Abstract

Increased cost associated with the used of high quality materials have led to the need for local soils to be used in civil engineering works. In this paper, geo-chemical approaches coupled with conventional geotechnical techniques has been used to investigate vertical and lateral peculiar engineering index properties (EIP) of micaschist derived soils from Mfou, Central-Cameroon for their uses in road construction. The X-ray diffraction (XRD) analysis conducted on the soils indicated the absence of swelling clays. The main mineral phases were quartz, kaolinite, goethite, magnetite and chlorite. Geo-chemical results show that the investigated soils are “true laterites” made up of 41 wt.% of Fe2O3, 35 wt.% of SiO2, 21 wt.% of Al2O3, 1.17 wt.% of K2O and 0.05 wt.% of CaO. The results of geotechnical tests suggest that the upper clayey layer (UCL) and bottom mottled clayey layer (MCL) of the weathering profiles are poorly graded soils with EIP (fines particles (FP) of 61 and 63%, plasticity index (PI) of 30 and 31%, Californian Bearing Ratio (CBR) at 95% of 21 and 19%), which do not allow their use as raw materials in road construction whereas, intermediate nodular layer (INL) are well graded soils having EIP (FP of 26%, PI of 26% and CBR of 39%) that meet the specification required for sub-base materials for light traffic roads. The relatively high sesquioxyde present in these residual soils may act as cementing agent, thereby making the compacted soils relatively brittle. The direct shear test results show that the soils have high bearing capacity (cohesion of 62 Kpa and 27.2° angle of internal friction) making them to be useful in slope stability and shallow foundation design. The comparison of the studied soils with some lateritic soils in Sub-Saharan Africa indicates that i) genesis and climatic conditions are potentials factors that influence EIP of lateritic soils, ii) lateritic soils developed under semi-arid conditions exhibits EIP better than those developed under tropicaland sub-tropical conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A considerable increase in soil utility for engineering works is expected as any country aspires towards improved infrastructural development. The relationship between all engineering infrastructure and their foundation soils is of paramount importance for designers and contractors. Incessant occurrence of road pavement deterioration and building collapse, mainly because of their poor geotechnical and mechanical properties has made it imperative for a proper understanding of the geotechnical properties of soils (Garg 2009). Soil is defined as a three-dimensional body with properties that reflect the impact of mankind, climate, vegetation, fauna and relief on the soil’s parent material over a variable time span (Deckers et al. 2001). The nature and relative importance of each of those “soil forming factors” varies in time and space. As far back as the eighteenth century, geologists identified that in warm, moist, temperate and tropical climates water percolating through rock has a strong weathering action (Millard 1993). Chemical reactions increase with an increase in rainfall and temperature, and accordingly soils from the tropics exhibit different engineering properties (Millard 1993). Despite the great effort that has been made by previous works to classify and differentiate tropical soils, a uniform nomenclature /classification system does not exist yet for these soils. Hence, the term “lateritic clays”, “lateritic gravels” and even “laterites” are still used by engineers to describe any reddish tropical soils (Northmore et al. 1992). Fortunately, for the engineering purposes it does not matter whether the classification is correct, but that the geological and engineering properties as predicted or derived from testing are reliable.

The soils used in road construction in “Sub-Saharan Africa” are mostly lateritic soils including lateritic gravels, lateritic clays and lateritic shales. Lateritic soils contribute to the general economy of the region where they are found (Lemougna et al. 2011). Their scope is very wide and include civil engineering, agronomic, mining research (iron, aluminum and manganese) deposits. In a tropical area such as Cameroon that is in a phase of infrastructural development, lateritic soils has been, and still a topic of interest and discussion. Due to the natural relative abundance of these soils, availability, favorable engineering properties, they have been very useful for construction of foundation, roads, airfields, low-cost housing and compacted fill in earth embankments (Gidigasu 1983; Autret 1983; Ekodeck 1984; Sikali and Mir-Emarati 1986; Bagarre 1990; Tardy 1992 Tockol et al. 1994; Ojo and Adeyemi 2003).

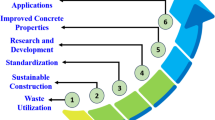

The road network in Cameroon covers a distance of about 50,000 km. Which About 5,000 km is paved, 18,016 km is unpaved, and 27,693 km are rural roads (Transport Policies in Sub-Saharan Africa” (TPSSA), 2004). According to the “TPSSA (2004)" report, about 90% of the total road network in Cameroon is made up of unpaved roads. Thus this limits trade exchanges between border countries and the link between the hinterland (high agricultural productivity area) and the biggest cities. Consequently, constraint the socio-economic development of the country. While several research activities have been done with regards to the engineering index properties (EIP), reliability and durability of soils used in road construction throughout the world (eg. Autret 1983; Bagarre 1990; Tardy 1992; Ojo and Adeyemi 2003; Bayewu et al. 2012), only few studies revealed the geotechnical characteristics of lateritic soils in Cameroon (eg. Sikali and Mir-Emarati 1986; Ekodeck 1985; Mbumbia et al. 2000; Onana 2010; Lemougna et al. 2011; Logmo et al. 2013). The results of their investigations showed that EIP of the lateritic soils in Cameroon vary according to the nature of the parent rocks and local climatic regime. Generally, they are of good to fair quality as raw materials used both in building and road constructions. However, as observed by Millogo et al. (2008) and references therein, lateritic soils chosen based only from the results of geotechnical tests behaved badly on the pavements after a short period. This behavior could be attributed to the insufficiency of the geotechnical tests justifying the choice of lateritic soils destined to the road construction. To backup this short coming, some authors (eg. Tockol 1994; Mahalinger-Iyer and Williams 1997; Millogo et al. 2008) suggest that chemical and mineralogical analysis must be conducted on lateritic soils in addition to the geotechnical classic tests. Accordingly, the purpose of this work is to combine geotechnical tests to chemical and mineralogical analysis to characterize micashist derived lateritic soils from Mfou, Central-Cameroon. Data from this study will not only contribute to evaluate the suitability of these soils for road construction but it will also provide baseline data for engineers, designers and contractors since the work was carried out when the road construction section Mfou-Nsimalen was on-going.

Study area

Administratively, Mfou is located in the Mefou and Afamba Division in the South-Eastern part of Yaounde. Geographically, the area under consideration lies between latitudes 3°40′ and 3°45′ and longitudes 11° 35′ and 11°40′ E, covering an estimated area of 85 km2 (Figure 1).

Despite being located at about 300 km from the coast, the area is subjected to maritime influence (Ndam et al. 1998). The climatic regime is Guinea equatorial and bimodal. It is characterized by four distinct seasons including two rainy season (from August to November and from April to June) and two dry season (from December to March and from June to July). The annual rainfall, annual average temperature and annual average relative humidity are 1600 mm, 24°C and 79%, respectively (Molua and Lambi 2006). The vegetation belongs to the dense moist forest type described by Vallerie (1995) as a semi-deciduous forest with Sterculiaceaes and Ulmaceaes as dominant species. As observed by Segalen (1967), this climatic regime promotes the physico-chemical alteration of the rocks in the southern part of Cameroon. The topography of the study site varies within a narrow range. It is characterized by asymmetrical gentle slopes and dissected shallow valleys. The land use is dominated by agricultural activities. The hydrographic network is heterogeneous and dense showing dendritic, parallel and rectangular facies.

The detailed background regarding the geology of the study area can be found in previous studies (eg., Gazel and Guiraudie 1967; Segalen 1967; Gidigasu 1983; Nzenti et al. 1988; Ekodeck 1984; Yongue 1986; Kamgang 1987; Onana 2010). Briefly, the basement is made up of metamorphic rocks of the central Neoproterozoic panafrican fold belt (Nzenti et al. 1988). These metamorphic rocks have been identified as greenschist bearing micaschist (Gazel and Guiraudie 1967).

Experiments

Sampling methodology

Prior to the sampling campaign, samples collection sites were selected on the 1:50,000 topographic map of Yaounde (sheet 4a NA – 32 – XXIV; source: National Institute of Cartography of Cameroon). Sample collection was undertaken in November 2010 where vertical and lateral variations of the weathering profiles were investigated. As shown in Figures 1, three holes (NKIL, NKOL and MFI) were dug and nine samples were collected from the upper clayey layer (UCL), intermediate nodular layer (INL) and bottom mottled clayey layer (MCL) of the weathering profiles. Undisturbed samples were collected from the UCL following the method described by Robitalle and Tremblay (1997). The method involved the placing of square template over the area to be sampled. The sample place was cleaned to remove the organo-mineral layer. A wood square template was fixed carefully on the pre-drilled hole in each corner to form a cage around the sample. The soil was excavated around the cage and the wood square template was later on carefully removed to avoid disturbance in the soil’s structure. A polyvinyl chlorite (PVC) cylinder with a diameter of 4.9 inches and length of 1 inch was inserted in the obtained cone of soil and later separated from it bottom part with a side walk scraper. Both sides were sealed with paraffin to prevent the exchange of moisture content between the sampled soil and the atmosphere. Disturbed samples were collected after undisturbed samples. At each site, samples were collected on a flat terrain to minimize the influence of topography on the engineering properties of the soils. The samples were then air-dried for 3 weeks and later subjected to engineering tests. Eighty kilograms of sample was collected from each layer of the holes and stored in bags. A sample of 10 kg of fresh rock was collected for petrographic studies. The color of the soil samples was determined using a Munsell color chart (1975).

Description and method of laboratory tests

Preparation of thin sections was carried out at the Institute of Geological and Mining Research (IRGM, Cameroon). Geotechnical and mechanical tests were done at the National Laboratory of Civil Engineering (LABOGENIE, Cameroon). X-ray diffraction (XRD) and X-ray fluorescence (XRF) were done at the Laboratory of Environmental Science and Engineering of University of Toyama (Japan).

Mineralogical and chemical analyses

Mineral content is the main factor controlling the size, shape, physical and chemical properties of soil mechanics. Two thin sections were prepared for the parent rock to decipher the texture, mineralogy and alteration. The slides were closely examined under plane polarized light. The stage of the microscope was rotated continuously to attain different views of the slides. Photomicrographs from each slide were taken under cross nicols to ascertain the compositional features. Detailed identification and description of the mineral composition were determined and their percentages were estimated.

Prior to XRD and XRF analysis, the samples were dried to remove moisture content and powdered until grain pass through sieve 80 μm. The XRD analyses was done using a Bruker D8 DISCOVER-TUS diffractometer equipped with a D8 goniometer with a precision of 1/10000° by a stepping motor and an optical encoder. The scan performed was recorded in 2θ in a range between 5 and 70 ° for a period of around 4 hours. The diffractograms were treated with DIFFRAC plus software (version 1.2.28).

The percentage of oxides (wt.%) in the soils was determined by X-ray spectrometric powder technique described by Leake et al. (1970). The test was performed using an X-Ray Spectrometer model EDX-700HS with Energy Dispersive. Only samples from intermediate nodular layer (INC) were subjected to the XRD and XRF analyses.

Engineering tests

Engineering tests were carried out to know the suitability of the sampled soils as compacted materials and for road performance. This involves i) the densimetric tests (specific gravity), ii) classification tests (grain size distribution, plasticity) and iii) geotechnical tests (compaction test, California Bearing Ratio and direct shear test).

The specific gravity which is the measure of the density of a soil relative to that of water was estimated by repeated weighing method as described by Bouassida and Boussetta (2007). Fifteen gram of the soil samples that passed through sieve of 0.425 mm was added to the pycnometer and weighed. Sufficient air-free distilled water was added to soil sample in the bottle and shaken to eliminate air indirection. The bottle and its content was weighed. The pycnometer was later filled with distilled water and weighed. To calculate the specific gravity of the samples, the following mathematical equation was used:

where P1 is the weight of the pycnometer, P2 is the weight of pycnometer containing sample, P3 is the weight of the bottle containing air-free distilled water and sample and P4 is the weight of the pycnometer filled with distilled water

The grain size distribution was determined following the NF P18-560 standard (AFNOR 1978) for particle size distribution by dry sieving and the NF P94-057 standard (AFNOR 1992) for particle size distribution by sedimentation. The liquid limit (LL) was measured and the plastic limit (PL) following the NF P94-051 standards (AFNOR 1993).

As recommended by the handbook of pavement design for tropical countries (CEBTP 1984), modified Proctor test was chosen for this study. The optimum moisture content (OMC) and the maximum dry density (MDD) were determined according to NF P 94–093 standard (AFNOR 1999).

The Californian Bearing Ratio test (CBR) after 4 days soaking with a surcharge weight of 5.5 kg was determined according to NF P94-078 standard (AFNOR 1997). The punching was achieved with a press Seditech made with a manometer for pressure measurement.

Direct shear test was used to determine a quantity known as the maximum past stress, which is often assumed to be the greatest effective overburden stress to which soil has ever been subjected. This test was determined using undisturbed samples following the standard method described by the NF P94-071-2 normalization (AFNOR 1999). Only the UCL sample was subjected to this test.

Results and discussions

Stratification

The weathering profile is made up of four visible layers (Figure 2): i) saprolite mottled clay layer, ii) intermediate nodular layer, iii) upper soft clayey layer and iv) organo-mineral, which has not been characterized. In the saprolite mottled clay layer (MCL), the micaschist architecture is partially preserved. This layer composed of red materials (5YR 5/8) with yellow patches. Altered garnets, quartz crystals and muscovite flakes are the most visible minerals of this layer. Transition with overlying layer is gradual and wavy. The intermediate nodular layer (INL) of about 1 m thick consists of reddish (5YR 5/8) sandy clay material containing nodules embedded in a mottled matrix with various shapes. Coarse grains of centimentric size represent about 70% of the total volume of this layer. The transition with over lying layer is sharp and wavy. The upper clay layer (UCL) had thickness that vary from 0.1 to 1 m and made up of sandy clay material. This layer is a porous reddish brown soil (7.5 YR 6/6). The clay matrix of this layer is poor in quartz grains.

In general, the lateritic soils in the study area are yellowish to brown-reddish in color and contain high percentage of iron oxides as discussed later. These pigmentations are consistent with the observation of De Graff-Johnson (1972) and Tardy (1992) on the lateritic soils formed under oxidized conditions and good drainage. Their strong pigmentation may also indicate the good aggregation of the soils due to their strong surface charge properties (Tardy 1992).

Petrographic characteristics of rock in the study area

The bedrock of the study area is composed of quartz, biotite, muscovite, garnet, chlorite, sillimanite, K-feldspar (orthoclase and microcline), and plagioclase (Figure 3). Accessory minerals are apatite, zircon and sphene. The textures of the sampled micaschist are lepidoblastic, granoblastic and porphyroblastic with sizes of minerals varying from a few mm to a few cm (Figure 3). Quartz exhibits undulatory extinction and occurs as an interpenetrative mosaic of almost equal grains, up to 1 mm in size that defines ribbons parallel to foliation planes. This mineral constitutes about 35 to 40% in both the matrix and as inclusions in garnet.

Biotite and muscovite make up 30% volume of the rock sample and vary in length from about 0.1 to 2 cm (Figure 3a and c). Two generations of micas were visible: 1) deformed flakes of up to 2 cm in size, which are most probably relics of the clasts protolith, 2) a second generation, in the matrix, is fine to medium grains. An anastomising configuration of biotite and muscovite around large garnet porphyroblasts (Figure 3a) indicates that schistosity postdated crystallization of garnet. Biotite and muscovite also occur in fractured garnets. Biotite is usually replaced with chlorite and fine grained ferrous oxides (Figure 3b).

Garnet occurs as subhedral to anhedral porphyroblasts from 0.2 to 10 mm in size, and are sometimes partially replaced by aggregates of chlorite and biotite (Figure 3a). Some garnet crystals contain sigmoidal to spiral quartz, micas and ilmenite, suggesting a synkinematic crystallization over printing crenulation cleavage (Ferry and Spear 1978). Most garnets are oriented parallel to the dominant foliation.

Mineralogical and chemical characteristics

The mineral assemblages and their modal composition are quartz (35%), muscovite (25%), biotite (15%), garnet (10%), chlorite (6%), sillimanite (3%), plagioclase (3%) and K-feldspar. The diffractogram obtained from the XRD analysis is shown in Figure 4. The X-ray patterns showed that the soils under investigation consist of quartz, kaolinite, goethite, magnetite and chlorite. This result is in agreement with previous finding reported on lateritic soils in south Cameroon (Ekodeck 1984; Onana 2010; Lemougna et al. 2011; Tsozué et al. 2012). Tsozué et al. (2012) showed that iron oxides in lateritic soils of south Cameroon are always associated to kaolinite. These authors further explained that the presence of goethite in lateritic soils developed on micashist is the result of the disruption of kaolinite-hematite association which characterizes the primary ion duricrust under hydratation. The mineralogical investigations also indicated the absence of swelling clays such as montmorillonite, hence undesirable swelling characteristics seems not expected in these soils. Nevertheless, the presence of goethite and other iron oxides existing in these residual soils may act as cementing agents, which as a consequence may contribute to tensile cracking by making the compacted structure relatively brittle. Indraratna and Nutalaya (1991) argued that the presence of high goethite content in the residual soil derived from weathered igneous and metamorphic rocks may have influenced cracking of the Shek Pik Dam in Hong Kong, China.

The chemical composition of the samples given in Table 1 shows the presence of 41 wt.% of Fe2O3 followed by 35 wt.% of SiO2 and 21 wt.% of Al2O3 and feeble content of 1.17 wt.% of K2O and 0.05 wt.% of CaO. This result agrees with the petrographic and mineralogical studies which indicated that quartz, iron-rich minerals and alumino-silicates are the dominant phases in both the parent rock and its derived products. Rossiter (2004) compiled the classification of soils according to the degree of laterization by evaluating silica–sesquioxide (S-S) ratio (SiO2 / (Fe2O3 + Al2O3)) (Table 1). Accordingly, soils having S-S ratio > 2 are considered as non-lateritic soils. For lateritic soils, this S-S ratio lies between 1.33 and 2 and for true laterites the ratio is < 1.33. The soils under investigation have S-S ratio (average of 0.6) lower than 1.33 suggesting that they are “true laterites” soils which has not undergone a considerable degree of laterization (Rossiter 2004).

Engineering characteristics of soils

Specific gravity

The results of the specific gravity of the investigated samples are presented in Table 2. The values range from 2.62 to 2.85, 2.34 to 2.85 and 2.07 to 2.80 for Nkil, Nkol and Mfi profiles, respectively. The lowest (average of 2.38 gf/cm3), and the highest values (average of 2.83 gf/cm3) of the specific gravity are found in UCL and INL samples, respectively. The results of studies conducted on lateritic soils (eg. Gidigasu 1983; Tockol 1994; Kabir and Taha 2004; Ramamurthy and Sitharam 2005; Que et al. 2008) have shown that specific gravity is closely linked with the mineralogy and/or the chemical composition of the soil. According to De Graff-Johnson, (1972), the higher the specific gravity, the higher the degree of laterization. Furthermore, the larger the clay fraction and the alumina concentration, the lower is the specific gravity. Thus, INL samples appear to be the most evolved samples in term of laterization (ferruginization) process.

Grain size distribution and Atterberg’s limits

Grain size distribution is one of the most important elements in the design of structures on, in, or composed of soils (Naresh and Nowatzki 2006). The results of grain size distribution analysis are given in Table 3. The statistical summary of obtained results are presented in Table 4 and represented graphically in Figure 5. The percentage of fines (% passing sieve 80 μm) has significant effect on the performance of the base / sub-base materials (Garg 2009). Too much fines will result in the reduction in the possible maximum density and strength and increase the susceptibility to weakening from water infiltration or seepage (Garg 2009). The results show that the amount of fines in UCL and MCL soil samples are quite similar (greater than 60%). Figure 5 shows that UCL and MCL are clayey soils that are poorly graded whereas INL are well graded gravel and sandy soils. The “well graded” curve (INL soil samples) represents a non-uniform soil with a wide range of particle sizes that are evenly distributed (Figure 5). Densification of a well-graded soil causes the smaller particles to move into the voids between the larger particles (Naresh and Nowatzki 2006). As the voids in the soil are reduced in the INL soil samples, the density and strength of the soil may increase. In contrast, poorly graded or uniform soils (UCL and MCL soil samples) are composed of a narrow range of particle sizes (Figure 5). During compaction of these soils, inadequate distribution of particle sizes prevents reduction of volume of voids with infilling by smaller particles. Thus, uniform soils are expected to have low mechanical properties. As clearly shown in Figure 5, only samples from INL meet the limit of not more than 35% of fines recommended by the CEBTP for sub-base materials (Table 5). None of the tested samples meet the CEBTP specification of not more than 20% of fines for base materials.

Sieve curves of soils samples from different layers of the weathering profiles in Mfou. UCL: upper clayey layer, INL: intermediate nodular layer, MCL: bottom mottled clayey layer. The continue gray curves represent the upper and lower bounds of typical lateritic soils intended to be used in road construction according to the road pavement standards for tropical countries (CEBTP, 1984)

The Atterberg consistency limit tests show that the UCL and MCL samples have in average a LL of 61% and 63%, PL of 31% and 33%, plasticity index (PI) of 29% and 30% while INL samples has in average a LL of 55%, PL of 30% and PI of 26% (Table 4). The results of Atterberg’s limit tests together with the grain size distribution results allowed the classification of UCL and MCL soil samples in the A-7-5 group of American Association of State Highway and Transportation Officials (AASHTO) classification scheme and in the A3 group of the “Guide des Terrassements Routiers” (GTR) classification. These groups are described as fair to poor clayey and silty soils. The INL soil samples belong to the class A-2-7 and B6, respectively according to the aforementioned classifications and are defined as gravelly and sandy soils. However, all the tested samples do not meet the CEBTP specification of not more than 15% plasticity index for base materials. Similarly, the results also indicate that the liquid limit of all the investigates samples are nearly within the range of not more than 60% for sub-base and exceed the maximum limit of 35% specified by the CEBTP for base materials (Table 5). Further, the plot in the Casagrande diagram (Figure 6) shows that all the samples are located along the A-line on the limit of high plasticity clays and silts domains. According to Day (2000) lateritic soils consisting mainly of un-swelling clay such as kaolinite are generally located below the A-line.

Satisfactory classification of expansive soils implies that the geotechnical parameters that characterize swelling are known (Millogo et al. 2008). The swelling rate (εs) which is defined as the percentage of swelling of a clay sample compacted at optimum Proctor and subjected to a load of 7 kPa was computed using the following equation (2) (Derriche and Kebaili 1998):

where εs is the swelling rate and PI the plasticity index.

According to Djedid et al. (2001) and references therein, the lateritic soils that contain clay fraction between 8 and 65% are considered as low, moderate and high swelling soils if εs value range between 0–1.5, 1.5-5, and 5–25, respectively. The εs values presented in Table 6 shows that UCL and MCL soil samples (average of 2.09 and 2.12, respectively) fall within the high swelling soils range whereas the INL samples (average of 1.4) are of low swelling potential. Based on the classification proposed by Bekkouche et al. (2000) which defined the swelling potential by the relation between clay content and PI (Figure 7), the INL samples are plotted in the moderate swelling potential area while INL and MCL samples plot toward very high swelling potential area. This indicates that the UCL and MCL samples could be more susceptible to considerable change in volume in a changing climate.

Domains of classification of soils according to their plasticity index (in Bekkouche et al., ( 2000 )). Ac: activity of clays.

Compaction test

The modified Protor test variables and results of the statistical summary are presented in Table 3 and Table 4, respectively. The maximum dry density (MDD) values obtained for the investigated samples are in average 1.7, 2.1 and 1.8 g/cm3 for UCL, INL and MCL, respectively. While the optimum moisture content (OMC) values are relatively higher and almost similar for UCL and MCL soil samples (average of 18.5 and 17.9%), it is lower for INL soil samples (average of 12.2%). In the overall samples, it can be seen that MDD is higher when OMC is lower (Table 3). However, the discrepancy of these parameters in the samples may be due to the different degree of laterization in the weathering profiles.

According to O’Flaherty (1988) the range of values that may be anticipated when using the modified proctor test methods are: for clay, MDD may fall between 1.4 and 1.7 g/cm3 and optimum moisture content (OMC) may fall between 20-30%. For silty clay MDD is usually between 1.6 and 1.8 g/cm3 and OMC ranged between 15-25%. For sandy clay, MDD usually ranged between 1.8 and 2.2 g/cm3 and OMC between 8 and 15%. Thus, looking at the results in Table 3, it could be noticed that INL samples belong to sandy clay soils whereas UCL and MCL samples are rather silty clay soils. As per CEBTP specification (CEBTP, 1984), lateritic soils having MDD value of 2.0 and 1.8 g/cm3 are recommended to be used as raw materials in base and sub-base, respectively in road construction. Only INL samples are consistent with this specification and can be rated as excellent materials for road works.

Californian bearing ratio (CBR)

The overall soaked CBR results presented in Table 3 and 4 show both lateral and vertical variation with the values range between 15 and 54%. The soil samples collected at the site MFI shows CBR values higher than those collected at sites NKIL and NKOL (Table 3). Along the vertical transect, the CBR values are generally higher (with average of 39 ± 19%) in the INL samples and lower (average of 19 ± 3%) in MCL samples (Table 4). However, the study of the vertical profile of lateritic soils indicates that samples with lower proportions of fines (<80 μm) (INL) have higher values of MDD and CBR and vice versa. Thus, it can be deduced that the lower the fine components, PI and OMC, the higher the MDD and CBR values.

Among the different investigated layers, only INL soil samples (average of 39 ± 19%) exceeded the CBR value of not less than 30% specified by the CEBTP for sub-base materials (Table 5). None of the tested sampled meet the CEBTP specification of not less than 80% for base materials. This suggest that INL samples may be useful as sub-base materials whereas the engineering properties of UCL and MCL samples are of poor quality which do not allow their uses as row materials in road pavement. However, due to its relative high PI, LL and swelling potential (Figure 6 and Tables 5), these soils require mechanical, physical and/or chemical improvements with hydraulic binders such as quicklime, bitumen and/or cement prior to their uses as base materials for road works.

Direct shear strength

The shear strength is one of the most important engineering properties of a soil, because it is required whenever a structure is dependent on the soil’s shearing resistance. For most of the geotechnical designs concerning foundations, earthworks and slope stability issues, the soils are required to withstand shearing stress along with compressive stress (Nakao and Fityus 2009). The test was conducted under saturated conditions. The shear rate was adopted to be 2 mm/min. The consolidation stress range of 100–300 kPa was considered. For a given material, shear vs. normal stresses at failure lay on a straight line in the τ- σ plane, named failure envelope. In soil mechanics, the failure envelope is traditionally known as Mohr-Coulomb failure criterion and expressed as (Eq. 3):

where τ and σ represent shear and normal stresses, respectively. c’ is the cohesion of soil and ψ is the internal friction angle. This failure criterion is obtained from a series of direct shear tests where maximum or residual stress are plotted against normal stress and then a failure envelope is calculated. The results of direct shear test is presented in Table 7. Figure 8b presents a Mohr-Coulomb envelope obtained from direct shear test of soils in the study area. Each experimental point corresponds to the maximum stress that the soils can withstand without cracking or breaking. Slope and intersect of the linear envelope correspond to angle of internal friction (ψ) and cohesion (c’), respectively. Figure 8a indicate that the shear stress corresponding to a fixed normal stress increases initially until it reaches the peak strength, which then decreases gradually toward its residual strength. The observed behavior is ascribed to overconsolidated soils. The corresponding stress path responses illustrated in Figure 8b exhibit essentially linear failure envelopes with respect to the normal stress axis. A best-fit envelope drawn through the data points in Figure 8b results in shear strength parameters c' and ψ of 62 kPa and 27.2°, respectively, suggesting that any shear stress or slope above these values may cause soil failure.

Stress path responses relative to direct shear strehgth for standard Protor campacted soils in the study area. (a) Plot of load per unit area vs horizontal displacement and (b) shear stress vs normal stress. The slope (62 Kpa) represents the cohesion and 27.2° represents the angle of the internal friction.

Consistent with the results reported in lateritic soils of Nigeria (cohesion range of 65–75 kPa and friction angle range between 26-31°) (Oladele et al. 2012; Aloa and Opaleye 2011), these values show that the soils in the study area have relative high bearing capacity as a result of their respective high cohesion and relatively medium angle of internal friction values. Furthermore, the plot of samples in the diagram of Dayre et al. (1978) modified by Ekodeck (1984) (Figure 9) shows that the samples have an elasto-plastic behavior. Hence, they can support slope stability and shallow foundation (Nakao and Fityus 2009).

Comparison of test results with some lateritic soils in Sub-Saharan Africa

To understand the regional variability of raw materials widely used in civil engineering works in Cameroon, the soils under consideration were compared with known lateritic soils in Sub-Saharan Africa. Globally, based on the CEBTP specification (CEBTP 1984) and as previously thought (Table 5), the engineering properties of these soils are all convenient to be used as sub-base materials and require pre-treatment before use as base materials (Table 8). However, significant differences are observed among their engineering parameters. The results show that there is an apparent similarity in parameters between soils formed under same climatic conditions. Despite their different parent rocks, lateritic soils under investigations have engineering properties relatively comparable with lateritic soils of Ghana, Ivory-Coast and Congo. Moreover, lateritic soils formed under semi-arid conditions have engineering properties higher than those formed under tropical and sub-tropical conditions. This is probably due to the intense weathering processes observed in tropical regions leading to removal of silica and accumulation of sesquioxides (IRRI 1989). Several studies showed that silica has a positive correlation with specific gravity and CBR value. As an example, lateritic soils of Burkina Faso which are silica rich materials (SiO2 of 56.19 wt.%) (Millogo et al. 2008) have CBR value at 95% MDD (43%) higher than that in the study area (average CBR at 95% of 39) which are rather iron rich soils (Fe2O3 of 40.88 wt.%). It is worth mentioning that lateritic soils developed under sub-tropical conditions seemingly have the fairest engineering properties. Despite incomplete information regarding rock types, the results show that laterites developed on metamorphic rocks (schist, gneiss and quartzite) have engineering properties better than those developed on igneous rocks (granite).

Conclusion

This research collates the baseline geotechnical information on tropical soils developed on micashist of Central-Cameroon and compares their geotechnical properties with some lateritic soils in Sub-Saharan Africa. Investigations on the lateral and vertical variability of the engineering properties of lateritic soils have helped in deducing the following conclusions:

-

1.

The texture of the studied micaschist is lepidoblastic, granoblastic and porphyroblastic with variable size of minerals. The mineral assemblages and their modal composition are of quartz (35%), muscovite (25%), biotite (15%), garnet (10%), chlorite (6%), sillimanite (3%), plagioclase (3%) and K-feldspar.

-

2.

The micashist derived lateritic soils from Mfou have a pigmentation varying from yellowish to reddish and were formed in an oxidizing environment having good drainage.

-

3.

The mineralogical investigations indicate the absence of high swelling clays such as smectite and montmorillonite. Chemical test shows that these soils are “true laterites” having high concentration of sesqueoxides (iron and aluminum oxides) which may act as cementing agents contributing to tensile cracking by making the compacted structure relatively brittle.

-

4.

The results of geotechnical tests reveal that samples from upper clay layer and bottom mottled clay layer are poorly graded soils with engineering properties (fines of 61 and 63%, plasticity index of 30 and 31%, CBR at 95% of 21 and 19%) which do not allow their use as raw materials in road construction. INL samples are gravel and sand soils well graded having engineering properties (fines of 26%, plasticity index of 26% and CBR of 39%) that meet specifications require for sub-base materials for light traffic roads. However, Atterberg’s consistency limit tests indicate that the samples are moderate to high plastic soils with moderate swelling potential. Hence, their use as base and sub-base construction materials for heavy traffic roads require pre-treatment with non-plastic soils, bitumen, cement and/or lime. The direct shear test results show that the soils have high bearing capacity (cohesion of 62 kPa and 27.2° of angle of internal friction) making them to be useful in slope stability and in shallow foundation design.

-

5.

The comparison of the studied soils with some lateritic soils in Sub-Saharan Africa indicates that genesis and climatic conditions are potentials factors that influence the engineering properties of lateritic soils. Further, the comparison also indicates that soils developed in semi-arid conditions exhibits the best engineering characteristics.

References

AFNOR (Association française de normalisation). (1978). NF P18-560, Analyse granulométrique par tamisage (p. 5).

AFNOR (Association française de normalisation). (1992). NF P94-057, Analyse granulométrique des sols, Méthode par sédimentation (p. 17).

AFNOR (Association française de normalisation). (1993). NF P94-051, Détermination des limites d’Atterberg (p. 15).

AFNOR (Association française de normalisation). (1997). NF P94-078, Indice CBR après immersion - Indice CBR immédiat - Indice Portant Immédiat (p. 14).

AFNOR (Association française de normalisation). (1999). NF P94-093, Détermination des références de compactage d’un matériau, NF P94-071-2, Essai de cisaillement direct-principe et méthode (p. 17).

Alao, D. A., & Opaleye, S. T. (2011). Geotechnical analysis of slope failure of a kaolin Quarry at Kura, Jos North-Central. Int J Sci Res, 1(1), 87–102.

Autret, P. (1983). Latérites et graveleux latéritiques. Laboratoire Central des Ponts et Chaussées (p. 38).

Bagarre, E. (1990). Utilisation des graveleux latéritiques en technique routière (p. 143). Paris: Institut des Sciences et des Techniques de l’Equipement et de l ’ Environnement.

Bayewu, O. O., Olountola, M. O., Mosuro, G. O., & Adeniyi, S. A. (2012). Petrographic and geotechnical properties of Lateritic Soils developed over different parent rocks in Ago-Iwoye area, Southwestern Nigeria. Int J of Appl Sci and Eng Res, 4, 584–594.

Bekkouche, A., Djedid, A., & Aissa Mamoune, S. M. (2000). An experimental investigation on the assessment of the swelling parameters, IV. Int Congr East Mediterr Univ Gazimagusa North Cyprus, 2, 627–633.

Bello, A. A., & Adegoke, C. W. (2010). Evaluation of geotechnical properties of Ilesha East Southwestern Nigeria’s Lateritic Soil. Pac J Sci Technol, 11, 617–624.

Bohi, Z. H. B. (2008). Caractérisation des sols latéritiques utilisés en construction routière. Cas de la région de l’Agnéby (Côte d’Ivoire). Thèse de Doctorat (p. 143). Paris: École Nationale des Ponts et Chaussées.

Bouassida, R., & Boussetta, R. (2007). Manuel de travaux pratiques de mécanique des sols (p. 116). Tunis, Tunisie: Centre de publication universitaire.

CEBTP (Centre Expérimental de Recherches et d’Etudes du Bâtiment et des travaux Publics). (1984). Guide pratique du dimensionnement des routes pour les pays tropicaux (p. 157).

Day, R. W. (2000). Geotechnical Engineer’s Portable Handbook. New York: McGraw-Hill.

Dayre, J., Fabre, D., Letourneur, J., Antoine, P., & Orengo, Y. (1978). Eléments pour une classification géotechnique des terrains (2nd ed., pp. 131–139). Madrid II: C.R. 3e Cong. AIGI.

De Graft-Johnson, J. W. S. (1972). Lateritic gravel evaluation of road construction. J soil Mech Div Amst Soc Civil Eng, 98, 1245–1265.

Deckers, J., Nachtergaele, F., & Spaargaren, O. (2001). Tropical Soils in the Classification Systems of USDA, FAO and WRB, KULeuven, Institute for Land and Water Management, Belgium. The Netherlands: Land and Water Development Division, International Soil Reference and Information Centre (ISRIC).

Derriche, Z., & Kebaili, M. (1998). Prévision du gonflement des argiles d’In-Aménas. Bulletin des Laboratoires des Ponts et Chaussées, 218, 15–23.

Djedid, A., Bekkouche, A., & Aissa Mamoune, M. (2001). Identification and prediction of the swelling behavior of some soils from the Tlemcen region of Algeria. Bulletin des Laboratoires des Ponts et Chaussées, 233, 69–77.

Ekodeck, G. E. (1984). L’altération des roches métamorphiques du Sud Cameroun et ses aspects géotechniques. Thèse de Doctorat D’Etat des Sciences Naturelles, IRGM (p. 368). France: Université Scientifique et Médicinal de Grenoble I.

Ekodeck, G. E. (1985). Implications géotechniques de l’altération des roches de la région de Yaoundé. Rev Sci et Tech série Science de la Terre, 1, 55–82.

Ferry, J. M., & Spear, F. S. (1978). Experimental calibration of the partitioning of Fe and Mg between biotite and garnet. Contrib Mineral Petrol, 66, 13–117.

Garg, S. K. (2009). Soil Mechanics and Foundation. Engineering (7th ed., pp. 673–683). New Delhi: Khana publishers.

Gazel, J., & Guiraudie. (1967). Carte géologique de reconnaissance du Cameroun au 1/500 000, feuille Yaoundé Est, N° NA 32 NE-E22 (5th ed., p. 29). Du Cameroon: Bul. Dir. Mines & Géol.

Gidigasu, M. D. (1983). Development of acceptance specifications for tropical gravel paving materials. Eng Geo, 19, 213–240.

Indraratna, B., & Nutalaya, P. (1991). Engineering characteristics of a compacted, lateritic residual soil. Geotech Geol Eng, 9, 125–137.

IRRI (International Rice Research Institute). (1989). Climate and Food Security (p. 602). Manila, Philippines: ᅟ.

Kabir, M. H., & Taha, M. R. (2004). Assessment of physical properties of a granite residual soil as an isolation barrier. Electron J Geotech Eng, 92, 13.

Kamgang Beyala, V. (1987). L’altération supergène des roches grenatifères de la région de Yaoundé (Cameroun): Pétrologie-Minéralogie. Thèse de Doctorat 3e Cycle (p. 170). France: Université de Poitiers.

Leake, B. E., Hendry, G. L., Kemp, A., Plant, A. G., Harvey, P. K., Wilson, J. R., Coats, J. S., Aucott, J. W., Lunel, T., & Howarth, RJ. (1970). The chemical analysis of rock powders by automatic X-ray fluorescence. Chem Geol, 5, 7–86.

Lemougna, P. N., Chinge Melo, U. F., Kamseu, E., & Tchamba, A. B. (2011). Laterite based stabilized products for sustainable building applications in tropical countries: review and prospects for the case of Cameroon. Sustainability, 3, 293–305. doi: 10.3390/su3010293.

Logmo, E. O., Ngon Ngon, G. F., Samba, W., Mbog, M. B., & Etame, J. (2013). Geotechnical, mineralogical and chemical characterization of the missole II clayey materials of Douala Sub-Basin (Cameroon) for construction materials. J Civ Eng. ᅟ, ᅟ. doi: 10.4236/ojce.2013.32A006.

Mahalinger-Iyer, U., & Williams, D. J. (1997). Properties and performance of lateritic soil in road pavements. Eng Geol, 46, 71–80.

Mbumbia, L., De Wilmarsa, A. M., & Tirlocp, J. (2000). Performance of lateritic soil bricks fired at low temperatures: a case study of Cameroon. Construct Build Mater, 14, 121–131.

Millard, R. S. (1993). Road Building in the Tropics (9th ed., p. 312). London, UK: Transport Research Laboratory, State of the Art Review, Hazardous Materials Storage Ordinance Publications.

Millogo, Y., Traore, K., Ouedraogo, R., Kabore, K., Blanchart, P., & Thomassin, J. H. (2008). Geotechnical, mechanical, chemical and mineralogical characterization of a lateritic gravels of Sapouy (Burkina Faso) used in road construction. Const Build Mat, 22, 70–76.

Molua, EL & Lambi, CM (2006). Climate hydrology and water resources in Cameroon CEEPA, Pretoria, p 37 ᅟ.

Munsell color charts. (1975). Color Guides (p. 34). Baltimore Md: Handbook manual.

Nakao, T., & Fityus, S. (2009). Direct shear testing of a marginal material using a large shear box. Geotech Test J, 31, 5. ID GTJ101237.

Naresh, C. S., & Nowatzki, P. E. (2006). Soils and foundations. Ref Man Fed Highway Adm, 2, 8–75.

Ndam, N. J. R., Braun, J. J., Meybeck, M., & Bedimo Bedimo, J. P. (1998). Réactualisation des données hydroclimatiques des bassins fluviaux de la Sanaga et du Nyong (Sud Cameroun). Presse Universitaire de Yaoundé, 2, 51–64.

Northmore, K. J., Culshaw, M. G., Hobbs, P. R., Hallam, J. R., & Entwisle, D. C. (1992). Engineering Geology of Tropical Soils – Summary Finding and their Application for Engineering Purposes. Nottingham: Technical report WN/93/15, Overseas Development Administration (ODA) and British Geological Survey (BGS.

Nzenti, J. P., Barbey, P., Macaudière, J., & Soba, D. (1988). Origin and evolution of the late Precambrian high-grade Yaoundé gneisses (Cameroon). Precam Res, 38, 91–109.

O’Flaherty, C. A. (1988). Highway Engineering (Vol. 2). London, UK: Edward Arnold Publishers.

Ojo, J. S., & Adeyemi, G. O. (2003). Opportunities for ventures in construction materials. In A. A. Elueze (Ed.), Prospects for Investment in Mineral Resources of Southwestern Nigeria (pp. 47–54).

Oladele, A. O., Olusolo, J. O., & Emmanuel, T. A. (2012). Engineering properties of lateritic soils around Dall Quarry in Sango area, Ilorin, Nigeria. Earth Sci Res, 1, 2. doi: 105539/esr.v1n2p71.

Onana, V. L. (2010). Les schistes de la série de Mbalmayo-Bengbis et leurs produits dérivés: Caractérisations altérologiques et géotechniques. Thèse de Doctorat Ph.D (p. 236). Yaoundé: Université de Yaoundé I.

Que, J., Wang, Q., Chen, J., Shi, B., & Meng, Q. (2008). Geotechnical properties of the soft soil in Guangzhou College City. Bull Eng Geol Environ, 67, 479–483.

Ramamurthy, T. N., & Sitharam, T. G. (2005). Geotechnical Engineering (p. 289). New Delhi: S. Chand.

Robitaille, V., & Tremblay, D. (1997). Mécanique des sols (théorie et pratique) (p. 652). Quebec-Canada: Modulo.

Rossiter, D.G., 2004. Digital soil resource inventories: status and prospects. Soil Use & Management 20(3)296–301

Segalen, P. (1967). Les sols et la géomorphologie du Cameroun. ORSTOM, 2, 137–187.

Sikali, F., & Mir-Emarati, D. (1986). Utilisation des latérites en technique routière au Cameroun. In Séminaire Régional sur les Latérites: Sols, Matériaux, Minerais, Douala (CMR) (pp. 277–288). ISBN 2-7099-0867-0.

Tardy, Y. (1992). Pétrologie des latérites et sols tropicaux. Masson (ed) (p. 459).

Tockol, I., Massiéra, M., Chiasson, P. A., & Maiga, M. S. (1994). Les graveleux latéritiques dans les pays du sahel: Cas des routes non revêtues (pp. 3423–3431). Rotterdam, Holland: 7ème Congrès International de l’AIGI.

TPSSA (Transport Policies in Subsaharienne Africa). (2004). Afrique-Cameroun-Road, Report (p. 54).

Tsozué, D., Bitom, D., & Yongue-Fouateu, R. (2012). Morphology, mineralogy and geochemistry of a lateritic sequence developed on micaschist in the Abong-Bang region, Southeast Cameroon. Geological Soc S Afr, 115, 103–116.

Vallerie, M. (1995). ATLAS Régional du Sud-Cameroun (p. 70). Paris: ORSTOM.

Yongue, F. R. (1986). Contribution à l’étude pétrologique de l’altération et des faciès de cuirassement ferrugineux des gneiss migmatitiques de la région de Yaoundé (p. p 214). Yaoundé: Thèse, Doctorat 3e cycle Univisité de Yaoundé.

Zelalem, A. (2005). Basic Engineering Properties of Lateritic Soils Found in Nejo-Mendi Road Construction Area, Welega, M. Sc. thesis (p. 97). Ethiopia: Addis Ababa University.

Acknowledgements

The work reported in this paper is part of on-going Ph.D research of the main author at the Graduate School of Engineering for Education, University of Toyama, Toyama City, Japan. Professor Georges Emmanuel Ekodeck and the personal of the National Laboratory of Civil Engineering (LABOGENIE) of Cameroon are gratefully acknowledged for Laboratory facilities. The authors wish to thank Professor Katsumi Marumo of the Departement of Environmental Biology and Chemistry, Faculty of Science, University of Toyama for his support to performing chemical analyses (X-ray fluorescence). An additional support was provided by the SATREPS-Nymo project. We also wish to express our gratitude to Mme. Emilia Bi Fantong, Mlle Edwige R. Tiodjio and for Dr. Jude M. Wirmvem for their vision, support and encouragement throughout the work. This paper has benefited from valuable contributions from two anonymous reviewers and we appreciate their efforts.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

This work was conceived by BTK, VLO, and JMO Field investigations were done by BTK, RFDN, MHDW, GBN, ANZ and JMO. Geo-chemical analysis and Geotechnical tests were performed by BTK, VLO and UA. Laboratory facilitiesas well as critical and valuable comments during the preparation of manuscript was provided by VKBK and WYF. The manuscript was written and approved by all the authors.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kamtchueng, B.T., Onana, V.L., Fantong, W.Y. et al. Geotechnical, chemical and mineralogical evaluation of lateritic soils in humid tropical area (Mfou, Central-Cameroon): Implications for road construction. Geo-Engineering 6, 1 (2015). https://doi.org/10.1186/s40703-014-0001-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-014-0001-0