Abstract

Ulva is one of the main green algae causing green tide disasters. Ulvan is the primarily component polysaccharide of the cell wall of Ulva and its complex structure and monosaccharide composition resulted in various biological activities. However, the high-value and effective utilization of extracted ulvan have been obstructed by limitations ranging from large molecular weight and low solubility to poor bioavailability. Ulva oligosaccharide obtained by degrading ulvan can not only ideally retain the various biological activities of ulvan very well but also effectively solve the problems of low solubility and poor bioavailability. The preparation and biological activity studies of ulvan and Ulva oligosaccharides have become a hot spot in the field of marine biological resources development research. At present, the comprehensive reviews of ulvan and Ulva oligosaccharides are still scarce. What are overviewed in this paper are the chemical composition, structure, extraction, and purification of ulvan and Ulva oligosaccharides, where research progress on the biological activities of ulvan and Ulva oligosaccharides is summarized and prospected. A theoretical and practical basis has been provided for further research on ulvan and Ulva oligosaccharides, as well as the high-value development and effective utilization of marine algae resources.

Graphical Abstract

Similar content being viewed by others

Introduction

Since 2008, ecological disasters such as green tides have frequently occurred in the Yellow Sea in China, and Ulva is one of the main algae that form green tides (Chen et al. 2022b; Wang et al. 2015; Ye et al. 2011; Zheng et al. 2022). Ulva (Ulva sp.) belongs to the Ulva family in the Ulva genus of Chlorophyta, and the common types of Ulva include U. prolifera, U. pertusa, and U. compressa (Beer 2023; Van Alstyne et al. 2015; Wang et al. 2015). Ulva has a high nutritional value, such as sulfated polysaccharides, lipids, proteins, dietary fibers, and vitamins, which support their use in medical applications (Cadar et al. 2023; Kidgell et al. 2019). Therefore, it has a wide range of application prospects in health food, agricultural feed, and fish–shrimp farming (Kidgell et al. 2019). Ulvan is the main water-soluble sulfated polysaccharide existing in the cell wall of Ulva algae (Ning et al. 2022; Zheng et al. 2022). It was found that ulvan was mainly composed of rhamnose, iduronic acid, xylose, glucuronic acid, and a small amount of galactose, and the composition of the monosaccharide and the degree of sulfation varied with the species, harvest season, cultivation methods, growth environment, and extraction methods of Ulva sp. (Kidgell et al. 2019; Ning et al. 2022; Olasehinde et al. 2019; Olsson et al. 2020). Ulvan, as the main active component of Ulva sp., has a variety of biological activities, such as anti-inflammatory (Kidgell et al. 2020), anticoagulant (Faggio et al. 2016), anti-tumor (Pradhan et al. 2020), antioxidant (Pradhan et al. 2022), anti-hyperlipidemia (Yuan et al. 2018), immune regulation (Fernández-Díaz et al. 2017), and plant growth-promoting activities (Shefer et al. 2022). Therefore, ulvan has application prospects in biomedicine, cosmetics, food, health products, and other industries (Berri et al. 2017; Cindana Mo’o et al. 2020; Morelli et al. 2019; Ning et al. 2022; Samah and Hadear 2019; Yaich et al. 2017). However, the high-value development and utilization of ulvan resources have been limited by their large molecular weight, poor solubility, and low bioavailability. On the contrary, the Ulva oligosaccharide obtained from the degradation of ulvan not only retains the biological activities of the original polysaccharide well but also improves the defects of the insolubility of ulvan in water and the low bioavailability, which makes the preparation of Ulva oligosaccharide and the research on its biological activity a hot spot in the field of the development and research of marine biological resources (Ning et al. 2022; Paulert et al. 2021).

At present, the research reports related to ulvan and its oligosaccharide are increasing, but there are no relevant papers to summarize and discuss the current research progress. In this paper, the chemical composition, structure, extraction, purification, and biological activities research reports of ulvan are systematically summarized, and the preparation methods of Ulva oligosaccharides and the activities of Ulva oligosaccharides are reviewed and analyzed. At the end of the paper, the main problems as well as technical bottlenecks, and application prospects in various fields in the development and utilization of ulvan are analyzed and prospected, providing a theoretical basis and research basis for promoting the effective utilization of ulvan, a kind of marine green biomass resource.

Chemical composition of ulvan

Ulvan is structurally more complex than other algal polysaccharides due to the complexity of their monosaccharide composition, glycosidic bonding, and group modifications. The chemical composition of ulvan will be affected by the type of Ulva sp. as the extraction source, the harvest season, and the extraction and purification methods of ulvan, so its composition is more complex (Table 1). Kidgella et al. analyzed the monosaccharide composition of the ulvan from blade (U. australis, U. rigida, U. sp. B, and Ulva sp.) and filamentous (U. flexuosa, U. compressa, U. prolifera, and U. ralfsii) species of cultivated Ulva and found that there was a large difference in the monosaccharide composition of them (Kidgell et al. 2021). Among them, the ulvan from blade species of cultivated Ulva mainly consists of rhamnose (~ 49 mol%), followed by glucuronic acid (~ 23.83 mol%), and the proportion of xylose and iduronic acid varies with the different types of Ulva sp. Ulvan from filamentous species of cultivated Ulva are quite different. The content of rhamnose in the ulvan from U. prolifera and U. flexuosa can reach 56 mol% and 60 mol%. Conversely, the content of rhamnose in the ulvan from U. ralfsii and U. compressa is about 43 mol%. However, the proportion of iduronic acid in ulvan from filamentous species of cultivated Ulva (~ 7 mol%) is generally lower than that from blade species of cultivated Ulva (~ 14 mol%). In addition, the content of iduronic acid in ulvan from U. rigida is the highest, reaching 18 mol%, and the proportion of galactose in ulvan from U. ralfsii reached 16 mol%, which was far more than that of ulvan from other Ulva sp. Samarasinghea et al. analyzed the monosaccharide composition of Ulva harvested at different months and found that the main composition of ulvan was not different, but the content of different types of monosaccharides was quite different (Samarasinghe et al. 2021). For example, the dry matter contents of rhamnose, xylose, galactose, glucose, and uronic acid in ulvan harvested in June were 3.65, 0.43, 0.41, 0.32, and 0.62 g/100 g, respectively; the dry matter contents of rhamnose, xylose, galactose, glucose, and uronic acid in ulvan collected in August were 0.84, 0.33, 0.22, 0.75, and 1.92 g/100 g, respectively. It can be clearly seen that the ulvan harvested in August has a higher content of glucose and uronic acid than the ulvan harvested in June. Furthermore, when Olsson et al. studied the effect of cultivation conditions (such as temperature, irradiance, pCO2, nitrogen, and phosphate) on the monosaccharide composition of ulvan, and they found that low sulfate concentration and high temperature could promote the increase of monosaccharide content, while increasing irradiance and temperature could increase the concentration of rhamnose and iduronic acid in the ulvan(Olsson et al. 2020). Guidara et al. extracted ulvan from Ulva lactuca by acid extraction (CA) and enzymatic chemical extraction (EE), respectively, and analyzed their monosaccharide components (Guidara et al. 2020). The results showed that the content of rhamnose and xylose in ulvan CA1 obtained by CA was higher than that of ulvan EE extracted by EE, and the content of uronic acid and glucose in EE was higher than that in CA1. The above research results show that the chemical composition of ulvan varies with Ulva sp., growth environment, harvest time, and extraction method, and this phenomenon is also common in the composition analysis of other algal polysaccharides (Benslima et al. 2021).

The structure of ulvan and Ulva oligosaccharide

The complex monosaccharide composition, different connection modes between monosaccharides, the existence of complex and diverse group modifications, and branched structures make the structure of ulvan far more complex than that of other algal polysaccharides such as alginate, carrageenan, and agarose (Stender et al. 2019). Therefore, it is difficult to elucidate the structure of ulvan. Lahaye et al. studied the structure of ulvan from U. rigida (Lahaye and Robic 2007). Six sample structures from the Canary Islands, namely, Δ(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl2S(1 → 4)l-Rha3S, Δ(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl(1 → 4)l-Rha3S, Δ(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl2S(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl(1 → 4)l-Rha3S, Δ (1 → 4)α-l-Rha3S (1 → 4) β-d-Xyl2S(1 → 4) α-l-Rha3S(1 → 4)β-d-Xyl(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl(1 → 4)l-Rha3S, Δ(1 → 4)l-Rha3S, and Δ(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl(1 → 4)l-Rha3S, were determined. And four structures of sample from the Brittany, Δ(1 → 4)α-l-Rha3S(1 → 4)β-d-GlcA(1 → 4)l-Rha3S, Δ(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl2S(1 → 4)l-Rha3S, Δ(1 → 4)[β-d-GlcA(1 → 2)]α-l-Rha3S(1 → 4)β-d-Xyl(1 → 4)l-Rha3S(20), and Δ(1 → 4)[β-d-GlcA(1 → 2)]α-l-Rha3S(1 → 4)β-d-Xyl2S(1 → 4)l-Rha3S, were also found, along with the same oligosaccharide structure as the previous sample, Δ(1 → 4)l-Rha3S and Δ(1 → 4)α-l-Rha3S(1 → 4)β-d-Xyl(1 → 4)l-Rha3S, where Δ refers to the unsaturated uronic acid 4-deoxy-l-threo-hex-4-enopyranosiduronic acid at the non-reducing end. The main disaccharide repeat structures of ulvan are A3s [→ 4)β-d-GlcA(1 → 4)-α-l-Rha3S(1 →] and B3s [→ 4)α-l-IdoA(1 → 4)-α-l-Rha3S(1 →] from different Ulva sp. samples. In addition, the analysis of these structures shows that there are another two repeating disaccharide units, U3s [→ 4)β-d-Xyl(1 → 4)-α-l-Rha3S(1 →] and U2’s,3s [→ 4)β-d-Xyl2S(1 → 4)-α-l-Rha3S(1 →]. Thanh et al. extracted highly purified ulvan and analyzed its structure by IR, NMR, SEC-MALL, and ESI–MS(Thanh et al. 2016). The study found that there were repeat disaccharide units of A3s [→ 4)-β-d-GlcA-(1 → 4) -α-l-Rha3S-(1 →], GlcA-(1 → 2)-Xyl and GlcA-(1 → 2)-Rha in the ulvan extracted from Ulva sp., of which A3s [→ 4)-β-d-GlcA-(1 → 4)-α-l-Rha3S-(1 →] was the main disaccharide repeat unit. Chi et al. used ulvan lyase to cleave ulvan from U. clathrata through β elimination reaction and obtained three degradation products with different molecular weights, UO-1, UO-2, and UO-3, and carried out structural analysis on them, respectively (Chi et al. 2020a). UO-1 and UO-2 have lower molecular weights and are disaccharides, D-ΔGlcA-(1 → 4)-α/β-L-Rha3S, and tetrasaccharides, D-ΔGlcA-(1 → 4)-α-l-Rha3S-(1 → 4)-β-d-Xyl-(1 → 4)-α/β-l-Rha3S, respectively. The study of the UO-3 structure with a large molecular weight found that it was mainly composed of A3s type and U3s type disaccharide repeat units, and there were also U2's, 3s type disaccharide repeat units. It can be seen that ulvan is a complex polysaccharide mainly composed of A3s or B3s type disaccharide repeat units and a small number of U3s or U2's, 3s type disaccharide repeat units (Fig. 1), and the content of different disaccharide repeat units will be affected by different sources of Ulva sp. Therefore, the research on the structure of ulvan will help strengthen the high-value development and utilization of ulvan resources.

Preparation of ulvan and its oligosaccharide

The preparation of ulvan can be divided into two steps: extraction and purification, and there are many reported methods for extracting and purifying ulvan. According to the extraction and purification process, we classify the extraction methods into the following three categories: solution extraction, physical-assisted extraction, and enzyme-assisted extraction. Similarly, the purification methods of ulvan can also be classified into three categories: dialysis, ultrafiltration, and column chromatography, of which column chromatography can be further divided into ion exchange chromatography and gel filtration chromatography.

Extraction methods of ulvan

The extraction method of ulvan is very similar to that of other algae polysaccharides, mainly using solution extraction and two auxiliary extraction methods based on it, namely, physical-assisted and enzyme-assisted extraction. Source, extraction method, and yield of ulvan extracted from different Ulva sp. are shown in Table 2.

Solution extraction

Solution extraction can be further subdivided into hot water extraction, pressurized hot water extraction, acid extraction, and weak alkaline extraction. Hot water extraction is a traditional polysaccharide extraction method and using that method the solubility of polysaccharides in water will rise with the increasing temperature. And the ratio of material to liquid, the temperature of hot water, extraction time, the extraction times, and other factors will affect the yield of polysaccharide. Pankiewicz et al. stirred and extracted ulvan for 7 h in a hot water bath at 75–85 ℃ according to the ratio of material to liquid of 1:30, centrifuged and filtered the supernatant rich in polysaccharide, and concentrated it (Pankiewicz et al. 2016). The yield of polysaccharide was 16.23%. Wahlström et al. first mixed with 70% ethanol according to the feed-to-liquid ratio of 1:10, then extracted at room temperature at 300 rpm for 8 h, centrifuged to obtain the polysaccharide sediment, and washed it with ethanol three times (Wahlström et al. 2020). Then, according to the material-to-liquid ratio of 1:16, add it to the hot mixer of ultrapure water to extract for 3 h at 90 ℃ and 750 revolutions. Collect the supernatant and extract it twice at the material-to-liquid ratio of 1:14 and then freeze dry it. The yield of ulvan is 11 ± 3%. Chen et al. extracted ulvan for 3 h in a 90 ℃ water bath using a material-to-liquid ratio of 1:20. After centrifugation and concentration, 95% ethanol was used for alcohol precipitation, and then 95% ethanol was used for repeated washing three times and dried in a vacuum oven at 50 ℃ for 1 h to achieve constant weight (Chen et al. 2021). The yield was 17.8 ± 0.6%. Gaio et al. selected the ratio of material to liquid of 1:10 to extract for 1 h in hot water at 90–100 ℃, repeated once, recovered the supernatant, and precipitated it in 1 volume of mixed water/ethanol at a ratio of 1:1 (v/v), and the polysaccharide yield was 7% (Paradossi et al. 1999). Chi et al. selected a material-to-liquid ratio of 1:30 to extract for 2 h in hot water at 100 ℃, centrifuged the supernatant, concentrated it, dialyzed it in cellulose membranes, and then precipitated it with 95% ethanol (Chi et al. 2020a). The polysaccharide yield was 11.27%. Klongklaewad et al. boiled for 90 min in the autoclave according to the feed-to-liquid ratio of 1:100, filtered the solid residues to retain the supernatant, and freeze-dried, and the polysaccharide yield was 15.2% (Klongklaew et al. 2021). However, hot water extraction has disadvantages, including a low extraction yield and a long extraction time. Pressurized hot water extraction is regarded as a green and efficient technique to extract solid samples with liquid water (Plaza and Marina 2019). This method intensified the destruction of the cell structure of Ulva sp. under higher temperature and pressure and increased the content of dissolved polysaccharides, thus improving the yield. Paulertab et al. selected a material/liquid ratio of 1:40 to extract ulvan for 1 h in pressurized hot water at 110 ℃. The recovered water extract was concentrated and then precipitated with ethanol, with a yield of 19.5%. Similarly, Toskasa et al. used pressurized hot water with a material-to-liquid ratio of 1:20 at 130 ℃ to extract for 30 min, filter it, and recover the hot water solution. After concentrating the hot water solution, use 95% ethanol for alcohol precipitation, then use 95% ethanol for repeated washing three times, and then dry it at 80 ℃. The average yield can reach 24.3%. Compared with the traditional hot water extraction method, the high-pressure hot water extraction method has the characteristics of a short extraction time and a high yield. However, the exorbitant temperature will cause the self-degradation of ulvan, which will lead to a decrease in its yield (Podolean et al. 2022). Therefore, it is helpful to optimize the hot water extraction scheme of ulvan according to the needs of the follow-up study of ulvan.

On the basis of hot water extraction, the extraction process of ulvan can be improved by adjusting the pH value of the extraction solution. Yaich et al. used the acid extraction method with a material-to-liquid ratio of 1:16.7 to extract ulvan (Yaich et al. 2013). Through multifactorial and multi-level experiments, they optimized the three factors, pH value, extraction temperature, and extraction time, and obtained the best extraction process, which is a pH value of 2, an extraction temperature of 90 ℃, and an extraction time of 3 h. The yield of ulvan under this process is 32.67%. Wahlström et al. added 0.01 M HCl (pH 2.0) according to the feed-to-liquid ratio of 1:25, heated it to 90 ℃, and extracted it for 4 h (Wahlström et al. 2020). The supernatant was recovered by centrifugation, dialyzed for 48 h, and then ethanol precipitated the dialysate. The precipitated part was collected and freeze-dried. The yield of ulvan was 18 ± 2%. Glasson et al. added the pretreated Ulva sp. to 1L of 0.05 M HCl, heated it to 85 ℃, extracted it for 1 h, then vacuum filtered it, adjusted the pH to 7 with 1 M NaOH, concentrated it, and freeze-dried it (Glasson et al. 2017). The polysaccharide yield was 8.1 ± 1.0%. Christopher et al. added 0.05 mol/L HCl solution adjusted to pH 2 by 1 M NaOH into U. Ohnoi, U. tepida, and U. prolifera from three different sources at a ratio of 1:25 to extract for 3 h at 37 ℃, filtered and recovered the extract, then filtered the extract in vacuum, concentrated by ultrafiltration, and freeze-dried after dialysis (Glasson et al. 2022). The final yield of ulvan was 3.5%, 3.9%, and 6.7%, respectively. In addition to HCl, Manikandan et al. also tried to use citric acid, a green chemical, to extract ulvan from foliose Ulva sp. and filamentous Ulva sp. and optimized it (Manikandan and Lens 2022). The polysaccharide extraction rates of foliose Ulva sp. and filamentous Ulva sp. were 0.41 (± 0.022) g/g and 0.39 (± 0.019) g/g, respectively, When the extraction temperature was 90 °C, the extraction time was 4 h, the minimum Ulva sp. load was 3 wt%, and the citric acid concentration was 1 wt%. Conversely, Christopher et al. tried to extract ulvan with sodium oxalate, but the yield was only 4.3 ± 0.5% and the content of protein was higher than that extracted by HCl (Glasson et al. 2017). Compared with hot water extraction, chemical extraction also improves the yield of ulvan by increasing the temperature and prolonging the extraction time, but its extraction conditions are more stringent. This is not only bad for industrial production but will also greatly increase the environmental maintenance costs in the production process.

Physical-assisted extraction

The physical-assisted extraction method mainly uses physical methods other than heating to help destroy the cell wall structure of Ulva sp., making it easier to extract polysaccharides from Ulva sp., thereby shortening the extraction time and improving the yield of ulvan. Chen et al. used the ultrasonic-assisted method to extract ulvan, mixed it according to the material-to-liquid ratio of 1:20, first treated it with ultrasonic for 30 min, and then extracted it in a 90 ℃ water bath for 2.5 h, with an extraction rate of 20.6 ± 1.2% (Chen et al. 2021). However, Tsubaki et al. used microwave-assisted technology to extract ulvan at 100 ℃ to 180 ℃ after mixing according to the material-to-liquid ratio of 1:20 (Tsubaki et al. 2016). At 160 ℃, the extraction rates of ulvan reached 40.4 ± 3.2% (U. meridionalis) and 36.5 ± 3.1% (U. ohnoi). Yuan et al. mixed the mixture in a 0.01 M HCl solution according to the feed–liquid ratio of 1:20 and received microwave irradiation at 120 ℃ for 15 min (Yuan et al. 2018). The yield of ulvan was 36.38 ± 0.94%. The cell wall of Ulva sp. was greatly damaged by the method of physical-assisted extraction, which greatly improved the efficiency of the next hot water extraction. In particular, the yield of microwave-assisted extraction is about 2–3 times that of traditional hot water extraction.

Enzyme-assisted extraction

Enzyme-assisted extraction is a new method to improve the yield of polysaccharides based on hot water extraction and enzyme technology. Before reaction, add cellulase and pectinase that can degrade cellulose, hemicellulose, and pectin in the cell wall of Ulva sp., and release more ulvan by destroying the structure of the cell wall (Fernandes et al. 2019). Chen et al. prepared the solution according to the material-to-liquid ratio of 1:20 and added 1 M HCl to adjust the pH value to 4.5 (Chen et al. 2021). First, they reacted with cellulase and the mixture in a water bath at 50 ℃ for 2.5 h, then raised the temperature to 90 ℃, and inactivated the enzyme for 30 min. The yield of ulvan was 25.3 ± 1.3%. Hardouin et al. added six enzymes including protease and cellulase into the mixture of Ulva sp. and ultrapure water to react at 50 ℃ for 3 h, heated to 90 ℃, and inactivate the enzyme for 15 min. The yield of polysaccharide was 35.3 ± 0.3%. It is obvious that the temperature and pH value required for the reaction can be greatly reduced by using the high efficiency and mildness of the enzyme, making the reaction environment milder. In addition, the yield of the enzyme-assisted extraction method is higher than that of the solution extraction method, which can make full use of marine biomass resources, and it is a method that can effectively use marine green biomass resources such as ulvan.

To sum up, the main extraction methods of ulvan are based on hot water extraction, and various extraction methods are derived by adding different auxiliary technologies at different stages, but there are some advantages and disadvantages of each method. Yaich et al. tried to combine the enzyme-assisted extraction method with the solution extraction method and compared them with the solution extraction method. The results showed that the yield of ulvan increased from 13.06 to 17.14% by the organic combination of the two methods. In likewise, Chen et al. combined ultrasonic-assisted extraction with enzyme-assisted extraction, and compared it with hot water extraction, enzyme-assisted extraction and ultrasonic-assisted extraction, respectively. The results showed that the yield of ultrasonic-assisted extraction and enzyme-assisted extraction was 26.7 ± 0.9% higher than that of the other three extraction methods. Therefore, by organically combining different extraction methods, the yield of ulvan can be improved and the extraction cost reduced, thus promoting follow-up research on ulvan.

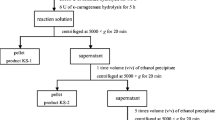

Purification methods of ulvan

The crude ulvan obtained by hot water extraction and other methods contains non-polysaccharide impurities such as protein and other small molecules. It needs to be further purified to obtain high-purity polysaccharide samples that can be used for structure and activity studies. The isolation and purification methods of ulvan mainly include dialysis, ultrafiltration, and column chromatography, of which the latter is divided into ion exchange column chromatography and gel column chromatography.

To achieve the purpose of purification, dialysis primarily employs the selective permeability of membranes to remove salt and low-molecular-weight impurities from the crude extract of ulvan via a dialysis bag with appropriate molecular weight retention (Wang et al. 2016). Similarly, ultrafiltration also uses the same principle to separate the salt and small molecular solute in the crude extract through the membrane, and it also has many advantages including low cost, high efficiency, environmental protection, and continuous operation (Zhang and Wang 2016). The ultrafiltration dialysis tube and membrane filter have various filtering pore diameters or molecular weight cutoffs (MWCO). For dialysis, the selection of pore size is based on the molecular size of ulvan. However, the selection of pore size for ultrafiltration is not only based on the molecular size of ulvan but also depends on the elution amount (which decreasing with the pore size). In order to balance the influence of elution amount and pore size, the MWCO of about 10 kDa was generally selected (Glasson et al. 2022, 2017).

Nevertheless, many extracts of ulvan contain more impurities, and it is difficult to further refine and classify them only through dialysis and ultrafiltration. As ulvan is a water-soluble anionic polysaccharide, it is suitable for further purification by ion exchange chromatography (IEC) or gel filtration chromatography (GFC). As shown in Table 2, although the separation columns are quite different, they are gradient eluted and purified with NaCl as the mobile phase. Among them, Glasson et al. purified ulvan from U. ohnoi, U. tepida, and U. prolifera, respectively, and the final polysaccharide yields were 1.45, 1.29, and 2.8% (Glasson et al. 2022). Li et al. gradient purified the ulvan from U. pertusa, collected the components eluted by 0, 0.5, and 1.0 M NaCl, and then measured the polysaccharide content by the phenol–sulfuric acid method and determined that the main polysaccharide fraction was at 1.0 M elute (Li et al. 2020a). Through chromatography, we can obtain purer ulvan, which enables us to further study the conformation, structure, activity, and structure–activity relationship of ulvan.

Preparation of Ulva oligosaccharide

Degraded ulvan, also known as Ulva oligosaccharide, is more bioavailability and soluble. Therefore, the degradation and preparation of Ulva oligosaccharides have attracted more and more attention. According to the preparation of Ulva oligosaccharides, they can be classified into chemical degradation, physical degradation, and enzymatic degradation.

Preparation of Ulva oligosaccharide by chemical and physical degradation

The chemical degradation method is used to prepare Ulva oligosaccharides by destroying the glycosidic bond in ulvan with strong acidic or strong oxidizing chemical reagents. In the process of extracting ulvan by Hela Yaicha et al., they found that a large number of low-molecular-weight components existed in the alcohol precipitated products under lower pH conditions, which provided a basis for the subsequent preparation of oligosaccharides through strong acids (Yaich et al. 2013). After that, Liu et al. and Roberta Paulert et al. degraded ulvan with H2SO4, HCl, and trichloroacetic acid and prepared oligosaccharides with molecular weights less than 3000 Da and non-sulfated dimers, respectively (Liu et al. 2019; Paulert et al. 2021). In addition, ulvan can also be degraded by strong oxidants. For example, Zhang et al. and Joel T. Kidgella et al. used H2O2 to degrade ulvan into oligosaccharide with 10.6 kDa and 6.8 kDa molecular weights, respectively (Kidgell et al. 2020; Zhang et al. 2008). Wu et al. combined H2O2 with ascorbic acid to degrade ulvan, and the molecular weight of its oligosaccharide is 956.71 Da, which is lower than before (Wu et al. 2020).

However, there are few studies on the physical degradation of ulvan, and only Yu et al. degrade ulvan through microwave and high pressure (Pengzhan et al. 2003). Furthermore, Simona et al. demonstrated that ulvan would self-hydrolyze in hot water solution at high temperature, and that by controlling the optimal temperature, 78.7% of the rare sugar rhamnose, glucuronic acid, and other minor degradation products could be recovered (Podolean et al. 2022). However, the physical degradation method requires a lot of energy to destroy the glycosidic bond in ulvan to prepare Ulva oligosaccharides, which has the same problems as the chemical method, such as harsh reaction conditions and a long degradation time (Tang et al. 2021).

Preparation of Ulva oligosaccharide by enzymatic degradation

Compared with chemical and physical methods for the degradation of ulvan, enzymatic degradation of ulvan has the advantages of mild reaction conditions, good product specificity, and environmental friendliness, which has attracted the extensive attention of researchers (Li et al. 2023; Tang et al. 2023). At present, the enzymes mainly used to degrade ulvan are PL24, PL25, PL28, and PL40 family ulvan lyases, which are the enzyme that specifically degrades ulvan. As shown in Table 3, LOR_107 from Alteromonas sp. LOR (Kopel et al. 2016), AsPL from Alteromonas sp. (AsPL) (Qin et al. 2020), PLSV from Pseudoalteromonas sp. strand PLSV (Qin et al. 2018), Uly1 from Catenovulum maritimum (Xu et al. 2021), LOR_29 from Alteromonas sp. LOR (Xu et al. 2021), FaUL from Formosa agariphila KMM 3901 (Konasani et al. 2018b), and FaPL28 from Formosa agariphila KMM 3901T (Reisky et al. 2018) have the highest activity between 30 and 45 ℃. And PLSV from Pseudoalteromonas sp. PLSV_3875 (Kopel et al. 2016), ALT3695 from Alteromonas sp. A321. ALT3695 (Gao et al. 2019), and NLR42 from Nonlabens ulvanivorans NLR42 (Nyvall Collén et al. 2011) showed the best activity at 50 ℃, while TsUly25B from Thalassomonas sp. LD5 reached 60 ℃ (Wang et al. 2022). The optimal pH of all ulvan lyases are between 7.5 and 9, showing high catalytic activity in a weak alkaline environment, which may be the adaptive evolution of marine bacteria to a weak alkaline seawater environment (Reisky et al. 2018). Ulaganathan studied the structure and degradation mechanism of PL24, PL25, and PL28 family ulvan lyase, respectively. Ulvan lyase primarily cleaved the β-(1 → 4)-glycosidic bond between L-rhamnose-3-sulfate (Rha3S) and D-glucuronic acid (GluA) or L-iduronic acid (IduA) via the β-elimination mechanism, producing two and four degrees polymerized (Dp) oligosaccharides (Ulaganathan et al. 2018a, 2018b, 2017). This is also the reason that almost all the degradation products of ulvan lyases are even oligosaccharides of DP2 and DP4. In addition, the β-elimination mechanism can effectively preserve the structural characteristics of rare sugars during the ulvan degradation, laying the groundwork for their high-value development. Furthermore, besides ulvan lyase, there are Cdf79930 from Formosa agariphila KMM 3901 (Konasani et al. 2018a), a lyase with broad spectrum activity, and P29_PDnc (Bäumgen et al. 2021), a dehydrating enzyme also from the same strain, which can participate in the degradation and further degrade the product into monosaccharide (Tables 4, 5, and 6). It provides different ideas for the enzymatic degradation of ulvan (Li et al. 2020b).

Biological activity of ulvan and Ulva oligosaccharide

Biological activity of ulvan

In recent years, with the continuous development of the extraction and purification technology of ulvan, more and more researchers have studied the activities of ulvan obtained from different extraction processes. At present, biological activities such as anti-virus, anti-inflammatory, antioxidant, anticoagulant, immune regulation, and induced plant defense have been reported by researchers.

Anti-virus activity

Much research shows that ulvan from different Ulva sp., such as Ulva compressa, U. lactuca, U. clathrata, U. intestinalis, U. armoricana, and U. pertusa, have the activity of anti-virus (Aguilar-Briseño et al. 2015; Hardouin et al. 2016; Lopes et al. 2017; Morán-Santibañez et al. 2016; Song et al. 2016). Ulvan is a natural sulfated polysaccharide, which in turn can have unique inhibitory effects on viruses and tumors. Recently, with the increasingly serious COVID-19 epidemic, Shefer et al. evaluated the antiviral SARS CoV-2 activity of ulvan extracted by ammonium oxalate (AOx scheme) and HCl (HCl scheme), respectively. The research results showed that ulvan extracted by the AOx scheme could protect VERO E6 cells from the cytopathic effect of SARS CoV-2, and they attributed it to the interaction of negatively charged groups of ulvan with the protein on the surface of the virus (Shefer et al. 2021). Sulfated polysaccharides bind to viral binding sites (CD4 receptors) on the surface of T cells, interfering with viral invasion, which may be due to the binding of sulfate groups to the polysaccharides through electrostatic interactions. The research of Chi et al. on the anti-vesicular stomatitis virus activity of ulvan also has similar research results, that is, ulvan may inhibit virus infection and replication by interacting with viral envelope glycoproteins or binding with cell surface receptors. And they also found that the higher-molecular-weight ulvan (38.5 kDa) had better antiviral activity, probably because the longer glycan chains more readily recognized and interacted with proteins attached to the viral surface (Chi et al. 2020b). In fact, the putative anti-virus mechanism of sulfated polysaccharide is to bind to glycoprotein on the virus or adsorb on the cell surface receptor to prevent the virus from entering the cell interior, as shown in Fig. 2 (Andrew and Jayaraman 2021; Lu et al. 2021).

Therefore, it can be hypothesized that molecular weight and charge also affect the antiviral activity of Ulva stramonium polysaccharides. However, an obstacle to the application of sulfated polysaccharides as antiviral drugs is that they usually have anticoagulant activity and thus side effects. Current research is directed toward the synthesis of sulfated derivatives with high antiviral activity and low anticoagulant activity.

Antioxidant activity

Oxidative stress is defined as an imbalance of oxidant and antioxidant levels in the body induced by reactive oxygen species (ROS), which disrupts redox signal transmission and regulation and can potentially cause molecular damage. It is implicated not only in the aging process but also in the pathophysiology of numerous illnesses (Chen et al. 2022a). As anti-oxidation research has progressed, the anti-oxidative activity of ulvan produced using various extraction techniques has been identified. For instance, Sulastri Evi et al. discovered that with the increase of the concentration of ulvan extracted with HCl in the hydrogel, its ability to scavenge hydroxyl radicals was continuously enhanced (Sulastri et al. 2021). Yuan et al. extracted ulvan by microwave-assisted extraction, which had a scavenging ability of 27.6% and 68.6% for DPPH free radicals and ABTS free radicals, respectively, and good reducing activity (Yuan et al. 2018). Chen et al. examined the antioxidant activity of ulvan extracted using hot water, enzyme-assisted extraction, microwave-assisted extraction, and microwave enzyme-assisted extraction and found that the enzyme-assisted extraction had the best DPPH scavenging capacity. In addition, Li et al. discovered that the scavenging capacity of purified ulvan (FU) and purified ulvan with high sulfate group (HFU) in hot water-extracted ulvan, FU, and HFU is superior to that of Vc, and in vivo tests on mice revealed that different dosages of HFU groups significantly increased the activities of catalase (CAT), glutathione peroxidase (GSH-Px), and superoxide dismutase (SOD), while lowering MDA levels text. These results indicate that ulvan have a strong capacity to scavenge DPPH and ABTS free radicals in vitro, probably because the hydroxyl groups of the polysaccharides provide hydrogen ions, leading to the reduction of DPPH radicals. Ulvan achieved antioxidant activity via influencing the activities of CAT, GSH-Px, and SOD in vivo. However, to determine the signaling pathways involved, further research on the method by which ulvan alters the expression of antioxidant enzymes in vivo is required.

Anti-hyperlipidemic activity

Hyperlipidemia is a major cause of vascular disease, and traditional treatment techniques have significant negative effects. As a result, studies on anti-hyperlipidemic components in natural foods are expanding (Ge et al. 2022). Ulvan, the primary active element in the green algal Ulva, has long been known to have anti-hyperlipidemic properties (Pengzhan et al. 2003). Currently, all the ulvan utilized in the investigation of anti-hyperlipidemic activity is produced using hot water extraction. Sathivel et al. (2008) tested the anti-hyperlipidemic activity of crude ulvan by feeding it to mature male albino rats. The findings revealed that ulvan could significantly inhibit the acute rise in serum triglyceride, free fatty acid, and total cholesterol levels while also significantly lowering high-density lipoprotein (HDL), very low-density lipoprotein (VLDL), and having a parallel inhibitory effect on the rise in low-density lipoprotein (LDL) (Sathivel et al. 2008). Following that, Li et al. compared the anti-hyperlipidemic ability of crude ulvan (U) and purified ulvan (F1 and F2). The result shows that F1, which can dramatically lower the level of low-density lipoprotein cholesterol (LDL-C) while increasing the level of high-density lipoprotein cholesterol (HDL-C) at a dose over 250 mg/Kg, and F2, which reduced serum total cholesterol (TC) and triglycerides (TG) levels considerably, have better anti-hyperlipidemic ability than U (Li et al. 2018). Furthermore, Qi et al. and Li et al. revealed that sulfated ulvan had better anti-hyperlipidemic activity than ulvan, while the latter discovered that the anti-hyperlipidemic activity of the pure ulvan was further boosted after sulfated, that is, the LDL-C content was reduced, HDL-C was raised to normal levels, and the TC and TG contents were significantly reduced at only half the dose of FU (Li et al. 2020a; Qi et al. 2012). These findings suggest that the anti-hyperlipidemic effect of ulvan is mediated by various pathways, the balance of which is determined by the structural properties of ulvan. This opens the door to tailoring anti-hyperlipidemic supplements for more specific purposes.

Anticancer activity

Abd-Ellatef et al. studied the prevention of carcinogenic activity in ulvan obtained by hot water extraction on the breasts of Wistar rats. The findings revealed that ulvan could not only raise the expression of the tumor suppressor protein p53 and the enzymatic activities of glutathione-S-transferase (GST), GPx, and CAT, but also considerably lower blood TNF-α and NO (Abdellatef et al. 2017). Shao et al. investigated the inhibitory impact of ulvan produced by hot water extraction, which, after partial desulfurization, inhibited the development of DLD intestine cancer cells, and found that the large molecular weight desulfurized sample DS-UFP3 inhibited cell growth well at a concentration of 4 mg/mL (Shao et al. 2014). The anticancer activity of ulvan appears to be exerted through multiple pathways, including the encouragement of cancer cell death, the decrease of cancer cell growth, and the activation of innate immune responses. Ulvan is a class of biological response modifiers, and if it can be used as anticancer drugs, its greatest advantage is that it have fewer toxic side effects, and it can be more effective when used in combination with chemotherapeutic drugs. Moreover, to a certain extent, ulvan can counteract the adverse reactions caused by chemotherapeutic drugs.

Immunomodulation activity

Klongklaewad et al. investigated the immunomodulation activity of ulvan prepared by hot water extraction on Pacific white shrimp and discovered that ulvan promoted the expression of immune-related genes (Anti-lipopolysaccharide factor (ALF), prophenoloxidase (proPO), SOD, transglutaminase (Trans), lysozyme (Lyso), C-type lectin (Clectin), and lipopolysaccharide and β-1,3-glucan binding protein (LGBP)) to varying degrees and had a good preventive effect on yellow head virus (YHV), significantly reducing its mortality (Klongklaew et al. 2021). Fernández-Dazde et al. evaluated the immunomodulation activity of ulvan isolated from sodium oxalate and discovered that ulvan can increase reactive oxygen species in macrophages (Fernández-Díaz et al. 2017). Ulvan is an immunostimulant that significantly promotes phagocytosis by macrophages and increases the weight of the spleen, an immune organ. According to Harikrishnan et al., who examined the immunomodulation activity of ulvan on Labeo rohita, it was discovered that ulvan can significantly increase phagocytic (PC) activity, respiratory burst (RB), alternative complement activity (ACP/ACH50), lysozyme (Lyz) activity, immunoglobulin M (IgM), and other cytokines or protein mRNA expression (Harikrishnan et al. 2021). In addition, ulvan promotes the expression of antioxidant-related genes (SOD, GPx, natural killer cell enhancer factor β (NKEF-β) gene, etc.) and anti-inflammatory-related genes (toll-like receptor 22 (TLR22), interleukin 1β (IL-1β), tumor necrosis factor α (TNF-α), etc.). Ulvan can achieve immunomodulatory effects by promoting the expression of immune-related genes and elevating the activities of PC, RB, and ACP/ACH50. In summary, it can be hypothesized that ulvan can play an antiviral role by regulating the body's immune status, enhancing the body's immunity, and promoting the value-added of T and B lymphocytes.

Plant defense activity

Ulvan also has positive impacts on plant defense. For example, the induction activity of thermochemically extracted ulvan on the defensive response system of table grapes was assessed by Shomron et al. The outcomes demonstrated that ulvan derived from Ulva rigida may raise active oxygen levels and catalase, superoxide dismutase, and chitinase enzyme activities, decreasing table grape rot (Shomron et al. 2022). According to Borba et al.'s study on wheat-to-wheat yeast resistance induced by ulvan extracted by hot water, while ulvan cannot directly play an antifungal function, it can indirectly activate the genes expressing PR proteins (PR-2 and PR-3), ROS metabolism (OXO), and the octadecanoid-based pathway (LOX and AOS). However, the utilization of ulvan would face challenges, including poor bioavailability and solubility brought on by its high molecular weight (de Borba et al. 2021). Paulert et al. investigated the immunomodulatory activity of hot water-extracted ulvan in parsley and basil, finding that ulvan can increase the levels of salicylic acid (SA), salicylic acid β-glucoside (SAG), and abscisic acid (ABA) in parsley and basil, as well as increase jasmonic acid (JA) accumulation in basil [86]. Ulvan demonstrated considerable bioinducer activity as well as the ability to operate as a promoter, improving plant health and resistance.

In conclusion, the biological activities of ulvan, such as anti-virus, anti-oxidation, anti-hyperlipidemic, anticancer, and immunomodulation, are strongly connected to its fundamental biological activities, and they have some regulatory effects on plant defense systems. It is important to note that the biological activity of ulvan is highly connected to their molecular weight, structural properties, and content. The mechanism related to the biological activity of ulvan is shown in Fig. 3.

Biological activity of Ulva oligosaccharide

At present, the relevant research and reports on the activity of Ulva oligosaccharides are increasing, but the literature reports are relatively scattered, and due to the complexity of the structure of Ulva oligosaccharides, the mechanism of related activities and the structure–activity relationship of oligosaccharides have not yet been determined. According to Chi et al.'s evaluation of the anti-vesicular stomatitis virus (VSV) activity of Ulva oligosaccharides made by ulvan lyase of the PL25 family, lower-molecular-weight degraded Ulva oligosaccharides demonstrated antiviral activity equal to that of undegraded ulvan at 100 L/mL. Low-molecular-weight polysaccharides are preferable for the creation of dietary supplements and medications due to their comparable action to natural polysaccharides (Chi et al. 2020b). Using an enzymatic method, Ulva oligosaccharides were prepared by Li et al. to study their anti-inflammatory bowel disease (IBD) properties. The study's findings revealed that Ulva oligosaccharides started to have a protective effect on IBD at a dose of 50 mg/kg and were most effective at 100–120 mg/kg. Ulva oligosaccharides may also lessen the harm dextran sodium sulfate (DSS) causes to colonic epithelial cells (Li et al. 2020c). According to Tabarsa et al., Ulva oligosaccharides with a high sulfate group composition and a low molecular weight may successfully multiply RAW264.7 macrophages, proving that they have a higher bioavailability. Additionally, Ulva oligosaccharides may stimulate RAW 264.7 cell production of cytokines with weak immunomodulatory activity, such as nitric oxide, IL-1β, TNF-α, IL-6, IL-10, and IL-12 (Tabarsa et al. 2018). And Berria et al. also found that the mRNA and protein expression of cytokines (such as CCL20, IL-8, and TNF-α) were increased when porcine intestinal epithelial (IPEC-1) cells were treated with Ulva oligosaccharides (Berri et al. 2017). The presence of Ulva oligosaccharides that have been degraded might enhance the anticancer activity of ulvan, according to research by Carvalho et al. on the cytotoxicity of Ulva oligosaccharides on human cervical cancer cells (de Carvalho et al. 2020). In contrast to high-molecular-weight ulvan, degraded Ulva oligosaccharides displayed stronger antioxidant activity, according to Qi et al. (2005). Using a male Wistar rat model, Yu et al. investigated the anti-hyperlipidemic activity of Ulva oligosaccharides and discovered that it increased HDL cholesterol by 2.0 times and decreased TG by 46.4% in rats given Ulva oligosaccharide. Accordingly, degraded Ulva oligosaccharides were superior to undegraded ulvan in treating hyperlipidemia caused by diabetes. The biological activities related to Ulva oligosaccharides are shown in Fig. 4.

In terms of enhancing plant defense activity, Ulva oligosaccharides also performed well. Paulert et al. investigated the oxidative burst activity of Ulva oligosaccharides prepared by acid hydrolysis to induce dicotyledonous plants, and the findings revealed that low-molecular-weight Ulva oligosaccharides can have the same activity as ulvan, and its inducing activity is not dependent on acid sulfation. Because of their solubility or high viscosity, large molecular weight polysaccharides are challenging to utilize in normal agricultural contexts (Paulert et al. 2021). AbourachaaZ et al. investigated the effects of ulvan and ulvan oligosaccharides produced by ulvan lyase on apple defense reactions and corruption. Ulva oligosaccharides may totally prevent the formation of blue and cyan molds on fruits, according to the findings. Ulva oligosaccharides, as opposed to ulvan, can also better stimulate the immune regulation system of apples, resulting in the activation of antioxidant-related enzymes and an increase in the activities of phenylalanine ammonia lyase (PAL), peroxidase (POD), and polyphenol oxidase (PPO) (Abouraïcha et al. 2015). However, researches on the action of Ulva oligosaccharides are limited. This is also due to the complexity of the structure of ulvan, and there is no suitable method for obtaining oligosaccharides with a specified fine structure to research the structure–activity connection of oligosaccharides.

Conclusion and outlook

The extraction rate of ulvan increased significantly as the extraction process was continuously optimized, going from a low yield of 7%–24% (Chen et al. 2021; Paradossi et al. 1999; Toskas et al. 2011) in the traditional extraction method to 35.3 ± 0.3% (Hardouin et al. 2016) in the enzyme-assisted extraction method and 40.4 ± 3.2% (Magnusson et al. 2019) in the microwave-assisted extraction method. In addition, obtaining high-purity ulvan by purification played a key role in the study of their structure and activity. As Glasson analyzed the monosaccharide composition and structure by purifying the polysaccharides from different sources and analyzed the in vivo and in vitro antioxidant activity and enzyme inhibitory activity of purified ulvan with a higher confidence level in their results. Enzymatic preparation of Ulva oligosaccharides has milder reaction conditions and higher reaction efficiencies and produces oligosaccharides with unsaturated bonds at the non-reducing end compared to chemical and physical methods. In addition, the rich biological activities of ulvan and Ulva oligosaccharides make them potentially applicable in food, medicine, cosmetics, and other fields.

However, studies on the structure and biological properties of ulvan are still at an early stage compared to other marine sulfate polysaccharides, carrageenan, and fucoidan. On one hand, the high-value development of ulvan is still affected by the immaturity and low purity of the large-scale preparation process, i.e., the industrial production of high-purity ulvan cannot be realized. On the other hand, the relationship between the physicochemical properties of ulvan and their biological activities, as well as the mechanism of action of the biological activities, remains unclear. This is due to the fact that studies related to the highly refined structure–function properties as well as the activity of fully characterized ulvan against highly precise targets are still scarce. In contrast, Ulva oligosaccharides, as degradation products of ulvan, retain various physiological activities and other excellent properties of ulvan. Although the tool enzyme ulvan lyase has been identified and certain research findings have been obtained, the reported enzymes still cannot match the demands of commercial applications due to a lack of sequence information, low stability, and low activity. As a result, ulvan lyases with high activity and exceptional stability, as well as their entire sequence information, are urgently required for commercial applications. Furthermore, precise fine structure analysis of ulvan and its oligosaccharides plays a significant role in increasing the structure–activity connection of ulvan and its oligosaccharides, as well as the high-value development and effective exploitation of ulvan. Ulvan, a rich green marine biomass resource, will be more fully utilized in the future with the realization of industrialized production of high-purity ulvan, the discovery of more and more excellent biochemical properties of ulvan lyases, and the clarification of the structure–activity relationship between ulvan and its oligosaccharides.

Availability of data and materials

Data may be made available on request.

References

Abdellatef G, Ahmed OM, Abdelreheim ES, Abdelhamid A (2017) Ulva lactuca polysaccharides prevent Wistar rat breast carcinogenesis through the augmentation of apoptosis, enhancement of antioxidant defense system, and suppression of inflammation. Breast Cancer Targets & Therapy 9:67–83

Abouraïcha E, El Alaoui-Talibi Z, El Boutachfaiti R, Petit E, Courtois B, Courtois J, El Modafar C (2015) Induction of natural defense and protection against Penicillium expansum and Botrytis cinerea in apple fruit in response to bioelicitors isolated from green algae. Sci Hortic 181:121–128. https://doi.org/10.1016/j.scienta.2014.11.002

Aguilar-Briseño JA, Cruz-Suarez LE, Sassi J-F, Ricque-Marie D, Zapata-Benavides P, Mendoza-Gamboa E, Rodríguez-Padilla C, Trejo-Avila LM (2015) Sulphated polysaccharides from Ulva clathrata and Cladosiphon okamuranus seaweeds both inhibit viral attachment/entry and cell-cell fusion. NDV Infect Mar Drugs 13(2):697–712

Andrew M, Jayaraman G (2021) Marine sulfated polysaccharides as potential antiviral drug candidates to treat Corona Virus disease (COVID-19). Carbohyd Res 505:108326

Bäumgen M, Dutschei T, Bartosik D, Suster C, Reisky L, Gerlach N, Stanetty C, Mihovilovic MD, Schweder T, Hehemann J-H, Bornscheuer UT (2021) A new carbohydrate-active oligosaccharide dehydratase is involved in the degradation of ulvan. J Biol Chem 297(4):101210. https://doi.org/10.1016/j.jbc.2021.101210

Beer S (2023) Photosynthetic traits of the ubiquitous and prolific macroalga Ulva (Chlorophyta): a review. Eur J Phycol. 1–9

Benslima A, Sellimi S, Hamdi M, Nasri R, Jridi M, Cot D, Li S, Nasri M, Zouari N (2021) The brown seaweed Cystoseira schiffneri as a source of sodium alginate: Chemical and structural characterization, and antioxidant activities. Food Biosci 40:100873. https://doi.org/10.1016/j.fbio.2020.100873

Berri M, Olivier M, Holbert S, Dupont J, Demais H, Le Goff M, Collen PN (2017) Ulvan from Ulva armoricana (Chlorophyta) activates the PI3K/Akt signalling pathway via TLR4 to induce intestinal cytokine production. Algal Res 28:39–47. https://doi.org/10.1016/j.algal.2017.10.008

Cadar E, Negreanu-Pirjol T, Sirbu R, Dragan A-ML, Negreanu-Pirjol B-S, Axente ER, Ionescu A-M (2023) Biocompounds from green algae of romanian black sea coast as potential nutraceuticals. Processes 11(6):1750

Chen J, Zeng W, Gan J, Li Y, Pan Y, Li J, Chen H (2021) Physicochemical properties and anti-oxidation activities of ulvan from Ulva pertusa Kjellm. Algal Res 55:102269. https://doi.org/10.1016/j.algal.2021.102269

Chen Y, Lin Q, Wang J, Mu J, Liang Y (2022a) Proteins, polysaccharides and their derivatives as macromolecular antioxidant supplements: a review of in vitro screening methods and strategies. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2022.10.181

Chen Z, Liu M, Yang Y, Bi M, Li M, Liu W (2022b) Environmental and economic impacts of different disposal options for Ulva prolifera green tide in the yellow sea, China. ACS Sustain Chem Eng 10(35):11483–11492. https://doi.org/10.1021/acssuschemeng.2c02638

Chi Y, Li H, Wang P, Du C, Ye H, Zuo S, Guan H, Wang P (2020a) Structural characterization of ulvan extracted from Ulva clathrata assisted by an ulvan lyase. Carbohyd Polym 229:115497. https://doi.org/10.1016/j.carbpol.2019.115497

Chi Y, Zhang M, Wang X, Fu X, Guan H, Wang P (2020b) Ulvan lyase assisted structural characterization of ulvan from Ulva pertusa and its antiviral activity against vesicular stomatitis virus. Int J Biol Macromol 157:75–82. https://doi.org/10.1016/j.ijbiomac.2020.04.187

Chi Y, Li H, Fan L, Du C, Zhang J, Guan H, Wang P, Li R (2021) Metal-ion-binding properties of ulvan extracted from Ulva clathrata and structural characterization of its complexes. Carbohyd Polym 272:118508

Cindana Mo’o FR et al (2020) Ulvan, a polysaccharide from macroalga Ulva sp.: a review of chemistry, biological activities and potential for food and biomedical applications. Appl Sci 10(16):5488

de Borba MC, Velho AC, Maia-Grondard A, Baltenweck R, Magnin-Robert M, Randoux B, Holvoet M, Hilbert J-L, Flahaut C, Reignault P, Hugueney P, Stadnik MJ, Siah A (2021) The algal polysaccharide ulvan induces resistance in wheat against Zymoseptoria tritici without major alteration of leaf metabolome. Front Plant Sci. https://doi.org/10.3389/fpls.2021.703712

de Carvalho MM, Noseda MD, Dallagnol JCC, Ferreira LG, Ducatti DRB, Gonçalves AG, de Freitas RA, Duarte MER (2020) Conformational analysis of ulvans from Ulva fasciata and their anticoagulant polycarboxylic derivatives. Int J Biol Macromol 162:599–608. https://doi.org/10.1016/j.ijbiomac.2020.06.146

Faggio C, Pagano M, Dottore A, Genovese G, Morabito M (2016) Evaluation of anticoagulant activity of two algal polysaccharides. Nat Prod Res 30(17):1934–1937. https://doi.org/10.1080/14786419.2015.1086347

Fernandes H, Salgado JM, Martins N, Peres H, Oliva-Teles A, Belo I (2019) Sequential bioprocessing of Ulva rigida to produce lignocellulolytic enzymes and to improve its nutritional value as aquaculture feed. Biores Technol 281:277–285. https://doi.org/10.1016/j.biortech.2019.02.068

Fernández-Díaz C, Coste O, Malta E-j (2017) Polymer chitosan nanoparticles functionalized with Ulva ohnoi extracts boost in vitro ulvan immunostimulant effect in Solea senegalensis macrophages. Algal Res 26:135–142. https://doi.org/10.1016/j.algal.2017.07.008

Foran E, Buravenkov V, Kopel M, Mizrahi N, Shoshani S, Helbert W, Banin E (2017) Functional characterization of a novel “ulvan utilization loci” found in Alteromonas sp. LOR Genome Algal Res 25:39–46

Gao J, Du C, Chi Y, Zuo S, Ye H, Wang P (2019) Cloning, expression, and characterization of a new PL25 family ulvan lyase from marine bacterium Alteromonas sp A321. Mar Drugs 17(10):568

Ge Y, Qiu H, Zheng J (2022) Physicochemical characteristics and anti-hyperlipidemic effect of polysaccharide from BaChu mushroom (Helvella leucopus). Food Chemistry: X 15:100443. https://doi.org/10.1016/j.fochx.2022.100443

Glasson CRK, Sims IM, Carnachan SM, de Nys R, Magnusson M (2017) A cascading biorefinery process targeting sulfated polysaccharides (ulvan) from Ulva ohnoi. Algal Res 27:383–391. https://doi.org/10.1016/j.algal.2017.07.001

Glasson CRK, Luiten CA, Carnachan SM, Daines AM, Kidgell JT, Hinkley SFR, Praeger C, Andrade Martinez M, Sargison L, Magnusson M, de Nys R, Sims IM (2022) Structural characterization of ulvans extracted from blade (Ulva ohnoi) and filamentous (Ulva tepida and Ulva prolifera) species of cultivated Ulva. Int J Biol Macromol 194:571–579. https://doi.org/10.1016/j.ijbiomac.2021.11.100

Guidara M, Yaich H, Benelhadj S, Adjouman YD, Richel A, Blecker C, Sindic M, Boufi S, Attia H, Garna H (2020) Smart ulvan films responsive to stimuli of plasticizer and extraction condition in physico-chemical, optical, barrier and mechanical properties. Int J Biol Macromol 150:714–726. https://doi.org/10.1016/j.ijbiomac.2020.02.111

Hardouin K, Bedoux G, Burlot A-S, Donnay-Moreno C, Bergé J-P, Nyvall-Collén P, Bourgougnon N (2016) Enzyme-assisted extraction (EAE) for the production of antiviral and antioxidant extracts from the green seaweed Ulva armoricana (Ulvales, Ulvophyceae). Algal Res 16:233–239. https://doi.org/10.1016/j.algal.2016.03.013

Harikrishnan R, Devi G, Van Doan H, Balasundaram C, Arockiaraj J, Jagruthi C (2021) Efficacy of ulvan on immune response and immuno-antioxidant gene modulation in Labeo rohita against columnaris disease. Fish Shellfish Immunol 117:262–273

Kidgell JT, Magnusson M, de Nys R, Glasson CRK (2019) Ulvan: a systematic review of extraction, composition and function. Algal Res 39:101422. https://doi.org/10.1016/j.algal.2019.101422

Kidgell JT, Glasson CRK, Magnusson M, Vamvounis G, Sims IM, Carnachan SM, Hinkley SFR, Lopata AL, de Nys R, Taki AC (2020) The molecular weight of ulvan affects the in vitro inflammatory response of a murine macrophage. Int J Biol Macromol 150:839–848. https://doi.org/10.1016/j.ijbiomac.2020.02.071

Kidgell JT, Carnachan SM, Magnusson M, Lawton RJ, Sims IM, Hinkley SFR, de Nys R, Glasson CRK (2021) Are all ulvans equal? A comparative assessment of the chemical and gelling properties of ulvan from blade and filamentous Ulva. Carbohyd Polym 264:118010. https://doi.org/10.1016/j.carbpol.2021.118010

Klongklaew N, Praiboon J, Tamtin M, Srisapoome P (2021) Chemical composition of a hot water crude extract (HWCE) from Ulva intestinalis and its potential effects on growth performance, immune responses, and resistance to white spot syndrome virus and yellowhead virus in Pacific white shrimp (Litopenaeus vannamei). Fish Shellfish Immunol 112:8–22

Konasani VR, Jin C, Karlsson NG, Albers E (2018a) A novel ulvan lyase family with broad-spectrum activity from the ulvan utilisation loci of Formosa agariphila KMM 3901. Sci Rep 8(1):14713. https://doi.org/10.1038/s41598-018-32922-0

Konasani VR, Jin C, Karlsson NG, Albers E (2018b) Ulvan lyase from Formosa agariphila and its applicability in depolymerisation of ulvan extracted from three different Ulva species. Algal Res 36:106–114. https://doi.org/10.1016/j.algal.2018.10.016

Kopel M, Helbert W, Belnik Y, Buravenkov V, Herman A, Banin E (2016) New family of ulvan lyases identified in three isolates from the Alteromonadales order. J Biol Chem 291(11):5871–5878

Lahaye M, Robic A (2007) Structure and functional properties of ulvan, a polysaccharide from green seaweeds. Biomacromol 8(6):1765–1774

Li W, Wang K, Jiang N, Liu X, Wan M, Chang X, Liu D, Qi H, Liu S (2018) Antioxidant and antihyperlipidemic activities of purified polysaccharides from Ulva pertusa. J Appl Phycol 30(4):2619–2627. https://doi.org/10.1007/s10811-018-1475-5

Li B, Xu H, Wang X, Wan Y, Jiang N, Qi H, Liu X (2020a) Antioxidant and antihyperlipidemic activities of high sulfate content purified polysaccharide from Ulva pertusa. Int J Biol Macromol 146:756–762. https://doi.org/10.1016/j.ijbiomac.2019.11.061

Li Q, Hu F, Zhu B, Ni F, Yao Z (2020b) Insights into ulvan lyase: review of source, biochemical characteristics, structure and catalytic mechanism. Crit Rev Biotechnol 40(3):432–441. https://doi.org/10.1080/07388551.2020.1723486

Li Y, Ye H, Wang T, Wang P, Liu R, Li Y, Tian Y, Zhang J (2020c) Characterization of low molecular weight sulfate ulva polysaccharide and its protective effect against IBD in mice. Mar Drugs 18(10):499

Li C, Tang T, Jiang J, Yao Z, Zhu B (2023) Biochemical characterization of a new ulvan lyase and its applicability in utilization of ulvan and preparation of Ulva oligosaccharides. Glycobiology. https://doi.org/10.1093/glycob/cwad068

Liu X-y, Liu D, Lin G-p, Wu Y-j, Gao L-y, Ai C, Huang Y-f, Wang M-f, El-Seedi HR, Chen X-h, Zhao C (2019) Anti-ageing and antioxidant effects of sulfate oligosaccharides from green algae Ulva lactuca and Enteromorpha prolifera in SAMP8 mice. Int J Biol Macromol 139:342–351. https://doi.org/10.1016/j.ijbiomac.2019.07.195

Lopes N, Ray S, Espada SF, Bomfim WA, Ray B, Faccin-Galhardi LC, Linhares REC, Nozawa C (2017) Green seaweed Enteromorpha compressa (Chlorophyta, Ulvaceae) derived sulphated polysaccharides inhibit herpes simplex virus. Int J Biol Macromol 102:605–612

Lu W, Yang Z, Chen J, Wang D, Zhang Y (2021) Recent advances in antiviral activities and potential mechanisms of sulfated polysaccharides. Carbohyd Polym 272:118526

Magnusson M, Glasson CRK, Vucko MJ, Angell A, Neoh TL, de Nys R (2019) Enrichment processes for the production of high-protein feed from the green seaweed Ulva ohnoi. Algal Res 41:101555. https://doi.org/10.1016/j.algal.2019.101555

Manikandan NA, Lens PNL (2022) Green extraction and esterification of marine polysaccharide (ulvan) from green macroalgae Ulva sp using citric acid for hydrogel preparation. J Clean Prod 366:132952. https://doi.org/10.1016/j.jclepro.2022.132952

Morán-Santibañez K, Cruz-Suárez LE, Ricque-Marie D, Robledo D, Freile-Pelegrín Y, Peña-Hernández MA, Rodríguez-Padilla C, Trejo-Avila LM (2016) Synergistic effects of sulfated polysaccharides from Mexican seaweeds against measles virus. Biomed Res Int 2016:8502123. https://doi.org/10.1155/2016/8502123

Morelli A, Massironi A, Puppi D, Creti D, Martinez ED, Bonistalli C, Fabroni C, Morgenni F, Chiellini F (2019) Development of ulvan-based emulsions containing flavour and fragrances for food and cosmetic applications. Flavour Fragr J 34(6):411–425. https://doi.org/10.1002/ffj.3519

Ning L, Yao Z, Zhu B (2022) Ulva (Enteromorpha) polysaccharides and oligosaccharides: a potential functional food source from green-tide-forming macroalgae. Mar Drugs 20(3):202

Nyvall Collén P, Sassi J-F, Rogniaux H, Marfaing H, Helbert W (2011) Ulvan lyases isolated from the flavobacteria Persicivirga ulvanivorans are the first members of a new Polysaccharide lyase family*. J Biol Chem 286(49):42063–42071. https://doi.org/10.1074/jbc.M111.271825

Olasehinde TA, Mabinya LV, Olaniran AO, Okoh AI (2019) Chemical characterization of sulfated polysaccharides from Gracilaria gracilis and Ulva lactuca and their radical scavenging, metal chelating, and cholinesterase inhibitory activities. Int J Food Prop 22(1):100–110

Olsson J, Toth GB, Oerbekke A, Cvijetinovic S, Wahlström N, Harrysson H, Steinhagen S, Kinnby A, White J, Edlund U, Undeland I, Pavia H, Albers E (2020) Cultivation conditions affect the monosaccharide composition in Ulva fenestrata. J Appl Phycol 32(5):3255–3263. https://doi.org/10.1007/s10811-020-02138-9

Pankiewicz R, Łęska B, Messyasz B, Fabrowska J, Sołoducha M, Pikosz M (2016) First isolation of polysaccharidic ulvans from the cell walls of freshwater algae. Algal Res 19:348–354. https://doi.org/10.1016/j.algal.2016.02.025

Paradossi G, Cavalieri F, Pizzoferrato L, Liquori AM (1999) A physico-chemical study on the polysaccharide ulvan from hot water extraction of the macroalga Ulva. Int J Biol Macromol 25(4):309–315

Paulert R, Brunel F, Melcher RLJ, Cord-Landwehr S, Niehues A, Mormann M, Moerschbacher BM (2021) The non-sulfated ulvanobiuronic acid of ulvans is the smallest active unit able to induce an oxidative burst in dicot cells. Carbohyd Polym 270:118338. https://doi.org/10.1016/j.carbpol.2021.118338

Pengzhan Y, Ning L, Xiguang L, Gefei Z, Quanbin Z, Pengcheng L (2003) Antihyperlipidemic effects of different molecular weight sulfated polysaccharides from Ulva pertusa (Chlorophyta). Pharmacol Res 48(6):543–549

Plaza M, Marina ML (2019) Pressurized hot water extraction of bioactives. TrAC, Trends Anal Chem 116:236–247. https://doi.org/10.1016/j.trac.2019.03.024

Podolean I, Coman SM, Bucur C, Teodorescu C, Kikionis S, Ioannou E, Roussis V, Primo A, Garcia H, Parvulescu VI (2022) Catalytic transformation of the marine polysaccharide ulvan into rare sugars, tartaric and succinic acids. Catal Today 383:345–357. https://doi.org/10.1016/j.cattod.2020.06.086

Pradhan B, Patra S, Behera C, Nayak R, Patil S, Bhutia SK, Jena M (2020) Enteromorpha compressa extract induces anticancer activity through apoptosis and autophagy in oral cancer. Mol Biol Rep 47:9567–9578

Pradhan B, Nayak R, Bhuyan PP, Patra S, Behera C, Sahoo S, Ki J-S, Quarta A, Ragusa A, Jena M (2022) Algal phlorotannins as novel antibacterial agents with reference to the antioxidant modulation: current advances and future directions. Mar Drugs 20(6):403

Qi H, Zhao T, Zhang Q, Li Z, Zhao Z, Xing R (2005) Antioxidant activity of different molecular weight sulfated polysaccharides from Ulva pertusa Kjellm (Chlorophyta). J Appl Phycol 17(6):527–534. https://doi.org/10.1007/s10811-005-9003-9

Qi H, Huang L, Liu X, Liu D, Zhang Q, Liu S (2012) Antihyperlipidemic activity of high sulfate content derivative of polysaccharide extracted from Ulva pertusa (Chlorophyta). Carbohyd Polym 87(2):1637–1640

Qin H-M, Xu P, Guo Q, Cheng X, Gao D, Sun D, Zhu Z, Lu F (2018) Biochemical characterization of a novel ulvan lyase from Pseudoalteromonas sp. strain PLSV. RSC Adv 8(5):2610–2615

Qin H-M, Gao D, Zhu M, Li C, Zhu Z, Wang H, Liu W, Tanokura M, Lu F (2020) Biochemical characterization and structural analysis of ulvan lyase from marine Alteromonas sp. reveals the basis for its salt tolerance. Int J Biol Macromol 147:1309–1317

Reisky L, Stanetty C, Mihovilovic MD, Schweder T, Hehemann J-H, Bornscheuer UT (2018) Biochemical characterization of an ulvan lyase from the marine flavobacterium Formosa agariphila KMM 3901T. Appl Microbiol Biotechnol 102(16):6987–6996. https://doi.org/10.1007/s00253-018-9142-y

Robic A, Rondeau-Mouro C, Sassi JF, Lerat Y, Lahaye M (2009) Structure and interactions of ulvan in the cell wall of the marine green algae Ulva rotundata (Ulvales, Chlorophyceae). Carbohyd Polym 77(2):206–216. https://doi.org/10.1016/j.carbpol.2008.12.023

Samah SM, Hadear AH (2019) Potential using of ulvan polysaccharide from ulva lactuca as a prebiotic in synbiotic yogurt production. J Prob Health. https://doi.org/10.35248/2329-8901.19.7.208

Samarasinghe MB, van der Heide ME, Weisbjerg MR, Sehested J, Sloth JJ, Bruhn A, Vestergaard M, Nørgaard JV, Hernández-Castellano LE (2021) A descriptive chemical analysis of seaweeds, Ulva sp., Saccharina latissima and Ascophyllum nodosum harvested from Danish and Icelandic waters. Animal Feed Sci Technol 278:115005. https://doi.org/10.1016/j.anifeedsci.2021.115005

Sathivel A, Raghavendran HRB, Srinivasan P, Devaki T (2008) Anti-peroxidative and anti-hyperlipidemic nature of Ulva lactuca crude polysaccharide on d-galactosamine induced hepatitis in rats. Food Chem Toxicol 46(10):3262–3267

Shao P, Pei Y, Fang Z, Sun P (2014) Effects of partial desulfation on antioxidant and inhibition of DLD cancer cell of Ulva fasciata polysaccharide. Int J Biol Macromol 65:307–313. https://doi.org/10.1016/j.ijbiomac.2014.01.043

Shefer SRA, Chemodanov A, Lebendiker M, Bostwick R, Rasmussen L, Lishner M, Gozin M, Golberg A (2021) Fighting SARS-CoV-2 with green seaweed Ulva sp. extract: extraction protocol predetermines crude ulvan extract anti-SARS-CoV-2 inhibition properties in in vitro Vero-E6 cells assay. PeerJ 9:e12398. https://doi.org/10.7717/peerj.12398

Shefer S, Lebendiker M, Finkelshtein A, Chamovitz DA, Golberg A (2022) Ulvan crude extract’s chemical and biophysical profile and its effect as a biostimulant on Arabidopsis thaliana. Algal Res 62:102609. https://doi.org/10.1016/j.algal.2021.102609

Shomron A, Duanis-Assaf D, Galsurker O, Golberg A, Alkan N (2022) Extract from the macroalgae Ulva rigida induces table grapes resistance to botrytis cinerea. Foods 11(5):723

Song L, Chen X, Liu X, Zhang F, Hu L, Yue Y, Li K, Li P (2016) Characterization and comparison of the structural features, immune-modulatory and anti-avian influenza virus activities conferred by three algal sulfated polysaccharides. Mar Drugs. https://doi.org/10.3390/md14010004

Stender EG, Andersen CD, Fredslund F, Holck J, Solberg A, Teze D, Peters GH, Christensen BE, Aachmann FL, Welner DH (2019) Structural and functional aspects of mannuronic acid–specific PL6 alginate lyase from the human gut microbe Bacteroides cellulosilyticus. J Biol Chem 294(47):17915–17930

Sulastri E, Zubair MS, Lesmana R, Mohammed AFA, Wathoni N (2021) Development and characterization of ulvan polysaccharides-based hydrogel films for potential wound dressing applications. Drug Design Dev Ther 15:4213–4226. https://doi.org/10.2147/DDDT.S331120

Tabarsa M, You S, Dabaghian EH, Surayot U (2018) Water-soluble polysaccharides from Ulva intestinalis: Molecular properties, structural elucidation and immunomodulatory activities. J Food Drug Anal 26(2):599–608

Tang T, Cao S, Zhu B, Li Q (2021) Ulvan polysaccharide-degrading enzymes: an updated and comprehensive review of sources category, property, structure, and applications of ulvan lyases. Algal Res 60:102477. https://doi.org/10.1016/j.algal.2021.102477

Tang T, Li C, Zhu B, Yao Z (2023) Efficient preparation and production of ulvan oligosaccharides by using a new PL25 family ulvan lyase from Alteromonas sp. J Appl Phycol. https://doi.org/10.1007/s10811-023-03034-8

Thanh TTT, Quach TMT, Nguyen TN, Vu Luong D, Bui ML, Tran TTV (2016) Structure and cytotoxic activity of ulvan extracted from green seaweed Ulva lactuca. Int J Biol Macromol 93:695–702. https://doi.org/10.1016/j.ijbiomac.2016.09.040

Toskas G, Hund R-D, Laourine E, Cherif C, Smyrniotopoulos V, Roussis V (2011) Nanofibers based on polysaccharides from the green seaweed Ulva rigida. Carbohyd Polym 84(3):1093–1102

Tsubaki S, Oono K, Hiraoka M, Onda A, Mitani T (2016) Microwave-assisted hydrothermal extraction of sulfated polysaccharides from Ulva spp. and Monostroma latissimum. Food Chem 210:311–316

Ulaganathan TS, Boniecki MT, Foran E, Buravenkov V, Mizrachi N, Banin E, Helbert W, Cygler M (2017) New ulvan-degrading polysaccharide lyase family: structure and catalytic mechanism suggests convergent evolution of active site architecture. ACS Chem Biol. https://doi.org/10.1021/acschembio.7b00126

Ulaganathan T, Banin E, Helbert W, Cygler M (2018a) Structural and functional characterization of PL28 family ulvan lyase NLR48 from Nonlabens ulvanivorans. J Biol Chem 293(29):11564–11573

Ulaganathan T, Helbert W, Kopel M, Banin E, Cygler M (2018b) Structure–function analyses of a PL24 family ulvan lyase reveal key features and suggest its catalytic mechanism. J Biol Chem 293(11):4026–4036

Van Alstyne KL, Nelson TA, Ridgway RL (2015) Environmental chemistry and chemical ecology of “Green Tide” seaweed blooms. Integr Comp Biol 55(3):518–532. https://doi.org/10.1093/icb/icv035

Wahlström N, Nylander F, Malmhäll-Bah E, Sjövold K, Edlund U, Westman G, Albers E (2020) Composition and structure of cell wall ulvans recovered from Ulva spp. along the Swedish west coast. Carbohyd Polym 233:115852. https://doi.org/10.1016/j.carbpol.2020.115852

Wang Z, Xiao J, Fan S, Li Y, Liu X, Liu D (2015) Who made the world’s largest green tide in China?—an integrated study on the initiation and early development of the green tide in Yellow Sea. Limnol Oceanogr 60(4):1105–1117. https://doi.org/10.1002/lno.10083

Wang Y, Hu X, Han J, Ni L, Tang X, Hu Y, Chen T (2016) Integrated method of thermosensitive triblock copolymer–salt aqueous two phase extraction and dialysis membrane separation for purification of lycium barbarum polysaccharide. Food Chem 194:257–264

Wang D, Li Y, Han L, Yin C, Fu Y, Zhang Q, Zhao X, Li G, Han F, Yu W (2022) Biochemical properties of a new polysaccharide lyase family 25 ulvan lyase TsUly25B from marine bacterium Thalassomonas sp. LD5. Mar Drugs 20(3):168

Wu D, Chen Y, Wan X, Liu D, Wen Y, Chen X, Zhao C (2020) Structural characterization and hypoglycemic effect of green alga Ulva lactuca oligosaccharide by regulating microRNAs in Caenorhabditis elegans. Algal Res 51:102083

Xu F, Dong F, Sun X-H, Cao H-Y, Fu H-H, Li C-Y, Zhang X-Y, McMinn A, Zhang Y-Z, Wang P, Chen X-L, Zhou N-Y (2021) Mechanistic insights into substrate recognition and catalysis of a new Ulvan lyase of polysaccharide lyase family 24. Appl Environ Microbiol 87(12):e00412-e421. https://doi.org/10.1128/AEM.00412-21

Yaich H, Garna H, Besbes S, Paquot M, Blecker C, Attia H (2013) Effect of extraction conditions on the yield and purity of ulvan extracted from Ulva lactuca. Food Hydrocolloids 31(2):375–382. https://doi.org/10.1016/j.foodhyd.2012.11.013

Yaich H, Garna H, Besbes S, Barthélemy J-P, Paquot M, Blecker C, Attia H (2014) Impact of extraction procedures on the chemical, rheological and textural properties of ulvan from Ulva lactuca of Tunisia coast. Food Hydrocolloids 40:53–63

Yaich H, Amira AB, Abbes F, Bouaziz M, Besbes S, Richel A, Blecker C, Attia H, Garna H (2017) Effect of extraction procedures on structural, thermal and antioxidant properties of ulvan from Ulva lactuca collected in Monastir coast. Int J Biol Macromol 105:1430–1439. https://doi.org/10.1016/j.ijbiomac.2017.07.141

Ye N-h, Zhang X-w, Mao Y-z, Liang C-w, Xu D, Zou J, Zhuang Z-m, Wang Q-y (2011) ‘Green tides’ are overwhelming the coastline of our blue planet: taking the world’s largest example. Ecol Res 26(3):477–485. https://doi.org/10.1007/s11284-011-0821-8

Yuan Y, Xu X, Jing C, Zou P, Zhang C, Li Y (2018) Microwave assisted hydrothermal extraction of polysaccharides from Ulva prolifera: functional properties and bioactivities. Carbohyd Polym 181:902–910

Zhang L, Wang M (2016) Polyethylene glycol-based ultrasound-assisted extraction and ultrafiltration separation of polysaccharides from Tremella fuciformis (snow fungus). Food Bioprod Process 100:464–468

Zhang H-J, Mao W-J, Fang F, Li H-Y, Sun H-H, Chen Y, Qi X-H (2008) Chemical characteristics and anticoagulant activities of a sulfated polysaccharide and its fragments from Monostroma latissimum. Carbohyd Polym 71(3):428–434

Zheng L, Wu M, Cui Y, Tian L, Yang P, Zhao L, Xue M, Liu J (2022) What causes the great green tide disaster in the South Yellow Sea of China in 2021? Ecol Ind 140:108988. https://doi.org/10.1016/j.ecolind.2022.108988

Acknowledgements

Dr. Zhu Benwei gratefully acknowledges the support of the Jiangsu Overseas Visiting Scholar Program for University Prominent Young and Mid-aged Teachers and Presidents.

Funding

This work was supported by the National Natural Science Foundation of China (31601410).

Author information

Authors and Affiliations

Contributions

CL, LN, and TT were responsible for conceptualization, investigation, writing––original draft, and visualization. LJ and YD were involved in conceptualization and visualization. BZ and ZY assisted in writing––editing, and performed project supervision.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, C., Tang, T., Du, Y. et al. Ulvan and Ulva oligosaccharides: a systematic review of structure, preparation, biological activities and applications. Bioresour. Bioprocess. 10, 66 (2023). https://doi.org/10.1186/s40643-023-00690-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40643-023-00690-z