Abstract

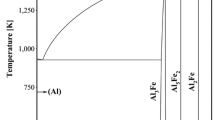

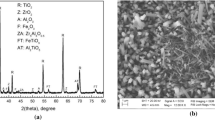

Using a Nd-YAG laser, laser processing of a series of Ti-Al alloys including pure Ti and Ti-Al intermetallic compounds has been studied. Scanning electron microscopy (SEM), x-ray photoelectron spectroscopy (XPS), and optical microscopy were used to determine the surface morphological, chemical, and compositional characteristics of the laser-processed samples. Analysis of results showed that cracks along grain boundaries caused by rapid heating and cooling of laser processing were the dominant characteristics of the surface morphologies of the laser-processed samples. The Al content in the Ti-Al alloys played a very important role in crack initiation and/or development. The more Al content in the samples, the more severe the cracks that developed after laser processing under the same conditions. The experiments were conducted at ambient conditions, resulting in surface oxidation layers being observed on the processed samples. The XPS results indicated that the oxidation layer consisted of adsorbed O2, Al2O3, TiO2, and TiO. In addition, Al enrichment was found in the oxide film of TiAl as well as in the oxidation layers formed on the surfaces of TiAl and Ti3Al intermetallics that were processed by the laser; this differs from the reported results for traditional oxidation of TiAl at elevated temperature.

Similar content being viewed by others

References

M. Yamaguchi: in Titanium ’92-Science and Technology, F.H. Froes and I. Caplan, eds., TMS, Warrendale, PA, 1993, p. 959.

W. Thompson and W. Chu: in Microstructure/Property Relationships in Titanium Aluminides and Alloys, Y.-W. Kim and R.R. Boyer, eds., TMS, Warrendale, PA, 1991, p. 165.

P.S. Liu, K.H. Hou, W.A. Baeslack III, and J. Hurley: in Titanium ’92-Science and Technology, F.H. Froes and I. Caplan, eds., TMS, Warrendale, PA, 1993, p. 1477.

S.G. Kumar, R.G. Reddy, and L. Brewer: J. Phase Equilibria, 1994, vol. 15 (3), pp. 279–84.

S.G. Kumar, R.G. Reddy, J. Wu, and J. Holthus: J. Mater. Eng. Performance, 1995, vol. 4, pp. 63–69.

S.G. Kumar and R.G. Reddy: Proc. Int. Symp. on Synthesis/Processing of Lightweight Metallic Materials, TMS, Warrendale, PA, 1995, pp. 129–39.

S.G. Kumar and R.G. Reddy: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 1121–26.

J. Mazumder: in Laser Materials Processing, M. Bass, ed., North-Holland Publishing Company, Amsterdam, Netherlands, 1983, p. 112.

W.M. Steen and J.N. Kamalu in Laser Materials Processing, M. Bass, ed., North-Holland Publishing Company, Amsterdam, Netherlands, 1983, p. 15.

M Querry: in High Power Lasers, A. Niku-Lari and B.L. Mordike, eds., Pergamon Press, Elmsford, NY, 1989, p. 195.

J.C. Beitialarrangoitia, G.E. Garcia de Vicuna, and S.K. Ghosh: in High Power Lasers, A. Niku-Lari and B.L. Mordike, eds., Pergamon Press, Elmsford, NY, 1989, p. 213.

M.J. Hsu and P.A. Molian: J. Mater. Sci., 1994, vol. 29, p. 5607.

K. Li and P. Sheng: in Manufacturing Science and Engineering-1995, E. Kannatey-Asibu, Jr., C.J. Li, Y. Rong, C.-Y. Shia, and F.J. Stango, eds., ASME, New York, NY, 1995, vol. 1, p.3.

S. Tsukamoto and O. Umezawa: Mater. Sci. Eng., 1997, vol. A223, p. 99.

X. Wen and R.G. Reddy: Processing and Fabrication of Advanced Materials V, TMS, Warrendale, PA, 1996, pp. 37–389.

R.G. Reddy, X. Wen, and Y. Li: in Titanium Extraction and Processing, B. Mishra and G.J. Kipouros, eds., TMS, Warrendale, PA, 1997, pp. 153–61.

S. Huang and D.S. Shih: in Microstructure/Property Relationships in Titanium Aluminides and Alloys, Y.-W. Kim and R.R. Boyer, eds., TMS, Warrendale, PA, 1991, p. 105.

J.U. Ejiofer, G.F. Fernando, and R.G. Reddy: J. Mater. Sci., 1998, vol. 33, pp. 4029–33.

C.I. Okafor and R.G. Reddy: JOM, 1999, vol. 47, pp. 35–39.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

McElroy, S., Yang, D. & Reddy, R.G. Laser processing of titanium aluminides. J. of Materi Eng and Perform 9, 506–515 (2000). https://doi.org/10.1361/105994900770345629

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994900770345629