Abstract

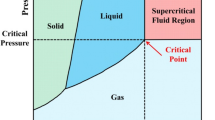

In this paper, a process to introduce nanoscale cells in homogeneous polyetherimide (PEI) is presented. The nanofoams produced have a bulk porosity (void fraction) in the range of 25–64%, with the average cell sizes in the range of 40–100 nm. Uniform nucleation of cells throughout the volume of the PEI specimen was observed. Supercritical CO2 at 20 MPa was used as the blowing agent and the specimens were foamed in a hot press to ensure flatness for further processing and characterization. Sorption studies showed that at 20 MPa, PEI can absorb about 10% CO2 by weight and that a 1-mm thick specimen can reach an equilibrium concentration in approximately 100 h at 45 °C. The effects of desorption time, foaming temperature, clamping pressure, and foaming time were investigated. Several nanoscale morphologies were observed through changes in the foaming temperature, which ranged from 165 to 210 °C. In one experiment, it was found that when the clamping force is increased from 1 to 10 tons, the average cell size increased from 40 to 4000 nm or by a factor of 100. This points to the clamping force as an important process variable to control the nanostructure introduced in PEI. Optimal processing conditions for the production of defect-free nanofoams are presented.

Similar content being viewed by others

References

X. Xu, C.B. Park, D. Xu, and R.P. Iliev: Effects of die geometry on cell nucleation of PS foams blown with CO2. Polym. Eng. Sci. 43, 1378 (2004).

S. Siripurapu, J.M. DeSimone, S.A. Khan, and R.J. Spontak: Low-temperature, surface-mediated foaming of polymer films. Adv. Mater. 16, 989 (2004).

M. Shimbo, I. Higashitani, and Y. Miyano: Mechanism of strength improvement of foamed plastics having fine cell. J. Cell. Plast. 43, 157 (2007).

S.S. Sundarram and W. Li: On thermal conductivity of micro and nanocellular polymer foams. Polym. Eng. Sci. (2013).

R.W.B. Sharudin and M. Ohshima: CO2-induced mechanical reinforcement of polyolefin-based nanocellular foams. Macromol. Mater. Eng. 296, 1046 (2011).

D.I. Collias, D.G. Baird, and R.J.M. Borggreve: Impact toughening of polycarbonate by microcellular foaming. Polymer 35, 3978 (1994).

B. Krause, G-H. Koops, N.F.A. van der Vegt, M. Wessling, M. Wübbenhorst, and J. van Turnhout: Ultralow-k dielectrics made by supercritical foaming of thin polymer films. Adv. Mater. 14, 1041 (2002).

J.L. Hedrick, T.P. Russell, J. Labadie, M. Lucas, and S. Swanson: High temperature nanofoams derived from rigid and semi-rigid polyimides. Polymer 36, 2685 (1995).

C.B. Park, A.H. Behravesh, and R.D. Venter: Low density microcellular foam processing in extrusion using CO2. Polym. Eng. Sci. 38, 1812 (2004).

D. Miller, P. Chatchaisucha, and V. Kumar: Microcellular and nanocellular solid-state polyetherimide (PEI) foams using sub-critical carbon dioxide I. Processing and structure. Polymer 50, 5576 (2009).

J.L. Hedrick, C.J. Hawker, R. DiPietro, R. Jérôme, and Y. Charlier: The use of styrenic copolymers to generate polyimide nanofoams. Polymer 36, 4855 (1995).

S. Hongliu and J.E. Mark: Preparation, characterization, and mechanical properties of some microcellular polysulfone foams. J. Appl. Polym. Sci. 86, 1692 (2002).

B. Krause, H.J.P. Sijbesma, P. Münüklü, N.F.A. Van der Vegt, and M. Wessling: Bicontinuous nanoporous polymers by carbon dioxide foaming. Macromolecules 34, 8792 (2001).

B. Krause, M.E. Boerrigter, N.F.A. Van der Vegt, H. Strathmann, and M. Wessling: Novel open-cellular polysulfone morphologies produced with trace concentrations of solvents as pore opener. J. Membr. Sci. 187, 181 (2001).

S.S. Zhang: A review on the separators of liquid electrolyte Li-ion batteries. J. Power Sources 164, 351 (2007).

J. Martini, N.P. Suh, and F.A. Waldman: Microcellular closed cell foams and their method of manufacture. Patent #4473665, September 25, 1984. Massechusetts Institute of Technology: USA, 1984.

J. Martini, F.A. Waldman, and N.P. Suh: The production and analysis of microcellular thermoplastic foam. SPE ANTEC Tech. Pap. 28, 674 (1982).

S. Huang, G. Wu, and S. Chen: Preparation of open cellular PMMA microspheres by supercritical carbon dioxide foaming. J. Supercrit. Fluids 40.2, 323 (2007).

V. Kumar and J.E. Weller: A process to produce microcellular PVC. Int. Polym. Proc. 8, 73 (1993).

V. Kumar and J. Weller: Production of microcellular polycarbonate using carbon dioxide for bubble nucleation. J. Eng. Ind. 116, 413 (1994).

R.E. Murray, J.E. Weller, and V. Kumar: Solid-state microcellular acrylonitrile-butadiene-styrene foams. Cell. Polym. 19, 413 (2000).

D.F. Baldwin, C.B. Park, and N.P. Suh: A microcellular processing study of poly (ethylene terephthalate) in the amorphous and semicrystalline states. Part I: Microcell nucleation. Polym. Eng. Sci. 36, 1437 (2004).

D.F. Baldwin and N.P. Suh: Microcellular poly (ethylene terephthalate) and crystallizable poly (ethylene terephthalate): Characterization of process variables, in ANTEC 92–Shaping the Future, Vol. 1; Society of Plastics Engineers, 1992; p. 1503–1507.

X. Wang, V. Kumar, and W. Li: Low density sub-critical CO2-blown solid-state PLA foams. Cell. Polym. 26, 11 (2007).

S.K. Goel and E.J. Beckman: Generation of microcellular polymers using supercritical CO2. Cell. Polym. 12, 251 (1993).

T.S. Chow: Molecular interpretation of the glass transition temperature of polymer-diluent systems. Macromolecules 13, 362 (1980).

T. Nemoto, J. Takagi, and M. Ohshima: Nanoscale cellular foams from a poly (propylene) rubber blend. Macromol. Mater. Eng. 293, 991 (2008).

T. Nemoto, J. Takagi, and M. Ohshima: Control of bubble size and location in nano/microscale cellular poly (propylene)/rubber blend foams. Macromol. Mater. Eng. 293, 574 (2008).

Y. Fujimoto, S.S. Ray, M. Okamoto, A. Ogami, K. Yamada, and K. Ueda: Well-controlled biodegradable nanocomposite foams: From microcellular to nanocellular. Macromol. Rapid Commun. 24, 457 (2003).

B. Krause, K. Diekmann, N.F.A. Van der Vegt, and M. Wessling: Open nanoporous morphologies from polymeric blends by carbon dioxide foaming. Macromolecules 35, 1738 (2002).

D. Miller and V. Kumar: Microcellular and nanocellular solid-state polyetherimide (PEI) foams using sub-critical carbon dioxide II. Tensile and impact properties. Polymer 52, 2910 (2011).

S.G. Kazarian: Polymer processing with supercritical fluids. Polymer Sci. 42, 78 (2000).

D.L. Tomasko, H. Li, D. Liu, X. Han, M.J. Wingert, L.J. Lee, and K.W. Koelling: A review of CO2 applications in the processing of polymers. Ind. Eng. Chem. Res. 42, 6431 (2003).

C. Zhou, N. Vaccaro, S.S. Sundarram, and W. Li: Fabrication and characterization of polyetherimide nanofoams using supercritical CO2. J. Cell. Plast. 48, 235 (2012).

L. Sorrentino, M. Aurilia, and S. Iannace: Polymeric foams from high performance thermoplastics. Adv. Polym. Tech. 30, 234 (2011).

J. Crank: The Mathematics of Diffusion (Oxford University Press: London, England, 1956), p. 45.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aher, B., Olson, N.M. & Kumar, V. Production of bulk solid-state PEI nanofoams using supercritical CO2. Journal of Materials Research 28, 2366–2373 (2013). https://doi.org/10.1557/jmr.2013.108

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.108