Abstract

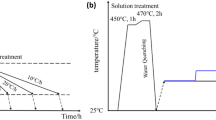

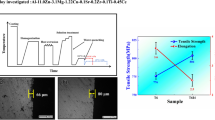

The mechanical properties, corrosion behavior and microstructures of the Al–Zn–Mg–Cu alloy under various ageing treatments were investigated comparatively. The results show that the tensile strength and corrosion resistance are strongly affected by the precipitate state. Massive fine intragranular precipitates contribute to high strength. Discontinuous coarse grain boundary precipitates containing high Cu content, as well as the narrow precipitate free zone, result in low corrosion susceptibility. After the non-isothermal ageing (NIA) treatment, the tensile strength of 577 MPa is equivalent to that of 579 MPa for the T6 temper. Meanwhile, the stress corrosion susceptibility rtf and the maximum corrosion depth are 97.8% and 23.5 μm, which are comparable to those of 92.8% and 26.7 μm for the T73 temper. Moreover, the total ageing time of the NIA treatment is only 7.25 h, which is much less than that of 48.67 h for the retrogression and re-ageing condition.

Similar content being viewed by others

References

H. Queudet, S. Lemonnier, E. Barraud, J. Ghanbaja, N. Allain, E. Gaffet, Mater. Sci. Eng. A 685, 71 (2017)

J.Z. Chen, L. Zhen, S.J. Yang, W.Z. Shao, S.L. Dai, Mater. Sci. Eng. A 500, 34 (2009)

K.K. Ma, T. Hu, H. Yang, T. Topping, A.L. Yousefiani, E.J. Lavernia, J.M. Schoenung, Acta Mater. 103, 153 (2016)

T. Marlaud, B. Malki, C. Henon, A. Deschamps, B. Baroux, Corros. Sci. 53, 3139 (2011)

M. Puiggali, A. Zielinski, J.M. Olive, E. Renauld, D. Desjardins, M. Cid, Corros. Sci. 40, 805 (1998)

L.P. Huang, K.H. Chen, S. Li, M. Song, Scripta Mater. 56, 305 (2007)

P.K. Rout, M.M. Ghosh, K.S. Ghosh, Mater. Sci. Eng. A 604, 156 (2014)

J. Wloka, T. Hack, S. Virtanen, Corros. Sci. 49, 1437 (2007)

J.F. Chen, X.F. Zhang, L.C. Zou, Y. Yua, Q. Li, Mater. Charact. 114, 1 (2016)

W.C. Yang, S.X. Ji, Q. Zhang, M.P. Wang, Mater. Des. 85, 752 (2015)

Y.C. Lin, J.L. Zhang, G. Liu, Y.J. Liang, Mater. Des. 83, 866 (2015)

P.K. Rout, M.M. Ghosh, K.S. Ghosh, Mater. Charact. 104, 49 (2015)

B.M. Cina, US Patent 3856584, (1974)

J.-P. Immarigeon, R.T. Holt, A.K. Koul, L. Zhao, W. Wallace, J.C. Beddoes, Mater. Charact. 35, 41 (1995)

A.F. Oliveira Jr., M.C. de Barros, K.R. Cardoso, D.N. Travessa, Mater. Sci. Eng. A 379, 321 (2004)

Z.H. Li, B.Q. Xiong, Y.G. Zhang, B.H. Zhu, F. Wang, H.W. Liu, J. Mater. Process. Technol. 209, 2021 (2009)

J.T. Staley, Durham US Patent, 0237113Al, (2007)

J.T. Jiang, Q.J. Tang, L. Yang, K. Zhang, S.J. Yuan, L. Zhen, J. Mater. Process. Technol. 227, 110 (2016)

D.M. Jiang, Y. Liu, S. Liang, W.L. Xie, J. Alloys Compd. 681, 57 (2016)

J.T. Jiang, W.Q. Xiao, L. Yang, W.Z. Shao, S.J. Yuan, L. Zhen, Mater. Sci. Eng. A 605, 167 (2014)

Y. Liu, D.M. Jiang, B.Q. Li, W.S. Yang, J. Hu, Mater. Des. 57, 79 (2014)

Y. Liu, D.M. Jiang, W.J. Li, J. Alloys Compd. 671, 408 (2016)

X.Y. Peng, Q. Guo, X.P. Liang, Y. Deng, Y. Gua, G.F. Xu, Zhimin Yin, Mater. Sci. Eng., A 688, 146 (2017)

GB 7998-2005, National standard of China

O.N. Senkov, S.V. Senkova, M.R. Shagiev, Effect of Sc on aging kinetics in a direct chill cast Al–Zn–Mg–Cu alloy. Metall. Mater. Trans. A 39, 1034 (2008)

R. Goswami, S. Lynch, N.J. Henry Holroyd, S.P. Knight, R.L. Holtz, Metall. Mater. Trans. A 44, 1268 (2013)

J.Z. Liu, J.H. Chen, X.B. Yang, S. Ren, C.L. Wu, H.Y. Xu, J. Zou, Scripta Mater. 63, 1061 (2010)

L. Hadjadj, R. Amira, D. Hamana, A. Mosbah, J. Alloys Compd. 462, 279 (2008)

L.K. Berg, J. Gjønnes, V. Hsnsen, X.Z. Li, M. Knutson-Wedel, G. Waterloo, D. Schryvers, L.R. Wallenberg, Acta Mater. 49, 3443 (2001)

E. Arzt, Acta Metall. 46, 5611 (1998)

J.M. Fragomeni, B.M. Hillberry, Acta Mech. 138, 185 (1999)

J.F. Li, N. Birbilis, C.X. Li, Z.Q. Jia, B. Cai, Z.Q. Zheng, Mater. Charact. 35, 1334 (2009)

K.S. Ghosh, K. Das, U.K. Chatterjee, Mater. Corros. 3, 181 (2007)

Y. Deng, Z.M. Yin, K. Zhao, J.Q. Duan, J. Hu, Z.B. He, Corros. Sci. 65, 288 (2012)

S.Y. Chen, K.H. Chen, G.S. Peng, L. Jia, P.X. Dong, Mater. Des. 35, 93 (2012)

R.G. Song, M.K. Tseng, B.J. Zhang, J. Liu, Z.H. Jin, K.S. Shin, Acta Mater. 44, 3241 (1996)

R.G. Song, W. Dietzel, B.J. Zhang, W.J. Liu, M.K. Tseng, Acta Mater. 52, 4727 (2004)

J.R. Pickens, T.J. Langan, Metall. Trans. A 18, 1735 (1987)

D. Najjar, T. Magnin, T.J. Warner, Mater. Sci. Eng. A 238, 293 (1997)

X.Y. Sun, B. Zhang, H.Q. Lin, Y. Zhou, L. Sunb, J.Q. Wang, E.H. Han, W. Ke, Corros. Sci. 77, 103 (2013)

Y.J. Shi, Q.L. Pan, M.J. Li, X. Huang, B. Li, Mater. Sci. Eng. A 621, 173 (2015)

K. Rajan, W. Wallace, J.C. Beddoes, J. Mater. Sci. 17, 2817 (1982)

G.A. YoungJr, J.R. Scully, Metall. Mater. Trans. A 33, 1167 (2002)

T. Ramgopal, P.I. Gouma, G.S. Frankel, Corros. 58, 687 (2002)

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, B. Baroux, Acta Mater. 58, 248 (2010)

S.P. Knight, N. Birbilis, B.C. Muddle, A.R. Trueman, S.P. Lynch, Corros. Sci. 52, 4073 (2010)

N. Birbilis, R.G. Buchheit, J. Electro. Soc. 152, 140 (2005)

M.B. Kannan, V.S. Raja, J. Mater. Sci. 42, 5458 (2007)

T. Ramgopal, P. Schmutz, G.S. Frankel, J. Electro. Soc. 148, 348 (2001)

Y. Deng, R. Ye, G.F. Xu, J.D. Yang, Q.L. Pan, B. Peng, X.W. Cao, Y.L. Duan, Y.J. Wang, L.Y. Lu, Z.M. Yin, Corros. Sci. 90, 359 (2015)

H. Qi, X.Y. Liu, S.X. Liang, X.L. Zhang, H.X. Cui, L.Y. Zheng, F. Gao, Q.H. Chen, J. Alloys Compd. 657, 318 (2016)

Acknowledgements

This investigation was financially supported by the Fundamental Research Funds for the Central Universities of Central South University (No. 2015zzts023) and the Guangdong Province Science and Research Plan Project (2016B090931004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, X., Li, Y., Xu, G. et al. Effect of Precipitate State on Mechanical Properties, Corrosion Behavior, and Microstructures of Al–Zn–Mg–Cu Alloy. Met. Mater. Int. 24, 1046–1057 (2018). https://doi.org/10.1007/s12540-018-0057-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0057-z