Abstract

Cellular agriculture is an innovative technology for manufacturing sustainable agricultural products as an alternative to traditional agriculture. While most cellular agriculture is predominantly centered on the production of cultured meat, there is a growing demand for an understanding of the production techniques involved in dairy products within cellular agriculture. This review focuses on the current status of cellular agriculture in the dairy sector and technical challenges for cell-cultured milk production. Cellular agriculture technology in the dairy sector has been classified into fermentation-based and animal cell culture-based cellular agriculture. Currently, various companies synthesize milk components through precision fermentation technology. Nevertheless, several startup companies are pursuing animal cell-based technology, driven by public concerns regarding genetically modified organisms in precision fermentation technology. Hence, this review offers an up-to-date exploration of animal cell-based cellular agriculture to produce milk components, specifically emphasizing the structural, functional, and productive aspects of mammary epithelial cells, providing new information for industry and academia.

Similar content being viewed by others

Introduction

The dairy farming system has been directed toward enhancing efficiency of milk production through concentrated animal feeding operations, larger herds, advanced breeding technologies [1]. Over the past 80 years, milk yield in dairy farming has witnessed a 16.7-fold increase, from 53 million metric tons (Mt) in 1944 to 887 Mt in 2021 [2,3,4]. Furthermore, global milk production is forecasted to increase to 1,060 Mt by 2031 [3]. Genetic improvement has been a significant contributor to the increase in milk productivity. Specifically, three factors including transitioning from breeds such as Jersey and Guernsey to Holstein, widespread adoption of artificial insemination, and advancements in genetic evaluation procedures have played pivotal roles. These factors have collectively driven notable genetic changes in milk productivity [2].

Dairy intensification has been associated with adverse effects on the environment [4], animal welfare [5], human health [6], and rural livelihoods [1]. From an environmental standpoint, the intensification of dairy farming, encompassing enteric and manure storage, concentrated feed production, and farm crop cultivation, leads to greenhouse gas emissions, soil acidification, and eutrophication [7]. In addition, animals in dairy farms are raised in highly artificial environments to maximize milk yield, prompting concerns about animal welfare [8]. Nitrate contamination of soil, aquifers, and rivers through the accumulation of cattle urine in dairy farming is another major concern for human health, as exposure to such contaminated water is associated with colorectal cancer [9]. Thus, dairy farming and industries are focusing on producing milk and milk products in a sustainable rather than traditional manner [10].

Cellular agriculture is receiving attention as a new sustainable technology for agricultural food production that can incrementally positively affect the environment and society [11]. Cellular agriculture holds considerable promise over traditional agriculture, offering potential benefits in terms of environmental sustainability, economic value, enhanced animal welfare, and improved human health and well-being [12]. Several companies across the globe are focusing on the production of cellular agricultural products, such as cultured meat and cell-cultured milk, based on cellular agriculture technology [13]. Nevertheless, this technology has been predominantly applied for production of cultured meat [11, 14, 15]. Therefore, comprehensive studies are required to understand the production of sustainable cell-cultured milk. This review aimed to comprehensively identify the current status of cellular agriculture in the dairy sector and to understand the fundamental knowledge and challenges associated with cell culture-based dairy technology.

Cellular agriculture in the dairy sector

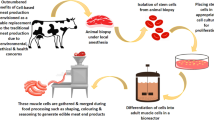

Cellular agriculture is a sustainable manufacturing technology that produces products such as meat components, milk components, and egg proteins using a cell culture system [16]. Various companies are currently trying to produce cell-cultured milk components using fermentation-based and animal cell culture-based technology (Fig. 1) [17]. However, prohibitive cost involved in the research, development, and production remain major obstacles [18]. Therefore, this section covers the techno-economic cost and technical state in current cell culture-based dairy field.

Techno-economic analysis

To assess the economic viability of cell-cultured milk components, a techno-economic analysis was conducted to estimate the cost-effectiveness of cell cultured milk components compared to whole milk. In the United States, a liter of whole milk typically costs around $1.00 USD [19]. One liter of milk contains about 26 g of casein (13 g of α-casein, 9.3 g of β-casein, and 3.3 g of κ-casein) and 40 g of fats [20]. Our previous research showed that MAC-T cells grown in a progesterone (P4)-based differentiation media were able to produce some key milk components [21]. Specifically, these cells synthesized 0.515 g of α-casein and 12.19 g of triglycerides per liter of media. However, it is important to consider that this media itself costs about $175 USD per liter [21]. Based on this cell-cultured milk technology, producing the same amounts of α-casein and triglycerides found in a liter of whole milk would be very expensive. The production for α-casein and triglycerides would likely cost around $4,417 USD and $574 USD, respectively. It is important to remember that this only considers the cell culture media. The actual production cost would be much higher because it excludes costs for labor, production facilities, separation and purifying the desired milk components, and other miscellaneous expenses. As a result, these projections indicate that the significant production expenses pose a significant obstacle in contemporary cellular agriculture. Therefore, it is important to develop cost-efficient methodologies to facilitate large-scale industrial production [18]. The primary focus of technical advancement involves enhancing cell lines, developing low-cost yet high-performance medium, optimizing bioreactors for efficiency, and refining down-stream processing methods for cost-effectiveness. These efforts are essential for realizing economically viable production of cell-cultured milk components.

Fermentation-based cellular agriculture

Fermentation-based cellular agriculture employs synthetic biology and genetic engineering to introduce specific genes into the DNA backbone of bacteria, yeast, or algae, to produce desired products [22]. Based on precision fermentation technology, various companies have developed and commercialized milk components, such as casein, whey protein, and lactoferrin (Table 1). However, most companies have chosen not to disclose details regarding the microorganisms or the techniques they utilized.

Fungi are known as the most suitable microbial hosts for precision fermentation because of their strong environmental adaptability [25]. From the metabolic engineering perspective, compared to bacteria, fungi possess better eukaryotic properties that allow them to express heterologous eukaryotic proteins, correcting protein folding and post-translation modifications [26, 27]. The filamentous fungus Trichoderma reesei is commonly utilized to synthesize recombinant food components because of its high protein productivity (up to 100 g/L); moreover, it is generally regarded as safe [22, 25]. Indeed, a prior study documented that T. reesei, employing precision fermentation technology, can produce β-lactoglobulin (BLG) at a level of 1 g/L, with the structural and functional properties of the recombinant BLG being consistent with bovine BLG [28].

Precision fermentation has enabled the production of sustainable milk components, an emerging food trend in the fourth industrial revolution of the food industry [29]. However, the commercialization of genetically modified organisms (GMOs) used in precision fermentation has raised public concerns about food safety [30]. Accordingly, the production of food components using GMOs requires careful regulation, thorough safety evaluations, and consideration of consumer concerns [22]. Therefore, although precision fermentation as an innovative technology is anticipated to reduce the reliance on traditional dairy farming, overcoming GMO concerns remains a major challenge for fermentation-based cellular agriculture.

Animal cell culture-based cellular agriculture

Animal cell and tissue culture-based cellular agriculture involves tissue engineering to produce functional tissues using minimal cells or cell lines obtained from living animals [16]. Recent biotech startups have emerged, securing funds to pioneer the development of cell-cultured milk production (Table 2) [31]. As current animal cell culture-based cellular agriculture has technical difficulties in synthesizing whole milk, they mainly aim to produce a single component of milk using mammary epithelial cells (ECs) [32].

Milk components, such as casein, whey protein, and triglycerides, are primarily synthesized and secreted by ECs of the mammary gland [34, 35]. Thus, the primary step in the in vitro production of cell-cultured milk components is to obtain ECs. Companies such as BIOMILQ and Wilk isolate ECs from the milk-secreting parenchymal tissue of the mammary gland. In contrast, Turtle Tree isolates mesenchymal stem cells from mammary tissues, adipose tissues, and the umbilical cord, subsequently inducing differentiation into ECs [23, 32]. Despite the focus of the mentioned startup companies on the production of cell culture-based milk, technology related to animal cell culture for producing milk components is still in its early stages. Consequently, novel strategies are essential to surmount the technical barriers of animal cell culture-based cellular agriculture, necessitating a deeper understanding of milk biosynthesis in the mammary gland.

Current knowledge and technical challenges for producing cell-cultured milk

The mammary gland itself is a complicated bioreactor comprised of alveolar structure including various cell types. Technical challenges for producing cell-cultured milk include replicating the structure of milk-secreting mammary glands and reconstructing it within an in vitro environment. Cell-cultured milk can be produced through the intricate processes such as the structural interaction of cells and the regulation of milk synthesis-related hormones while cell-cultured meat is generally produced by culturing muscle cells or adipocytes [36]. Therefore, a detailed process of the milk synthesis and secretion in the mammary gland to produce cell-cultured milk would be described in this section. The short-term objective is to produce individual milk components using a two-dimensional (2D) culture of mammary cells, while the ultimate long-term goal is to achieve the production of whole milk through the three-dimensional (3D) culture of mammary glands [15]. To accomplish these objectives, the primary technical challenges will involve ensuring the sustainable resourcing of mammary cells, optimizing cell culture media, establishing a robust cell culture system, and down-stream processing of cell-cultured milk components (Fig. 2) [32].

Principal processes and technical challenges for producing cell-cultured milk using animal cell culture-based technology. The production of cell-cultured milk, found on the cultivation of mammary epithelial cells (ECs), is through a series of sequential processes as follows: (1) isolation of mammary ECs from parenchymal tissues or milk, (2) cultivation of isolated mammary ECs for the establishment of a cell line, (3) evaluation of cellular characteristics, (4) optimization of cell culture media, (5) establishment of three-dimensional cell culture system using extracellular matrix, (6) upscale of cell cultivation using stirred tank bioreactor and microcarrier, (7) down-stream processing of cell culture media, (8) production of cell-cultured milk components, and (9) processing of cell-cultured milk components. The major technical challenges for the production of cell-cultured milk are resourcing the cell line (1–3), optimizing the cell culture media (4), establishing the cell culture system (5–6), and separating milk components (7–8). Comprehensive and detailed technical challenges for cell-cultured milk production are discussed in this review

Understanding functional and structural features of the mammary gland

The mammary gland (breast) is a distinctive organ exclusive to mammals, characterized by an anatomical structure designed for the secretion of milk to nourish a newborn (Fig. 3) [37]. Herein, mammary alveolus is a fundamental constituent of mature mammary glands for milk production. Alveolar parenchyma comprises inner milk secretory ECs that surround the lumen, outer myoepithelial cells (MCs) that attach to the basal mammary epithelium, and the basement membrane (BM) that contacts the MCs. The stromal compartment comprises various stromal cells, including fibroblasts (FBs), adipocytes, endothelial cells, and extracellular matrix (ECM) [35, 38]. Thus, milk components are structurally synthesized by ECs, contracted by MCs, and secreted into the lumen [39].

Internal structure of mammary gland and mammary alveolus. The mammary gland is composed of lobes that comprise lobules containing 150–220 alveoli. Mammary alveoli are fundamental constituents that produce milk components. The mammary alveolus consists of parenchymal and stromal compartments based on the basement membrane. The parenchyma is constructed of inner milk secretory epithelial cells that surround a central lumen and outer myoepithelial cells that attach to the base of the mammary epithelium. In addition, the stroma is constituted of adipocytes and extracellular matrix

The functional capabilities of the mammary gland for milk synthesis and secretion occur primarily during physical development [40]. The mammary gland develops throughout the four growth stages (i.e., pre-puberty, post-puberty, pregnancy, and lactation), experiencing repeated apoptosis and growth in response to pregnancy cycles, parturition, lactation, and involution [40, 41]. In particular, the mature functional development of the mammary gland, which directly enables the synthesis and secretion of milk, occurs primarily during pregnancy and lactation [42], and is primarily regulated by the reproductive and metabolic hormones. Among the various hormones, prolactin (PRL) and P4 directly induce the alveologenesis and secretory differentiation through receptor activator of nuclear factor kappa-B ligand during pregnancy. In addition, 17β-estradiol (E2), cortisol (CORT), insulin (INS), and growth hormones support this development of mammary gland. After that, a decrease of P4 concentration in the presence of PRL, CORT, and INS triggers the secretory activation and the onset of milk production for the transition to lactation [43]. These features of the mammary gland are essential for the synthesis of milk components and are tightly regulated through the coordinated action of hormones within mammary cells.

Considering the structural and functional properties of the mammary gland as summarized above, the activation of mammary ECs or secretory differentiation through hormonal regulation are essential for producing cell-cultured milk components. To initiate this process in the laboratory, the first step involves isolating milk-secreting ECs and establishing their cellular characteristics.

Resourcing of mammary epithelial cells

ECs can be isolated from the mammary gland tissues or milk of animals and humans, depending on the type of milk desired for production (Table 3). Isolating ECs from tissue is typically used in current research field due to its technical ease to apply. However, as the ECs can be obtained from the parenchymal tissue of the mammary gland after biopsy or slaughter, the procedures are uneconomical, time-consuming, and inconvenient. Furthermore, as mammary gland tissue comprises various cell populations such as ECs, MCs, FBs, adipocytes, and ECM [35], disassociating mammary gland tissue is essential to isolate ECs. Diverse enzymes such as collagenase, hyaluronidase, and trypsin have been used to isolate and purify ECs. In particular, trypsin has been widely used to remove FBs from the mammary gland tissue. However, according to a recent study, the combination of collagenase type 1 and hyaluronidase more effectively isolated ECs with better preservation of the physiological properties than trypsin [44]. Therefore, optimization of dissociation by applying multiple enzyme combinations would improve the physiological properties of isolated ECs, contributing to cell line resourcing.

Recently, isolating ECs from milk is receiving attention as a novel strategy because it has several advantages, including non-invasiveness, repeatability, and less contamination by FBs. Notably, the cytoskeletal characteristics and milk productivity of primary bovine ECs extracted from milk were comparable to those of cells isolated from tissue [58]. In addition, human breast milk was a rich source of heterogeneous cell types such as milk-secreting ECs, MCs, progenitor cells, and multipotent mesenchymal stem cells [59, 60]. Therefore, isolating ECs from milk can be another effective alternative method for sustainable resourcing of ECs [52]. However, further study is required to demonstrate the suitability as an alternative to the tissue culture regarding gene expression and cellular functionality.

The cytoskeleton plays a crucial role in cellular integrity, structure, and function and expresses specific cytoskeletal proteins depending on the cell type [32]. Milk-producing ECs specifically express cytokeratin (CK) 8 [61]. ECs, MCs, and FBs selectively express CK18/19, α-smooth muscle actin (α-SMA), and vimentin as specific markers, respectively [62]. Accordingly, various cytoskeletal protein markers, including CK8, CK18, CK19, vimentin, and α-SMA, can be utilized to distinguish mammary cell line types. Taken together, isolating ECs from milk and evaluating reliable biomarker would contribute to the stable resourcing of the mammary cells.

Optimization of cell culture media for mammary epithelial cells

Optimal cultivation conditions for ECs can be established by imitating the in vivo circulatory system and physiological environment of the mammary alveolus. As all of the precursors for milk production are supplied from the blood [63], it plays an important role in providing hormones and nutrients for the growth, development, and lactation of the mammary gland [64]. Therefore, the most fundamental factor for the production of cell-cultured milk is to optimize the growth and differentiation media of ECs based on the levels of constituents in the blood during the development and lactation of the mammary gland [65].

Cell culture media are composed of a basal medium (comprising amino acids, vitamins, inorganic salts, glucose, among others), serum or serum alternatives (source of growth factors, hormones, and attachment factors), and several supplements [66]. Generally, Dulbecco’s Modified Eagle’s Medium/Nutrient Mixture F-12 Ham (DMEM/F12) with the addition of 10% fetal bovine serum (FBS) is used for cultivating ECs. In addition, antibiotics such as penicillin, streptomycin, gentamicin, and amphotericin B are added for aseptic cell culture. Therefore, the most fundamental growth media for the cultivation of ECs consist of DMEM/F12, 10% FBS, 1% penicillin/streptomycin, and 5 µg/mL amphotericin B (Table 4).

Amino acids, fatty acids, glucose, vitamins, and minerals are key nutrients for the structural development of and milk component biosynthesis by ECs [67]. Reproductive and metabolic hormones such as PRL, P4, E2, CORT, and INS are also essential for the proliferation and differentiation of ECs [43]. Therefore, amino acids and hormones can promote the proliferation and differentiation of ECs [43, 67, 68]. The increase in the number of ECs through proliferation and differentiation enhanced the milk productivity in the development and lactation of mammary gland [69]. In addition, milk fat composed of triglycerides (98%), diglycerides (about 2%), cholesterol (less than 0.5%), phospholipids (about 1%), and free fatty acids (about 0.1%), are mainly biosynthesized by ECs from more than 400 different fatty acids [70]. The most abundant fatty acids in milk consist of long-chain fatty acids in the order of palmitic acid (C 16:0), oleic acid (18:1), stearic acid (18:0), and myristic acid (14:0) [71]. These long-chain (C18 and some C16) fatty acids are derived from the blood plasma lipid originating from the diet, while medium- and short-chain fatty acids are synthesized through de novo synthesis in ECs [72, 73]. Therefore, various additives, including hormones, amino acids, and fatty acids, can be supplemented to the cell culture media to promote the proliferation and differentiation of ECs, thereby enabling the production of cell-cultured milk components [74]. Finally, the optimal proliferation and differentiation media needs to be established based on the concentration of hormones, amino acids, and fatty acids in blood plasma during pregnancy and lactation (Table 5).

Establishment of a cell culture system for mammary epithelial cells

ECs have typically been cultured using the 2D cell culture method to study the function of the mammary gland [49, 50]. Two-dimensional cultivation has the experimental advantage of promoting homogenous growth and proliferation of cells by supplying a consistent amount of nutrients and growth factors from cell culture media [88]. However, as 2D cell culture cannot completely mimic the structural shape of the tissues observed in the mammary gland, the bioactivities of the cells appear considerably different compared to those of tissues [89]. Furthermore, it has been reported that 2D-based cell culture is manual- and labor-intensive, demanding a significant amount of space and incurring a high manufacturing cost [90]. Consequently, 2D cell culture raises several strategic problems from the perspective of structural and productive cultivation of ECs for producing cell-cultured milk.

A 3D cell culture system is a potential approach for more effective production of cell-cultured milk. The first goal for 3D cell culture is to precisely mimic the structural and functional formation of mammary gland tissue. From the structural and functional perspectives of mammary alveolus, ECs are in contact with the thin and dense layers of a specialized ECM, termed the BM [89]. The BM, composed of a polymeric network of proteins, including laminins, collagen IV, heparin sulfate proteoglycan, and nidogen, has been reported to interact with ECs in the proliferation, differentiation, and metabolism processes [91,92,93]. Indeed, the culture of ECs with 3D collagen gels resulted in the maintenance of differentiation and synthesis of milk proteins, suggesting that ECM plays a key regulatory role in 3D cell culture [94, 95]. Therefore, the application of BM proteins is required for establishing a 3D cell culture of ECs.

Spheroids and scaffolds represent various 3D cell culture strategies. Additionally, microcarrier technology has emerged as suitable tool to apply BM proteins [96, 97]. Microcarriers are support matrices 100−300 μm diameter that enable the cultivation of anchorage-dependent adherent cells in a bioreactor system [98]. Several microcarriers are commercially synthesized using various materials, including glass, dextran, polystyrene, cellulose, collagen, gelatin, collagen, alginate, and chitosan [99]. These microcarriers can be coated with ECM proteins, such as laminin, collagen, and fibronectin, for the efficient adhesion of the cells. ECM proteins provide many RGD tripeptide (arginine-glycine-aspartate) motifs that can specifically bind to cell surface receptors [100]. Therefore, ECM proteins can enhance the cell attachment of microcarriers along with a high surface-to-volume ratio [101]. Indeed, a culture of 3 g/L Cytodex 1 (190 μm) and 3 (175 μm) microcarrier provides a surface area of 8.1–13.2 × 103 cm2 in 1L, which is equivalent to 108–176 of 75 cm2 cell culture flasks [101]. Various types of microcarriers have been mainly applied to cultivate human mesenchymal and pluripotent stem cells for cell therapy in clinical trials [101,102,103]. However, most studies related to ECs have primarily utilized microcarriers to establish 3D in vitro breast tumor models [104, 105]. Only one study reported the optimal cell adhesion, growth, and differentiation conditions on collagen-coated microcarriers (Cytodex 3) using bovine mammary epithelial cell line MAC-T [106]. Therefore, the optimization and application of ECs to ECM-coated microcarriers are required to overcome the structural and productive limitations of synthesizing cell-cultured milk.

To facilitate the upscale production of ECs, it is imperative to introduce a culture system that is more space-, labor-, and cost-efficient. A bioreactor stands out as a promising culture system for the large-scale cultivation of ECs [107]. Bioreactors have been extensively used for the industrial large-scale cultivation of mammalian cells under a controlled microenvironment [108]. Therefore, several bioreactor systems (stirred tank, wave, rotating wall, hollow fiber, and packed-bed), primarily developed for cultivating conventional mammalian cells, can potentially apply to the cultivation and scale-up of ECs [109]. Among the various bioreactor systems, a stirred tank bioreactor has many advantages for the commercial scale production, including ease of design, scale-up, in situ monitoring, and operation in different batch. While this bioreactor does have limitations in meeting the oxygen demand of large volumes (such as high-density cell cultures) and controlling excessive shear stress caused by the impeller, these challenges can be addressed through process optimization strategies. [110]. Considering the structural and functional characteristics of ECs and the application of microcarriers, a stirred tank bioreactor would be one of the most applicable systems for cell-cultured milk production. Stirred tank bioreactor is one of the most conventional bioreactors, which consist of a tank equipped with an impeller for efficient mixing and suspension [110]. The impeller, a core component of a stirred tank bioreactor, controls the culture environment, including pH, dissolved oxygen, temperature, nutrients, and metabolites through agitation [109, 111]. These bioreactors are simple and easy to monitor and control for large-scale cell cultivation [112]. Indeed, mammary epithelial stem cells inoculated at a 7.5 × 104 cells/mL in 125, 500, and 1,000 mL of stirred bioreactors resulted in the expansion of cell density of 3.38, 3.76, and 4.21 × 105 cells/mL, respectively, with the formation of aggregates (mammospheres) [113]. Moreover, stirred culture systems have the advantage of easy application of microcarrier technology that enhances the productivity of cells and their derivatives through an increase in the high surface-to-volume ratio [102]. Comprehensively, applying an ECM-coated microcarrier in a stirred tank bioreactor would be the most suitable cell culture system for the upscaled production of cell-cultured milk.

Down-stream processing of milk components from cell culture media

ECs cultured in a cell culture system secrete milk proteins and fat globules into the cell culture media. Concurrently, various cell culture additives including serum, hormones, and antibiotics used for the cellular proliferation and differentiation are contained in the cell culture media. However, only milk components should be separated and purified from the cell culture media. In these perspectives, membrane-based techniques can be effectively employed for isolating, purifying, and processing the milk components from the cell culture media.

Pressure-driven membrane separation process technology has widely been applied to produce high-value added dairy components in the dairy industry and to remove the hormones and antibiotics in the wastewater treatment industry [114, 115]. Membrane separation processes are classified as reverse osmosis (< 1 nm), nanofiltration (1–10 nm), ultrafiltration (10–100 nm), and microfiltration (100–10,000 nm) depending on the membrane pore size and molecular weight cutoff [114, 115]. One liter of milk contains 26 g casein micelles, 7 g whey proteins, and 40 g fat globules with sizes of 20–300 nm (average 110 nm), 3–6 nm, and 100–15,000 nm (average 3,400 nm), respectively [20, 116, 117]. Accordingly, fat globules, casein micelles, and whey proteins in the cell culture media can be separated using microfiltration, ultrafiltration, and nanofiltration [117]. In addition, since hormones and antibiotics have molecular weight of average 0.25–0.5 kDa, nanofiltration and reverse osmosis can be used for the removal [118, 119]. In detail, microfiltration, with a 1,400 nm pore size, is a standard method for separating fat globules and bacteria [120]. Microfiltration, with a 100–200 nm pore size, is employed to separate casein micelles from whey protein. Ultrafiltration and nanofiltration, featuring pore sizes of 1–100 nm and 2 nm, respectively, are used to concentrate whey protein [121]. Additionally, nanofiltration and reverse osmosis, which have a molecular weight cut off of 0.3–1 kDa and 0.1 kDa, respectively, are applied for removing the various types of hormones and antibiotics (Table 6) [114, 115].

Two types of tubular ceramic membranes (TCMs) and spiral-wound membranes (SWMs) are typically applied in the separation of milk components using microfiltration, ultrafiltration, and nanofiltration [117]. TCM is widely used for membranes because of its narrow pore distribution, high hydraulic performance, and high thermal stability [125, 126]. However, compared with SWM, TCM has high transmembrane pressure (∆pTM), which increases the flux value (L/m2·h) and membrane fouling, resulting in high energy consumption and low separation efficiency for milk protein fractionation [127]. Thus, recent studies have focused on optimizing the efficiency of milk protein separation using SWM to improve membrane fouling [128, 129]. A 0.3-µm pore size SWM can achieve a whey protein separation ratio of up to 97% from skim milk, surpassing the 95% ratio achieved with the 0.1-µm pore size TCM [128]. Furthermore, although pore size did not affect the flux value in 0.1- and 0.2-µm pore size SWM, the 0.1-µm pore size SWM was more suitable for milk protein separation because of a high loss of protein in the 0.2-µm SWM [129]. Therefore, establishing an optimal process of SWM based on the pore size can increase the separation efficiency of milk components from cell culture media. In summary, the milk components present within cell culture media can be effectively separated into fat globules, casein micelles, and whey proteins by implementing an optimal process that integrates microfiltration, ultrafiltration, and nanofiltration, using SWM.

Conclusions

Cellular agriculture in the dairy sector may provide a wide range of opportunities for the sustainable production of dairy products, such as milk components or cell-cultured milk. Cellular agriculture in the dairy sector is categorized into fermentation-based and animal cell culture-based cellular agriculture. While several companies predominantly focus on producing milk components through fermentation-based technology, precision fermentation technology still faces the challenges with respect to GMO concerns. Several startup companies are attempting to produce milk components by cultivating ECs in animal cell culture-based technology. However, the technology is still in its early stages of development. This review summarized the structural and functional attributes of the mammary gland and discussed the technologies for cell-cultured milk production. The major technologies were (1) resourcing of mammary EC line, (2) optimizing the cell culture media, (3) establishing the cell culture system, and (4) down-stream processing of milk component. Additionally, future developments and areas of further research include several key areas. Firstly, there is a need to efficiently cultivate milk-derived mammary ECs, achieved through the identification of reliable biomarkers and the use of optimal proliferation and differentiation media. Secondly, the application of 3D cell culture techniques, bioreactors, and membrane separation systems holds promise for scaling up the production of cell-cultured milk. Lastly, it is imperative to reduce the cost of cell-cultured milk compared to traditional milk, ensuring consumer accessibility to the product. In conclusion, this review presents current insights and challenges regarding cell culture-based dairy production and offers implications for ongoing efforts required to produce commercially significant quantities of cell-cultured milk.

Availability of data and materials

Not applicable.

Abbreviations

- 2D:

-

Two-dimensional

- 3D:

-

Three-dimensional

- BLG:

-

β-lactoglobulin

- BM:

-

Basement membrane

- CK:

-

Cytokeratin

- CORT:

-

Cortisol

- DMEM/F12:

-

Dulbecco’s Modified Eagle’s Medium/Nutrient Mixture F-12 Ham

- E1:

-

Estrone

- E2:

-

17β-Estradiol

- ECM:

-

Extracellular matrix

- ECs:

-

Epithelial cells

- EDTA:

-

Ethylene-diamine-tetraacetic acid

- EGF:

-

Epidermal growth factor

- FBS:

-

Fetal bovine serum

- FBs:

-

Fibroblasts

- FCS:

-

Fetal calf serum

- GMO:

-

Genetically modified organism

- IGF-1:

-

Insulin growth factor-1

- INS:

-

Insulin

- ITS:

-

Insulin-transferrin-selenium

- MCs:

-

Myoepithelial cells

- Mt:

-

Million metric tons

- MUFA:

-

Monounsaturated fatty acid

- P4:

-

Progesterone

- PRL:

-

Prolactin

- PUFA:

-

Polyunsaturated fatty acid

- SFA:

-

Saturated fatty acid

- α-SMA:

-

α-Smooth muscle actin

- SWM:

-

Spiral-wound membrane

- TCM:

-

Tubular ceramic membrane

References

Clay N, Garnett T, Lorimer J. Dairy intensification: Drivers, impacts and alternatives. Ambio. 2020;49:35–48. https://doi.org/10.1007/s13280-019-01177-y.

Capper JL, Cady RA, Bauman DE. The environmental impact of dairy production: 1944 compared with 2007. J Anim Sci. 2009;87(6):2160–7. https://doi.org/10.2527/jas.2009-1781.

OECD/FAO. OECD-FAO Agricultural Outlook 2021–2030. OECD Publishing. 2021. https://doi.org/10.1787/19428846-en.

Salou T, Le Mouël C, van der Werf HM. Environmental impacts of dairy system intensification: the functional unit matters! J Clean Prod. 2017;140:445–54. https://doi.org/10.1016/j.jclepro.2016.05.019.

Tucker CB, Mench JA, von Keyserlingk MAG. Animal welfare: an integral component of sustainability. In: Kebreab E, editor. Sustainable animal agriculture. Wallingford: CAB International; 2013. p. 42–52. https://doi.org/10.1079/9781780640426.0042.

Westhoek H, Lesschen JP, Rood T, Wagner S, De Marco A, Murphy-Bokern D, et al. Food choices, health and environment: Effects of cutting Europe’s meat and dairy intake. Glob Environ Change. 2014;26:196–205. https://doi.org/10.1016/j.gloenvcha.2014.02.004.

Bava L, Sandrucci A, Zucali M, Guerci M, Tamburini A. How can farming intensification affect the environmental impact of milk production? J Dairy Sci. 2014;97(7):4579–93. https://doi.org/10.3168/jds.2013-7530.

Godfray HCJ, Garnett T. Food security and sustainable intensification. Philos Trans R Soc B-Biol Sci. 2014;369(1639):20120273. https://doi.org/10.1098/rstb.2012.0273.

Joy M. The environmental and human health impacts of dairy intensification: a Canterbury case study. Vetscript. 2019;32(8):32–6.

Feil AA, Schreiber D, Haetinger C, Haberkamp ÂM, Kist JI, Rempel C, et al. Sustainability in the dairy industry: a systematic literature review. Environ Sci Pollut Res. 2020;27:33527–42. https://doi.org/10.1007/s11356-020-09316-9.

Mattick CS. Cellular agriculture: the coming revolution in food production. Bull Atom Scient. 2018;74(1):32–5. https://doi.org/10.1080/00963402.2017.1413059.

Kadim IT, Mahgoub O, Baqir S, Faye B, Purchas R. Cultured meat from muscle stem cells: A review of challenges and prospects. J Integr Agric. 2015;14(2):222–33. https://doi.org/10.1016/S2095-3119(14)60881-9.

Mouat MJ, Prince R. Cultured meat and cowless milk: On making markets for animal-free food. J Cult Econ. 2018;11(4):315–29. https://doi.org/10.1080/17530350.2018.1452277.

Nyika J, Mackolil J, Workie E, Adhav C, Ramadas S. Cellular agriculture research progress and prospects: Insights from bibliometric analysis. Curr Res Biotechnol. 2021;3:215–24. https://doi.org/10.1016/j.crbiot.2021.07.001.

Hong TK, Shin D-M, Choi J, Do JT, Han SG. Current issues and technical advances in cultured meat production: a review. Food Sci of Anim Resour. 2021;41(3):355. https://doi.org/10.5851/kosfa.2021.e14.

Stephens N, Di Silvio L, Dunsford I, Ellis M, Glencross A, Sexton A. Bringing cultured meat to market: Technical, socio-political, and regulatory challenges in cellular agriculture. Trends Food Sci Technol. 2018;78:155–66. https://doi.org/10.1016/j.tifs.2018.04.010.

Stephens N, Ellis M. Cellular agriculture in the UK: a review. Wellcome Open Res. 2020;5:12. https://doi.org/10.12688/wellcomeopenres.15685.2.

Bhat ZF, Kumar S, Fayaz H. In vitro meat production: Challenges and benefits over conventional meat production. J Integr Agric. 2015;14(2):241–8. https://doi.org/10.1016/S2095-3119(14)60887-X.

Liu Y, Rabinowitz AN. The impact of the COVID-19 pandemic on retail dairy prices. Agribusiness. 2021;37(1):108–21. https://doi.org/10.1002/agr.21687.

Pereira PC. Milk nutritional composition and its role in human health. Nutrition. 2014;30(6):619–27. https://doi.org/10.1016/j.nut.2013.10.011.

Kwon HC, Jung HS, Kim DH, Han JH, Han SG. The role of progesterone in Elf5 activation and milk component synthesis for cell-cultured milk production in MAC-T cells. Animals. 2024;14(4):642. https://doi.org/10.3390/ani14040642.

Augustin MA, Hartley CJ, Maloney G, Tyndall S. Innovation in precision fermentation for food ingredients. Crit Rev Food Sci Nutr. 2023:1–21. https://doi.org/10.1080/10408398.2023.2166014.

Waltz E. Cow-less milk: the rising tide of animal-free dairy attracts big players. Nat Biotechnol. 2022;40:1534–6. https://doi.org/10.1038/s41587-022-01548-z.

Linder T. Beyond agriculture-how microorganisms can revolutionize global food production. ACS Food Sci Technol. 2023;3(7):1144–52. https://doi.org/10.1021/acsfoodscitech.3c00099.

Chai KF, Ng KR, Samarasiri M, Chen WN. Precision fermentation to advance fungal food fermentations. Curr Opin Food Sci. 2022;47:100881. https://doi.org/10.1016/j.cofs.2022.100881.

Lyu X, Lee J, Chen WN. Potential natural food preservatives and their sustainable production in yeast: terpenoids and polyphenols. J Agric Food Chem. 2019;67(16):4397–417. https://doi.org/10.1021/acs.jafc.8b07141.

Zhang Y, Ma L, Su P, Huang L, Gao W. Cytochrome P450s in plant terpenoid biosynthesis: discovery, characterization and metabolic engineering. Crit Rev Biotechnol. 2023;43(1):1–21. https://doi.org/10.1080/07388551.2021.2003292.

Aro N, Ercili-Cura D, Andberg M, Silventoinen P, Lille M, Hosia W, et al. Production of bovine beta-lactoglobulin and hen egg ovalbumin by Trichoderma reesei using precision fermentation technology and testing of their techno-functional properties. Food Res Int. 2023;163:112131. https://doi.org/10.1016/j.foodres.2022.112131.

Hassoun A, Bekhit AE-D, Jambrak AR, Regenstein JM, Chemat F, Morton JD, et al. The fourth industrial revolution in the food industry—part II: Emerging food trends. Crit Rev Food Sci Nutr. 2022:1–31. https://doi.org/10.1080/10408398.2022.2106472.

Banovic M, Grunert KG. Consumer acceptance of precision fermentation technology: A cross-cultural study. Innov Food Sci Emerg Technol. 2023;88:103435. https://doi.org/10.1016/j.ifset.2023.103435.

Cohen M, Cassidy T. Milk from Mars. The challenges of regulating lab-produced (human) milk. Food & Drug Law J. 2022;77:6.

Gan J, Cao C, Stahl B, Zhao X, Yan J. Advances and challenges for obtaining human milk oligosaccharides: Extraction from natural sources and synthesis by intentional design. Trends Food Sci Technol. 2023;141:104203. https://doi.org/10.1016/j.tifs.2023.104203.

Eibl R, Senn Y, Gubser G, Jossen V, van den Bos C, Eibl D. Cellular agriculture: Opportunities and challenges. Annu Rev Food Sci Technol. 2021;12:51–73. https://doi.org/10.1146/annurev-food-063020-123940.

Weaver S, Hernandez L. Autocrine-paracrine regulation of the mammary gland. J Dairy Sci. 2016;99(1):842–53. https://doi.org/10.3168/jds.2015-9828.

Jaswal S, Jena MK, Anand V, Jaswal A, Kancharla S, Kolli P, et al. Critical review on physiological and molecular features during bovine mammary gland development: recent advances. Cells. 2022;11(20):3325. https://doi.org/10.3390/cells11203325.

Post MJ, Levenberg S, Kaplan DL, Genovese N, Fu J, Bryant CJ, et al. Scientific, sustainability and regulatory challenges of cultured meat. Nat Food. 2020;1(7):403–15. https://doi.org/10.1038/s43016-020-0112-z.

Macias H, Hinck L. Mammary gland development. Wiley Interdiscip Rev -Dev Biol. 2012;1(4):533–57. https://doi.org/10.1002/wdev.35.

Biswas SK, Banerjee S, Baker GW, Kuo C-Y, Chowdhury I. The mammary gland: basic structure and molecular signaling during development. Int J Mol Sci. 2022;23(7):3883. https://doi.org/10.3390/ijms23073883.

McManaman JL, Neville MC. Mammary physiology and milk secretion. Adv Drug Deliv Rev. 2003;55(5):629–41. https://doi.org/10.3390/ijms23073883.

Yart L, Lollivier V, Marnet P-G, Dessauge F. Role of ovarian secretions in mammary gland development and function in ruminants. Animal. 2014;8(1):72–85. https://doi.org/10.1017/S1751731113001638.

Inman JL, Robertson C, Mott JD, Bissell MJ. Mammary gland development: cell fate specification, stem cells and the microenvironment. Development. 2015;142(6):1028–42. https://doi.org/10.1242/dev.087643.

Hassiotou F, Geddes D. Anatomy of the human mammary gland: Current status of knowledge. Clin Anat. 2013;26(1):29–48. https://doi.org/10.1002/ca.22165.

Hannan FM, Elajnaf T, Vandenberg LN, Kennedy SH, Thakker RV. Hormonal regulation of mammary gland development and lactation. Nat Rev Endocrinol. 2023;19(1):46–61. https://doi.org/10.1038/s41574-022-00742-y.

Hu Z, Chen Y, Gao M, Chi X, He Y, Zhang C, et al. Novel strategy for primary epithelial cell isolation: Combination of hyaluronidase and collagenase I. Cell Prolif. 2023;56(1):e13320. https://doi.org/10.1111/cpr.13320.

Anand V, Dogra N, Singh S, Kumar SN, Jena MK, Malakar D, et al. Establishment and characterization of a buffalo (Bubalus bubalis) mammary epithelial cell line. PLoS ONE. 2012;7(7):e40469. https://doi.org/10.1371/journal.pone.0040469.

Pantschenko A, Woodcock-Mitchell J, Bushmich S, Yang T. Establishment and characterization of a caprine mammary epithelial cell line (CMEC). In Vitro Cell Dev Biol -Anim. 2000;36:26–37. https://doi.org/10.1290/1071-2690(2000)036%3c0026:EACOAC%3e2.0.CO;2.

Hu H, Wang J, Bu D, Wei H, Zhou L, Li F, et al. In vitro culture and characterization of a mammary epithelial cell line from Chinese Holstein dairy cow. PLoS ONE. 2009;4(11):e7636. https://doi.org/10.1371/journal.pone.0007636.

Zhao K, Liu HY, Zhou MM, Liu JX. Establishment and characterization of a lactating bovine mammary epithelial cell model for the study of milk synthesis. Cell Biol Int. 2010;34(7):717–21. https://doi.org/10.1042/CBI20100023.

Lu C, Yang R, Liu B, Li Z, Shen B, Yan S, et al. Establishment of two types of mammary epithelial cell lines from Chinese Holstein dairy cow. J Anim Vet Adv. 2012;11(8):1166–72. https://doi.org/10.3923/javaa.2012.1166.1172.

Jedrzejczak M, Szatkowska I. Bovine mammary epithelial cell cultures for the study of mammary gland functions. In Vitro Cell Dev Biol -Anim. 2014;50:389–98. https://doi.org/10.1007/s11626-013-9711-4.

Danowski K, Gross JJ, Meyer H, Kliem H. Effects of induced energy deficiency on lactoferrin concentration in milk and the lactoferrin reaction of primary bovine mammary epithelial cells in vitro. J Anim Physiol Anim Nutr. 2013;97(4):647–55. https://doi.org/10.1111/j.1439-0396.2012.01305.x.

Sorg D, Fandrey E, Frölich K, Meyer H, Kliem H. Mammary immunity of White Park and Highland cattle compared with Brown Swiss and Red Holstein. Anim Genet Resour. 2013;52:91–104. https://doi.org/10.1017/S2078633612000781.

Hillreiner M, Müller NI, Koch HM, Schmautz C, Küster B, Pfaffl MW, et al. Establishment of a 3D cell culture model of primary bovine mammary epithelial cells extracted from fresh milk. In Vitro Cell Dev Biol -Anim. 2017;53:706–20. https://doi.org/10.1007/s11626-017-0169-7.

Tong H-L, Li Q-Z, Gao X-J, Yin D-Y. Establishment and characterization of a lactating dairy goat mammary gland epithelial cell line. In Vitro Cell Dev Biol -Anim. 2012;48:149–55. https://doi.org/10.1007/s11626-012-9481-4.

Jin L, Qu Y, Gomez LJ, Chung S, Han B, Gao B, et al. Characterization of primary human mammary epithelial cells isolated and propagated by conditional reprogrammed cell culture. Oncotarget. 2018;9(14):11503. https://doi.org/10.18632/oncotarget.23817.

Dahanayaka S, Rezaei R, Porter W, Johnson G, Burghardt R, Bazer F, et al. Isolation and characterization of porcine mammary epithelial cells. J Anim Sci. 2015;93(11):5186–93. https://doi.org/10.2527/jas.2015-9250.

Fu M, Chen Y, Xiong X, Lan D, Li J. Establishment of mammary gland model in vitro: culture and evaluation of a yak mammary epithelial cell line. PLoS ONE. 2014;9(12):e113669. https://doi.org/10.1371/journal.pone.0113669.

Sorg D, Potzel A, Beck M, Meyer H, Viturro E, Kliem H. Effects of cell culture techniques on gene expression and cholesterol efflux in primary bovine mammary epithelial cells derived from milk and tissue. In Vitro Cell Dev Biol -Anim. 2012;48:550–3. https://doi.org/10.1007/s11626-012-9544-6.

Patki S, Kadam S, Chandra V, Bhonde R. Human breast milk is a rich source of multipotent mesenchymal stem cells. Hum cell. 2010;23:35–40. https://doi.org/10.1111/j.1749-0774.2010.00083.x.

Witkowska-Zimny M, Kaminska-El-Hassan E. Cells of human breast milk. Cell Mol Biol Lett. 2017;22(1):11. https://doi.org/10.1186/s11658-017-0042-4.

Lemay DG, Hovey RC, Hartono SR, Hinde K, Smilowitz JT, Ventimiglia F, et al. Sequencing the transcriptome of milk production: milk trumps mammary tissue. BMC Genomics. 2013;14:872. https://doi.org/10.1186/1471-2164-14-872.

Ontsouka EC, Bertschi JS, Huang X, Lüthi M, Müller S, Albrecht C. Can widely used cell type markers predict the suitability of immortalized or primary mammary epithelial cell models? Biol Res. 2016;49:1. https://doi.org/10.1186/s40659-015-0063-2.

Pandey Y, Taluja J, Vaish R, Pandey A, Gupta N, Kumar D. Gross anatomical structure of the mammary gland in cow. J Entomol Zool Stud. 2018;6(4):728–33.

Cai J, Wang D, Liu J. Regulation of fluid flow through the mammary gland of dairy cows and its effect on milk production: a systematic review. J Sci Food Agric. 2018;98(4):1261–70. https://doi.org/10.1002/jsfa.8605.

Arora M. Cell culture media: a review. Mater Methods. 2013;3(175):24.

Yao T, Asayama Y. Animal-cell culture media: History, characteristics, and current issues. Reprod Med Biol. 2017;16(2):99–117. https://doi.org/10.1002/rmb2.12024.

Rezaei R, Wu Z, Hou Y, Bazer FW, Wu G. Amino acids and mammary gland development: nutritional implications for milk production and neonatal growth. J Anim Sci Biotechnol. 2016;7:20. https://doi.org/10.1186/s40104-016-0078-8.

Akers RM. Lactation and the mammary gland. Ames: Blackwell publishing company; 2016. p. 165–98.

Capuco AV, Choudhary RK. Symposium review: Determinants of milk production: Understanding population dynamics in the bovine mammary epithelium. J Dairy Sci. 2020;103(3):2928–40. https://doi.org/10.3168/jds.2019-17241.

Lindmark MH. Fatty acids in bovine milk fat. Food Nutr Res. 2008;52(1):1821. https://doi.org/10.3402/fnr.v52i0.1821.

Markiewicz-Kęszycka M, Czyżak-Runowska G, Lipińska P, Wójtowski J. Fatty acid profile of milk-a review. J Vet Res. 2013;57(2):135–9. https://doi.org/10.2478/bvip-2013-0026.

Mohammad MA, Sunehag AL, Haymond MW. De novo synthesis of milk triglycerides in humans. Am J Physiol -Endocrinol Metab. 2014;306(7):E838–47. https://doi.org/10.1152/ajpendo.00605.2013.

Rodríguez-Bermúdez R, Fouz R, Rico M, Camino F, Souza TK, Miranda M, et al. Factors affecting fatty acid composition of Holstein cow’s milk. Animals. 2023;13(4):574. https://doi.org/10.3390/ani13040574.

Lee DY, Lee SY, Jung JW, Kim JH, Oh DH, Kim HW, et al. Review of technology and materials for the development of cultured meat. Crit Rev Food Sci Nutr. 2023;63(27):8591–615. https://doi.org/10.1080/10408398.2022.2063249.

Duarte RT, Carvalho Simões MC, Sgarbieri VC. Bovine blood components: fractionation, composition, and nutritive value. J Agric Food Chem. 1999;47(1):231–6. https://doi.org/10.1021/jf9806255.

Rius A, Appuhamy J, Cyriac J, Kirovski D, Becvar O, Escobar J, et al. Regulation of protein synthesis in mammary glands of lactating dairy cows by starch and amino acids. J Dairy Sci. 2010;93(7):3114–27. https://doi.org/10.3168/jds.2009-2743.

Brickell J, McGowan M, Wathes D. Effect of management factors and blood metabolites during the rearing period on growth in dairy heifers on UK farms. Domest Anim Endocrinol. 2009;36(2):67–81. https://doi.org/10.1016/j.domaniend.2008.10.005.

Bionaz M, Loor JJ. Gene networks driving bovine mammary protein synthesis during the lactation cycle. Bioinform Biol Insights. 2011;5:BBI-S7003.

Mukherjee J, Mallick S, Chaudhury M, Prakash B, Dang A. Infradian rhythmicity in milk leukocyte activity together with plasma cortisol and prolactin levels throughout the lactation period in high-yielding crossbred cows. Biol Rhythm Res. 2015;46(6):909–17. https://doi.org/10.1080/09291016.2015.1066544.

Fustini M, Galeati G, Gabai G, Mammi L, Bucci D, Baratta M, et al. Overstocking dairy cows during the dry period affects dehydroepiandrosterone and cortisol secretion. J Dairy Sci. 2017;100(1):620–8. https://doi.org/10.3168/jds.2016-11293.

Hiew M, Megahed A, Horstman L, Constable P. Clinical utility of plasma progesterone and blood and plasma glucose concentrations in predicting parturition in Holstein cows. J Dairy Sci. 2020;103(6):5575–90. https://doi.org/10.3168/jds.2019-17800.

Kamada H. Effects of selenium-rich yeast supplementation on the plasma progesterone levels of postpartum dairy cows. Asian Australasian J Animal Sci. 2017;30(3):347. https://doi.org/10.5713/ajas.16.0372.

Erb R, Chew B, Keller H. Relative concentration of extrogen and progestrone in milk and blood, and excretion of estrogene in urine. J Anim Sci. 1977;45(3):617–26. https://doi.org/10.2527/jas1977.453617x.

Accorsi P, Govoni N, Gaiani R, Pezzi C, Seren E, Tamanini C. Leptin, GH, PRL, insulin and metabolic parameters throughout the dry period and lactation in dairy cows. Reprod Domest Anim. 2005;40(3):217–23. https://doi.org/10.1111/j.1439-0531.2005.00581.x.

Zachut M, Arieli A, Lehrer H, Livshitz L, Yakoby S, Moallem U. Effects of increased supplementation of n-3 fatty acids to transition dairy cows on performance and fatty acid profile in plasma, adipose tissue, and milk fat. J Dairy Sci. 2010;93(12):5877–89. https://doi.org/10.3168/jds.2010-3427.

Szczechowiak J, Szkudelska K, Szumacher-Strabel M, Sadkowski S, Gwozdz K, El-Sherbiny M, et al. Blood hormones, metabolic parameters and fatty acid proportion in dairy cows fed condensed tannins and oils blend. Ann Anim Sci. 2018;18(1):155. https://doi.org/10.1515/aoas-2017-0039.

Contreras G, O’boyle N, Herdt T, Sordillo L. Lipomobilization in periparturient dairy cows influences the composition of plasma nonesterified fatty acids and leukocyte phospholipid fatty acids. J Dairy Sci. 2010;93(6):2508–16.

Duval K, Grover H, Han L-H, Mou Y, Pegoraro AF, Fredberg J, et al. Modeling physiological events in 2D vs. 3D cell culture. Physiology. 2017;32(4):266–77.

Vidi PA, Bissell MJ, Lelièvre SA. Three-dimensional culture of human breast epithelial cells: the how and the why. Methods Mol. 2013;945:193–219. https://doi.org/10.1007/978-1-62703-125-7_13.

Abraham E, Gupta S, Jung S, McAfee E. Bioreactor for scale-up: process control. In: Biswanathan S, Hematti P, editors. Mesenchymal Stromal Cells. UK: Elsevier; 2017. p.139–178. https://doi.org/10.1016/B978-0-12-802826-1.00006-4.

Kruegel J, Miosge N. Basement membrane components are key players in specialized extracellular matrices. Cell Mol Life Sci. 2010;67:2879–95. https://doi.org/10.1007/s00018-010-0367-x.

Finot L, Chanat E, Dessauge F. Mammary gland 3D cell culture systems in farm animals. Vet Res. 2021;52(1):78. https://doi.org/10.1186/s13567-021-00947-5.

Kass L, Erler JT, Dembo M, Weaver VM. Mammary epithelial cell: influence of extracellular matrix composition and organization during development and tumorigenesis. Int J Biochem Cell Biol. 2007;39(11):1987–94. https://doi.org/10.1016/j.biocel.2007.06.025.

Emerman JT, Pitelka DR. Maintenance and induction of morphological differentiation in dissociated mammary epithelium on floating collagen membranes. In Vitro. 1977;13(5):316–28. https://doi.org/10.1007/BF02616178.

Hall HG, Farson DA, Bissell MJ. Lumen formation by epithelial cell lines in response to collagen overlay: a morphogenetic model in culture. Proc Natl Acad Sci. 1982;79(15):4672–6. https://doi.org/10.1073/pnas.79.15.4672.

Huang L, Abdalla AM, Xiao L, Yang G. Biopolymer-based microcarriers for three-dimensional cell culture and engineered tissue formation. Int J Mol Sci. 2020;21(5):1895. https://doi.org/10.3390/ijms21051895.

Justice BA, Badr NA, Felder RA. 3D cell culture opens new dimensions in cell-based assays. Drug Discov Today. 2009;14(1–2):102–7. https://doi.org/10.1016/j.drudis.2008.11.006.

YekrangSafakar A, Acun A, Choi JW, Song E, Zorlutuna P, Park K. Hollow microcarriers for large-scale expansion of anchorage-dependent cells in a stirred bioreactor. Biotechnol Bioeng. 2018;115(7):1717–28. https://doi.org/10.1002/bit.26601.

Koh B, Sulaiman N, Fauzi MB, Law JX, Ng MH, Idrus RBH, et al. Three dimensional microcarrier system in mesenchymal stem cell culture: a systematic review. Cell Biosci. 2020;10(1):75. https://doi.org/10.1186/s13578-020-00438-8.

Derakhti S, Safiabadi-Tali SH, Amoabediny G, Sheikhpour M. Attachment and detachment strategies in microcarrier-based cell culture technology: A comprehensive review. Mater Sci Eng C. 2019;103:109782. https://doi.org/10.1016/j.msec.2019.109782.

Chen AK-L, Reuveny S, Oh SKW. Application of human mesenchymal and pluripotent stem cell microcarrier cultures in cellular therapy: achievements and future direction. Biotechnol Adv. 2013;31(7):1032–46. https://doi.org/10.1016/j.biotechadv.2013.03.006.

Badenes SM, Fernandes TG, Rodrigues CA, Diogo MM, Cabral JM. Microcarrier-based platforms for in vitro expansion and differentiation of human pluripotent stem cells in bioreactor culture systems. J Biotechnol. 2016;234:71–82. https://doi.org/10.1016/j.jbiotec.2016.07.023.

Couto PS, Rotondi M, Bersenev A, Hewitt C, Nienow A, Verter F, et al. Expansion of human mesenchymal stem/stromal cells (hMSCs) in bioreactors using microcarriers: lessons learnt and what the future holds. Biotechnol Adv. 2020;45:107636. https://doi.org/10.1016/j.biotechadv.2020.107636.

Yang C, Burg KL. Designing a tunable 3D heterocellular breast cancer tissue test system. J Tissue Eng Regen Med. 2015;9(3):310–4. https://doi.org/10.1002/term.1660.

Becker JL, Blanchard DK. Characterization of primary breast carcinomas grown in three-dimensional cultures. J Surg Res. 2007;142(2):256–62. https://doi.org/10.1016/j.jss.2007.03.016.

Roper AM. Growth of a bovine mammary epithelial cell line (Mac-T) on Cytodex 3 microcarriers. 1993. https://escholarship.mcgill.ca/concern/theses/b2773z07d. Accessed 8 Jan 2024.

Moritz MS, Verbruggen SE, Post MJ. Alternatives for large-scale production of cultured beef: A review. J Integr Agric. 2015;14(2):208–16. https://doi.org/10.1016/S2095-3119(14)60889-3.

Stephenson M, Grayson W. Recent advances in bioreactors for cell-based therapies. F1000Research. 2018;7:517–25. https://doi.org/10.12688/f1000research.12533.1.

Kropp C, Massai D, Zweigerdt R. Progress and challenges in large-scale expansion of human pluripotent stem cells. Process Biochem. 2017;59:244–54. https://doi.org/10.1016/j.procbio.2016.09.032.

Kumar A, Starly B. Large scale industrialized cell expansion: producing the critical raw material for biofabrication processes. Biofabrication. 2015;7(4):044103. https://doi.org/10.1088/1758-5090/7/4/044103.

Yang ST. Bioprocessing for value-added products from renewable resources: new technologies and applications. Amsterdam: Elsevier; 2011. p. 491–507.

Warnock JN, Al-Rubeai M. Bioreactor systems for the production of biopharmaceuticals from animal cells. Biotechnol Appl Biochem. 2006;45(1):1–12. https://doi.org/10.1042/BA20050233.

Youn BS, Sen A, Kallos MS, Behie LA, Girgis-Gabardo A, Kurpios N, et al. Large-scale expansion of mammary epithelial stem cell aggregates in suspension bioreactors. Biotechnol Prog. 2005;21(3):984–93. https://doi.org/10.1021/bp050059f.

Benoit S, Chamberland J, Doyen A, Margni M, Bouchard C, Pouliot Y. Integrating pressure-driven membrane separation processes to improve eco-efficiency in cheese manufacture: a preliminary case study. Membranes. 2020;10(10):287. https://doi.org/10.3390/membranes10100287.

Shojaee Nasirabadi P, Saljoughi E, Mousavi SM. Membrane processes used for removal of pharmaceuticals, hormones, endocrine disruptors and their metabolites from wastewaters: A review. Desalination Water Treat. 2016;57(51):24146–75. https://doi.org/10.1080/19443994.2016.1140081.

Korhonen H, Pihlanto A. Technological options for the production of health-promoting proteins and peptides derived from milk and colostrum. Curr Pharm Design. 2007;13(8):829–43. https://doi.org/10.2174/138161207780363112.

Carter B, Cheng N, Kapoor R, Meletharayil G, Drake M. Invited review: Microfiltration-derived casein and whey proteins from milk. J Dairy Sci. 2021;104(3):2465–79. https://doi.org/10.3168/jds.2020-18811.

Koyuncu I, Arikan OA, Wiesner MR, Rice C. Removal of hormones and antibiotics by nanofiltration membranes. J Membr Sci. 2008;309(1–2):94–101. https://doi.org/10.1016/j.memsci.2007.10.010.

Yang L, Xia C, Jiang J, Chen X, Zhou Y, Yuan C, et al. Removal of antibiotics and estrogens by nanofiltration and reverse osmosis membranes. J Hazard Mater. 2024;461:132628. https://doi.org/10.1016/j.jhazmat.2023.132628.

Reig M, Vecino X, Cortina JL. Use of membrane technologies in dairy industry: An overview. Foods. 2021;10(11):2768. https://doi.org/10.3390/foods10112768.

Kowalik-Klimczak A. The possibilities of using membrane filtration in the dairy industry. J Mach Constr Maintenance. 2017;2:99–108.

Brans G, Schroën C, Van der Sman R, Boom R. Membrane fractionation of milk: state of the art and challenges. J Membr Sci. 2004;243(1–2):263–72. https://doi.org/10.1016/j.memsci.2004.06.029.

Kumar P, Sharma N, Ranjan R, Kumar S, Bhat Z, Jeong DK. Perspective of membrane technology in dairy industry: A review. Asian Australasian J Anim Sci. 2013;26(9):1347. https://doi.org/10.5713/ajas.2013.13082.

Pouliot Y. Membrane processes in dairy technology—From a simple idea to worldwide panacea. Int Dairy J. 2008;18(7):735–40. https://doi.org/10.1016/j.idairyj.2008.03.005.

Zulewska J, Newbold M, Barbano D. Efficiency of serum protein removal from skim milk with ceramic and polymeric membranes at 50 °C. J Dairy Sci. 2009;92(4):1361–77. https://doi.org/10.3168/jds.2008-1757.

Fernández García L, Riera Rodríguez FA. Microfiltration of milk with third generation ceramic membranes. Chem Eng Commun. 2015;202(11):1455–62. https://doi.org/10.1080/00986445.2014.950731.

Schopf R, Schmidt F, Linner J, Kulozik U. Comparative assessment of tubular ceramic, spiral wound, and hollow fiber membrane microfiltration module systems for milk protein fractionation. Foods. 2021;10(4):692. https://doi.org/10.3390/foods10040692.

Beckman S, Zulewska J, Newbold M, Barbano D. Production efficiency of micellar casein concentrate using polymeric spiral-wound microfiltration membranes. J Dairy Sci. 2010;93(10):4506–17. https://doi.org/10.3168/jds.2010-3261.

Mercier-Bouchard D, Benoit S, Doyen A, Britten M, Pouliot Y. Process efficiency of casein separation from milk using polymeric spiral-wound microfiltration membranes. J Dairy Sci. 2017;100(11):8838–48. https://doi.org/10.3168/jds.2017-13015.

Acknowledgements

None.

Funding

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (No. 2022R1A2C1008327).

Author information

Authors and Affiliations

Contributions

HCK and SGH conceptualized the review. HCK, HSJ, and VK wrote the manuscript. HCK, HSJ, and VK collected the data. VK corrected the language. HCK and SGH revised and finalized the manuscript. SGH supervised the review. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Kwon, H.C., Jung, H.S., Kothuri, V. et al. Current status and challenges for cell-cultured milk technology: a systematic review. J Animal Sci Biotechnol 15, 81 (2024). https://doi.org/10.1186/s40104-024-01039-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40104-024-01039-y