Abstract

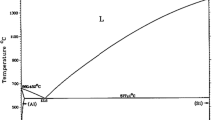

The explosive reactions or self-propagating high temperature synthesis (SHS) take place during milling Ni20Ti50C30 and Ni50Ti30C20 elemental powder mixtures. The coexistence of agglomerates and powders in products indicates the occurrence of melting and solidification. TiC phase and NiTi compound were obtained during millingNi20Ti50C30, while no compound of nickel and titanium was observed when milling Ni50Ti30C20, the final product of which is TiC and Ni. It is suggested that the explosive reaction is ignited by the heat releasing from initial formation of TiC through heavy collisions of milling balls, and the reaction between Ni and Ti, as well as the existence of Ni–Ti liquid, make the following reaction self-sustained. The variation of the addition of nickel did not affect the reaction time in both compositions, but made the reaction temperature different due to the difference of composition of Ni and Ti. It is estimated that the temperature during the reaction in Ni20Ti50C30 rises above 1112 °C, while in Ni50Ti30C20, it might rise above 1349 °C. However, no phenomenon suggests the melting of pure elemental Ti; the formation of TiC is mainly controlled by the diffusion mechanism in SHS.

Similar content being viewed by others

References

R. B. Schwarz, R.R. Petrich, and C.K. Saw, J. Non-Cryst. Solids 76, 281 (1985).

R. Schultz, M. Trudeau, J. Y. Huot, and A. V. Neste, Phys. Rev. Lett. 62, 2849 (1989).

A. E. Ermakov, E.E. Yurchikov, and V.A. Barinov, Phys. Met. Metall. 52, 50 (1981).

M. Atzmon, Phys. Rev. Lett. 64, 487 (1990).

G. B. Schaffer and P. G. McCormick, Metall. Trans. 21A, 2789 (1990).

Z. A. Munir, Ceram. Bull. 67, 342 (1988).

E. Ma, J. Pagan, G. Cranford, and M. Atzmon, J. Mater. Res. 8, 1836 (1993).

K. Y. Wang, A. Q. He, and J. T. Wang, Metall. Trans. 24A, 225 (1993).

S. B. Holt and Z. A. Munir, J. Metal. Sci. 21, 251 (1986).

L. L. Ye and M.X. Quan, Nanostruct. Mater. 5, 25 (1995).

Z. G. Liu, J.T. Guo, L. L. Ye, G.S. Li, and Z. Q. Hu, Appl. Phys. Lett. 65, 2666 (1994).

S. D. Dunmead, D.W. Readey, C. E. Semler, and J.B. Holt, J. Am. Ceram. Soc. 72, 2318 (1989).

R. T. Leonard and C.C. Koch, Nanostruct. Mater. 1, 47 (1992).

L. L. Ye, Z.G. Liu, J. Y. Huang, and M.X. Quan, Mater. Lett. 25, 117 (1995).

S. C. Deevi, J. Mater. Sci. 26, 3343 (1991).

V. Hlavacek, Am. Ceram. Bull. 70, 240 (1991).

Z. A. Munir, Metall. Trans. 23A, 7 (1992).

C. J. Smithells, Metals Reference Book, 5th ed. (Butterworths, London and Boston, 1976), pp. 326, 865.

Y. Choi and S.W. Rhee, J. Mater. Res. 8, 3202 (1993).

E. K. Storm, The Refractory Carbides (Academic Press, New York and London, 1967), p. 1.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ye, L.L., Huang, J.Y., Liu, Z.G. et al. Effect of nickel addition on the combustion reaction of the Ti–C system during mechanical alloying. Journal of Materials Research 11, 2092–2097 (1996). https://doi.org/10.1557/JMR.1996.0263

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1996.0263