Abstract

Purpose

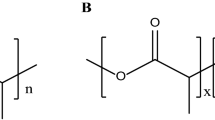

It has recently been shown that the addition of polyethylene glycol 6000 (PEG) to lipidic implants fundamentally affects the resulting protein release kinetics and moreover, the underlying mass transport mechanisms (Herrmann, Winter, Mohl, F. Siepmann, & J. Siepmann, J. Control. Release, 2007). However, it is yet unclear in which way PEG acts. It was the aim of this study to elucidate the effect of PEG in a mechanistic manner.

Materials and Methods

rh-interferon α-2a (IFN-α)-loaded, tristearin-based implants containing various amounts of PEG were prepared by compression. Protein and PEG release was monitored in phosphate buffer pH 4.0 and pH 7.4. IFN-α solubility and stability were assessed by reverse phase and size exclusion HPLC, SDS PAGE, fluorescence and FTIR.

Results

Importantly, in presence of PEG IFN-α was drastically precipitated at pH 7.4. In contrast, at pH 4.0 up to a PEG concentration of 20% no precipitation occurred. These fundamental effects of PEG on protein solubility were reflected in the release kinetics of IFN-α from the tristearin implants: At pH 7.4 the protein release rates remained nearly constant over prolonged periods of time, whereas at pH 4.0 high initial bursts and continuously decreasing release rates were observed. Interestingly, it could be shown that IFN-α release was governed by pure diffusion at pH 4.0, irrespective of the PEG content of the matrices. In contrast, at pH 7.4 both—the limited solubility of the protein as well as diffusion through tortuous liquid-filled pores—are dominating.

Conclusions

For the first time it is shown that the release of pharmaceutical proteins can be controlled by an in-situ precipitation within inert matrices.

Similar content being viewed by others

References

S. Herrmann, G. Winter, S. Mohl, F. Siepmann, and J. Siepmann. Mechanisms controlling protein release from lipidic implants: effects of PEG addition. J. Control. Release (2007). http://www.sciencedirect.com/science/journal/01683659.

J. L. Cleland. Protein delivery from biodegradable microspheres. Pharm. Biotechnol. 10:1–43 (1997).

W. R. Gombotz and D. K. Pettit. Biodegradable polymers for protein and peptide drug delivery. Bioconjug. Chem. 6:332–351 (1995).

J. Siepmann and A. Goepferich. Mathematical modeling of bioerodible, polymeric drug delivery systems. Adv. Drug Deliv. Rev. 48:229–247 (2001).

V. R. Sinha and A. Trehan. Biodegradable microspheres for protein delivery. J. Control. Release 90:261–280 (2003).

R. Bawa, R. A. Siegel, B. Marasca, M. Karel, and R. Langer. An explanation for the controlled release of macromolecules from polymers. J. Control. Release 1:259–267 (1985).

R. A. Siegel and R. Langer. Controlled release of polypeptides and other macromolecules. Pharm. Res. 1:2–10 (1984).

R. A. Siegel, J. Kost, and R. Langer. Mechanistic studies of macromolecular drug release from macroporous polymers. I. Experiments and preliminary theory concerning completeness of drug release. J. Control. Release 8:223–236 (1989).

K. Fu, A. M. Klibanov, and R. Langer. Protein stability in controlled-release systems. Nat. Biotech. 18:24–25 (2000).

M. Morlock, H. Koll, G. Winter, and T. Kissel. Microencapsulation of rh-erythropoietin, using biodegradable poly(D, L-lactide-co-glycolide). Protein stability and the effects of stabilizing excipients. Eur. J. Pharm. Biopharm. 43:29–36 (1997).

S. P. Schwendeman, M. Cardamone, A. Klibanov, R. Langer, and M. R. Brandon. Stability of proteins and their delivery from biodegradable polymer microspheres. Drugs Pharm. Sci. 77:1–49 (1996).

M. van de Weert, W. E. Hennink, and W. Jiskoot. Protein instability in poly(lactic-co-glycolic acid) microparticles. Pharm. Res. 17:1159–1167 (2000).

A. Maschke, A. Lucke, W. Vogelhuber, C. Fischbach, T. Appel, T. Blunk, and A. Goepferich. Lipids: an alternative material for protein and peptide release. In A.C.S. Symp. Ser. 79 (Carrier-Based Drug Delivery), 2004, pp. 176–196.

T. Pongjanyakul, N. J. Medlicott, and I. G. Tucker. Melted glyceryl palmitostearate (GPS) pellets for protein delivery. Int. J. Pharm. 271:53–62 (2004).

H. Reithmeier, J. Herrmann, and A. Goepferich. Lipid microparticles as a parenteral controlled release device for peptides. J. Control. Release 73:339–350 (2001).

W. Vogelhuber, E. Magni, M. Mouro, T. Spruss, C. Guse, A. Gazzaniga, and A. Goepferich. Monolithic triglyceride matrices: a controlled-release system for proteins. Pharm. Dev. Technol. 8:71–79 (2003).

P. Y. Wang. Lipids as excipient in sustained release insulin implants. Int. J. Pharm. 54:223–230 (1989).

S. Mohl and G. Winter. Continuous release of rh-interferon alpha-2a from triglyceride matrices. J. Control. Release 97:67–78 (2004).

R. L. Cleek, K. C. Ting, S. G. Eskin, and A. G. Mikos. Microparticles of poly(DL-lactic-co-glycolic acid)/poly(ethylene glycol) blends for controlled drug delivery. J. Control. Release 48:259–268 (1997).

W. J. Lin and C. C. Yu. Comparison of protein loaded poly(γ-caprolactone) microparticles prepared by the hot-melt technique. J. Microencapsul. 18:585–592 (2001).

J. W. Jiang and S. P. Schwendeman. Stabilization and controlled release of bovine serum albumin encapsulated in poly(D, L-lactide) and poly(ethylene glycol) microsphere blends. Pharm. Res. 18:878–885 (2001).

J. M. Péan, F. Boury, M. C. Venier-Julienne, P. Menei, J. E. Proust, and J. P. Benoit. Why does PEG 400 co-encapsulation improve NGF stability and release from PLGA biodegradable microspheres? Pharm. Res. 16:1294–1299 (1999).

I. J. Castellanos, R. Crespo, and K. Griebenow. Poly(ethylene glycol) as stabilizer and emulsifying agent: a novel stabilization approach preventing aggregation and inactivation of proteins upon encapsulation in bioerodible polyester microspheres. J. Control. Release 88:135–145 (2003).

S. Mohl. The development of a sustained and controlled release device for pharmaceutical proteins based on lipid implants. PhD thesis, LMU Munich, Munich (2004). Document available from http://edoc.ub.uni-muenchen.de/.

J. M. Vergnaud. Controlled Drug Release of Oral Dosage Forms. Ellis Horwood Limited, Chichester (1993).

J. M. Harris. Poly(ethylene glycol) Chemistry: Biotechnical and Biomedical Applications. Plenum, New York (1992).

A. McPherson. Introduction to protein crystallization. Methods 34:254–265 (2004).

T. Arakawa and S. N. Timasheff. Mechanism of poly(ethylene glycol) interaction with proteins. Biochem. 24:6756–6761 (1985).

D. H. Atha and K. C. Ingham. Mechanism of precipitation of proteins by polyethylene glycols, analysis in terms of excluded volume. J. Biol. Chem. 256:12108–12117 (1981).

I. L. Shulgin and E. Ruckenstein. Preferential hydration and solubility of proteins in aqueous solutions of polyethylene glycol. Biophys. Chem. 120:188–198 (2006).

B. Shenoy, Y. Wang, W. Shan, A. L. and Margolin. Stability of crystalline proteins. Biotechnol. Bioeng. 73:358–369 (2004).

J. C. Falkner, A. M. Al-Somali, J. A. Jamison, J. Zhang, S. L. Adrianse, R. L. Simpson, M. K. Calabretta, W. Radding, G. N. Phillips, Jr., and V. L. Colvin. Generation of size-controlled, submicrometer protein crystals. Chem. Mater. 17:2679–2686 (2005).

R. T. Bartus, M. A. Tracy, D. F. Emerich, and S. E. Zale. Sustained delivery of proteins for novel therapeutic proteins. Science 281:1161–1162 (1998).

O. L. Johnson, W. Jaworowicz, J. L. Cleland, L. Bailey, M. Charnis, E. Duenas, C. Wu, D. Shepard, S. Magil, T. Last, A. J. S. Jones, and S. D. Putney. The stabilization and encapsulation of human growth hormone into biodegradable microspheres. Pharm. Res. 14:730–735 (1997).

O. L. Johnson, J. L. Cleland, H. J. Lee, M. Charnis, E. Duenas, W. Jaworowicz, D. Shepard, A. Shihzamani, A. J. S. Jones, and S. D. Putney. A month-long effect from a single injection of microencapsulated human growth hormone. Nature Med. 2:795–799 (1996).

P. van de Wetering, A. T. Metters, R. G. Schoenmakers, and J. A. Jeffrey. Poly(ethylene glycol) hydrogels formed by conjugate addition with controllable swelling, degradation, and release of pharmaceutically active proteins. J. Control. Release 102:619–627 (2005).

L. P. Stratton, A. Dong, M. C. Manning, and J. F. Carpenter. Drug delivery matrix containing native protein precipitates suspended in a poloxamer gel. J. Pharm. Sci. 86:1006–1010 (1997).

A. Dong, P. Huang, and W. S. Caughey. Protein secondary structures in water from second derivative amid I infrared spectra. Biochemistry 29:3303–3308 (1990).

V. K. Sharma and D. S. Kalonia. Temperature- and pH-induced multiple partially unfolded states of recombinant human Interferon-α2a: Possible Implications in protein stability. Pharm. Res. 20:1721–1729 (2003).

W. Wang. Protein aggregation and its inhibition in biopharmaceutics. Int. J. Pharm. 289:1–30 (2005).

Dustrup. Interferon formulations. US Pat. Appl. Publ. 41 (2003).

E. Maeyer and P. Somer. Influence of pH on interferon production and activity. Nature 194:1252–1253 (1962).

Acknowledgements

This study was financially supported by the Centre de Coopération Franco-Bavarois. We further express our grateful thanks to Roche Diagnostics (Penzberg, Germany) for the supply of interferon α-2a and Sasol (Witten, Germany) for the donation of the lipids.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Herrmann, S., Mohl, S., Siepmann, F. et al. New Insight into the Role of Polyethylene Glycol Acting as Protein Release Modifier in Lipidic Implants. Pharm Res 24, 1527–1537 (2007). https://doi.org/10.1007/s11095-007-9271-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-007-9271-y