birbilis, C.X. Li, Z.Q. Jia, B. Cai, and Z.Q. Zheng: Influence of retrogression temperature and time on the mechanical properties and exfoliation corrosion behavior of aluminium alloy AA7150. Mater. Charact. 60, 1334 (2009).

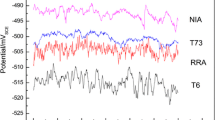

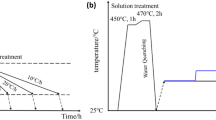

Y.C. Lin, J.L. Zhang, G. Liu, and Y.J. Liang: Effects of pre-treatments on aging precipitates and corrosion resistance of a creep-aged Al–Zn–Mg–Cu alloy. Mater. Des. 83, 866 (2015).

Y.C. Lin, G. Liu, M.S. Chen, Y.C. Huang, Z.G. Chen, X. Ma, Y.Q. Jiang, and J. Li: Corrosion resistance of a two-stage stress-aged Al-Cu-Mg alloy: Effects of stress-aging temperature. J. Alloys Compd. 657, 855 (2016).

Y.C. Lin, Y.Q. Jiang, X.M. Chen, D.X. Wen, and H.M. Zhou: Effect of creep-aging on precipitates of 7075 aluminum alloy. Mater. Sci. Eng., A. 588, 347 (2013).

L.T. Li, Y.C. Lin, H.M. Zhou, Y.C. Xia, and Y.Q. Jiang: Modeling the high-temperature creep behaviors of 7075 and 2124 aluminum alloys by continuum damage mechanics model. Comput. Mater. Sci. 73, 72 (2013).

J.T. Maximov, G.V. Duncheva, A.P. Anchev, and M.D. Ichkova: Modeling of strain hardening and creep behaviour of 2024T3 aluminium alloy at room and high temperatures. Comput. Mater. Sci. 83, 381 (2014).

J.T. Maximov, G.V. Duncheva, and A.P. Anchev: An approach to modeling time-dependent creep and residual stress relaxation around cold worked holes in aluminium alloys at room temperature. Eng. Failure Anal. 45, 1 (2014).

Y.Q. Jiang, Y.C. Lin, C. Phaniraj, Y.C. Xia, and H.M. Zhou: Creep and creep–rupture behavior of 2124-T851 aluminum alloy. High Temp. Mater. Processes 32, 533 (2013).

Y.C. Lin, Y.C. Xia, X.S. Ma, Y.Q. Jiang, and M.S. Chen: High-temperature creep behavior of Al-Cu-Mg alloy. Mater. Sci. Eng., A. 550, 125 (2012).

N. Mahathaninwong, Y. Zhou, S.E. Babcock, T. Plookphol, J. Wannasin, and S. Wisutmethangoon: Creep rupture behavior of semi-solid cast 7075-T6 Al alloy. Mater. Sci. Eng., A. 556, 107 (2012).

A. Yousefiani, F.A. Mohamed, and J.C. Earthman: Creep rupture mechanisms in annealed and overheated 7075 Al under multiaxial stress states. Metall. Mater. Trans. 31, 2807 (2000).

V. Srivastava, J.P. Williams, K.R. McNee, G.W. Greenwood, and H. Jones: Low stress creep behaviour of 7075 high strength aluminium alloy. Mater. Sci. Eng., A. 382, 50 (2004).

A.G. Leacock, C. Howe, D. Brown, O.G. Lademob, and A. Deering: Evolution of mechanical properties in a 7075 Al-alloy subject to natural ageing. Mater. Des. 49, 160 (2013).

J. Buha, R.N. Lumley, and A.G. Crosky: Secondary ageing in an aluminium alloy 7050. Mater. Sci. Eng., A. 492, 1 (2008).

J.N. Florando, J.D. Margraf, J.F. Reus, A.T. Anderson, R.C. McCallen, M.M. LeBlanc, J.R. Stanley, A.M. Rubenchik, S.S. Wu, and W.H. Lowdermilk: Modeling the effect of laser heating on the strength and failure of 7075-T6 aluminum. Mater. Sci. Eng., A. 640, 402 (2015).

Y. Liu, D. Jiang, B. Li, W.S. Yang, and J. Hu: Effect of cooling aging on microstructure and mechanical properties of an Al–Zn–Mg–Cu alloy. Mater. Des. 57, 79 (2014).

N.C. Danh, K. Rajan, and W. Wallace: A TEM study of microstructural changes during retrogression and reaging in 7075 aluminum. Metall. Mater. Trans. 14, 1843 (1983).

J.F. Li, Z.W. Peng, C.X. Li, Z.Q. Jia, W.J. Chen, and Z.Q. Zheng: Mechanical properties, corrosion behaviors and microstructures of 7075 aluminium alloy with various aging treatments. Trans. Nonferrous Met. Soc. China 18, 755 (2008).

J.K. Park and A.J. Ardell: Precipitate microstructure of peak-aged 7075 Al. Scr. Mater. 22, 1115 (1988).

Z.W. Du, Z.M. Sun, B.L. Shao, T.T. Zhou, and C.Q. Chen: Quantitative evaluation of precipitates in an Al–Zn–Mg–Cu alloy after isothermal ageing. Mater. Charact. 56, 121 (2006).

M.H. Li, Y.Q. Yang, Z.Q. Feng, B. Huang, X. Luo, J.H. Lou, and J.G. Ru: Precipitation sequence of η phase along low-angle grain boundaries in Al-Zn-Mg-Cu alloy during artificial aging. Trans. Nonferrous Met. Soc. China 24, 2061 (2014).

X.F. Xu, Y.G. Zhao, B.D. Ma, and M. Zhang: Electropulsing induced evolution of grain-boundary precipitates without loss of strength in the 7075 Al alloy. Mater. Charact. 105, 90 (2015).

P. Lejcek: Grain boundary segregation in metals, 1st ed. (Springer, Berlin, Germany, 2010); pp. 173–201.

R.G. Faulkner: Segregation to boundaries and interfaces in solids. Int. Mater. Rev. 41, 198 (1996).

C. Panseri, F. Gatto, and T. Federighi: Interaction between solute magnesium atoms and vacancies in aluminium. Acta Metall. 6, 198 (1958).

C. Panseri and T. Federighi: Evidence for the interaction between Mg atoms and vacancies in Al–Zn 10%–Mg 0.1% alloy. Acta Metall. 11, 575 (1963).

T.D. Xu, K. Wang, and S.H. Song: Theoretical progress in non-equilibrium grain-boundary segregation (I): Thermally induced non-equilibrium grain-boundary segregation and intergranular embrittlement. Sci. China, Ser. E: Technol. Sci. 52, 893 (2009).

H. Bakker, H.P. Bonzel, C.M. Bruff, M.A. Dayananda, W. Gust, J. Horváth, I. Kaur, G.V. Kidson, A.D. LeClaire, H. Mehrer, G.E. Murch, G. Neumann, N. Stolica, and N.A. Stolwijk: Diffusion in solid metals and alloys, 1st ed. Vol. 26, (Springer, Berlin, Germany, 1990); pp. 7–10.

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, and B. Baroux: Influence of alloy composition and heat treatment on precipitate composition in Al–Zn–Mg–Cu alloys. Acta Mater. 58, 248 (2010).

L. Ratke and P.W. Voorhees: Growth and coarsening: Ostwald ripening in material processing, 1st ed. (Springer, Berlin, Germany, 2013); pp. 150–193.

R.A. Oriani: Ostwald ripening of precipitates in solid matrices. Acta Mater. 12, 1399 (1964).

R.C. Dorward: Precipitate coarsening during overaging of Al–Zn–Mg–Cu alloy. Mater. Sci. Technol. 15, 1133 (1999).

G. Fribourg, Y. Bréchet, J.L. Chemin, and A. Deschamps: Evolution of precipitate microstructure during creep of an AA7449 T7651 aluminum alloy. Metall. Mater. Trans. 42, 3934 (2011).

M. Kahlweit: Ostwald ripening of precipitates. Adv. Colloid Interface Sci. 5, 35 (1975).

P.W. Voorhees: The theory of Ostwald ripening. J. Stat. Phys. 38, 231 (1985).

M. Zhou, Y.C. Lin, J. Deng, and Y.Q. Jiang: Hot tensile deformation behaviors and constitutive model of an Al–Zn–Mg–Cu alloy. Mater. Des. 59, 141 (2014).

M.E. Kassner and T.A. Hayes: Creep cavitation in metals. Int. J. Plast. 19, 1715 (2003).

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation Council of China (Grant Nos. 51375502, 51305466), the National Key Basic Research Program (Grant No. 2013CB035801), the Project of Innovation-driven Plan in Central South University (Grant No. 2015CX002), the Natural Science Foundation for Distinguished Young Scholars of Hunan Province (Grant No. 2016JJ1017), and the Graduate Degree Thesis Innovation Foundation of Central South University (Grant No. 2015zzts202).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, Y.C., Wang, ZW., He, DG. et al. Effects of pre-treatments on precipitate microstructures and creep-rupture behavior of an Al-Zn-Mg-Cu alloy. Journal of Materials Research 31, 1286–1295 (2016). https://doi.org/10.1557/jmr.2016.144

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.144