Abstract

Slope stabilities are mainly designed using the conventional design approach (CDA), where the limit equilibrium methods (LEMs) are performed. Fellenius and Bishop’s simplified methods are the two commonly LEMs adopted as recommended in most design codes. In the design process of CDA, the safety factors (FS) of slopes are checked with specified FSs to ensure stability. The CDA has inherent drawbacks because the design process does not account for uncertainties. Moreover, different LEMs using different assumptions to solve the safety factors might include some amount orders of approximations. This study conducts probabilistic analyses, i.e., Monte Carlo simulations (MCSs) and uncertainty quantification, to obtain insights into the two LEMs applied to clay and sand slopes. The results reveal that the reliability indexes (RIs) obtained from the two LEMs-based MCSs are relatively identical for the same slope. Concerning the soil types, however, the RIs of the clay slope are significantly lower than those estimated for the sand slope, regardless of the LEMs used. The uncertainty quantifications for the clay slopes reveal that the two LEMs have relatively similar bias factors regarding FSs. Nevertheless, using the Fellenius method underestimates the probabilistic safety (about 17% in terms of the mean of FSs) for the sand slope compared to Bishop’s simplified method. Moreover, the coefficients of variation of FS obtained from the clay slope are consistently larger than those from the sand slope. These observations imply that the clay slope is more uncertain than the sand slope, and the Fellenius method results in lower FSs for sand slopes. Therefore, the FSs specified in the design codes should be connected to the soil type or the LEMs used to achieve the same probabilistic safety levels. Finally, the equivalent FSs associated with a RI of 1.75 are derived for each slope and each LEM used.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In design practices, soil slopes are mainly designed using a conventional design approach (CDA) [1,2,3], wherein the safety factors (FSs) of the design solutions are commonly checked with a minimum value of FS specified in design codes. Notably, uncertainties that are inherently involved in the soil media are not accounted for in the CDA; hence, design solutions obtained from CDA are not uniform and inconsistent [3, 4]. As a result, it is challenging to save investment costs and efficiently use materials when design solutions are leaned on a single FS [5, 6]. For example, a design solution may require a higher price but not as reliable as a cheaper one, although they are all designed with the same FS.

Recently, probabilistic analyses have been implemented to assess the probabilistic outcomes, such as the failure probability or reliability index (RI) of the geotechnical problems [3, 7, 8]. Three methods, including the mean value first-order second-moment method (MVFOSM), the first-order reliability method (FORM), and Monte Carlo simulation (MCS), are commonly applied to assess probabilistic safety levels. MVFOSM, the simplest method, is the earliest procedure employed to deal with uncertainties [4, 8, 9]. MVFOSM uses Taylor’s series to approximate the first two terms of statistical properties, i.e., the mean and standard deviation, to assess RIs. However, the MVFOSM cannot derive statistical information on the performance functions; hence, the Normal or Lognormal distributions are frequently assumed to evaluate RIs. However, considering different distributions may result in other solutions. Moreover, the results obtained from MVFOSM also differ for different limit equations utilized.

In FORM, the performance functions are transformed into the standard normalized space and linear approximated at the most probable points. The RI is then estimated by the distance from the most probable points to the origin. The main drawback of the FORM is it requires derivative calculations; hence, it is solely applicable to explicit performance functions [3, 7, 10]. MCS is a straightforward and robust method to evaluate failure probability. In addition, MCS also derives statistical information on the performance functions, making it superior to the two abovementioned methods. Particularly, MCS is the most suitable method to directly apply to both explicit and implicit performance functions [10,11,12]. Recently, the MCSs have been progressively implemented with computer aid to overcome the repetitive calculations required in MCS.

Fellenius and Bishop’s simplified methods, based on the limit equilibrium calculations, are the two most common slice methods and are frequently recommended for design practices [1, 2, 13,14,15]. The minimum FSs are differently prescribed for each method. For example, a safety factor of 1.2 is specified for the Fellenius method. In contrast, a value of 1.4 is set as the minimum threshold for FS when Bishop’s simplified method (BSM) is executed to assess the stability of roads constructed on soft foundations in Vietnam [1]. It should be recalled that the interaction forces between slices are neglected in the Fellenius model (FM), whereas only the shear interaction is omitted in BSM; therefore, different FSs recommended in the codes seem reasonable. However, the quantifications of differences are not presented, and the thresholds are roughly specified.

This study focuses on the probabilistic analyses, i.e., using MCS integrated with two slice methods of Fellenius and Bishop to assess the probabilistic terms of the clay and sand slopes. After that, the uncertainty quantifications of the two limit equilibrium methods (LEMs) and two slopes are examined. For this purpose, MATLAB programs are developed to calculate the safety factors of slopes using FM and BSM deterministically. Other MATLAB programs are developed for MCS and uncertainty quantification. The programs are applied to two slopes, including clay and sand slopes, and the results and observations are presented.

Probabilistic slope stability and uncertainty quantification

Monte Carlo simulation integrated with limit equilibrium methods

Reliability analyses assess the failure probability of the performance of the problems at hand. In reliability analysis, a limit state function needs to be defined first; then, some probabilistic analyses are applied to evaluate the failure probability of the performance. Since the probabilistic analyses are implemented, the uncertainties inherently involved in the problems need to be identified. Based on the uncertainties of the input variables, the probability of failure or RIs are calculated. This makes the probabilistic analysis superior to the CDA. MVFOSM, FORM, and MCS are the three most common reliability methods, and MCS is carried out in this study because it can deal with implicit problems [4, 12, 16].

The method of MCS is utilized because it provides not only the probability of failure but also insights into the distribution of the performance function. Moreover, MCS is the most suitable method to assess the system failure probability. In the slope reliability analyses, each failure surface is considered as a failure mode, and the slope will fail if any failure mode occurs. So, the limit state function can be defined in Eq. (1). In the equation, x is a vector consisting of n uncertain variable Xi (i = 1 − n). FSmin is the minimum safety factor obtained from all potential failure surfaces. [FS] is the limit state value of FS. Equation (1) indicates that the slope is stable if FSmin is not lower than the limit value and vice versa.

In this study, the safety factors estimated for all potential failures are determined using Fellenius and Bishop’s simplified methods since they are the two most common methods recommended in the design practice. The safety factors evaluated by FM and BSM are written in Eqs. (2) and (3), respectively.

In the equations, c′ and f′ are effective cohesion and friction angle of the soil at the failure surface, respectively. Dl is the base length of the slice, whereas a is the angle of the baseline with the horizontal direction. u is pore pressure, and W denotes the weight of the slice. The pore pressure in the equations is zero without consideration of groundwaters. It is worth noting that both FM and BSM are classified as limit equilibrium methods wherein the failure mass is divided into slices, and the static equilibrium conditions are used to determine the safety factors. BSM is reported as a better method because it considers the interaction in the horizontal direction between the slices. Meanwhile, the interactions are totally neglected in FM [17]. Noticeably, the FS presents on both sides of Eq. (3); therefore, it is determined through a trial and error process.

The failure probability or the probability that g(x) is lower than zero is defined in Eq. (4) as an integral over the domain of all uncertain variables.

In the equation, indicator function I takes a value of one if g(x) is negative and zero if g(x) is nonnegative. fi is the probability density function of the uncertain variable Xi.

It is difficult to directly determine failure probability using Eq. (4) since it includes n layers of integral. Thus, MCS is commonly applied to derive the approximate solution. Using MCS, the failure probability in Eq. (4) can be predicted by Eq. (5).

In the equation, NMCS is the size of the simulation and the indicator function I is defined previously. Thus, the numerator indicates the number of failure events recorded in the simulation. It is seen in Eq. (5) that the probability of failure estimated is closer to the exact solution in Eq. (4) if the size of the simulation (NMCS) is increased. The coefficient of variation (COV) of the Pf estimated using Eq. (5) can be calculated using Eq. (6).

Finally, the reliability index associated with the failure probability can be estimated using Eq. (7).

where Φ is the cumulative probability function of the standard normal distribution.

Uncertainty quantification

Based on the MCS, the uncertainty of each deterministic model and each slope are quantified. From the MCS, realizations of FS estimated using each LEM are established, and their statistical properties are estimated. The mean value (µFS) and standard deviation (sFS) of realizations can be determined using Eqs. (8) and (9), respectively.

In the above equations, FSi denotes the ith FS that is determined for the ith sample of input x.

Two scalar values, i.e., bias factor (lFS) and COV (COVFS), are commonly employed to indicate the uncertainty of models, as shown in Eqs. (10) and (11), respectively.

FSn in Eq. (10) is the nominal safety factor estimated using the nominal input variables. It is seen in Eq. (10) that the nominal safety factor is underestimated if the bias factor is higher than one and vice versa. Moreover, the higher the COV, the more uncertain the model is estimated, as can be seen in Eq. (11).

Numerical simulation

This work investigates two slope examples, i.e., Example 1 and Example 2, corresponding to Figs. 1 and 2. The slope in Example 1, which is adapted from [18, 19], is made of two clayed layers placed on a hard layer. Example 2, adapted from [18], is called sand slope since cohesions are relatively small.

Three levels of uncertainties, reflected by their COVs, are recommended in the previous studies for soil strength parameters [3, 20]. They are the low, medium, and high variations, as listed in Table 1. The values in paratheses indicate the range of referenced values, and the outside values are employed in the present studies. It should be noted that the soil density is generally well-calibrated and also shows minor effects on the safety factor; hence, the same COV of 5% is adopted in this study. The uncertainties of cohesion are commonly larger than those for friction angle, as reported in the literature. All variables are assumed to have normal distributions in this work.

It should be noted that this study focuses on investigations of LEMs and their model uncertainties when applied to the clay and sand slopes. Therefore, the slope geometries and soil stratifications of the two examples are kept as those in the references (i.e., Refs. [18, 19]). Moreover, the soil properties in Example 2 are taken as those in the reference, whereas the soil properties in Example 1 are adjusted to make the safety factors of the two examples reasonably similar. Namely, the cohesions of the two clays in Example 1 are modified from 120 kPa and 160 kPa (interest readers are referred to Table 1 in [18] or Table 1 in [19]) to 80 kPa and 120 kPa. Using the modified cohesions, the deterministic safety factor for Example 1 reduces from 1.993 (reported in [19]) to 1.451 (as presented later in Fig. 3). This safety factor is reasonably close to those specified in the design practices and the safety factor estimated for Example 2 (i.e., 1.406 as reported in [18] and 1.405 as evaluated in Fig. 4).

Results and discussion

In this section, the failure modes predicted by the two LEMs in deterministic calculations are first investigated for the two considered slopes. After that, the probabilistic analyses and uncertainty quantifications are executed. Because LEMs-based MCSs are implicit processes and expensive to perform, the feasible sizes are first explored to find the reasonable size for MCSs. The probabilistic results obtained for the two slopes based on the two LEMs are presented using the selected size for MCSs. Each LEM is based on different assumptions; hence, the statistical properties of each model are examined and depicted by the bias factors of the safety factors. It will be found that model uncertainties depend on not only the LEMs but also the soil types; therefore, different values of safety factors need to be specified for design practices to ensure that the same probabilistic safety levels can be achieved. Eventually, a target RI of 1.75 is employed, and the equivalent FSs are determined for each LEM and each type of slope.

Differences in failure modes

In CDA, numerous potential failure surfaces are generated, and the safety factors are predicted for each candidate failure mode. The most critical failure surface is then identified by the lowest FS estimated among all potential surfaces. In Example 1, 1600 potential failures are employed, while 4000 candidate failure surfaces are used in Example 2. Then, both FM and BSMs are implemented, and the results are reported in Figs. 3 and 4 for Example 1 and Example 2, respectively. It is seen that the critical failure surfaces are identical for the two LEMs used in the case of the clay slope. However, the failure modes are different for the two LEMs when the sand slope is examined. Notably, the deterministic FS is the same for the clay slope regardless of the methods used. For the sand slope, however, the deterministic FS estimated using the FM (1.229) is lower than that using BSM (1.405), as recorded in Fig. 4. Here, it is evidenced that the interaction forces between the slices can be properly neglected for the clay soils, but for sands, omitting the interactions like FM might result in a lower FS.

Failure probability comparisons

The results obtained from MCSs are sensitive to the size of MCS, i.e., the value of NMCS. Thus, the size of MCS is surveyed to find a suitable value that provides stable results. The low variation in Table 2 is utilized to find the proper size of MCS since it is expected to have the lowest failure probability. Figure 5 presents the failure probabilities and their COVs estimated from different sizes of MCSs. It is seen in the figures that the accuracy of the failure probability will be improved when the size of MCSs is increased. The figures show that the 100,000 and 600,000 are reasonable sizes to derive stable results in MCS for Example 1 and Example 2, respectively. Using the suggested sizes of MCS, the COVs of the predicted failure probabilities might be lower than 20%, which is lower than the value recommended in previous studies [10, 21]. These sizes of MCS will be applied to other cases of uncertain variations.

The results of RIs are reported in Table 3 for all levels of uncertainty and two slope examples wherein two LEMs are used. The second column of the table summarises the nominal FSs, which are assessed deterministically. Figure 6 summarizes the failure probabilities regarding the uncertain variations. It is seen in the table and the figure that the RIs show an inverse relationship with the orders of variations, and the failure probabilities show the same trend with the variation levels. The probabilistic results (RIs and failure probabilities) are relatively identical for each example, considering the same uncertain levels. Particularly, BSM-based MCSs provide slightly lower probabilistic safety for the sand slope compared to FM-based MCSs, although their nominal safety factors are higher than those of FM. Interestingly, the RIs of Example 2 are significantly larger than those for Example 1, even though they have relatively similar deterministic FS. This observation evidenced that using the same specified FS does not ensure a uniform probabilistic safety level. For instance, failures might occur more frequently (about seven times) in the clay slope than in the sand slope if the low variation is considered. Noticeably, failure events might dramatically increase (more than 200 times) in the clay slope compared to the sand slope when high variation is accounted for. This investigation implies that different FS should be specified for each soil type in slopes to achieve uniform and consistent probabilistic safety levels.

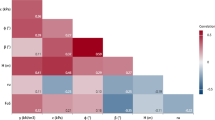

Bias model and statical properties of each model

Figures 7 and 8 present typical histograms of FSs obtained from the MCS for Example 1 and Example 2, considering the low variations. In the figures, the upper panels show the results from FM, whereas the lower panels report for BSM-based MCS. The nominal FSs of each model are also shown in the figures. It is seen in the figures that bias factors estimated using Eq. (10) for clay slope are close to one. This phenomenon is the same for the sand slope using BSM. However, the bias factor is larger than one when FM-based MCS is applied to the sand slope. That means the nominal FS estimated deterministically using FM is lower than the mean of the realizations, as captured in Fig. 8a. Interestingly, the mean values of FSs estimated using the two LEMs are close to each other for the two slopes. The COVs reported in Figs. 7 and 8 are relatively similar for each slope. Moreover, the COVs illustrate that the uncertainties in the clay slope are significantly larger than those for sand slopes; hence, their RIs are dramatically reduced compared to the sand slope. These observations show the same behaviors as reported previously in Table 3.

Similarly, Tables 2 and 4 summarized, respectively, the bias factors and the COVs of the FSs for all considered cases. It is seen in Table 2 that regardless of the LEMs used, the bias factors are relatively identical for the clay slope, and the bias factors slightly increase when the uncertainty levels increase. For sand slope, however, the bias factors of FS are always larger than unity if FM is utilized. Contrastingly, the bias factors are close to unity for sand slope when BSM is executed. These observations imply that the two models of FM and BSM show the same behaviour for clayed soil. For sand slope, the FM presents an underestimate of FS; meanwhile, BSM shows minor biases.

COVs in Table 4 indicate that the higher the variation of the input variables, the larger the uncertainty of the outcome FSs. The COVs are generally similar for the two LEMs used. Therefore, the outcome RIs are not considerably different when using the two LEMs, as reported in Table 3, because they are inversely relative to the COVs [10]. The COVs obtained from the clay slope are significantly larger than those from the sand slope. This explains why their RIs are considerably lower than those for the sand slope, as reported in Table 3.

Equivalent FSs for a target RI of 1.75

As discussed above, the two slice models show different uncertain models. In addition, larger nominal FSs do not ensure larger RIs, as evidenced by higher nominal FS but lower RI in the case of the clay slope (see Table 3). This section identifies the equivalent nominal FSs for each slope and each LEM to achieve a uniform probabilistic safety level. For this purpose, the same target RI of 1.75 is assumed, and the associated FSs are determined for each slope and each LEM.

Figure 9 summarizes the FSs for each method concerning the target RI of 1.75. Figure 9a presents results for Example 1, where the cohesions of the clay soils are repetitively modified, and MCS-based reliability analysis is executed until the outcome RI is close enough to the target of 1.75. Similarly, Fig. 9b summarizes the results for Example 2. The figure indicates that the safety factors generally exhibit positive correlations with uncertain orders to achieve the same probabilistic safety level. That means the higher the uncertainties of the input value, the more significant FS should be employed and vice versa. Moreover, Fig. 9a shows that FM and BSM provide the same FS thresholds for the clay slope. On the other hand, Fig. 9b discloses that different values of FS should be specified for each LEM used to achieve the same probabilistic safety when the sand slope is considered. Particularly, the results indicate that different thresholds of FS need to be applied to different soil types to ensure the same probabilistic safety levels. Generally, the clay slope requires larger thresholds of FS compared to the sand slope. Furthermore, the differences are dramatically enlarged when the uncertainties increase. The reason is attributed to the wider gap between COV of strength properties in clay and sand when the high variation is considered, as shown in Table 1. The RIs of design solutions are expected to be close to the target RI regardless of the slice methods used or the type of soils when using the FSs calibrated; hence, uniform and consistent design solutions can be established.

Conclusions

This study investigates the probabilistic slope stability and uncertainty quantification of the two LEMs that are commonly employed in design practice. Monte Carlo simulation is carried out to assess the probabilistic safety levels. Three orders of variations are examined, and the strength properties of soil slopes are simulated as random variables. Both Fellenius and Bishop’s simplified methods are integrated with MCS to determine the safety factor for each simulation. The equivalent safety factors are finally evaluated to a given reliability index of 1.75 for each deterministic method and each type of soil slope. Based on the investigation, several important conclusions are derived as follows:

-

1.

FM and BSM show the same behaviors for the clay slope in both deterministic calculation and probabilistic assessments. Therefore, the more straightforward method of Fellenius is recommended for the design practice of clay slopes.

-

2.

Uncertainty quantifications reveal that FM underestimates safety factors, as evidenced by bias factors larger than one (about 1.17). Interestingly, the mean values obtained from MCSs are relatively identical for the two deterministic models employed. However, the outcome COVs of safety factors show positive correlations with the uncertain levels of input variables. The COVs of safety factors in the clay slope are considerably larger than those obtained from the sand slope, which explains why the reliability index in the clay slope is significantly smaller than that for the sand slope.

-

3.

The threshold values of FSs associated with a reliability index of 1.75 are determined for each slope and each order of variation. The threshold FSs exhibit a linear correlation with the uncertain orders. The different values of FS should be specified for sand slopes when FM or BSMs are utilized. Additionally, the clay slope requires significantly large nominal safety factors to achieve the same probabilistic safety levels in comparison with sand slopes.

References

Ministry of Transportation (2000) TCN 262–2000. Specification for surveying and desinging highway embankments on soft ground, vol 22. Hanoi, Vietnam

KPHA (2018) Design standard for port and harbor. Korea Port and Harbor Association, Certified Ministry of Land, Transport and Maritime Affairs in Korea. KPHA, Seoul, Korea

Phoon K-K, Ching J (2018) Risk and reliability in geotechnical engineering. CRC Press, New York. https://doi.org/10.1201/b17970

Doan NS, Huh J, Mac VH, Kim D, Kwak K (2020) Probabilistic risk evaluation for overall stability of composite caisson breakwaters in Korea. J Mar Sci Eng 8:1–19. https://doi.org/10.3390/jmse8030148

Gayton N, Mohamed A, Sorensen JD, Pendola M, Lemaire M (2004) Calibration methods for reliability-based design codes. Struct Saf 26:91–121. https://doi.org/10.1016/S0167-4730(03)00024-9

Paikowsky SG, Birgisson B, McVay M, Nguyen T, Kuo C, Baecher GB et al (2004) Load and resistance factor design (LRFD) for deep foundations, NCHRP Report 507. Transportation Research Board of the National Academies, Washington, DC, USA

Sekhavatian A, Janalizadeh Choobbasti A (2018) Comparison of point estimate and Monte Carlo probabilistic methods in stability analysis of a deep excavation. Int J Geo-Eng. https://doi.org/10.1186/s40703-018-0089-8

Osorio J, Viviescas JC, Osorio JP (2021) Probabilistic analysis of the active earth pressure on earth retaining walls for c-ϕ soils according to the Mazindrani and Ganjali method. Int J Geo-Eng 12:1–13. https://doi.org/10.1186/s40703-021-00148-1

Haldar A, Mahadevan S, Probability, (2000) Reliability and statistical methods in engineering design. Wiley, Hoboken

Doan NS (2022) Fully probabilistic approaches for calibration of load and resistance factors in the limit state design of foundations supporting caisson breakwaters. Ph.D. Thesis, Department of Architecture and Civil Engineering, Chonnam National University

Doan NS (2023) A study on the probabilistic safety assessment of the truss structure designed by the LRFD code. J Sci Technol Civ Eng HUCE 17:111–124. https://doi.org/10.31814/stce.nuce2023-17(1)-09

Doan NS, Huh J, Mac VH, Kim DH, Kwak K (2021) Calibration of load and resistance factors for breakwater foundations under the earthquake loading. Sustainability 13:1730. https://doi.org/10.3390/su13041730

MLIT (2009) Technical standard and commentaries for port and harbor facilities in Japan. Tokyo, Japan: Ministry of Land, Infrastructure, Transport and tourism (MLIT). Ports and Harbors Bureau

Ifediniru C, Ekeocha NE (2022) Performance of cement-stabilized weak subgrade for highway embankment construction in Southeast Nigeria. Int J Geo-Eng 13:1–16. https://doi.org/10.1186/s40703-021-00166-z

Hazari S, Ghosh S, Sharma RP (2020) Seismic analysis of slope considering log-spiral failure surface with numerical validation. Int J Geo-Eng. https://doi.org/10.1186/s40703-020-00118-z

Doan NS, Dang P, Van Huh J, Mac VH, Haldar A (2022) Efficient approach for calibration of load and resistance factors in the limit state design of a breakwater foundation. Ocean Eng 251:111170. https://doi.org/10.1016/j.oceaneng.2022.111170

Duncan JM, Wright SG, Brandon TL (2014) Soil strength and slope stability, 2nd edn. Wiley, New Jersey

Ji J, Low BK (2012) Stratified response surfaces for system probabilistic evaluation of slopes. J Geotech Geoenviron Eng 138:1398–1406. https://doi.org/10.1061/(asce)gt.1943-5606.0000711

Kang F, Han S, Salgado R, Li J (2015) System probabilistic stability analysis of soil slopes using gaussian process regression with latin hypercube sampling. Comput Geotech 63:13–25. https://doi.org/10.1016/j.compgeo.2014.08.010

Youssef DS, Massih A, Soubra A, Low BK (2008) Reliability-based analysis and design of strip. Footings Bearing Capacit Fail 134:917–928

Ching J, Phoon K-K, Hu Y-G (2009) Efficient evaluation of reliability for slopes with circular slip surfaces using importance sampling. J Geotech Geoenviron Eng 135:768–777. https://doi.org/10.1061/(asce)gt.1943-5606.0000035

Author information

Authors and Affiliations

Contributions

NSD: Conceptualization, Methodology, Software, Validation, Resources, Writing—original draft, Writing—review & editing, Visualization.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Doan, N.S. Reliability analysis and uncertainty quantification of clay and sand slopes stability evaluated by Fellenius and Bishop’s simplified methods. Geo-Engineering 14, 22 (2023). https://doi.org/10.1186/s40703-023-00200-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-023-00200-2