Abstract

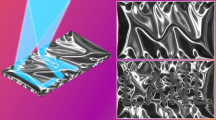

We have studied the effects of focused-ion-beam (FIB) irradiation and prestraining on the mechanical properties of nearly defect-free Au microparticles on a sapphire substrate. The Au microparticles, which were produced by a solid-state diffusion dewetting technique, were FIB-irradiated and/or prestrained, the latter using a nanoindenter with a flat ended punch operating under a nanohammering mode. Also, the prestrained Au microparticles were exposed to FIB to examine the effects of ion-beam damage on the properties of crystals containing mobile dislocations. We found that both FIB irradiation and prestraining reduced the yield strength of pristine Au microparticles significantly and made the stress–strain curves jerky. However, FIB irradiation does not affect the mechanical properties of prestrained Au microparticles very significantly. Once a microparticle contains mobile dislocations, its mechanical properties are not influenced much by the defects generated by FIB irradiation, even at the submicrometer scale.

Similar content being viewed by others

References

W.D. Nix, J.R. Greer, G. Feng, and E.T. Lilleodden: Deformation at the nanometer and micrometer length scales: Effects of strain gradients and dislocation starvation. Thin Solid Films 515, 3152 (2007).

M.D. Uchic, D.M. Dimiduk, J.N. Florando, and W.D. Nix: Sample dimensions influence strength and crystal plasticity. Science 305, 986 (2004).

J.R. Greer, W.C. Oliver, and W.D. Nix: Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821 (2005).

C.A. Volkert and E.T. Lilleodden: Size effects in the deformation of sub-micron Au columns. Philos. Mag. 86, 5567 (2006).

D. Kiener, C. Motz, M. Rester, M. Jenko, and G. Dehm: FIB damage of Cu and possible consequences for miniaturized mechanical tests. Mater. Sci. Eng., A 459, 262 (2007).

H. Bei, S. Shim, E.P. George, M.K. Miller, E.G. Herbert, and G.M. Pharr: Compressive strengths of molybdenum alloy micro-pillars prepared using a new technique. Scr. Mater. 57, 397 (2007).

G. Richter, K. Hillerich, D.S. Gianola, R. Mönig, O. Kraft, and C.A. Volkert: Ultrahigh strength single crystalline nanowhiskers grown by physical vapor deposition. Nano Lett. 9, 3048 (2009).

A.T. Jennings, M.J. Burek, and J.R. Greer: Microstructure versus size: Mechanical properties of electroplated single crystalline Cu nanopillars. Phys. Rev. Lett. 104, 135503 (2010).

H. Sadan and W.D. Kaplan: Au–Sapphire (0001) solid–solid interfacial energy. J. Mater. Sci. 41, 5099 (2006).

D. Mordehai, M. Kazakevich, D.J. Srolovitz, and E. Rabkin: Nanoindentation size effect in single-crystal nanoparticle and thin films: A comparative experimental and simulation study. Acta Mater. 59, 2309 (2011).

H. Bei, S. Shim, G.M. Pharr, and E.P. George: Effects of pre-strain on the compressive stress–strain response of Mo-alloy single-crystal micropillars. Acta Mater. 56, 4762 (2008).

S. Shim, H. Bei, M.K. Miller, G.M. Pharr, and E.P. George: Effects of focused-ion-beam milling on the compressive behavior of directionally solidified micropillars and the nanoindentation response of an electropolished surface. Acta Mater. 57, 503 (2009).

D. Mordehai, S-W. Lee, B. Eckert, D.J. Srolovitz, W.D. Nix, and E. Rabkin: Size effect in compression of single-crystal gold microparticles. Acta Mater. 59, 5202 (2011).

S-W. Lee, S.M. Han, and W.D. Nix: Uniaxial compression of fcc Au nanopillars on an MgO substrate: The effects of prestraining and annealing. Acta Mater. 57, 4404 (2009).

J.R. Greer and W.D. Nix: Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 73, 245410 (2006).

S. Brinckmann, J-Y. Kim, and J.R. Greer: Fundamental differences in mechanical behavior between two types of crystals at the nanoscale. Phys. Rev. Lett. 100, 155502 (2008).

J.F. Ziegler, J.P. Biersack, and U. Littmark: The Stopping Range of Ions in Matter (Pergamon Press, New York, 1985), p. 321.

J.A. El-Awady, C. Woodward, D.M. Dimiduk, and N.M. Ghoniem: Effects of focused ion beam induced damage on the plasticity of micropillars. Phys. Rev. B 80, 104104 (2009).

Acknowledgment

S-W. Lee and W.D. Nix were supported by the Office of Science, Office of Basic Energy Sciences of the U.S. Department of Energy under Contract No. DE- FG02-04ER46163. D. Mordehai was supported in part by a Fine Fellowship. Partial support of the Russell Berry Nanotechnology Institute at the Technion is heartily acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

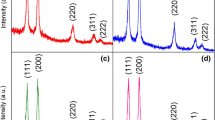

We used the Stopping and Range of Ions in Matter (SRIM) simulation to study the penetration depth and the number of implanted Ga+ ions. According to the SRIM calculation, the penetration depths of Ga+ ion beam are ~30 nm for {111} plane and ~25 nm for {100} plane for Au microparticles. Figure Al shows that the penetration depth at 4° incidence (the side surface of micropillars) is about one-third of penetration depth at 90° incidence (the top surface of microparticles). The simulation results also provide the number of implanted and backscattered ions. For a given number of applied ions, the total number of implanted ions for the normal incidence is about three times higher than that of 4° incidence. Thus, our microparticle appears to be more damaged than the micropillar. However, we have to consider the current density of the beam since we used the large circular pattem to reduce the current density. The schematic in Fig. A2 shows the geometry of micropillar and microparticle for the calculation of current densities. Suppose that the Au microparticle with a top diameter of 400 nm and a central diameter of 1 µm is exposed to the 10 pA beam for 7 s. Since we used a 5-µm diameter circular pattem, the current density of the beam is (10 pA)/ (π × (2.5 µm)2) = 0.51 C/(m2 s). Then, the total dose of Ga+ ions per unit area can be obtained by multiplying the current density by the beam exposure time. So, the total dose per unit area is (0.51 C/(m2 s))/(1.6 × 10−19 C) × (7 s) = 2.23 × 1019 ions/m2 for 7 s. Assume that the concentric circular pattem is used for the micropillar with D ~ 400 nm, a similar top diameter. For the final milling process, suppose that the inner diameter of concentric pattern is 420 nm and the outer diameter is 460 nm. In this case, the current density is (10 pA)/[π × ((230 nm)2 − (210 nm)2)] = 362 C/(m2 s). For 1 s final thinning, the total ion dose per unit area is 362 C/(m2 s)/(l.6 × 10−19 C) × (1 s) = 2.3 × 1020 ions/m2 for 1 s.

Suppose that the spherical shape of microparticle with the top and center diameters of 400 nm and 1 µm, respectively. Then, the side surface area, which is exposed to FIB, can be obtained by subtracting the cap area from the area of hemisphere. The beam exposed area of microparticle is the sum of the top surface and the side surface, which is π(200 nm)2 + [2π(500 nm)2− π((200 nm)2 + (42 nm)2)] = 1.57 × 106nm2. In the case of pillar geometry with the same top diameter of 400 nm, let us assume that the aspect ratio (L/D) is three, there is no tapering, and only the side surface is exposed to FIB. Then, the side surface area is 2π(200 nm)(3 × 400 nm) = 1.51 × 106 nm2. Thus, the beam exposed area is similar for the both geometries. Consequently, for the given top diameter, the ion dose of micropillars is about 10 times higher than that of microparticles due to the 10 times higher current density and the similar surface area. Here, the calculations were done for D ~ 400 nm, but even for the different diameters, the difference in beam exposed areas does not differ significantly.

Results of Stopping and Range of Ions in Matter (SRIM) calculations for 30 keV Ga ion implantation into pure Au at (a) glancing incidence (35.3°) for the {100} top plane, (b) normal incidence (90°) for the {111} top plane, and (c) glancing incidence (4°) for the side surface of nanopillar. The total 10,000 ions collided with the gold surface in these simulations.

Rights and permissions

About this article

Cite this article

Lee, SW., Mordehai, D., Rabkin, E. et al. Effects of focused-ion-beam irradiation and prestraining on the mechanical properties of FCC Au microparticles on a sapphire substrate. Journal of Materials Research 26, 1653–1661 (2011). https://doi.org/10.1557/jmr.2011.221

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.221