Abstract

Economical, highly robust, selective, precise, and eco-friendly RP-UPLC and spectrophotometric methods were developed and validated for the concurrent estimation of selected pharmaceutical drugs represented in ceftazidime (CFZ) and pyridine (PYD) in their solutions using Agilent Zorbax SB-C18 RRHD (50 × 2.1 mm, 1.8 μm) column at flow rate 0.3 mL/min with wavelength 254 nm. Box-Behnken design (BBD) established Response surface methodology (RSM) to achieve the optimum chromatographic condition with minimal trials conducted. Three independent variables specifically acetonitrile ratio 60–70%, pH 3–7, and temperature 25–35 °C were implemented to evaluate the influences of these variables on the responses as resolution and retention time. Desirability and overlay plots were carried out to adjust the optimal condition that achieved the shortest retention time of less than 2 min and desired resolution of more than 1.5 using a mobile phase consisting of acetonitrile: purified water (70:30, v/v) at pH 5.0 adjusted by 0.1% orthophosphoric acid with the column oven temperature 30 °C and column void volume 0.46 mL. Mean centering of ratio spectra (MCR) and ratio subtraction (RS) methods were effectively applied to resolve drugs' spectral superposition at 220 nm, 255.4 nm, 260.3 nm, and 254.6 nm for CFZ and PYD, respectively. Linearity range was accomplished for UPLC, MCR, and RS methods over the concentration range of 2–100, 1–50,3–30 and 5–30 µg/mL for CFZ and PYD, respectively with correlation coefficient > 0.999 and good recovery results within 98–102%. Six Sigma methodology was achieved using the process capability index (Cpk) to compare the suggested and USP methods showing that both are highly capable with Cpk > 1.33. The proposed method was successfully validated depending on ICH guidelines and ANOVA results and applied for the accelerated stability study.

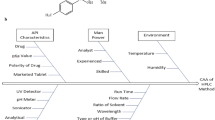

Graphical Abstract

Similar content being viewed by others

Introduction

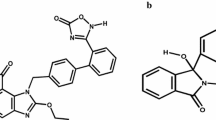

Cephalosporin antibiotic products have been widely detected in the aquatic environments. However, their environmental interactions are poorly understood. Ceftazidime (CFZ) pentahydrate is a semi-synthetic substance developed through a fermentation process that is like a third-generation cephalosporin but has better effectiveness against Gram-negative bacteria. Ceftazidime's activity against Pseudomonas species distinguishes it from other cephalosporins. Ceftazidime is given intravenously (IV) or intramuscularly (IM), and its appearance is described as a white or nearly white, crystalline powder. It has a unique chemical feature for solubility, as it is partially soluble in water and methanol but generally insoluble in acetone and ethanol (96 percent). It is soluble in alkaline and acidic solutions, Fig. 1a [1]. Pyridine (PYD) is also known as azabenzene in organic chemistry. It has the chemical formula C5H5N and a molecular weight of 79.10. PYD is a colorless, transparent liquid, hygroscopic, and highly soluble in water and ethanol (96 percent). It is also used in manufacturing pharmaceutical drugs, vitamins, and flavors with low concentrations. It is dangerous if breathed, digested, or absorbed via the skin. It is predominantly recognized to decrease spermatogenesis and is carcinogenic, Fig. 1b [1].

The future progress in liquid chromatography is UPLC which increases sensitivity, efficiency, and accuracy. UPLC system uniquely offers amelioration in the detection and separation and decreases the run time tenfold compared to HPLC methods [2]. Response surface methodology is a collection of sophisticated design of experiments (DOE) methodologies. RSM supplies a unique advantage over traditional. RSM can assist in optimizing responses and better understanding the interaction between independent variables through quadratic terms in the polynomial equation. RSM can efficiently reduce the analysis cost by minimizing the number of experimental trials [3,4,5,6,7,8,9,10]. In the recent past, before the implementation of Six Sigma, almost pharmaceutical factories were suffering from high scrap and reprocessing without prior detection of an error, so the applications of the six-sigma methodology have become imperious in pharmaceutical industries to avoid wasting time, removing defects, and increase capability index in the process [11,12,13]. The stability study aims to offer data concerning how the performance of the pharmaceutical product varies gradually due to environmental variables such as light, humidity, and temperature, as well as to determine the shelf life of the drug product [14]. Using green ideas in analytical chemistry without changing or affecting the merit numbers is hard. As most chromatographic procedures need toxic solvents, eliminating their usage is crucial to greening an analytical method. Nevertheless, there is a trend toward employing "green solvents," which raises additional concerns. We must come up with green ways to identify different environmental toxins because there is a growing need around the world to stop using toxic chemicals and cut down on releases that are bad for the environment. To make analytical procedures safe, dangerous solvents should be swapped out for safer ones, or waste should be eliminated [15,16,17,18,19,20]. BBD is a novel method for enhancing the precision of experimental outcomes. The method development and validation of the HPLC analytical technique used BBD-optimized chromatographic conditions. These conditions are good for routine analysis. It was common for HPLC procedures to keep changing one chromatographic parameter until the peak resolution was good enough. If more than one parameter is analyzed, more trials are required. Nevertheless, this is manageable using the BBD technique [21].

British Pharmacopoeia (BP) and United States Pharmacopeia (USP) mentioned a different HPLC method for the quantification of CFZ and PYD, respectively [1, 22]. Various HPLC-based analytical techniques for estimating CFZ and PYD alone or combined with other drugs have been described. [23,24,25,26,27,28,29,30], UPLC [31,32,33,34,35,36,37,38], LC–MS [39,40,41,42,43,44,45], and Spectrophotometric methods [46,47,48,49,50,51]. Several analytical HPLC method for concurrent estimation of both pharmaceutical drugs in eye drops formulation [52,53,54,55] and intravenous (IV), intramuscular (IM) [56,57,58,59].

The uniqueness of this study lies in the development of a robust UPLC method for concurrent estimation of a binary mixture in a single run using BBD, which requires fewer trials and is more efficient than the traditional "one factor at a time and green solvents, which have many benefits for cost savings, reduced waste, removing expensive treatment, toxic waste disposal, and sustaining health and safety. Moreover, RS and MCR methods were performed to solve the overlapping in the binary mixture without a sophisticated program and accomplishment of six sigma to evaluate the proposed method and the referenced USP one showing that CpK > 1.33 for both. To our endeavor, no UPLC, RS, and MCR methods were reported to simultaneously determine of CFZ and PYD in their powder for the injection dosage form. So, the essential objective of the current work is to establish novel, robust, and rapid RP-UPLC, RS, and MCR methods for the concurrent quantification of both drugs and the application of six sigma and accelerated stability studies.

Experimental

Instrument

The ACQUITY Arc System is upgraded by Waters (Massachusetts, USA) to achieve the linking and easily switch between HPLC and UHPLC. Arc UHPLC is supplied with a UV detector, column manager with a temperature range (4–90 °C) to accomplish the robustness of method development, autosampler needle which decreases carryover by constantly washing the needle during injections and Empower 3 software for processing and reporting.

The UV-1900i was devised by (Shimadzu, Japan) to cater to high accuracy and usability requirements with a wavelength range from 190 to 1100 nm and provided Lab Solutions UV–Vis’s software used for measurements and data analysis.

The stability cabinet (Weiss Technik, Reiskirchen, Germany) was annually verified for keeping the drug products and equipped with SIMPATI software for data monitoring and trending of temperature and relative humidity, also creation of a stability program was managed using the SAP QM module.

pH meter (Mettler-Toledo, Columbia, USA) was employed for measuring the pH in the solution and calibrated before use by three consecutive buffers (4, 7, 10) with an acceptable limit of 90–105%.

Design-Expert software version 13 was used for approaching response surface methodology and quality by design, MATLAB 2015a was established for handling the mean centering method, Six Sigma, and the process capability index was evaluated by using Minitab 2018 software.

Materials and reagent

CFZ USP reference standard (Lot No# R08540) was purchased from the USP store with a potency of 98.9% as an anhydrous base. Kefadim 500 mg (B. No #183,066) and Kefadim 1.0 g (B. No # 183,092) were provided by hikma pharmaceutical company (Beni-Suef, Egypt). Pyridine, orthophosphoric analytical grade, and acetonitrile HPLC grade were procured from (Scharlau, Spain). syringe filters (PTFE) 0.45 ϻm and membrane filter (GHP) 0.2 μm were procured from Noor Scientific & Trade, the authorized agent for Merck-Millipore in Egypt.

Procedures

Solvent preparation

For UPLC method

Acetonitrile: Acidic water adjusted at pH 5.0 (10:90).

For UV methods

0.1 N HCl

Preparation of working standard solutions (Laboratory prepared mixture)

Carefully weigh 58 mg of CFZ pentahydrate reference standard is equivalent to 50 mg CFZ base and 7 mg of PYD in a 200 mL volumetric flask, add 75 mL from solvent and sonicate for 5 min and complete to mark, then dilute 10 mL from the stock solution and transfer to 100 mL volumetric flask and filter through 0.45 µm PTFE syringe filter to obtain the final concentration of 25 µg/mL from CFZ and 3.5 µg/mL PYD, respectively.

Test preparation

Weigh and disperse ten filled vials and determine the average content per vial. Transfer accurately weighed quantity 290 mg containing the equivalent to 250 mg CFZ and 35 PYD, respectively in 500 mL volumetric flask, dissolve on sonication for 5 min. Transfer 5 mL of this solution into a 100 mL volumetric flask. Discard the first 4 mL, then filter through a PTFE filter of 0.45-µm.

Procedure

Chromatographic conditions

The isocratic system was established on Arc UPLC for the separation of the UPLC method for concurrent estimation of CFZ and PYD using RRHD Zorbax SB-C18 column (50 × 2.1 mm, 1.8 μm) and a mobile phase consisting of acetonitrile: purified water (70:30, v/v) at pH 5.0 adjusted by 0.1% orthophosphoric acid with flow rate 0.3 mL/min, column oven temperature 30 °C, and injection volume 0.3 µL at UV detection 254 nm. The mobile phase was filtered through a 0.2 µm membrane filter (GHP) and degassed for 10 min on the ultrasonic bath. All solvent lines and seal wash were primed by gradient wash with the following sequence (i) 15 min with mobile phase, (ii) 40 min with (20% organic: 80% H2O), 30 min with (70% organic: 30% H2O) to avoid air bubbles and buffer precipitations in the instrument tubing.

Calibration curves construction

A series dilution of 10 mL volumetric flasks was taken from the standard stock solution to obtain the final concentration range of 2–100 and 1–50 µg/mL for CFZ and PYD in the UPLC method and 3–30, 5–30 µg/mL for CFZ and PYD, respectively in RS and MCR methods. The sequence was started by six system suitability injections, two injections of standard solution (1, 2), two injections of Test solution (1, 2, 3), and two injections of standard check #01. Data processing and sign-off reports were performed on Empower 3 software for the sample set, the calibration curves were established versus the relevant concentrations and the regression equations were calculated for UPLC, RS, and MCR techniques.

Design of experiment for optimizing RP-UPLC method

Essential parameters affected directly by chromatographic separation were evaluated in the initial screening analysis. Three variables at three levels of BBD with RSM were implemented for optimizing chromatographic conditions with good resolution and the shortest retention time for both drugs with the least number of experimental runs. Independent factors of pH, the ratio of acetonitrile in the mobile phase, and column oven temperature were selected. The retention time and resolution were used as responses. Experimental 17 runs were displayed in Table 1. The second-order polynomial equation obtained from ANOVA results describes the quadratic models. Further, a 3D response surface was used to indicate the independent variables' interaction. Finally, the desirability function and overlay plots were employed to predict the optimum final condition.

Application of six sigma methodology

The main advantage of the process capability index is that companies will understand process behavior to decrease scrap, increase product quality and consistency, and reduce production costs and cost loss due to poor quality. A high process capability index (Cpk) indicates how near a process is to its specified center limit against the process's considerable variation. The low Cpk value indicates that the process needs improvement and can be calculated as follows [60, 61].

Where; \({\overline{X }}\) is the mean of process, LSL is the lower specification limit, USL is the upper specification limit, and \(\sigma\) is the standard deviation of the process.

Cpk always ≤ Cp (Process Capability).

Cpk = Cp when the method is correctly focused.

If a Cpk is negative, it means that the process average has exceeded the specified limit.

If a Cpk equals 0, the processes mean is close to the prescribed limits.

If the Cpk is even less than 1.0, the process does not match the specification limit.

If a Cpk is equal to 1.0 indicates that the process meets the specification limit.

A Cpk of 1.33 [4 sigma] or greater is required to satisfy most clients.

Ratio subtraction method

The primary benefit of the ratio subtracting method is the ability to perform simple measurements and solve the interfering spectra of a binary mixture. The scanned spectra of both drugs (X) and (Y) were divided by the chosen concentration of 10 μg/mL (Y) as a divisor, and new ratio spectra with constant were obtained. Average absorbance values (1.026) were subtracted in the plateau region (242–260 nm), the resulting spectra were then multiplied by the divisor of 10 g/mL (Y). Lastly, the new zero-order (X) was gained at 260.3 nm. The absorbances of zero-order spectra were calibrated against the appropriate concentrations, and regression equations were constructed at 260.3 nm. Also, (Y) could be obtained by dividing the stored spectra of the combination on the selected concentration 10 μg/mL (X) as a divisor. Then, constant values (1.051) were subtracted in the plateau region (275–320 nm), and the gained spectra were multiplied by the divisor 10 μg/mL (X), resulting in new original spectra of (Y) at 254.6 nm [62].

Mean centering of ratio spectra method

An advanced spectrophotometric method was implemented to overcome the overlapping found between the binary mixture of CFZ and PYD based on mean centering ratio spectra without prior derivative steps [63].

Assume a three-dimensional vector (X) to illustrate the mean centering equation [64].

The mean vector of X is

The vector S's mean centering could be expressed as

It is simple to establish that if a vector v is multiplied by a constant n, the mean center vector is likewise multiplied by n and that if n is added to the vector v, the mean center does not change. The total absorbance of a combination of binary mixture CFZ and PYD without interaction and obeying Beer's low may be calculated as follows:

where \(\mathrm{Abx}\) is the absorbance vector of the combination, \({C}_{CFZ}\) and \({C}_{PYD}\) are the concentrations of the relevant drugs, and the molar absorptivity of these drugs are \({\alpha }_{CFZ}\) and \({\alpha }_{bPYD}\).

1st spectrum (\(CFZ\)) is obtained by dividing the absorbance vector of the mixtures by \({\alpha }_{PYD}\)

Zero values of \({\alpha }_{CFZ}\) disregarded for completing the dividing step, the consequence of MCR on a constant is zero. Therefore,

By operating the MCR on Eq. (2), thus

Equation (4) is the statistical base of binary mixture analysis that declares the estimation of the concentration of each drug without overlapping with the other drug. A calibration curve was constructed individually or in a binary mixture by graphing MC (CZF) against the concentration of CFZ. Calibration curves for PYD were computed in the same manner for CFZ.

Stability studies

An accelerated stability study was conducted to study degradation pathways and estimate shelf life by using extreme conditions of high temperature and humidity. Intermediate stability must be performed if there is a substantial change such as decreasing assay results in the accelerated stability at any point by more than 5%, and intermediate stability samples should be kept for one year [65].

Results and discussion

Preliminary study

The main objective of the suggested work is to progress a specific and robust UPLC method for concurrent estimation of binary mixture CFZ and PYD in their powder for injection with good resolution and shortest retention time. So, various trials were executed to select the best wavelength and column type and adjust the mobile phase ratio. Scanning wavelength at 200–400 nm for a concentration of 10 µg/mL of CFZ, 20 µg/mL of PYD, and 30 µg/mL of dosage form using 0.1N HCl as blank (Fig. 2), showing that the best wavelength was 254 nm regarding high sensitivity and minimal noise. Varied column types were evaluated including CORTECS Shield C18 (50 mm × 2.1 mm, 1.6 μm), Zorbax SB-C18 RRHD (50 × 2.1 mm, 1.8 μm), and ACE C18 (5 cm × 2.1 mm, 2.0 μm) columns. Preliminary data fixed that the Agilent Zorbax SB-C18 RRHD column (50 × 2.1 mm, 1.8 μm) efficiently separated the examined drugs with the least void volume. Different flow rates ranging from 0.1 to 1 mL/min were tested; the flow rate of 0.3 mL/min demonstrated the quickest elution with good separation. The optimal mobile phase for the concurrent estimation of both drugs was found to be acetonitrile and purified water adjusted with 0.1% orthophosphoric acid. Altering the acetonitrile concentration, pH, and temperature significantly changed the retention time. Column temperature, pH, and the ratio of acetonitrile in the mobile phase were chosen as the crucial variables because they were discovered to have the most effective influence on responses.

Design of experiments (DoE)

DoE technique with BBD was implemented to adjust the optimum chromatographic conditions with the least number of trials and to study the quadric effect and the interaction between the variables and responses. The factors pH, column temperature, and acetonitrile ratio in the mobile phase were identified, while retention time and resolution were chosen as responses. Linear polynomial equations were investigated for a better grasp of the effects of engagement between independent factors and responses. Listed below is a depiction of the linear polynomial equations that ANOVA generated:

The observed data from Eq. (5) demonstrates that the independent variables with a negative sign negatively influence on the resolution. A positive sign in the interaction terms indicates that the two variables interact positively as shown in (Fig. 3a–f) for Contour and 3D-response surface plots. Equation (6) shows that column temperature and the ratio of acetonitrile have a negative impact on retention time. In contrast, the quadratic effects have a positive effect implying that any slight increase in column temperature and acetonitrile ratio from low to high levels resulted in a decrease in retention time as depicted in (Fig. 3g–l). ANOVA data for resolution and retention time responses displayed in Table 2 shows that the probability P-value < 0.05 means that the model and terms were significant. The R-squared and adjusted values were 0.96, 0.97, 0.91, and 0.94 with a standard deviation less than 0.4 and a lack fit of 0.8440 and 0.2038 for resolution and retention time responses, respectively, indicating that experimental responses were an exemplary appropriate. The numerical optimization function was employed to predict the responses and accomplish the best separation parameters by maximizing desirability to obtain good resolution > 1.5 and retention time less than 2.0 min, as shown in Fig. 4a–c. Overlay plots (Fig. 4d–f) displayed the best variables that led to the desired responses. Parameters were implemented in the laboratory to verify the predicted method. The optimum chromatographic system was acetonitrile: purified water (70:30, v/v) at pH 5.0 adjusted by 0.1% orthophosphoric acid at 30 °C as good resolution, asymmetric peak, and shorter retention time as depicted in Fig. 5.

Ratio subtraction method

The scanned spectra of the laboratory prepared mixture were divided by the chosen concentration of 10 μg/mL for CFZ (divisor). As a result of this, a new ratio spectrum was formed. The obtained average absorbance values (1.026) were subtracted in the plateau area (275–320 nm) as depicted in (Fig. 6a, b), The obtained spectra were therefore multiplied by a divisor. Ultimately, new zero order spectra were obtained for PYD at 254.6 nm as displayed in Fig. 6c. Linear calibration curves were generated by graphing absorbance values for the zero order spectra of PYD at 254.6 nm against the relevant concentrations and then computing the regression equations as displayed in Table 2. Furthermore, the new spectra of CFZ were gained by dividing the prepared mixture of both drugs by the selected concentration of 10 μg/mL of CFZ (divisor), then the average absorbances values (1.151) of the constant were subtracted in the plateau area (242–260 nm) as depicted in (Fig. 6d, e). Lastly, new CFZ spectra were produced at 260.3 nm by multiplying the previous CFZ spectra by the divisor, Fig. 6f. The calibration graph was constructed by graphing absorbance values of zero order against their concentrations and the regressing equation is calculated, Table 3.

Mean centering of ratio spectra method

The MCR method was employed to separate CFZ and PYD drugs in a combination of a binary mixture in one shot without pre-separation. Several divisor concentrations were examined to enhance the suggested method. The most appropriate concentration of the divisor is 5 µg/mL. The drug spectra were generated in the range 200–270 nm for CFZ and 200–300 nm for PYD, as depicted in Fig. 7a, c. The absorbance values of 5–30 µg/mL of CFZ, PYD, and the laboratory-prepared combination were imported into the MATLAB software. Equations from 1 to 4 were applied to determine MCR for each drug without interfering with the other. As shown in (Fig. 7b, d), CFZ and PYD were estimated at suitable wavelengths 220 and 255.4 nm, respectively. The calibration curves were established by graphing the obtained amplitudes against their respective concentrations, and regression equations were calculated as in Table 3.

Process capability sixpack

Trend assay results for the proposed and USP methods of CFZ and PYD of 100 batches for Kefadim IV/IM for the last quarter of 2022 were collected and analyzed using Minitab®18.1.0. As shown in Fig. 8, interprets process capability six-pack report generated from quality tools indicates that the process is consistent in both X bar and R charts, with no points outside the control limitations. The last 20 subgroups plot shows that the data are randomly dispensed and uniformly around the processing center. Histogram, average probability, and capability plots show that the process is roughly centered on the target and that the results are within the specified limitations. The Cpk value of CFZ and PYD in USP and proposed methods is greater than 1.33, indicating that both methods are significant and the proposed method more accurate than the USP method as the Cpk values in the proposed method are 2.18, 2.73 (Fig. 8a, c), while in USP methods are 1.77, 2.42 (Fig. 8b, d) for CFZ and PYD, respectively. As shown in Table 4, the values of variance, standard error, and deviation in the proposed method are less than in the USP method.

Accelerated stability study

Assay summary results in Table 5 of the accelerated stability study for intervals (0,1, 3, and 6 months) indicate that neither significant change nor degradation by more than 5% of active pharmaceutical ingredient (API) assay from the initial value and the results are capable through the study, Fig. 9a, b.

Method validation

The suggested MCR, UPLC, and RS methods were performed and validated as per ICH recommendation [66].

Linearity and range

Linearity test was established for UPLC, RS, and MCR methods over the concentration range (2–100), (1–50), (3–30), and (5–30) µg/mL for CFZ and PYD, respectively. Each concentration was injected in triplicates. The obtained data appeared good linearity results with a correlation coefficient > 0.9996, see Table 3.

Limit of detection and quantitation

Detection (LOD) and quantitation limit (LOQ) were executed on a validated Excel sheet using the formula (3.3σ/S) and (10σ/S) for the calculation LOD and LOQ, respectively, where σ refer to the standard deviation of the intercept and S to the slope of the calibration curve. The lower the LOQ and LOD values, the better sensitivity of the proposed methods, as displayed in Table 3.

Accuracy and recovery

The accuracy of the proposed UPLC, RS, and MCR methods was established for the studied drugs by preparing three different concentrations (10, 15, and 20 µg/mL) for each drug in triplicate. Good recovery results were obtained and complied with the acceptance criteria (98.0–102.0% with RSD less than 2.0) as shown in Table 6.

Assay of pharmaceutical formulation

The Assay test solution was evaluated by preparing three samples in duplicate and applying for UPLC, RS, and MCR methods. The obtained results showed good assay results for the examined drugs CFZ and PYD in Kefadim 500 mg &1.0 g IV/IM, as reported in Table 7.

Precision

System Precision. The repeatability test was performed by preparing a concentration of 20 µg/mL for each drug in six replicates. The system is precise as RSD for six replicates less than 0.5%, as displayed in Table 3.

Intermediate precision. Laboratory variations, various days, different analysts, and different equipment make ruggedness obvious. Good results were reported in Table 8.

Robustness

The robustness of the analytical proposed methods was executed to confirm that the analytical methods are still competent and unaltered by minor intended alterations in method parameters such as the influence variation in pH, column, temperature, wavelength, and flow rate as recorded in Table 8.

Standard solution stability

The standard solution was stocked in different storage conditions as refrigerator and room temperature for 72 h. Then, solutions were analyzed against the freshly prepared solution. The recovered stored standard against the freshly prepared one with good results within the limit of 100% ± 2.0% with RSD < 2.0, as displayed in Table 8.

System suitability

BBD was optimized for the chromatographic conditions to select the optimum parameters. The system suitability test was implemented to evaluate the UPLC method through the investigation parameters of the theoretical plates, resolution, tailing factor, and retention time. The acquired results confirm that the UPLC method is suitable, see Table 9.

Conclusion

An eco-friendly, novel, rapid, and highly robust RP-UPLC, RS, and MCR methods were established and validated as per ICH guidelines for concurrently estimation of a binary mixture of CFZ and PYD in their solutions. UPLC highly progresses detection and separation while reducing run time tenfold. BBD and RSM were used to adjust chromatographic conditions with acceptable resolution and the lowest retention time for both drugs using the minimum experimental runs allowed. In addition, Rs and MCR methods were implemented to solve the interference between the binary mixture of CFZ and PYD without prior derivative steps or sophisticated programs. The techniques are also appropriate and valid for use in quality control, lacking HPLC apparatus. Moreover, the application of six sigma was applied to increase product quality and consistency, reduce production costs, and ensure the process is close to the specified center limit. The accelerated stability study was conducted to confirm that active material is not affected by extreme conditions of high temperature and humidity. The proposed methods are valid and can be implemented in the research lab.

Availability of data and materials

This article has all the data generated or evaluated during this work.

Abbreviations

- RP-UPLC:

-

Reversed phase ultra-performance liquid chromatography

- RP-HPLC:

-

Reversed phase high-performance liquid chromatography

- UV:

-

Ultraviolet

- CFZ:

-

Ceftazidime

- PYD:

-

Pyridine

- DOE:

-

Design of experiments

- BBD:

-

Box-Behnken design

- RSM:

-

Response surface methodology

- MCR:

-

Mean centering of ratio spectra

- RS:

-

Ratio subtraction

- Cpk:

-

Process capability index

- USP:

-

United States Pharmacopeia

- BP:

-

British Pharmacopeia

- ICH:

-

International Council for Harmonisation

- IV:

-

Intravenously

- IM:

-

Intramuscularly

- LOD:

-

Limit of detection

- LOQ:

-

Limit of quantitation

- RSD:

-

Relative standard deviation

References

British Pharmacopoeia. Stationary Office, Medicines and Healthcare Products Regulatory Agency, London.2022.

Mohamed MA. Stability-Indicating New RP-UPLC method for simultaneous determination of a quaternary mixture of paracetamol, pseudoephedrine, chlorpheniramine, and sodium benzoate in (Cold–Flu) Syrup Dosage Form. J AOAC Int. 2022. https://doi.org/10.1093/jaoacint/qsac002.

Elkady EF, Fouad MA, Mozayad AN. Application of Box-Behnken experimental design and response surface methodology for selecting the optimum RP-HPLC conditions for the simultaneous determination of methocarbamol, indomethacin and betamethasone in their pharmaceutical dosage form. BMC Chem. 2022. https://doi.org/10.1186/s13065-022-00908-9.

Fares MY, Hegazy MA, El-Sayed GM, Abdelrahman MM, Abdelwahab NS. Quality by design approach for green HPLC method development for simultaneous analysis of two thalassemia drugs in biological fluid with pharmacokinetic study. RSC Adv. 2022. https://doi.org/10.1039/D2RA00966H.

Muchakayala SK, Katari NK, Dongala T, Marisetti VM, Vyas G, Vegesna RV. Eco-friendly and green chromatographic method for the simultaneous determination of chlorocresol and betamethasone dipropionate in topical formulations using Box-Behnken design. J Iran Chem Soc. 2022. https://doi.org/10.1007/s13738-021-02388-5.

Vemuri DK, Akshinthala P, Konduru N, Kowtharapu LP, Katari NK, Jonnalagadda SB, Gundla R. Unique quality by design approach for developing HPLC and LC-MS method for estimation of process and degradation impurities in pibrentasvir, antiviral agent for hepatitis C. ACS Omega. 2022. https://doi.org/10.1021/acsomega.2c04617.

Patel KY, Dedania ZR, Dedania RR, Patel U. QbD approach to HPLC method development and validation of ceftriaxone sodium. Future J Pharm Sci. 2021. https://doi.org/10.1186/s43094-021-00286-4.

Attimarad M, Venugopala KN, SreeHarsha N, Aldhubiab BE, Nair AB. Validation of rapid RP-HPLC method for concurrent quantification of amlodipine and celecoxib in pure and formulation using an experimental design. Microchem J. 2020. https://doi.org/10.1016/j.microc.2019.104365.

Chaudhari SR, Shirkhedkar AA. Design of experiment avenue for development and validation of RP-HPLC-PDA method for determination of apremilast in bulk and in in-house tablet formulation. J Anal Sci Technol. 2019. https://doi.org/10.1186/s40543-019-0170-8.

Dinç Zor Ş, Aşçı B, Aksu Dönmez Ö, Yıldırım KD. Simultaneous determination of potassium sorbate, sodium benzoate, quinoline yellow and sunset yellow in lemonades and lemon sauces by HPLC using experimental design. J Chromatogr Sci. 2016. https://doi.org/10.1093/chromsci/bmw027.

Abd Allah FI, Abdelhmaid A, Himida M, Mostafa Elkashlan A, El-Attar AAM. Fully validated UPLC–MS/MS method for quantifying Favipiravir in human plasma boosted lean six sigma: an application for a bioequivalence study. Biomed Chromatogr. 2022. https://doi.org/10.1002/bmc.5381.

Elgazzar E, Attala K, Abdel-Atty S, Abdel-Raoof AM. A screen printed methodology optimized by molecular dynamics simulation and Lean Six Sigma for the determination of xylometazoline in the presence of benzalkonium chloride in nasal drops. Talanta. 2022. https://doi.org/10.1016/j.talanta.2022.123321.

Mohamed MA. Simultaneous Quantification of Cephalexin and Sodium Benzoate in their Dosage forms by high analytical technique. Application of Lean Six Sigma and In-Vitro Dissolution studies. Ann Pharm Fr. 2021. https://doi.org/10.1016/j.pharma.2020.09.006.

ICH Q1A (R2). Stability testing guidelines: Stability testing of new drug substances and products. ICH Steering Committee. 2003;4:1–24.

Prajapati P, Shahi A, Acharya A, Shah S. Chemometric and design of experiments-based analytical quality by design and green chemistry approaches to multipurpose high-pressure liquid chromatographic method for synchronous estimation of multiple fixed-dose combinations of azilsartan medoxomil. J AOAC Int. 2023. https://doi.org/10.1093/jaoacint/qsac086.

Prajapati P, Patel A, Shah S. DoE-based analytical quality risk management for enhanced AQbD approach to economical and eco-friendly RP-HPLC method for synchronous estimation of multiple FDC products of antihypertensive drugs. J Chromatogr Sci. 2022. https://doi.org/10.1093/chromsci/bmab123.

Prajapati PB, Radadiya K, Shah SA. Quality risk management based: analytical quality by design approach to eco-friendly and versatile chromatography method for simultaneous estimation of multiple fixed-dose-combination products of anti-diabetic drugs. J Pharm Innov. 2020. https://doi.org/10.1007/s12247-020-09506-5.

Prajapati P, Shah H, Shah SA. Implementation of QRM and DoE-based quality by design approach to VEER chromatography method for simultaneous estimation of multiple combined dosage forms of paracetamol. J Pharm Innov. 2020. https://doi.org/10.1007/s12247-020-09490-w.

Prajapati PB, Bodiwala KB, Shah SA. Analytical quality-by-design approach for the stability study of thiocolchicoside by eco-friendly chromatographic method. JPC-J Planar Chromat. 2018. https://doi.org/10.1556/1006.2018.31.6.8.

Safwat N, Ayad M, Farouk M. Development of an eco-friendly reversed-phase HPLC method for the simultaneous determination of three emerging contaminants in water samples. APS-ASU. 2020. https://doi.org/10.21608/APS.2020.2001.1025.

Alam P, Shakeel F, Taleuzzaman M, Foudah AI, Alqarni MH, Aljarba TM, Alshehri S, Ghoneim MM. Box-Behnken Design (BBD) application for optimization of chromatographic conditions in RP-HPLC method development for the estimation of thymoquinone in nigella sativa seed powder. Processes. 2022. https://doi.org/10.3390/pr10061082.

The United States pharmacopeia 43. National formulary 38. Rockville (MD): United States Pharmacopeial Convention; 2023; https://doi.org/10.31003/USPNF_M14124_03_01.

Günther S, Reimer A, Vogl H, Spenke S, Dinges HC, Schubert AK, Eberhart LH, Geldner G. Determination of meropenem, ceftazidime and piperacillin levels in serum and meropenem in cerebrospinal fluid by liquid chromatography for routine quantification. J Pharm Pharmacol. 2022. https://doi.org/10.26502/fjppr.062.

Kaur R, Saini S, Patel A, Sharma T, Kaur R, Katare OP, Singh B. Developing a validated HPLC method for quantification of ceftazidime employing analytical quality by design and monte carlo simulations. J AOAC Int. 2021. https://doi.org/10.1093/jaoacint/qsab014.

Bergman J, Harvill L, Hawkins S, Sladky K, Cox S. Determination of ceftazidime in plasma by RP-HPLC and ultraviolet detection. Biomed Chromatogr. 2021. https://doi.org/10.1002/bmc.5104.

Abd El Aziz Shama SA, Abd El Azim S, Elham A, Shaimaa HN. A Simultaneous, Validated RP-HPLC method for determination of eight cephalosporins in pharmaceutical formulations. Sys Rev Pharm. 2021;12:646–53.

Sanli S, Sanli N, Gumustas M, Ozkan SA, Karadas N, Aboul-Enein HY. Simultaneous estimation of ceftazidime and ceftizoxime in pharmaceutical formulations by HPLC method. Chromatographia. 2011. https://doi.org/10.1007/s10337-011-2116-1.

Nawaz M, Arayne MS, Sultana N. Simultaneous determination of cefpirome, cefaclor, ceftazidime, and cephradine in pharmaceutical formulations by reversed phase HPLC. Acta Chromatogr. 2011. https://doi.org/10.1556/achrom.23.2011.2.2.

Pinder N, Brenner T, Swoboda S, Weigand MA, Hoppe-Tichy T. Therapeutic drug monitoring of beta-lactam antibiotics–Influence of sample stability on the analysis of piperacillin, meropenem, ceftazidime and flucloxacillin by HPLC-UV. J Pharm Biomed Anal. 2017. https://doi.org/10.1016/j.jpba.2017.05.037.

Hassouna MEM, Mohamed MA. Efficient HPLC method for determination of cephalosporin residues on spiked stainless-steel plates and human plasma: application of a worst-case product for Cosa® CIP. Int J Environ Anal Chem. 2020. https://doi.org/10.1080/03067319.2019.1631301.

Barnabas KS, Suvaitha SP, Dhinagaran G, Venkatachalam K. A novel method development and validation of ceftazidime in bulk drug and pharmaceutical dosage forms using RRLC method Iran. J Sci Technol Transact A Sci. 2022. https://doi.org/10.1007/s40995-022-01333-2.

Raju SV, Rao SV, Manikandan A. Estimation of ceftazidime and avibactam in their bulk and formulations by a newly developed and validated of stability indicating RP-UPLC method. Res J Pharm Technol. 2021. https://doi.org/10.52711/0974-360X.2021.00432.

Hassouna MEM, Mohamed MA. Modeling and optimization of a novel RP-UPLC and MCR spectrophotometric methods for simultaneous determination of five cephalosporins in spiked human plasma: application to lean six sigma thinking hats and antimicrobial activity. Microchem J. 2019. https://doi.org/10.1016/j.microc.2019.104161.

Mortensen JS, Jensen BP, Doogue M. Preanalytical stability of flucloxacillin, piperacillin, tazobactam, meropenem, cefalexin, cefazolin, and ceftazidime in therapeutic drug monitoring: a structured review. Ther Drug Monit. 2022. https://doi.org/10.1097/FTD.0000000000000975.

Fage D, Deprez G, Fontaine B, Wolff F, Cotton F. Simultaneous determination of 8 beta-lactams and linezolid by an ultra-performance liquid chromatography method with UV detection and cross-validation with a commercial immunoassay for the quantification of linezolid. Talanta. 2021. https://doi.org/10.1016/j.talanta.2020.121641.

Piestansky J, Cizmarova I, Mikus P, Parrak V, Babiak P, Secnik P, Kovac A. An ultra-high-performance liquid chromatography-tandem mass spectrometry method for simultaneous determination of 4 β-lactam antibiotics, tazobactam, and linezolid in human plasma samples. Ther Drug Monit. 2022. https://doi.org/10.1097/FTD.0000000000001017.

Lefeuvre S, Bois-Maublanc J, Hocqueloux L, Bret L, Francia T, Billaud EM, Barbier F, Got L. A simple ultra-high-performance liquid chromatography-high resolution mass spectrometry assay for the simultaneous quantification of 15 antibiotics in plasma. J Chromatogr B. 2017. https://doi.org/10.1016/j.jchromb.2017.09.014.

Casals G, Hernández C, Hidalgo S, Morales B, López-Púa Y, Castro P, Fortuna V, Martínez JA, Brunet M. Development and validation of a UHPLC diode array detector method for meropenem quantification in human plasma. Clin Biochem. 2014. https://doi.org/10.1016/j.clinbiochem.2014.08.002.

Saha S, Mistri R, Ray BC. Determination of pyridine, 2-picoline, 4-picoline and quinoline from mainstream cigarette smoke by solid-phase extraction liquid chromatography/electrospray ionization tandem mass spectrometry. J Chromatogr A. 2010. https://doi.org/10.1016/j.chroma.2009.11.050.

Evans J, Wang TC, Heyes MP, Markey SP. LC/MS analysis of NAD biosynthesis using stable isotope pyridine precursors. Anal Biochem. 2002. https://doi.org/10.1006/abio.2002.5715.

Cheng Y, Chen M, Zhang B, Lin H, Li X, Cai Y, Zhang H, Que W, Liu M, Qiu H. Rapid, simple, and economical LC–MS/MS method for simultaneous determination of ceftazidime and avibactam in human plasma and its application in therapeutic drug monitoring. J Clin Pharm Ther. 2022. https://doi.org/10.1111/jcpt.13693.

Martens-Lobenhoffer J, Angermair S, Bode-Böger SM. Quantification of ceftazidime/avibactam in human plasma and dried blood spots: Implications on stability and sample transport. J Chromatogr B. 2022. https://doi.org/10.1016/j.jchromb.2022.123164.

Wang Q, Zheng Y, Liu L, Ji P, Jiang W, Zhao J, Ren J, Yang L. Simultaneous determination of ceftazidime and avibactam in human plasma and cerebrospinal fluid by high-performance liquid chromatography-tandem mass spectrometry (HPLC-MS/MS). Anal Lett. 2022. https://doi.org/10.1080/00032719.2022.2105859.

Bellouard R, Deslandes G, Morival C, Li J, Boutoille D, Jolliet P, Dailly É, Grégoire M. Simultaneous determination of eight β-lactam antibiotics in human plasma and cerebrospinal fluid by liquid chromatography coupled to tandem mass spectrometry. J Pharm Biomed Anal. 2020. https://doi.org/10.1016/j.jpba.2019.112904.

Abdulla A, Bahmany S, Wijma RA, van der Nagel BC, Koch BC. Simultaneous determination of nine β-lactam antibiotics in human plasma by an ultrafast hydrophilic-interaction chromatography–tandem mass spectrometry. J Chromatogr B. 2017. https://doi.org/10.1016/j.jchromb.2017.06.014.

Reddy TS, Acharyulu ML. Two oxidative visible spectrophotometric methods for the determination of ceftazidime in pharmaceutical formulations using n-bromo succinimide. Int J Appl Eng Res. 2021;16:283–7.

de Haro MA, Salgado HR. Rapid and selective UV spectrophotometric method for the analysis of ceftazidime. J AOAC Int. 2009. https://doi.org/10.1093/jaoac/92.3.820.

Moreno AD, Salgado HR. Spectrophotometric determination of ceftazidime in pharmaceutical preparations using neocuproin as a complexing agent. Anal Lett. 2008. https://doi.org/10.1080/00032710802240818.

Hiremath B, Mruthyunjayaswamy BH. Development and validation of spectrophotometric methods for determination of ceftazidime in pharmaceutical dosage forms. Acta Pharm. 2008. https://doi.org/10.2478/v10007-008-0017-0.

Mahramyari S, Pourbasheer E, Banaei A, Ganjali MR, Norouzi P. Simultaneous spectrophotometric determination of ceftazidime and sulbactam using multivariate calibration methods. RSC Adv. 2014. https://doi.org/10.1039/C4RA05562D.

Chauhan C, Namdev S. Spectrophotometric method development for thiophante methyl based systemic fungicide Roko formulation. Mater Tdy Proc. 2022. https://doi.org/10.1016/j.matpr.2022.08.481.

Barnes AR. Determination of Ceftazidime and pyridine by HPLC: Application to a viscous eye drop formulation. J Liq Chromatogr Relat Technol. 1995. https://doi.org/10.1080/10826079508010437.

Porra R, Farina A, Cotichini V, Lecce R. Analysis of ceftazidime and related compounds by micellar electrokinetic chromatography. J Pharm Biomed Anal. 1998. https://doi.org/10.1016/S0731-7085(98)00178-2.

Barnes AR, Nash S. Stability of ceftazidime in a viscous eye drop formulation. J Clin Pharm Ther. 1999. https://doi.org/10.1046/j.1365-2710.1999.00230.x.

Kodym A, Hapka-Zmich D, Gołab M, Gwizdala M. Stability of ceftazidime in 1% and 5% buffered eye drops determined with HPLC method. Acta Pol Pharm. 2011;68:99–107.

Favetta P, Janoly A, Allombert C, Breysse C, Guitton J, Bureau J. Simultaneous quantification of ceftazidime and pyridine, its main degradation product, by high-performance liquid chromatography. Anal Lett. 2008. https://doi.org/10.1080/00032710008543202.

Hassouna MEM, Mohamed MA. Stability Indicating Rp-HPLC method for simultaneous estimation of ceftazidime pentahydrate and its impurity product pyridine in powder used for making solution in vial for IM & Iv injections. Ann Rev Resear. 2018;1: 555561.

Nguyen TT, Harmanjeet H, Wanandy T, Castelino RL, Sud K, Jose MD, Peterson GM, Zaidi ST, Patel RP. Pyridine levels in ceftazidime–peritoneal dialysis admixtures stored at body temperature. Peritoneal Dial Int. 2020. https://doi.org/10.1177/0896860819887636.

Nguyen T, Menten L, Spriet I, Quintens C, Van Schepdael A, Adams E. Liquid chromatographic method to follow-up ceftazidime and pyridine in portable elastomeric infusion pumps over 24 h. Electrophoresis. 2022. https://doi.org/10.1002/elps.202100275.

Ibrahim AM, Hendawy HAM, Hassan WS, Shalaby A, El-sayed HM. Six Sigma quality approach for HPLC-UV method optimization. Microchem J. 2019. https://doi.org/10.1016/j.microc.2018.09.023.

Mahapatra AP, Song J, Shao Z, Dong T, Gong Z, Paul B, Padhy I. Concept of process capability indices as a tool for process performance measures and its pharmaceutical application. J Drug Deliv Ther. 2020. https://doi.org/10.22270/jddt.v10i5.4288.

Hassouna MEM, Mohamed MA. Novel and facile spectrophotometric techniques for the determination of sofosbuvir and ledipasvir in their tablet dosage form. J Anal Pharm Res. 2018. https://doi.org/10.15406/japlr.2018.07.00207.

Darwish HW, Hassan SA, Salem MY, El-Zeiny BA. Three different spectrophotometric methods manipulating ratio spectra for determination of binary mixture of Amlodipine and Atorvastatin. Spectrochim. 2011. https://doi.org/10.1016/j.saa.2011.08.005.

Afkhami A, Bahram M. Mean centering of ratio spectra as a new spectrophotometric method for the analysis of binary and ternary mixtures. Talanta. 2005. https://doi.org/10.1016/j.talanta.2004.12.004.

Bajaj S, Singla D, Sakhuja N. Stability testing of pharmaceutical products. J Appl Pharm Sci. 2012. https://doi.org/10.7324/JAPS.2012.2322.

Guidelines ICH. Validation of analytical procedures: text and methodology, Q2 (R1), 2005.

Acknowledgements

The authors extend their sincere appreciation to Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2023R85), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia.

Funding

Open access funding is provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). This research was funded by Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2023R85), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

NS: Application of Quality by Design and lean six sigma methodology; writing the first draft of the manuscript; revision and editing. MM: owner of the research idea, performed the analysis in the lab, data processing and analysis, validated the methods, writing and editing. HA; Handling of the mean centering method using MATLAB software; Organization and presentation of data; Support and supervision. HN (corresponding author): supervision, investigation, reviewing and editing, software.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Al-Kadhi, N.S., Mohamed, M.A., Ahmed, H.A. et al. Facile synthesis and eco-friendly analytical methods for concurrent estimation of selected pharmaceutical drugs in their solutions: application to quality by design, lean six sigma, and stability studies. BMC Chemistry 17, 136 (2023). https://doi.org/10.1186/s13065-023-01028-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13065-023-01028-8