Abstract

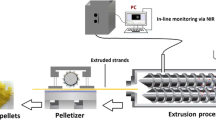

Extrudates based on varying ratios of the triglyceride tripalmitin and the hydrophilic polymer polyethylene glycol as matrix formers were produced as oral dosage forms with controlled release characteristics. The extrudates were processed below the melting points of the excipients and contained the hydrophobic model drug chloramphenicol. The influence of the ratio of the matrix formers on drug dissolution was investigated, with an increase in the water-soluble polymer content increasing the drug release rate. In addition, the effect of varying the extrusion process on the extrudate structure and drug dissolution was investigated. Two-step extrusion was performed, which comprised an initial extrusion step of drug and one matrix component followed by milling these extrudates and a second extrusion step for the milled extrudates mixed with the second matrix component. Initial extrusion with polyethylene glycol led to increased dissolution rates, while initial extrusion with tripalmitin led to decreased dissolution rates compared to the dissolution characteristics of extrudates containing the same composition produced by one-step extrusion. Thus, two-step solid lipid extrusion can successfully be used as a process to modify the dissolution behavior of extrudates.

Similar content being viewed by others

References

Jones C, Burtan MA, Gray BN, Hodgkin J. In vitro release of cytotoxic agents from ion exchange resins. J Control Release. 1989;8:251–7.

Bagyalakshmi J, Vamskrishna RP, Manavalan R, Ravi TK, Manna PK. Formulation development and in vitro evaluation of membrane-moderated transdermal systems of ampicillin sodium in ethanol: pH 4.7 buffer solvent system. AAPS Pharm Sci Tech. 2007;8:E1–6.

Ozguney I, Shuwisitkul D, Bodmeier R. Development and characterization of extended release Kollidon® SR mini-matrices. Eur J Pharm Biopharm. 2009;73:140–5.

Theeuwes F. Elementary osmotic pump. J Pharm Sci. 1975;64:1987–99.

Gallardo D, Skalsky D, Kleinebudde P. Controlled release solid dosage forms using combinations of (meth)acrylate copolymers. Pharm Dev Technol. 2008;13:413–23.

Douglas SJ, Davis SS, Illum L. Nanoparticles in drug delivery. CRC Crit Rev Ther Drug Carr Syst. 1987;3:233–61.

Oppenheim RC. Solid colloidal drug delivery systems: nanoparticles. Int J Pharm. 1981;8:217–34.

Fites AL, Banker GS, Smolen VF. Controlled drug release through polymeric films. J Pharm Sci. 1970;59:610–3.

Samuelov Y, Donbrow M, Friedman M. Sustained release of drugs from ethylcellulose–polyethylene glycol films and kinetics of drug release. J Pharm Sci. 1979;68:325–9.

Zentner GM, Rork GS, Himmelstein KJ. Osmotic flow through controlled porosity films: an approach to delivery of water soluble compounds. J Control Release. 1985;2:217–29.

Muhammed NA, Boisvert W, Harris MR, Weiss J. Modifying the release properties of Eudragit L30D. Drug Dev Ind Pharm. 1991;17:2497–509.

Thommes M, Kleinebudde P. Use of k-carrageenan as alternative pelletisation aid to microcrystalline cellulose in extrusion/spheronisation. II. Influence of drug and filler type. Eur J Pharm Biopharm. 2006;63:68–75.

Henrist D, Remon JP. Influence of the process parameters on the characteristics of starch based hot stage extrudates. Int J Pharm. 1999;189:7–17.

Lyons JG, Blackie P, Higginbotham CL. The significance of variation in extrusion speeds and temperatures on a PEO/PCL blend based matrix for oral drug delivery. Int J Pharm. 2008;351:201–8.

Davis SS, Illum L. Polymeric microspheres as drug carriers. Biomaterials. 1999;9:111–5.

Hamdani J, Moes AJ, Amighi K. Development and evaluation of prolonged release pellets obtained by the melt pelletization process. Int J Pharm. 2002;245:167–77.

Prabhu S, Ortega M, Ma C. Novel lipid based formulations enhancing the in vitro dissolution and permeability characteristics of a poorly water-soluble model drug, piroxicam. Int J Pharm. 2005;301:209–16.

Qi S, Deutsch D, Craig DQ. An investigation into the mechanism of drug release from taste-masking fatty acid microspheres. J Pharm Sci. 2008;97:3842–54.

Hamdani J, Moes AJ, Amighi K. Physical and thermal characterization of Precirol® and Compritol® as lipophilic glycerides used for the preparation of controlled release matrix pellets. Int J Pharm. 2003;260:47–57.

Humberstone AJ, Charman WN. Lipid based vehicles for the oral delivery of poorly water soluble drugs. Adv Drug Deliv Rev. 1997;25:103–28.

Jannin V, Musakhanian J, Marchaud D. Approaches for the development of solid and semi-solid lipid-based formulations. Adv Drug Del Rev. 2008;60:734–46.

Michalk A, Kanikanti VR, Hamann HJ, Kleinebudde P. Controlled release of active as a consequence of the die diameter in solid lipid extrusion. J Control Release. 2008;132:35–41.

Windbergs M, Strachan CJ, Kleinebudde P. Understanding the solid-state behavior of triglyceride solid lipid extrudates and its influence on dissolution. Eur J Pharm Biopharm. 2009;71:80–7.

Breitkreutz J, El Saleh F, Kiera C, Kleinebudde P, Wiedey W. Pediatric drug formulations of sodium benzoate: II. Coated granules with a lipophilic binder. Eur J Pharm Biopharm. 2003;53:255–60.

Pinto J, Silverio NP. Assesment of the extrudability of three different mixtures of saturated polyglycolysed glycerides by determination of the “specific work of extrusion” and cappillar rheometry. Pharm Dev Technol. 2001;6:117–28.

Reitz C, Strachan C, Kleinebudde P. Solid lipid extrudates as sustained-release matrices: the effect of surface structure on drug release properties. Eur J Pharm Sci. 2008;35:335–43.

Verhoeven E, De Beer TRM, Schacht E, Van den Mooter G, Remon JP, Vervaet C. Influence of polyethylene glycol/polyethylene oxide on the release characteristics of sustained-release ethylcellulose mini-matrices produced by hot-melt extrusion: in vitro and in vivo evaluations. Eur J Pharm Biopharm. 2009;72:463–70.

Herrmann S, Mohl S, Siepmann F, Siepmann J, Winter G. New insights into the role of polyethylene glycol acting as protein release modifier in lipidic implants. Pharm Res. 2007;8:1527–37.

Windbergs M, Strachan CJ, Kleinebudde P. Tailor-made dissolution profiles by extruded matrices based on lipid polyethylene glycol mixtures. J Control Release. 2009;137:211–6.

Windbergs M, Strachan CJ, Kleinebudde P. Influence of structural variations on drug release from lipid/polyethylene glycol matrices. Eur J Pharm Sci. 2009;37:555–62.

Rodriguez-Gonzalez FJ, Virgilio N, Ramsay BA, Favis BD. Influence of melt drawing on the morphology of one- and two-step processed LDPE/Thermoplastic starch blends. Adv Polym Tech. 2003;22:297–305.

Hagemann JW. Thermal behaviour and polymorphism of acylglycerides. In: Garti N, Sato K, editors. Crystallization and polymorphism of fats and fatty acids. New York: Marcel Dekker; 1988. p. 9–95.

Craig DQM, Newton JM. Characterisation of polyethylene glycols using differential scanning calorimetry. Int J Pharm. 1991;74:33–41.

Marciniec B, Stawny M, Kozak M, Naskrent M. The effect of ionizing radiation on chloramphenicol. J Therm Anal Calorim. 2006;84:741–6.

Sarisuta N, Kunstitchai S, Pichert L, Mueller BW. Drug solubility in phospholipid carrier as a predictive parameter for drug recovery in microparticles produced by the aerosol solvent extraction system (ASES) process. Drug Dev Ind Pharm. 2007;33:932–44.

Windbergs M, Jurna M, Offerhaus HL, Herek JL, Kleinebudde P, Strachan CJ. Chemical imaging of oral solid dosage forms and changes upon dissolution using coherent anti-Stokes Raman scattering. Anal Chem. 2009;81:2085–91.

Acknowledgments

The Sasol GmbH and Clariant are acknowledged for generous provision of their substances.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Windbergs, M., Gueres, S., Strachan, C.J. et al. Two-Step Solid Lipid Extrusion as a Process to Modify Dissolution Behavior. AAPS PharmSciTech 11, 2–8 (2010). https://doi.org/10.1208/s12249-010-9395-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-010-9395-y