Abstract

This study reports on the effect of artists’ paint formulation on degradation rates of TiO2-based oil paints. Titanium white oil paint exists in a multitude of different recipes, and the effect of the formulation on photocatalytic binder degradation kinetics is unknown. These formulations contain, among others, one or both titanium dioxide polymorphs, zinc oxide, the extenders barium sulfate or calcium carbonate and various additives. Most research performed on the photocatalytic degradation process focusses on pure titanium white-binder mixtures and thus does not take into account the complete paint system. Since photocatalytic oil degradation is a process initiated by the absorption of UV light, any ingredient or combination of ingredients influencing the light scattering and absorption properties of the paint films may affect the degradation rate. In this study three sets of experiments are conducted, designed using the design of experiments (DoE) approach, to screen for the most important formulation factors influencing the degradation rate. The benefits of using DoE, compared to a more traditional ‘one factor at a time approach’ are robustness, sample efficiency, the ability of evaluate mixtures of multiple components as well as the ability to evaluate factor interactions. The three sets of experiments investigate (1) the influence of the TiO2 type, (2) the impact of different mixtures of two types of TiO2, ZnO and the additive aluminum stearate and (3) the influence of common extenders in combination with photocatalytic TiO2, on the photocatalytic degradation of the oil binder. The impact of the formulation on the degradation rate became apparent, indicating the shortcoming of oversimplified studies. The protective effect of photostable TiO2 pigments, even in a mixture with photocatalytic TiO2 pigments, as well as the negative effect of extenders was demonstrated. Furthermore, the ambiguous role of ZnO (photocatalytic or not) and aluminum stearate is highlighted. Neither can be ignored in a study of degradation behavior of modern oil paints and require further investigation.

Similar content being viewed by others

Introduction

The degradation of titanium white artists’ oil paints has been under investigation in recent years [1, 2]. This degradation is of interest because, while it is expected to occur, it is not yet commonly observed. Until now, only one clear example of indoor titanium-white initiated photocatalytic degradation was described in the literature [3]. One possible hypothesis for this lack of reported degradation problems is the possible inhibiting effects of other components in the paint on the degradation rate, investigated in this paper.

Titanium white pigments were introduced to the market around 1920. Especially the early pigments exhibited undesirably high photocatalytic activity [4, 5]. The photocatalytic activity of titanium white pigments can lead to several degradation phenomena, such as the breakdown of the binding medium leading to chalking, or the degradation of colored pigments [1, 6, 7]. Photocatalytic degradation occurs when UV excitation of an electron leads to radical formation at the pigment surface. These radicals can attack their surroundings and thus cause degradation [4, 8]. In the case of oil paint, the binder is broken down into volatile components until the pigment is left unbound at the paint surface (chalking). UV absorption is the first step in photocatalytic degradation [9, 10]. The penetration of light into a paint film is dependent on absorption and scattering of light by the binding medium and particles within it [11], which in turn are dependent on their intrinsic properties (e.g. refractive index and photocatalytic properties), composition and particle size, as well as on the quality of dispersion [9]. The combination of short penetration depths of short wavelengths and the presence of UV-absorbing pigments will confine the degradation to the top surface of the paint [12, 13].

The decrease of gloss was shown to be an accurate measure of photocatalytic oil degradation for home-made paint samples in previous research by the authors [1]. Therefore, the changing gloss during UV aging, forms the basis of this investigation. Gloss is a measure of smoothness. Thus, an agglomerate appearing at the surface, the so-called “tip of the iceberg effect,” results in an increased roughness, observed as a decrease in gloss [14, 15]. Another aspect relating to the gloss of paint is the pigment-volume-concentration, PVC. The gloss decreases with increasing PVC, most notably when it surpasses the critical-pigment-volume-concentration, cPVC [16]. PVC also has another effect on degradation, in the sense that a higher TiO2 content results in higher UV-absorption. Depending on the photocatalytic activity of the TiO2, this leads to higher radical formation or UV-scavenging capabilities [14].

Titanium white exists in many different qualities, with different photocatalytic activities, which differ among others in the crystal structure, surface treatment, and production process. When titanium white was first used as a pigment, the anatase crystal structure was used. More recently, the rutile structure is being used, as it is known to have much lower photocatalytic activity than anatase [4]. Both organic and inorganic surface treatments have been applied to adjust pigment properties such as wettability (which affects dispersion) or photocatalytic activity [4, 17,18,19,20]. In case of photocatalytic TiO2 (nano)powders, powder characteristics such as particle size, surface area, or doping differently influence the photocatalytic activity of the different polymorphs [21, 22]. However, for pigments, the crystal structure and the inorganic coating are the most important characteristics influencing photocatalytic activity [5]. Uncoated anatase pigments have the highest photocatalytic activity, while inorganically coated rutile pigments are relatively photostable and even photoprotective [1, 4, 5, 23,24,25].

Titanium white oil paints exist in a wide range of formulations. They can contain a combination of: titanium white (one or more types), zinc white, common extenders such as calcium carbonate (CaCO3) or barium sulfate (BaSO4), additives (e.g. metal stearates or drying agents) and the binder (in this study linseed oil) [26]. Most earlier investigations have focused on pure titanium white-binder mixtures to elucidate degradation phenomenology [1, 2, 23, 25, 27]. However, for the investigation of degradation rates, this constitutes an oversimplified formulation. In order to predict degradation rates (and thus risk) in real paintings, understanding the effect of the formulation on the degradation rate is important. To that end, three screening phase sets of experiments are conducted, which are based on the Design of Experiments (DoE) methodology, to determine the significant formulation factors and factor interactions which affect the photocatalytic oil degradation rate. DoE is a well-known methodology often used in industry to establish factor-response relationships in a robust and sample efficient way [28,29,30,31]. DoE offers significant time and complexity advantages over the traditional ‘one factor at a time approach’, which are illustrated in the present study.

Experimental

Aging chamber

The paints were aged in an Opsytec Dr. Gröbel BS-02 UV chamber (46 by 32 cm) with dose control. Dose control was performed using the ‘UV-MAT’ controller connected to a UV sensor from the same company. The chamber is equipped with UVA lamps (300–400 nm). The light distribution of the chamber was determined by measuring UV intensity at each sample spot. Thus at every irradiation interval, each sample has been exposed to a specific irradiation value, based on the sample location in the chamber. Samples were aged during 2 months reaching a total irradiation of approximately 104 J/cm2. The number of paint samples that can be aged at the same time is restricted to 30 samples for practical reasons: the gloss meter requires a specific area for analysis (2.5 by 7.5 cm) and the size of the aging chamber is about 30 times that area (46 by 32 cm). Thus, the designed experiment sets (referred to as experiments) were purposely limited to this number of samples (referred to as runs). Blocking, which would allow for a larger design size, was considered a too time-consuming option considering the time per aging cycle. Optimal use, based on theory, of the Design of Experiments methodology, can sometimes be compromised by practical restrictions. In this study which describes the experimental phase of screening, the driver to use DoE was to conduct an informative and time-efficient investigation to identify the factors and factor interaction that significantly affect the degradation behavior.

Paint preparation

All powders, Table 1, were used as received and added by weight. The binder is a bleached linseed oil (Van Beek, Amsterdam) and was added to the powder mixture using a micropipette. A Co/Zr drying agent (0.1% v/v in oil, unknown brand), was used to accelerate oil polymerization. The paint compositions of each run within experiments I, II and III respectively are reported in the result tables of “Results” section. Paint was prepared following a protocol commonly used in industry and in other studies [1, 2] in order to achieve reproducible and smooth paints of a fixed layer thickness. The paint mixture was pre-mixed with a palette knife and subsequently mixed on a glass-plated paint mill (automatic muller from an unknown brand) twice for 25 rotations, with a weight of 5 kg. Between mixing, the paint mixture was scraped together and centered on the mill. The paints were spread out on a Melinex support with a drawdown bar applying a fixed layer thickness of 100 µm and left to dry in controlled ambient laboratory conditions until they were touch dry. Linseed oil dries via a chemical drying process based on cross-linking of the triglyceride components [32]. Previous studies indicated that the required drying time to reach a touch dry state is approximately 2 weeks for paints of this thickness and composition [1, 2]. Prior to aging, the drying time of the samples varied between 14 and 16 days, which was shown in a preliminary experiment to have a negligible influence on degradation rate [33]. For each paint sample three drawdowns were produced, and after drying the most pristine of these three was chosen for the aging process and cut to the required size with household scissors. All paint samples were produced in a randomized order (following DoE theory) and care was taken to perform the paint production identically for all paint samples following the provided steps.

Gloss analysis

At irradiation intervals (between ~ 100 J/cm2 at the beginning of the aging cycle up to ~ 1200 J/cm2 at the end of the aging cycle), gloss at an angle of 60° was measured using a Sheen Instruments Ltd Tri-GLOSSmaster. 60° gloss was chosen for its sensitivity to both high and low gloss values and can thus be used over the full range of gloss decay. The gloss was determined in triplicate per time point, and the apparatus was repositioned in between each analysis. The three gloss measurements were subsequently averaged. Plotting the averaged gloss value against irradiation yields gloss decay curves which can be fitted with an exponential decay function:

where ‘k’ can be considered the reaction rate coefficient.

Equation 1 was used to calculate the gloss value at fixed irradiation doses. For very slow degradation and stable paints, the gloss curve remains in the linear regime and thus cannot be fitted with an exponential decay curve. This is the case for many paints containing CR(inorg). For these samples, a linear fit was used to calculate the gloss value at fixed irradiation doses.

To compensate for the variable initial gloss, relative gloss decay after a certain amount of irradiation (500 J/cm2 for experiment I and III and 750 J/cm2 for experiment II), Eq. 2, was used to compare reaction rates.

The results for both reaction coefficient ‘k’ as for the relative gloss decay were analyzed using analysis of variance (“Design analysis” section) yielding equivalent results. In other words, both parameters represent the same process because the change in gloss derives from the reaction rate coefficient. In this study we choose to present the relative gloss decay as it is a more tangible parameter.

State of chalking

Chalking, the final stage of photocatalytic binder degradation, can present itself in different ways. In some cases, e.g. for well-dispersed paints, chalking starts evenly, but the layer of loose pigment on the surface remains very thin. In other cases, the chalking starts in ‘patches’ on the surface. This can be in one or multiple spots, before reaching an even chalking stage. Assessment of the state of chalking was carried out by swiping a black cotton swab (brand: Malian) across the paint surface. The contrast between the white pigment and the black cotton swab enhances chalk visibility.

In this study, chalking was determined visually and assessed on a three or a five level scale. The three level scale, used for experiment II, has the following levels: ‘no chalking’ = 0, ‘slight chalking or patched chalking’ = 0.5 and ‘complete and even chalking’ = 1. The five level scale was introduced for experiment III because the paints displayed a larger variety of chalking effects. It has the following levels: ‘no chalking’ = 0, ‘chalk spots covering < 50% of surface’ = 0.25, ‘chalk sports covering > 50% of surface’ = 0.5, ‘even but thin chalking’ = 0.75, ‘complete and even chalking’ = 1. In experiment III, all runs contain the photocatalytic pigment and will thus eventually chalk. Therefore in this experiment the state of chalking was assessed during the aging process at two different levels of irradiation: I6 (2355–3381 J/cm2) and I8 (3633–5214 J/cm2).

The use of a non-continuous scale, such as the chalking scale, is common in the paint industry for application testing. It is based on practical considerations and should not be used in a DoE optimization study.

Experiments

In the scope of this work three experiments were designed each containing a specific number of runs (paint samples). The benefit of using designed experiments rather than the tradition approach is that complex mixtures containing multiple ingredients can directly be investigated. These experiments addressed the following research questions:

-

I.

What is the effect of TiO2 pigment type on degradation rate?

-

II.

How do mixtures of two TiO2 types (photocatalytic + photostable), zinc oxide and aluminum stearate affect the degradation rate?

-

III.

What is the effect of common extenders such as barium sulfate and calcium carbonate, introduced to a formulation containing photocatalytic TiO2, on the degradation rate?

The software DesignExpert® version 10 by Stat-Ease, was used to design and analyze the experiments.

Experiment I: the effect of different TiO2 pigments

Experiment I is a univariate factorial experiment in which only the TiO2 type is varied. The 22 runs prepared for this experiment are reported in Table 2. In all runs, the same pigment content (15% v/v) was added to linseed oil (“Paint preparation” section) to reach workable paints with the different types of titanium white pigments. Prior knowledge of the pigments characteristics, specifically their crystal structure and the presence of a coating, as well as previous results from photocatalytic activity experiments [4, 5], were used to code the pigment type. From A to E the pigments are ranked in the following order from photostable to highly photocatalytic: CR(inorg), CA(inorg), CR(org), CA(org), UA. In preceding studies, TiO2-linseed oil paint samples were prepared following the standard protocol and aged under identical conditions [1, 2]. Hence, additional gloss decay results were available and included for the analysis of variance as additional replicates.

Experiment II: rutile, anatase, ZnO and aluminum stearate mixtures

Experiment II is a D-optimal randomized mixture design containing 30 runs, built to evaluate a special cubic model. It is built up by 25 runs to estimate the model terms, three replicate runs and two runs to conduct the lack of fit test. In a mixture design, the sum of all components is required to sum up to 1. The components in this experiment are CR(inorg), UA, ZnO, AlSt and linseed oil (Table 1). These components were chosen because they represent a photostable TiO2 reference, a photocatalytic TiO2 reference, a common admixed pigment and a common oil paint additive respectively. The compositions of the 30 runs are summarised in Table 3. The boundary conditions (factor ranges and constraints) for this mixture design are:

-

A: TiO2 [UA], range 0–0.2 v/v.

-

B: TiO2 [CR(inorg)], range 0–0.2 v/v.

-

C: [ZnO], range: 0–0.2 v/v.

-

D: [Binder] (linseed oil), range 0.78–0.9 v/v.

-

E: Aluminum stearate [AlSt], range 0–0.035 v/v at 3 levels (0, 0.02, 0.035).

-

Constraint: A + B+C > 0.1 (in other words, the pigment-volume-concentration of all pigments combined is minimally 10%).

Experiment III: anatase, calcium carbonate and barium sulfate mixtures

Experiment III is a D-optimal randomized mixture design, built to evaluate a special cubic model (seven runs to estimate the model terms), containing three replicates and eleven samples to conduct the lack of fit test. The number of samples to estimate the lack of fit was increased due to additional space in the aging chamber and to function as back-up samples. The components in this experiment are UA, CaCO3, BaSO4 and linseed oil. These components were chosen as the photocatalytic TiO2 reference (fixed volume), to ensure photocatalytic degradation, filled with the two most common extenders found in recipes from important twentieth century paint manufacturers [26]. The compositions of the 21 paint samples are summarised in “Experiment III: anatase, calcium carbonate and barium sulfate mixtures” section. The boundary conditions for this mixture design are:

-

A: TiO2 [UA], fixed at v/v = 0.14.

-

B: CaCO3, range 0–0.14 v/v.

-

C: BaSO4, range: 0–0.14 v/v.

-

D: Oil (linseed oil binder), range: 0.72–0.86 v/v.

Design analysis

Analysis of variance (ANOVA) was performed on the initial gloss, the relative gloss decay after a specific irradiation dose, and on the state of chalking to determine factors and factor interactions with a significant effect on those responses. No mathematical transformations were performed before analysis of variance except for the analysis of the state of chalking. For that response a logit transformation was used to force the response to stay between 0 and 1, to ensure the response has physical meaning (described in “State of chalking”) [34]. Model reduction was performed based on hierarchical backward p value selection (p < 0.05) [34, 37]. The resulting model describes significant differences between the samples and are not compromised by a lack of fit. The reduced models were evaluated on robustness using numerical and graphical diagnostics such as adjusted and predicted R2, Cooks distance, leverage and residuals analysis [35,36,37]. Contour plots were produced to visualize the reduced models and to interpret the system. In this (screening) experimental phase the models are not validated for prediction.

Results

Experiment I: the effect of different TiO2 pigments

Table 2 presents the initial gloss and relative gloss decay on which ANOVA was performed. The initial gloss is not significantly affected by the TiO2 type (p = 0.0725). On the other hand, the gloss decay after 500 J/cm2, Fig. 1, is significantly affected by the TiO2 type (p < 0.0001).

Experiment II: rutile, anatase, ZnO and aluminum stearate mixtures

Table 3 presents the composition, initial gloss, gloss decay, and state of chalking of the runs. ANOVA was performed on the three responses.

The initial gloss of mixtures containing UA, CR(inorg), ZnO, AlSt, and linseed oil can be described by a reduced model containing the linear mixture (p < 0.0001), the interaction between UA and CR(inorg) (‘A–B’, p = 0.0492), and the interaction between UA and ZnO (‘A–C’, p = 0.0014), illustrated in Fig. 2.

Contour plots for the initial gloss in relation to the formulation in Experiment II. a Contour plot for low oil content and no aluminum stearate. b Contour plot for high oil content and no aluminum stearate. c Contour plot for high oil content and added aluminum stearate. All numbers are volume fractions (summing up to 1)

The reduced model for the gloss decay of those mixtures contains the linear mixture (p < 0.0001) and the interaction between the binder and the AlSt (‘D–E’, p = 0.0359), represented in Fig. 3. The interaction ‘D–E’ is significant for I < 1500 J/cm2 and insignificant for I ≥ 1500 J/cm2, Table 4.

Chalking (the end stage of degradation) can be described by a reduced model containing the linear mixture (p < 0.0001) and the interactions between UA and CR(inorg) (‘A–B’, p = 0.0042) and ZnO and CR(inorg) (‘B–C’, p = 0.0044), Fig. 4. At the end of the exposure, the samples have been subjected to an extreme dose of UV (unrealistic for a regular indoor environment). Thus ‘no chalking’ (‘0’) is assumed to represent a paint type that would not chalk on a realistic timescale, in a regular indoor environment.

a Contour plot for the state of chalking at the end of the full aging procedure (around 10.000 J/cm2) in relation to the formulations of Experiment II. b 3D projection of figure a showing the completely flat CR(Inorg) corner. All numbers represent volume fractions. The analysis was performed applying a logit transformation, forcing the response to stay between 0 and 1

Experiment III: anatase, calcium carbonate and barium sulfate mixtures

Table 5 represents the composition, initial gloss, gloss decay and state of chalking of runs in experiment III. ANOVA was performed on the four responses.

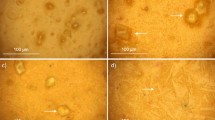

Figure 5 presents the contour plots for the initial gloss, the gloss decay, and the state of chalking at two different irradiation levels of mixtures of photocatalytic TiO2 with extenders CaCO3 and BaSO4. The reduced model for the initial gloss contains significant effects from the linear mixture (p < 0.0001) and the interaction between the BaSO4 and the binder (‘C–D’, p = 0.0086). The gloss decay after 500 J/cm2, is described by a reduced model containing only a significant effect from the linear mixture, (p < 0.0001). In this case, interactions do not play a role. The reduced model for chalking at I6 again contains the linear mixture (p = 0.0009) and the interaction between the BaSO4 and the binder (‘C–D’, p = 0.0142). Finally the reduced model for chalking at I8 only contains the linear mixture (p = 0.0010). For each figure, the bottom left corner of the contour plot (only UA + oil) is used to compare to the rest of the plot (replacing part of the oil by CaCO3, BaSO4, or both).

Contour plots for a initial gloss, b calculated relative gloss decay at 500 J/cm2, c state of chalking at I6 and d state of chalking at I8 in relation to the formulations of Experiment III. All mixtures contain a fixed volume fraction (0.14) of UA. Mind that in figure a red indicates a high gloss while in figure b, c red indicates high degradation and thus a low gloss

Discussion

The experiments are interpreted taking the parameters presented in Fig. 6 under consideration. In this study the formulation (paint recipe) is directly connected to the degradation rate. The steps in between, which can be challenging to quantify, are not under investigation here. However, it is taken into account that differences in degradation rates are partly due to differences in quality of dispersion, powder properties, light absorption and scattering, photocatalytic activity and so on. Because the paint production was kept constant, we assume that these properties directly relate back to the mixture composition or pigment type and are thus characteristic for a specific recipe. Exact underlying causes for differences in degradation rate, at this stage, can only be speculated upon. Nevertheless, the components in the formulation playing a role can be identified, which is the aim of this screening phase.

Experiment I: the effect of different TiO2 pigments

Experiment I, Fig. 1, confirms that uncoated anatase (photocatalytic) and inorganically coated rutile (photostable), behave completely differently regarding gloss decay under UV irradiation [1, 2, 4, 5, 23,24,25], which validates their use as photocatalytic and photostable references. Furthermore, we previously showed the order of the photocatalytic activity of the TiO2 powders to be UA > CA(org) > CR(org) > CR(inorg) [5]. This is also found in experiment I, underlining the predictive value of the previously published photocatalytic activity test [5]. It is interesting to note the similarity between CR(inorg), CA(inorg) and CR(org), confirming the effective anti-photocatalytic properties of rutile titanium white and of inorganic coatings. Finally, experiment I illustrates the reproducibility obtained for a stable paint, originating from a retained gloss, compared to the wide spread in results obtained from a degrading paint.

Interestingly, the initial gloss of the paints with different TiO2 types is not significantly affected by the type of pigment. This indicates that, below the critical PVC, the influence of particle size (ranging from 100 to 250 nm for the different TiO2 pigments), crystal structure and coating is of minor influence, or compensate each other, on the quality of dispersion and thus the gloss.

Experiment II: rutile, anatase, ZnO and aluminum stearate mixtures

When components other than TiO2 are added to the paint, experiment II, the initial gloss becomes affected by the composition, Fig. 2. The initial gloss decreases, as expected, with higher pigment volume concentration. However, at the same total pigment volume concentration, paints containing ZnO have a lower initial gloss. This could be due to the significantly different average size [38, 39] of the pigment compared to TiO2 pigments or to a difference in dispersion quality which in turn affect the interaction of the paint film with light. This effect is stronger in interaction with UA than in interaction with CR(inorg). AlSt further decreases the initial gloss, which is unexpected as it is used as a wetting agent [40], which should improve dispersion. Several explanations for this phenomenon could be considered. Firstly, AlSt is known to gellify [41]. It is a possibility that the critical concentration is reached, causing a ‘gel haze’ on the paint surface which reduces the gloss. Secondly, technical stearates often contain considerable amounts of free fatty acids, which may be responsible for a matting behavior. The variation in initial gloss is accounted for by comparing relative gloss decay.

Comparison between Figs. 3 and 4 shows that samples in the CR(inorg) corner do lose gloss (around 20 gloss units), but do not end up chalking. In fact, half the samples (14 out of 30) do not end up chalking, illustrating the protective effect of CR(inorg). The remaining 16 samples do reach a degree of chalking, but five of them are not completely chalked at the end of the extreme aging cycle. These five samples are expected to reach the fully chalked state if they would be subjected to continued exposure. The ratio at which chalking is still prevented by CR(inorg) in this design space is: 40% CR(inorg) to 60% UA + ZnO. We propose that, in the protected mixtures, the initial photocatalytic breakdown caused by UA or ZnO leads to a small initial gloss decay and thus a rougher surface, which subsequently enhances the UV scavenging properties of CR(inorg) at the surface.

At the chalking stage (Fig. 4), two interactions, ‘A–B’ (‘UA-CR(inorg)’) and ‘B-C’ (‘CR(inorg)-ZnO’), are significant that were insignificant for the relative gloss decay in the early stage of degradation. These interactions are of the same order of magnitude in terms of their effect on the response. The interactions indicate that there is an inhibiting effect caused by CR(inorg) on both UA and ZnO, which is likely related to the UV scavenging behavior of rutile that prevents chalking. It shows that coated rutile equally protects anatase- and zinc oxide-photocatalyzed chalking. Communication with Talens, a Dutch artists’ paint manufacturer, indicates that while paint manufacturers commonly order one type of TiO2, the delivered powders sometimes consist of mixtures. Such mixtures have been found in a Talens paint tube from the 1970 s [26]. Unknowingly, the presence of coated rutile within a batch of uncoated anatase pigment may protect the artwork from degradation.

At low irradiation dose, the interaction ‘D–E’ is found to be significant. At low binder content (0.78–0.80), adding aluminum stearate enhances the gloss decay (Fig. 3a, b). On the other hand, at high binder content (0.85–0.87) aluminum stearate has no effect on the gloss decay (Fig. 3c, d). Additionally, an increased amount of binder (automatically decreasing the amount of pigment and thus of photocatalytic material), as expected, slows down the degradation (Fig. 3b, d). Technical stearates can contain free fatty acids (stearic acid) that can be degraded via TiO2 photocatalysis [42, 43]. As these are smaller molecules than the oil network, decomposition into volatile components occurs faster. This effect is minor, due to the very small amount of aluminum stearate added to the paint. We propose that the effect is negligible at high oil content and noticeable at lower oil content. Consequently, when all free acids from the technical stearate have been degraded, at higher irradiation doses, the interaction becomes insignificant. This hypothesis requires the stearates to be in proximity to the pigments, which is to be expected from a wetting agent [44].

Finally, the symmetry of the contour plot in Figs. 3 and 4, indicates that UA, chosen for its extreme photocatalytic activity [5], has the same effect on the gloss decay as ZnO. Even though it is known that zinc oxide can behave as a photocatalyst, this similar behavior was unexpected as the photocatalytic activity of ZnO is considered to be lower [45]. The similarity may alternatively stem from a dispersion effect, as mixtures containing ZnO, based on the initial gloss, may have a lower quality of dispersion. Thus less oil needs to be degraded for a similar relative loss of gloss. Nevertheless, ZnO-containing paints also reach the chalking stage. Thus ZnO definitely contributes to the degradation. It would be interesting to investigate different qualities of ZnO pigments and their effect on oil degradation rates. Furthermore, the relation between ZnO photocatalytic activity and other ZnO-related degradation problems such as soap formation [46, 47] may be an interesting avenue to pursue further. While ZnO is known for its reactivity towards stearates, the interaction between ZnO and AlSt does not play a role in the gloss decay, either indicating that soap formation does not influence the gloss of a painting (at this time scale) or indicating that photocatalytic degradation is preferred over soap formation under the conditions used. While both degradation phenomena may be competitive in natural aging, soap formation was not noted as being enhanced by the UV light aging regime used in this study.

Experiment III: anatase, calcium carbonate and barium sulfate mixtures

Figure 5a indicates that the extenders have a lowering effect on the initial gloss, which is partly due to the increased solid content (PVC) of the paint. This negative effect is larger for CaCO3 than for BaSO4, which is suggested to be due to the differences in particle sizes and oil absorption properties and thus the quality of dispersion of the extenders. Barium sulfate and calcium carbonate both consist of much larger and non-spherical particles in comparison to titanium white.Footnote 1 In the case of barium sulfate, a substantial part of the oil can be replaced by the filler without influencing the initial gloss (‘Oil-BaSO4’ axis), which is described in the model by the significance of the ‘C–D’ interaction. This could be related to the statement by Kremer Pigmente that BaSO4 “lowers oil absorption”. Again, the variable initial gloss is accounted for by comparing relative gloss decay rather than absolute gloss decay.

Experiment III has a fixed amount of uncoated anatase (photocatalytic material) in the mixtures. This results in a variable ‘UA:oil’ ratio (active material vs. degradable material) due to the addition of extenders, which replace part of the oil. An increase of active material vs. degradable material (‘catalyst loading’) should, as illustrated in Fig. 3, increase gloss decay/degradation [48]. However, if this were the only effect at play, the graphs would be symmetrical. In other words, the same enhancement would be expected for BaSO4 as for CaCO3. Since this is not the case, the results can be used to investigate the effect of the different types of extenders on the degradation rate. However, care must be taken during interpretation because the extent of the effect based on the change in ‘UA-oil’ ratio was not verified. Both extenders transmit light in the UV region [39, 49], which results in a deeper penetration depth of the UV light and a larger volume of paint in which radicals can be formed. Both extender types have a larger particle size than the anatase pigments by a factor 20 and 200 respectively for BaSO4 and CaCO3, which will affect the distribution of the active particles within the paint film. These aspects all contribute to the observed enhanced degradation rates. The substantially increased gloss decay when BaSO4 is added, shown in Fig. 5, is problematic as many titanium white oil paints contain BaSO4 extenders, such as those by Weber (Permalba) [26].

Figure 5c, d illustrate the chalking of the samples. All samples contain photocatalytic uncoated anatase; thus, eventually, all samples will chalk. Similar to the gloss decay, a higher chalking rate is observed for the paints that contain extenders, with a larger negative effect for the barium sulfate containing paints. As CaCO3 has a much larger particle size, a thicker layer of binder needs to be degraded before the particles are unbound and complete chalking is observed. This could account for the lower state of chalking for CaCO3 containing paints.

Conclusion

The results presented in this screening study indicate that photocatalytic degradation rate is complex and influenced by common paint components and by the TiO2 quality, which in turn influences quality of dispersion, critical PVC, and interaction with light. Despite the differences in degradation rates that are indeed caused by differences in formulation, it seems that the photocatalytic activity of the titanium white remains the most important factor governing photocatalytic degradation rates. The only inhibiting factor that was confirmed in this study is the presence of photostable TiO2 pigments, such as inorganically coated rutile pigments. This effect is substantial and very beneficial for mixtures of both pigments in paintings. The presence of extenders, often added to bring the price of paints down enhance rather than decrease degradation rate. Additionally, factors that ambiguously influence the degradation behavior were identified. These include the role of ZnO (photocatalytic or not) and aluminum stearate. Neither can be ignored in a study of degradation behavior of modern oil paints and both deserve further investigations.

Paint formulation is often a tradeoff between cost reduction and paint quality. However, quality is often not intended for hundreds of years, as we would like it to be for artworks. Thus, time will tell how titanium white containing oil paints will behave in the long term. Here, a start has been made to understand their behavior in relation to paint composition in a sample efficient and robust manner using DoE. In addition to sample efficiency and robustness, DoE provides the benefit of studying multicomponent formulations rather than the traditional method to change one ingredient at a time. This methods allows us to study complex paint formulations, and can potentially be very useful in the field of heritage science to study the effect of formulation on material behavior. Follow-up studies can further validate the findings of these screening phase experiments so that degradation can be predicted and possibly prevented.

Terminology

-

Analysis of variance (ANOVA): A statistical method that splits the variability in the response by the selected factors in the analysis and supplies information about the significance of these factors on the response.

-

Blocking: To account for certain uncontrollable factors by splitting and grouping the design (e.g. day 1/day 2). Blocking results in an additional run.

-

Constraints: Applied boundary conditions that have to be met in the design space.

-

Contour plot: Visualization of the component effect on the response. Mixture designs are always represented as a (subset) of a triangle.

-

Design: Combination of factor settings, model order and constraints used to build the experimental set.

-

Design of experiments (DoE): A statistical research approach, often applied in several industries with the aim of designing a set of runs in order to explain/model variation in the response (also known as experimental design).

-

Design space: Multidimensional space characterized by the factor ranges and levels.

-

Diagnostics: Graphs or numerical values to evaluate outliers and model robustness.

-

Experiment: Selection of runs produced based on design criteria.

-

Factor: Variable tested for its influence on the response (this can be a component or a process condition, such as temperature).

-

Factor interaction: When the effect of two factors is different than the effect of the sum of both (linear mixture). An ‘A–B’ interaction is a second order interaction; these are common in mixtures. An ‘A–B–C’ interaction is a third order interaction—DoE experience shows that 3rd order interactions are uncommon in mixtures.

-

Factor range: Boundary conditions set for a specific factor/component.

-

Formulation: Term used to denote the recipe of a mixture, in this manuscript a paint.

-

Inhibition: When a factor or factor interaction causes a preventive effect.

-

Lack of fit sample: Run(s) included in the experimental design to check if the polynomial model order is correct.

-

Lack of fit test: Test to check if the model order is correct.

-

Levels: Chosen settings for discrete/categorical factors. For instance, when studying five different TiO2 types, these are five levels for the factor ‘TiO2 type’.

-

Linear mixture: When only the pure components contribute to the model.

-

Logit transformation: A mathematical transformation that forces the predicted response to be between two set values (in this case 0 and 1). Used in this study for the state of chalking to ensure physical meaning in the contour plot.

-

Mathematical transformation: A mathematical transformation of the response can be performed before ANOVA to obtain a constant error in the response range. This is one of the assumptions of ANOVA.

-

Mixture design: Design used specifically for determining the effect of formulations (vide infra) on certain properties. It has the characteristic that all factors are interdependent due to the convention that the total sum of the mixture components has to sum to 100% or 1.

-

Model reduction: Process of model analysis and evaluation to reach a reduced model that describes the significant effects on the response. Process used in this study is described in “Experimental” section.

-

Optimized design: Optimization following a specific algorithm (I-optimal, D-optimal, A-optimal). This algorithm chooses runs that minimize the integral of the prediction variance across the factor space. In this study, we use D-optimal designs. D-optimal designs are used to best estimate the factor effect and are optimized by minimizing the matrix determinant of the squared design matrix.

-

Pigment-volume-concentration (PVC): Volume ratio of solid material vs. binder material: Vpigment/(Vpigment + Vbinder).

-

cPVC: The stage where there is just sufficient binder to wet the pigments.

-

p value: Value used to determine significance of model terms against a predetermined value: α.

-

Randomization: To carry out the runs in the experiment in completely random order to spread the contribution of uncontrolled factors across all the modeled factors and interactions.

-

Reduced model: Model that includes only the significant model terms based on the selected design order.

-

Replication: Runs included in the design used to estimate the pure error. These runs have to be produced and treated completely separately and thus cannot be produced from the same paint batch or measured from the same paint sample as their replicate. The whole process has to be reproduced to properly assess the pure error.

-

Run: Sample in the experiments. In this study run refers to a specific home-made paint sample produced by following a predetermined recipe.

-

Significance: In any statistical analysis, significance is evaluated based on a chosen cut off value (p < α). Here we use the common cut-off α < 0.05.

-

Special cubic: Third order interaction model specifically for mixtures.

-

Univariate: An experiment in which only one variable is changed.

Notes

Manufacturer information: CaCO3 ≈ 20 μm, BaSO4 ≈ 1.7 μm, TiO2 ≈ 0.1 μm.

References

van Driel BA, Wezendonk TA, van den Berg KJ, Kooyman PJ, Gascon J, Dik J. Determination of early warning signs for photocatalytic degradation of titanium white oil paints by means of surface analysis. Spectrochim Acta A. 2017;172:100–8.

Morsch S, van Driel BA, van den Berg KJ, Dik J. Investigating the photocatalytic degradation of oil paint using ATR-IR and AFM-IR. ACS Appl Mater Interfaces. 2017;9(11):10169–79.

Lauridsen CB, Sanyova J, Simonsen KP. Analytical study of modern paint layers on metal knight shields: the use and effect of titanium white. Spectrochim Acta A. 2014;124:638–45.

Laver M. Titanium white. In: FitzHugh EW, editor. Artists’ pigments: a handbook of their history and characteristics, vol. 3. Washington: National gallery of Art; 1997. p. 295–355.

van Driel BA, Kooyman PJ, van den Berg KJ, Schmidt-Ott A, Dik J. A quick assessment of the photocatalytic activity of TiO2 pigments—from lab to conservation studio! Microchem J. 2016;126:162–71.

Johnston-Feller R, Feller RL, Bailie CW, Curran M. The kinetics of fading: opaque paint films pigmented with alizarin lake and titanium dioxide. JAIC. 1984;23(2):114–29.

Samain L, Silversmit G, Sanyova J, Vekemans B, Salomon H, Gilbert B, et al. Fading of modern Prussian blue pigments in linseed oil medium. J Anal Atom Spectrom. 2011;26(5):930–41.

Völz H, Kaempf G, Fitzky H, Klaeren A. The chemical nature of chalking in the presence of titanium dioxide pigments. In: Winslow FH, editor. Photodegradation photostabilization of coatings ACS symposium series, vol. 151. Washington D.C: American Chemical Society; 1981. p. 163–84.

Egerton T. UV-absorption—the primary process in photocatalysis and some practical consequences. Molecules. 2014;19(11):18192.

Egerton TA, Tooley IR. Effect of changes in TiO2 dispersion on its measured photocatalytic activity. J Phys Chem B. 2004;108(16):5066–72.

Thomson G. Penetration of radiation into old paint films. Natl Gallery Tech Bull. 1979;3:25–33. http://www.nationalgallery.org.uk/technical-bulletin/thomson1979. Accessed 15 Dec 2017.

Creagh DC, Bradley D. Physical techniques in the study of art, archaeology and cultural heritage, vol. 2. Amsterdam: Elsevier; 2007. p. 203.

Pfaff G. Chapter 3: white pigments. In: Inorganic pigments. Berlin: Walter de Gruyter GmbH; 2017. ISBN: 978-3-11-048451-9.

Colling JH, Dunderdale J. The durability of paint films containing titanium dioxide—contraction, erosion and clear layer theories. Prog Org Coat. 1981;9(1):47–84.

Paints and coatings Industry. A comprehensive understanding of TiO2 pigment durability. 2005. http://www.pcimag.com/articles/a-comprehensive-understanding-of-tio2-pigment-durability. Accessed 15 Dec 2017.

Zorll U. New aspects of gloss of paint film and its measurement. Prog Org Coat. 1972;1(2):113–55.

Rogge CE, Arslanoglu J. Distinguishing manufacturing practices for titanium white pigments: new Raman markers for dating commercial oil-based paints. Stud Conserv. 2016;61(sup2):324–6.

Werner AJ. Titanium dioxide pigment coated with silica and alumina. Google Patents; 1969.

Nelson WK. Chalk-resistant titanium dioxide pigment and method for preparing the same. Google Patents; 1944.

Jacobson HW. Light-stable titanium dioxide pigment composition. Google Patents; 1980.

Linsebigler AL, Lu G, Yates JT. Yates, photocatalysis on TiO2 surfaces: principles, mechanisms, and selected results. Chem Rev. 1995;95(3):735–58.

Fujishima A, Rao TN, Tryk DA. Titanium dioxide photocatalysis. J Photochem Photobiol C. 2000;1(1):1–21.

Gaumet S, Siampiringue N, Lemaire J, Pacaud B. Influence of titanium dioxide pigment characteristics on durability of four paints (acrylic isocyanate, polyester melamine, polyester isocyanate, alkyd). Surf Coat Int. 1997;80(8):367–72.

de Keijzer M. The history of modern synthetic inorganic and organic artists’ pigments. In: Mosk JA, editor. Contributions to conservation: research in conservation at the Netherlands Institute for Cultural Heritage (ICN Instituut Collectie Nederland). London: James & James; 2002. p. 42–54.

Gesenhues U. Influence of titanium dioxide pigments on the photodegradation of poly(vinyl chloride). Polym Degrad Stab. 2000;68(2):185–96.

Phenix A, van den Berg KJ, Soldano A, van Driel BA. The might of white: formulations of titanium dioxide-based oil paints as evidenced in archives of two artists’ colourmen mid-twentieh century. In: ICOM-CC Triennial conference 2017, Copenhagen. 2017.

Spathis P, Karagiannidou E, Magoula AE. Influence of titanium dioxide pigments on the photodegradation of paraloid acrylic resin. Stud Conserv. 2003;48(1):57–64.

Cornell JA. Experiments with mixtures: designs, models, and the analysis of mixture data. New York: Wiley; 2011.

Goos P, Jones B. Optimal design of experiments: a case study approach. Hoboken: Wiley; 2011.

Brereton RG, Jansen J, Lopes J, Marini F, Pomerantsev A, Rodionova O, Roger JM, Walczak B, Tauler R. Chemometrics in analytical chemistry—part I: history, experimental design and data analysis tools. Anal Bioanal Chem. 2017;409(25):5891–9.

Brereton RG. Statistical experimental design. J Chemometr. 2017;31(7):e2902.

Tumosa CS, Mecklenburg MF. The influence of lead ions on the drying of oils. Stud Conserv. 2005;50(Supplement-1):39–47.

van Driel BA. Unpublished data; 2017.

Stat-Ease. Handbook for experimenters. http://www.statease.com/pubs/handbk_for_exp_sv.pdf. Accessed 15 Dec 2017.

Weisberg S. Applied linear regression. 2nd ed. New York: Wiley; 1985.

Raymond M. Classical and modern regression with applications. New York: Duxbury Press; 1986.

McCullagh PM, Nelder JA. Generalized linear models. 2nd ed. London: Chapman and Hall; 1990.

Lohmander S. The influence of particle shape of coating pigments on their packing ability and on the flow properties of coating colours. Trita-PMT, Institutionen för pappers-och massateknologi. 2000; 5:71.

Feller RL, Roy A. Barium sulfate. In: Feller RL, editor. Artists’ pigments: a handbook of their history and characteristics, vol. 1. London: Archetype Publications. 1986; p. 47.

Lower ES. The properties of aluminium stearate and its uses in the coating and allied industries. Pigment Resin Technol. 1982;11(2):13–8.

Wang X, Rackaitis M. Gelling nature of aluminum soaps in oils. J Colloid Interface Sci. 2009;331(2):335–42.

Vicente JP, Gascoin T, Barboux P, Boilot JP, Rondet M, Gueneau L. Photocatalytic decomposition of fatty stains by TiO2 thin films. Int J Photoenergy. 2003;5(2):95–8.

Mills A, Hill C, Robertson PKJ. Overview of the current ISO tests for photocatalytic materials. J Photochem Photobiol A. 2012;237:7–23.

van den Berg KJ. Issues in contemporary oil paint. Switzerland: Springer International Publishing; 2014.

Kobayashi M, Kalriess W. Photocatalytic activity of titanium dioxide and zinc oxide. Cosmet Toilet Mag. 1997;112:83–5.

Osmond G. Zinc white: a review of zinc oxide pigment properties and implications for stability in oil-based paintings. AICCM Bull. 2012;33(1):20–9.

Hermans JJ. Metal soaps in oil paint, structure mechanisms and dynamics. Ph.D. thesis at Van ‘t Hoff Institute for Molecular Sciences, Universiteit van Amsterdam. 2017. ISBN: 978-94-629-5578-3. http://hdl.handle.net/11245.1/53663926-183c-40aa-b7b3-e6027979cb7d. Accessed Sept 2017.

Akpan UG, Hameed BH. Parameters affecting the photocatalytic degradation of dyes using TiO2-based photocatalysts: a review. J Hazard Mater. 2009;170(2–3):520–9.

Kuhn H. Zinc oxide. In: Feller RL, Roy A, editors. Artists’ pigments: a handbook of their history and characteristics. Cambridge: Cambridge University Press London; 1986. p. 169–86.

Authors’ contributions

BAVD performed all experiments and data interpretations and wrote and adjusted the manuscript according to co-authors suggestions. ND and MS were involved in teaching BAVD the ins and outs of DoE, setting up the experimental design and discussing the interpretation. VDB and JD supervise BAVD’s Ph.D. and contributed to the final manuscript. PJK was actively involved in the writing phase. All authors read and approved the final manuscript.

Acknowledgements

This work has been financially supported and co-authored by AkzoNobel and organized and hosted by the Rijksmuseum Amsterdam. AkzoNobel is further acknowledged for providing access to an in-house Design of Experiments course. Old Holland (Driebergen) is acknowledged for the paint muller on loan at the RCE and Pieter Keune for providing the paint drier. Furthermore, the authors acknowledge Bill Wei at the Cultural Heritage agency of the Netherlands (RCE) for the availability of the Sheen Instruments Ltd Tri-GLOSSmaster. Finally, Dr. M.J.M. Stols-Witlox (UvA) and Dr. L. Megens (RCE) are acknowledged for their feedback on the initial manuscript during the writing stage.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

Not applicable.

Ethics approval and consent to participate

Not applicable.

Funding

van Driel’s Ph.D. is funded by AkzoNobel. The research presented in the paper was performed in close collaboration with AkzoNobel researchers. The funding body also provided access to a company Design of Experiments course.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding author

Additional information

A terminology list is included at the end of the paper

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

van Driel, B.A., van den Berg, K.J., Smout, M. et al. Investigating the effect of artists’ paint formulation on degradation rates of TiO2-based oil paints. Herit Sci 6, 21 (2018). https://doi.org/10.1186/s40494-018-0185-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-018-0185-2