Abstract

Background

Rational engineering studies for deoxycytidine production were initiated due to low intracellular levels and tight regulation. To achieve high-level production of deoxycytidine, a useful precursor of decitabine, genes related to feed-back inhibition as well as the biosynthetic pathway were engineered. Additionally, we predicted the impact of individual gene expression levels on a complex metabolic network by microarray analysis. Based on these findings, we demonstrated rational metabolic engineering strategies capable of producing deoxycytidine.

Results

To prepare the deoxycytidine producing strain, we first deleted 3 degradation enzymes in the salvage pathway (deoA, udp, and deoD) and 4 enzymes involved in the branching pathway (dcd, cdd, codA and thyA) to completely eliminate degradation of deoxycytidine. Second, purR, pepA and argR were knocked out to prevent feedback inhibition of CarAB. Third, to enhance influx to deoxycytidine, we investigated combinatorial expression of pyrG, T4 nrdCAB and yfbR. The best strain carried pETGY (pyrG-yfbR) from the possible combinatorial plasmids. The resulting strain showed high deoxycytidine yield (650 mg/L) but co-produced byproducts. To further improve deoxycytidine yield and reduce byproduct formation, pgi was disrupted to generate a sufficient supply of NADPH and ribose. Overall, in shake-flask cultures, the resulting strain produced 967 mg/L of dCyd with decreased byproducts.

Conclusions

We demonstrated that deoxycytidine could be readily achieved by recombineering with biosynthetic genes and regulatory genes, which appeared to enhance the supply of precursors for synthesis of carbamoyl phosphate, based on transcriptome analysis. In addition, we showed that carbon flux rerouting, by disrupting pgi, efficiently improved deoxycytidine yield and decreased byproduct content.

Similar content being viewed by others

Background

Deoxycytidine (dCyd) is a commercially useful precursor in the chemical synthesis of various drugs including decitabine (Dacogen™, 5-aza-2′-deoxycytidine), which is used to treat myelodysplastic syndromes, a class of conditions where certain blood cells are dysfunctional, and for acute myeloid leukemia [1, 2]. A similar analogue, azacitidine (5-aza-2′cytidine) derived from cytidine (Cyd) is also used for this purpose [3]. However, because azacitidine is a potential substrate for the DNA replication machinery after metabolism to its deoxy derivative, there are subtle differences in efficacy between azacitidine and decitabine. A recent report described the production of Cyd by rationally engineered Escherichia coli, in which pentose phosphate pathway (PPP) genes were amplified to supply precursor [4]. And Zhu et al. also reported the production of Cyd by deregulation of the pyr operon and the overexpression of the prs, pyrG and pyrH genes in Bacillus subtilis [5]. In contrast, so far, the studies for dCyd production have not been achieved by rational engineering, due to low intracellular levels and tight gene regulation. To date, dCyd production has only been achieved by traditional engineering employing bacteria belonging to the genera Corynebacterium [6]. However, while dCyd production by rational engineering is not well studied, another pyrimidine deoxynucleoside, thymidine, has been studied actively [7–11]. In previous work, we showed that deletion of three repressors (purR, pepA and argR) involved in the regulation of carbamoyl phosphate synthetase (carA/carB), positively affected thymidine production [7]. To enhance the reduction of nucleotides, we overexpressed T4 NDP reductase subunits. In an effort to develop a new deoxy pyrimidine nucleoside-producing strain that might spawn similar engineering towards development of a thymidine producer, we focused on dCyd production by E. coli.

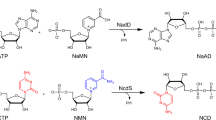

As illustrated in Figure 1, de novo biosynthesis of dUMP occurs through two distinct pathways in pyrimidine biosynthesis [12, 13]. The quantitatively more important pathway involves the deamination of dCTP to dUTP by dCTP deaminase, followed by the hydrolysis of dUTP by dUTP nucleotidohydrolase (dUTPase) to yield dUMP with 75% of endogenous dUMP arising through this route. The second pathway generating the remaining 25% of dUMP consists of the reduction of UDP by ribonucleoside diphosphate reductase to dUDP, which is phosphorylated by nucleoside diphosphokinase (encoded by ndk) to dUTP and subsequently hydrolyzed to dUMP by dUTPase [14]. Alternatively, dUMP may be produced by pyrimidine salvage through reaction of deoxyuridine with thymidine kinase. The deoxyuridine, in turn, may arise either from dCyd through deamination catalyzed by Cyd (dCyd) deaminase (encoded by cdd) or by the condensation of uracil and deoxyribose 1-phosphoate mediated by thymidine phosphorylase (encoded by deoA), although this latter reaction is believed to act predominantly in the catabolic direction [13, 15]. As explained here, most of the dCTP biosynthetic pathway has shared pathways with dTTP biosynthesis, but dCTP is synthesized via a more complex route than dTTP.

The deoxycytidine biosynthetic pathway. The steps engineered in this study are indicated by the bold arrows and lines. Components of the catabolic pathways are as follows: carAB carbamoyl phosphate synthase, pyrBI aspartate-carbamoyl transferase, pyrC dihydroorotase, pyrD dihydroorotate oxidase, pyrE orotate phosphoribosyl transferase, pyrF OMP decarboxylase, pyrG CTP synthetase, pyrH UMP kinase, yfbR dCMP phosphohydrolase, nrdCAB nucleotide diphosphate reductase, thyA thymidylate synthase, dcd dCTP deaminase, udk uridine kinase, deoA thymidine phosphorylase, tdk thymidine kinase, udp uridine phosphorylase, dut deoxyribonucleotide triphosphatase, ndk nucleotide diphosphate kinase, tmk TMP kinase, cdd cytidine deaminase, codA cytosine deaminase, deoD purine nucleoside phosphorylase, rihA, rihB ribosyl pyrimidine nucleosidase, cmk cytidylate kinase, purR purine repressor, pepA aminopeptidase A, argR arginine repressor.

In this study, CTP synthetase (encoded by pyrG) and T4 NDP reductase (encoded by nrdCAB) were overexpressed to increase dCMP pools. While a highly specific dCMP phosphohydrolase was needed to generate dCyd from increased dCMP, all 5′-nucleotidases studied so far are enzymes with broad specificity on NMP and dNMP (e.g. those encoded by ushA, surE, yjjG and yfbR) [16]. Especially, UshA and SurE are active on only NMP, with no apparent activity on dNMP. YjjG, known as the house-cleaning enzyme, catalyzes CMP, dUMP and dTMP as substrates but not dCMP [17]. In contrast, YfbR uses dCMP as a substrate but prefers other dNMPs, exhibiting higher activity on dGMP, dUMP and dAMP than dCMP [18]. In particular, the activity on dUMP of E. coli yfbR is higher than dCMP by 1.5-fold (dGMP > dUMP > dAMP > dCMP > GMP > dTMP > NMPs) [19]. Other than purine nucleotides, the higher activity of YfbR on dUMP may be problematic, because dUMP can be increased proportionally with dCMP. Among 5′-nucleotidases studied so far, however, YfbR is the best available candidate, as, to date, no highly specific dCMP phosphohydrolase has been identified or engineered.

Based on the information known about nucleotide biosynthesis and our experience developing thymidine producing strains, we prepared a novel dCyd-producing strain by rational metabolic reprogramming. Our approach, first, involved the deletion of known nucleoside degrading enzymes and branching enzymes, followed by the deletion of the thymidylate synthase gene (thyA). Next, to enhance influx to pyrimidine, the genes encoding the CarAB repressors were deleted and the bottleneck enzymes (NDP reductase, CTP synthetase and dCMP phosphohydrolase) were overexpressed. In this approach, unwanted problems may arise from increasing unexpected byproducts and losing control of the biosynthesis of purine, pyrimidine and arginine, which may affect cell growth and maintenance. Because purine and pyrimidine nucleotides constitute components of nucleic acids, cofactors in enzymatic reactions, intracellular and extracellular signals, phosphate donors, and the major carriers of cellular energy, imbalances between these different nucleotide pools can significantly perturb normal cellular function [20–22]. Here, we analyzed metabolic change by partial transcriptome microarray and investigated byproduct profiles of the strain derivatives generated at each engineering stage. Based on these findings, we demonstrated the use of rational metabolic engineering of E. coli to produce dCyd with less byproducts formation.

Results

The deletion of salvage and branching pathway genes in cells with high dCyd resistance

E. coli DeoA, Udp and DeoD have essential roles in pyrimidine nucleotide salvage pathways and are known to catalyze reversible reactions [9, 12]. Hence, these nucleoside phosphatases might have potential roles in the degradation of intracellular dCyd. Using a high concentration of dCyd resistant strain (up to 10 g/L, Additional file 1: Figure S1), deoA, udp and deoD were deleted sequentially by PCR-mediated disruption to construct HLC003 (Additional file 1: Figure S2A). If overall phosphatase activity of any unidentified pathway members is less than the contribution of these three enzymes (DeoA, Udp and DeoD) to the salvage pathway, the deletion of deoA, udp and deoD should be enough to prevent degradation of dCyd in at least low dCyd-producing cells. To test this notion, an in vitro dCyd degradation assay was carried out for evaluation. The assay profile, however, showed that, during the time tested, dCyd degradation in vitro was apparently not completely blocked by disrupting deoA, udp and deoD (Figure 2), perhaps because dCyd degradation is closely linked to the conversion steps of dCTP, dCyd and cytosine into dUMP, deoxyuridine and uracil, respectively [12]. Hence, this suggested the branching nodes into other nucleotide pathways would be good targets for further strain engineering to increase dCyd influx by blocking additional dCyd degradation. Based on the nucleotide synthetic pathway, dcd, cdd and codA, which encode enzymes that catalyze deamination of dCTP, dCyd and cytosine, respectively, were disrupted step-by-step, resulting in HLC006. Additionally, thyA, which plays a key role in dTTP synthesis, was disrupted in the parental HLC006 strain (Additional file 1: Figure S2B). However, because the resulting strain, HLC007, had no way to synthesize dTTP due to deletions of thyA, deoA, deoD and udp, it could not synthesize dTTP by de novo nucleotide synthetic pathway. Afterward, 20 mg/L of thymidine was added to all media for complementation of growth. Interestingly, in dCyd degradation assay, dCyd degradation was still observed in HLC004 strain but not in HLC005 strain (Figure 2; Table 1). This result means that the possible paths, whereby dCyd can be degraded by detouring dCyd to deoxyuridine, were blocked completely by disrupting cdd as well as dcd.

Deoxycytidine degradation assay. To eliminate possible degradation of dCyd which was produced during fermentation, known pyrimidine nucleoside degradation enzymes were disrupted. The disruption of deoA, udp and deoD, which are active on deoxyuridine and thymidine, was not sufficient to block dCyd degradation completely. However, after the disruption of both dcd and cdd, dCyd degradation was not observed in the in vitro assay. Negative control with dCyd (open circle), BL21(DE3) (filled circle), HLC001 (ΔdeoA) (open square), HLC003 (ΔdeoA ΔdeoD Δudp) (filled square), HLC004 (ΔdeoA ΔdeoD Δudp Δdcd) (open triangle) and HLC005 (ΔdeoA ΔdeoD Δudp Δdcd Δcdd) (filled triangle).

The elimination of CarAB repressors increases the influx of precursors into nucleotide synthesis

E. coli CarAB is controlled tightly by at least five transcription factors. Among known transcription factors, PurR, PepA and ArgR are capable of controlling CarAB activity by the coordination of intracellular levels of arginine and nucleotides [21]. We previously demonstrated that the disruption of three repressors governing carAB transcription could be leveraged to enhance thymidine production in E. coli [7]. Here, we speculated that the disruption of three repressors governing carAB transcription could be similarly applied to dCyd production. Using HLC007, the repressor genes, purR, pepA and argR were deleted sequentially by the same deletion method, resulting in HLC010 (Additional file 1: Figure S2C). We hypothesized that CarAB activity in HLC010 might scarcely be affected by intracellular nucleotide or nucleoside levels, and subsequently, influx of nucleotide precursors could be increased by less regulation. To test this hypothesis, we analyzed transcriptional levels of genes related to the supply of precursors by microarray assay. Not surprisingly, the transcription levels of tested genes, which synthesize carbamoyl phosphate and aspartate, were increased significantly (P < 0.05) (Additional file 1: Table S1), when PurR, PepA and ArgR were absent (Figure 3, black colored box), indicating that the increase in the supply of major precursors was caused by enhanced transcriptional levels of the tested genes. These results could not completely explain these phenomena, however, because we only tested a limited number of genes without measuring intracellular nucleoside and nucleotide levels. Regardless, this result showed that the transcription of carAB as well as many genes involved in supplying precursors was increased significantly under the same conditions, and subsequently dCyd yield was also increased by 1.2 fold (Figure 4). Taken together, these results supported our hypothesis.

Transcriptional change of pyrimidine and arginine biosynthetic genes by disruption of CarAB repressors (PurR, PepA and ArgR). The numbers are the ratios of the expression levels in HLC010 vs. HLC007. The shaded numbers indicate significantly up-regulated genes in HLC010 (P < 0.05). a The transcriptional change of genes for precursor supply and pyr operon. α-ketoglutarate and oxaloacetate introduced from the TCA cycle might be converted quickly into carbamoyl phosphate and aspartate. The resulting increased precursors can enhance the production of dCyd. b The transcriptional change of the arg operon. Most of the Arg biosynthetic genes were up-regulated except for argG. The decrease of argG transcription may be the rate-limiting step for synthesizing arginine. AKG α-ketoglutarate, OAA oxaloacetate, GLU l-glutamate, GLN l-glutamine, CarP carbamoyl phosphate, ASP l-aspartate, C-ASP carbamoyl aspartate, ORO orotate, OMP orotate mono phosphate, NAG N-acetyl glutamate, NAGP N-acetyl glutamate phosphate, NAGsA N-acetyl glutamate semi aldehyde, NAO N-acetyl ornithine, ORN ornithine, CITR citrulline, Arg-Suc argino succinate, ARG l-arginine.

dCyd production by all engineered BL21 derivative strains. Seed cultures were grown in 5 mL of Luria–Bertani media overnight, and then transferred to 500-mL baffled flasks containing 50 mL of production media (see “Methods”). The strains carrying expression plasmids were induced for protein expression with isopropyl β-d-1-thiogalactopyranoside (IPTG; 0.5 mM) when cells reached OD600 ≈ 0.6. All flask cultures were incubated at 37°C and 250 rpm for 36 h. The dCyd concentration in the media was determined from the supernatants of cultivation samples. Values are mean ± SD of triplicate flasks experiments performed at the same time.

The overexpression of nucleotide biosynthetic genes favors dCyd production

The HLC010 strain was potentially a good host for producing dCyd because most of its intrinsic genes related to degradation of dCyd and regulation of CarAB were deleted. Accordingly, if proper nucleotide biosynthetic genes were overexpressed in this host cell, it might be a good dCyd producing strain. Considering the overall nucleotide biosynthetic pathway (Figure 1), we selected three essential steps and their corresponding genes, NDP reduction (nrdCAB), UTP amination (pyrG), and dCMP hydrolysis (yfbR). The overexpression of NDP reductase (NrdCAB) is known as the best way to increase intracellular dNTP level [9]. Also, as the transcription of the pyrG gene is regulated by a CTP pool, the overexpression of CTP synthetase (PyrG) can overcome the limitation of the excessive synthesis of CTP. The overexpression of cytidine phosphohydrolase (YfbR) can result in accelerating dCyd synthesis by the demand of dCMP for DNA synthesis. In case of NDP reductase, we used T4 NDP reductase which was previously used successfully for thymidine production [9], instead of E. coli intrinsic enzyme, to eliminate possible feedback inhibition by the nucleotide pool.

To test their combinatorial effect on dCyd production, T4 nrdCAB + pyrG, T4 nrdCAB + yfbR, yfbR + pyrG, and yfbR + pyrG + T4 nrdCAB were each assembled into synthetic operons under the control of a Tac promoter in plasmid, pETDuet. The resulting plasmids, pETNG, pETNY pETGY, and pETNGY permitted combinatorial co-expression of T4 nrdCAB, yfbR and pyrG (Additional file 1: Figure S3). Following expression of each of the synthetic combinatorial operons in HLC010 cells (Additional file 1: Figure S4), we investigated dCyd production in flask cultures. In HLC010-pETNG, which overexpressed T4 nrdCAB and pyrG, 401 mg/L of dCyd were produced in flask culture (Figure 4, Additional file 1: Figure S5). This dCyd yield was approximately 4-fold greater, compared to host cells, HLC010. In addition, HLC010-pETNY, which overexpressed T4 nrdCAB and yfbR, produced 410 mg/L of dCyd. These results indicated that the overexpression of two genes with distinct roles (nrdCAB and yfbR), was more effective than overexpression of similar genes related to the supply of cytidine nucleotide (nrdCAB and pyrG). Before testing HLC010-pETGY, we investigated dCyd production by HLC010-pETNGY, which appeared to be the best strain. In case of HLC010-pETNGY, which overexpressed T4 nrdCAB, yfbR and pyrG, dCyd yield was highly increased to 552 mg/L, as expected. However, as dCyd production was increased, several byproducts were also increased (Additional file 1: Figure S5F). In contrast, in case of HLC010-pETGY, which overexpressed only yfbR and pyrG, the quantity of byproducts was decreased in the HPLC profile, compared to HLC010-pETNGY. In return, dCyd production yield of HLC010-pETGY was increased to 650 mg/L, with less byproduct formation (Figure 4, Additional file 1: Figure S5G). In HLC010-pETGY, most of the distinct peaks were decreased in the HPLC profile, compared to HLC010-pETNGY.

The yield of dCyd can be improved by disrupting pgi in HLC010-pETGY

Eliminating pgi, a gene necessary for the EMP pathway, completely blocks isomerization of glucose 6-phosphate to fructose 6-phosphate, detouring the metabolism of glucose to the pentose phosphate (PP) pathway. Since the main role of the PP pathway is to supply NADPH and ribose, shifting metabolism towards this pathway could increase NADPH levels and ribose precursor in cells [7]. The disruption of pgi in HLC010 was performed using a linear PCR fragment with 50 nucleotides of homology extensions to construct strain HLC015 (Additional file 1: Figure S3D). The best plasmid, pETGY, as determined above, was used to transform HLC015 cells. In this experiment, we needed to change the carbon source in the medium from glycerol to glucose, because HLC015-pETGY cannot use glycerol efficiently via the PP pathway. HLC015-pETGY did not grow in production medium with glycerol, and likewise, HLC010-pETGY showed decreased growth in production medium with glucose. Accordingly, to compare these two strains, we used the optimal cultivation medium for each. Under these conditions, HLC010-pETGY produced 650 mg/L of dCyd in the production medium with glycerol, and HLC015-pETGY produced 967 mg/L of dCyd in the production medium with glucose during similar cultivation times (30 and 32 h, respectively) (Figure 5). Generally, pgi disruption prevents or delays the normal utilization of glucose in cells, which retards cell growth due to a limited capacity for the re-oxidation of overproduced NADPH [23, 24]. However, in HLC015-pETGY, the retardation of cell growth was not observed, suggesting that the over-accumulation of NADPH and ribose precursors was alleviated due to NADPH-recycling and ribose consumption during dCyd overproduction. Interestingly, the byproduct peaks also disappeared or considerably decreased in HPLC profiles of the broth supernatant (Additional file 1: Figure S5H). In return, the dCyd production yield of HLC015-pETGY was considerably increased, which could also be seen as increased yield caused by decreasing the byproducts. One of our objectives was to prepare a high dCyd producer with no byproducts like deoxyuridine, cytosine, uracil or thymine, while retaining the ability to produce dCyd. Even though the optimization of overall fermentation processes is still required, dCyd production was achieved successfully without significant co-produced byproducts, thereby demonstrating the potential of our engineered cells for developing industrial dCyd production and purification processes.

Cultivation profiles of HLC010-pETGY and HLC015-pETGY in flask scale. HLC015-pETGY showed slower growth rate but higher productivity than HLC010-pETGY by additional pgi deletion. a Fermentation profile using HLC010-pETGY. Glycerol was used as the carbon source. b Fermentation profile using HLC015-pETGY. Glucose, at a concentration (60 g/L) equivalent to that of cultures with glycerol, was used as the carbon source. Values are mean ± SD from three independent experiments performed in triplicate.

Discussion

In this study, we developed promising dCyd producing strains by metabolic reprogramming of E. coli, based on recent information on pyrimidine metabolism and uncovered the metabolic change in our cells by transcriptome analysis. Specifically, the remarkable feature of our strain is that the approach produced the reduced form of cytidine by controlling regulations as well as pathway recombineering. Indeed, dCyd production by rational design was relatively more difficult than the oxidized form in terms of reducing power regeneration as well as supply of precursors. In this study, to complement a reducing power in all strains but HLC015-pETGY, glycerol was used as carbon source instead of glucose. We were supposed that HLC015-pETGY also had higher NADPH/NADP ratio than other strains, because glucose can be passed through PP pathway with generating NADPH, but glycerol cannot. In similar case of previous study for developing thymidine producer, we have obtained the supporting data that NADPH/NADP ratio of pgi-disrupting cells showed higher level in continuous culture with glucose, while NADH/NAD ratio showed lower, compared to those of parental cells in continuous culture with glycerol [11]. The fermentation using glycerol has an advantage of producing extra NADH, which can be easily converted into NADPH in the presence of extra phosphate [13, 25, 26]. In addition, its effect can be amplified by overexpressing intrinsic NAD kinase or soluble transhydrogenase [10, 11, 27, 28]. While there are less supporting data as to which approach is more efficient between PP pathway rerouting and glycerol fermentation, both approaches highlight the importance of supplying reducing power.

Interestingly, HPLC analysis of the culture supernatants of HLC010-pETNGY and HLC010-pETGY broth revealed the formation of byproducts in addition to dCyd production (Additional file 1: Figure S5), which potentially lowers dCyd productivity and makes downstream purification processes difficult. HLC010-pETGY showed higher productivity, compared to HLC010-pETNGY, and co-produced less byproducts (Figure 4). One possible explanation is that the excessive reduction of UDP by strong overexpression of T4 NDP reductase might have a negative effect on UTP amination by PyrG. In the case of HLC010-pETNGY, NDP reductase was overexpressed without any regulation, probably acting to convert more UDP into dUDP, while simultaneously decreasing the UTP supply for conversion to CTP by PyrG. Subsequently, excess dUMP can be readily degraded into deoxyuridine by YfbR, which has higher activity on dUMP by twofold compared to dCMP [19], because there is no pathway to convert deoxyuridine and dUTP into deoxycytidine and dCTP, respectively, in HLC010 cells where dcd, cdd and codA were deleted. In contrast, in HLC010-pETGY cells, more UTP can be converted into CTP by the expressed PyrG than in HLC010-pETNGY cells. Thus, if we express a dCMP phosphohydrolase with higher affinity for dCMP than yfbR, the simultaneous expression of a NDP reductase might be effective to improve productivity.

In HLC015-pETGY, more NADPH and ribose precursors were supplied by rerouting from the EMP pathway to the PP pathway, compared to HLC010-pETGY. The PyrG-associated supply of sufficient precursors and redox potential could have given rise to the increased dCMP/dUMP ratio of HLC015-pETGY cells, leading to enhanced dCMP hydrolysis by YfbR. In support of this, we obtained several lines of evidence that byproduct formation was further decreased when YfbR was expressed under control of the T7 promoter, compared to the arabinose promoter (data not shown). While further experiments are needed to clearly explain the relationship of YfbR activity and dCyd biosynthesis, we postulate that the balance between YfbR and PyrG activity may be very closely linked to byproduct formation in HLC010-pETGY.

In further engineering, the complete elimination of degradation enzymes with broad activity may be very important in further developing a dCyd producer, because dCyd is released to the media, instead of accumulating inside cells. While not investigated here, it is possible that ribonucleoside hydrolases and analogues, RihA, RihB, and RihC may be involved in dCyd nicking via an unknown mechanism [29]. This would explain how residual nucleoside byproducts still existed in vivo, even though the in vitro dCyd degradation assay showed HLC005 appeared to block dCyd hydrolysis completely. The contribution of RihA, B, and C for byproduct formation remains to be examined in vivo. Nonetheless, this potential activity of RihA, B, and C is not entirely unexpected in light of the other degradation enzymes for dCyd (or Cyd). For example, a pyrimidine requiring cdd mutant of E. coli can utilize cytidine as a pyrimidine source by an alternative pathway, which involves hydrolysis of cytidine by RihA, B, and C [29]. Likewise, RihA, B, and C are predicted to fulfill degradation roles for dCyd/Cyd in our cells by participating in the salvage pathway.

As mentioned, CarAB is controlled by at least five transcription factors [30, 31]. Among these repressors, those encoded by purR, pepA, and argR are known as representative binders to the carAB promoter P1 (upstream) and P2 (downstream), which are adjacent to each other [32]. PurR and ArgR repress transcription by binding to each carAB promoter P1 and P2, respectively. In contrast, PepA shares a binding site with PurR and ArgR partially, so it influences regulation of both promoters. According to previous study, in the case of purine metabolism in purR-deficient cells, genes related to ribose moiety supply and the flux into IMP, are generally increased but genes related to AMP or GMP biosynthesis from IMP are decreased in expression [21]. By eliminating argR, many genes in arginine and aspartate biosynthesis, which are directly regulated by the ArgR repressor, are up-regulated [33–35]. Likewise, the third repressor PepA influences both metabolism and the intracellular nucleotide pool. However, the simultaneous disruption of purR, pepA and argR may appear to give cells more complex metabolic changes in nucleotide metabolism and arginine metabolism, compared to the separate one gene disruption.

The arginine biosynthetic pathway is competitive with the pyrimidine biosynthetic pathway in utilizing carbamoyl phosphate [21, 33]. If arginine overproduction occurred in our strain, this would be disadvantageous to pyrimidine biosynthesis. However, in this study, we did not observe arginine overproduction in the three repressor-deficient cells, while dCyd overproduction was observed. Interestingly, down-regulation of ArgG in the three repressor-deficient cells was observed. One possible explanation for this is that the down-regulation of ArgG may resulted from co-disruption of pepA/purR and amplification of other nucleotide synthetic pathways in HLC010. This would explain why previous studies, which all involved argR regulation but not co-disruption of pepA and purR, did not observe argG down-regulation. Even though we cannot explain the clearly complex regulation in the recombineered cells, it is plausible that the decrease of ArgG expression in the three repressor-deficient cells slowed the conversion rate of carbamoyl phosphate into the arginine precursor, thereby enabling metabolism of carbamoyl phosphate mainly via the pyrimidine pathway.

As shown in Figure 3a, expression of pyrBI, pyrC, pyrD and pyrE were kept off or slightly down-regulated in HLC010, which is consistent with the earlier observation that these genes are kept off even in the absence of the repressors encoded by purR, pepA and argR, through attenuation control by coupled transcription and translation [36]. We speculate that this attenuation might be the result of increased intracellular UTP and CTP levels that arise in the metabolically engineered strain. In support of this notion, the transcription of pyrBI and pyrE are controlled negatively by UTP-sensitive attenuation [37–39]. Additionally, the transcription of pyrBI is regulated by reiterative transcription at high UTP levels [40]. Translation of pyrC is controlled negatively by preventing ribosome binding to the Shine–Dalgarno (SD) box via shifting transcription start sites at high CTP levels [41, 42]; pyrD may be regulated by a similar mechanism [43]. Such UTP- and CTP-sensitive regulation of these genes might limit pyrimidine biosynthesis, even when the supply of precursors and the downstream dCyd flux are increased. Despite severe UTP- and CTP-sensitive regulation, the additional overexpression of genes of the pyr operon in our cells may be a reliable approach.

Conclusions

From a technological standpoint, a notable outcome of the studies described here was the preparation of a dCyd producing strain with fewer byproducts by rational metabolic engineering. We demonstrated that high dCyd yield could be readily achieved by recombineering in combination with disruption of dCyd degrading enzymes and repressors for carbamoyl phosphate synthetase, and amplification of dCyd synthesis enzymes. In addition, we showed that carbon flux rerouting by disrupting pgi, was a very efficient approach in our cells. In particular, we showed how nucleotide metabolic flow was changed by microarray analysis, which could easily be leveraged for further improvement of the dCyd-producing strain.

Methods

Bacterial strains and growth conditions

All strains used in this study are shown in Table 1. Parental strain E. coli BL21(DE3) was used for preparing dCyd producing strains. To eliminate the possibility of dCyd degradation by endogenous nucleosides degradation enzymes, a triple knockout strain was prepared by sequential knockout of deoA, udp and deoD in BL21(DE3) by PCR mediated gene disruption as described previously [44]. The first-step generated strain HLC003, which was then subject to disruption of genes encoding branching enzymes (dcd, cdd, codA and thyA), followed by removal of the chloramphenicol marker (Cm) in each target gene using pCP20 by the same method. The resulting strain, HLC007 was then subject to disruption of genes encoding the CarAB repressors (purR, pepA and argR), resulting in strain HLC010. Finally, the pgi gene of HLC010 was knocked out by the described method, resulting in strain HLC015 (BL21(DE3) ΔdeoA Δudp ΔdeoD Δdcd Δcdd ΔcodA ΔthyA ΔpurR ΔpepA ΔargR Δpgi::Cm). E. coli XL1-Blue was used for cloning genes.

Typically, cultures were grown in Luria–Bertani (LB) medium supplemented with antibiotic as needed. Antibiotics were provided at the following concentrations: chloramphenicol (Cm), 20 μg/mL; ampicillin (Amp), 100 μg/mL.

For dCyd production experiments, a suspension of cells was inoculated into a 250 mL flask containing 50 mL of LB medium and incubated at 37°C and 250 rpm for 8 h. For flask culture, 5 mL of culture broth was transferred to a 500-mL baffled flask containing 50 mL of production medium (60 g/L glycerol (glucose in case of HLC015), 10 g/L CaCO3, 10 g/L yeast extract, 0.4 g/L MgSO4·7H2O, 14.84 g/L soytone, 100 μg/mL ampicillin, and trace elements) and 0.5 mM IPTG for induction, and then incubated at 37°C and 250 rpm for 36 h.

Plasmid construction

All plasmids used in this study are listed in Table 1 and all primer sequence used for constructing vectors are listed in Additional file 1: Table S2. For expression of the dCyd biosynthetic genes T4 nrdCAB, pyrG and yfbR, plasmid pETDuet (Novagen) was used in this study. To generate plasmids pETNG and pETNY, PCR-amplified T4 nrdB (P23 and P24) was cloned into the NcoI/SalI restriction sites of pETDuet, and then PCR-amplified pyrG and yfbR (P27 and P28) were cloned into the NdeI/XhoI restriction sites, respectively. PCR-amplified T4 RBS-nrdCA (P25 and P26) was then ligated into each of the above plasmids using the SalI restriction site (Additional file 1: Figure S3A, B). Plasmid pETGY was generated by inserting PCR-amplified pyrG (P29 and P30) into the NcoI/SalI restriction sites and then inserting PCR-amplified yfbR (P31 and P32) into the NdeI/XhoI restriction sites of pETDuet (Additional file 1: Figure S3C). To generate the plasmid pETNGY, PCR-amplified T4 nrdB (P23 and P24) was inserted into the NcoI/SalI restriction sites of pETDuet and then PCR-amplified pyrG (P27 and P28) was cloned into the NdeI/XhoI restriction sites. PCR-amplified RBS-yfbR (P33 and P32) was inserted into the XhoI restriction site of the resulting plasmid. After checking gene orientation, PCR-amplified T4 RBS-nrdCA (P25 and P26) was ligated into the SalI restriction site (Additional file 1: Figure S3B, D). All plasmids were confirmed by DNA sequencing.

In vitro dCyd degradation assay

Equal amounts of transformed cells were harvested by centrifugation and washed with 10 mM Tris (pH 7.4) containing a protease inhibitor mixture (Complete™, Amersham Phamacia). Each enzyme solution was prepared by sonication and its protein concentration was determined by the Lowry assay. For the enzyme assay, 100 μL of 1 mM dCyd was mixed with 100 μL of enzyme solution (1.2 mg/mL) and the reaction mixture was incubated at 30°C for 16 h with sampling for analysis (1, 3, and 13 h). Then enzyme reaction was stopped by the filtration with PVDF and the residual thymidine concentration was measured in the reaction mixture.

Transcriptome analysis

Total cellular RNA was extracted from mid-log phase cells with a QIAGEN RNEasy Mini Kit (Qiagen, Valencia, CA, USA) as described by the manufacturer. RNase-free DNaseI (Takara Bio, Shiga, Japan) was used during the isolation procedure to eliminate possible DNA contamination. cDNA probes for cDNA microarray analysis were prepared by the reverse-transcription of total RNA (25 μg) in the presence of aminoallyl-dUTP and 6 μg of random primers (Invitrogen, Carlsbad, CA) for 3 h. The cDNA probes were cleaned up using Microcon YM-30 columns (Millipore, Bedford, MA, USA) and then coupled to Cy3 dye (for reference HLC007) or Cy5 dye (for test sample HLC010) (Amersham Pharmacia, Uppsala, Sweden). The Cy3- or Cy5-labeled cDNA probes were purified with QIAquick PCR Purification Kit (Qiagen, Valencia, CA). Dried Cy3- or Cy5-labeled cDNA probes were resuspended in hybridization buffer (30% formamide, 5X SSC, 0.1% SDS, and 0.1 mg/mL salmon sperm DNA). The Cy3- or Cy5-labeled cDNA probes were mixed together and hybridized to a customized microarray slide (Mycroarray.com, Ann Arbor, MI, USA). After washing and drying slide, which was scanned by Axon 4000B (Axon Instrument, Union City, CA, USA) to generate hybridization images.

Hybridization images were analyzed by GenePix Pro 3.0 software (Axon Instrument, Union City, CA, USA) to obtain gene expression ratios (M value = (Cy5 signalHLC010 − background)/(Cy3 signalHLC007 − background)). Microarray data analysis was carried out by Genowiz 4.0™ (Ocimum Biosolutions, India). The mean signal intensity values of the duplicate spots were averaged (A value = [(Cy5 signalHLC010 − background) + (Cy3 signalHLC007 − background)]/2) and then normalized by the global normalization method.

Analytical methods

Biomass measured by the OD600 was converted to DCW using a standard curve (1.0 OD600 = 0.45 gdcw/L). Quantitative determinations of bases and nucleosides were performed by HPLC with modifying previous condition for thymidine [9]. The operating conditions were as follows: column, Zorbax SB-C18, 5 μm (4.6 × 150 mm) (Agilent Co., Ltd., Santa Clara, CA, USA); solvent, 1% (v/v) acetonitrile in water; flow rate, 1 mL/min; detection at 265 nm. All standards for HPLC were purchased from Sigma.

References

Kantarjian H, Issa JP, Rosenfeld CS, Bennett JM, Albitar M, DiPersio J et al (2006) Decitabine improves patient outcomes in myelodysplastic syndromes: results of a phase III randomized study. Cancer 106:1794–1803

Kantarjian HM, O’Brien S, Cortes J, Giles FJ, Faderl S, Issa JP et al (2003) Results of decitabine (5-aza-2′deoxycytidine) therapy in 130 patients with chronic myelogenous leukemia. Cancer 98:522–528

Stresemann C, Lyko F (2008) Modes of action of the DNA methyltransferase inhibitors azacytidine and decitabine. Int J Cancer 123:8–13

Fang H, Xie X, Xu Q, Zhang C, Chen N (2013) Enhancement of cytidine production by coexpression of gnd, zwf, and prs genes in recombinant Escherichia coli CYT15. Biotechnol Lett 35:245–251

Zhu H, Yang SM, Yuan ZM, Ban R (2015) Metabolic and genetic factors affecting the productivity of pyrimidine nucleoside in Bacillus subtilis. Microb Cell Fact 14:54

Lee YB, Baek H, Kim SK, Hyun HH (2011) Deoxycytidine production by metabolically engineered Corynebacterium ammoniagenes. J Microbiol 49:53–57

Koo BS, Hyun HH, Kim SY, Kim CH, Lee HC (2010) Enhancement of thymidine production in E. coli by eliminating repressors regulating the carbamoyl phosphate synthetase operon. Biotechnol Lett 33:71–78

Lee HC, Ahn JM, Lee SN, Kim JH (2004) Overproduction of thymidine by recombinant Brevibacterium helvolum amplified with thymidine monophosphate phosphohydrolase gene from bacteriophage PBS2. Biotechnol Lett 26:265–268

Lee HC, Kim JH, Kim JS, Jang W, Kim SY (2009) Fermentative production of thymidine by a metabolically engineered Escherichia coli strain. Appl Environ Microbiol 75:2423–2432

Lee HC, Kim JS, Jang W, Kim SY (2009) Thymidine production by overexpressing NAD+ kinase in an Escherichia coli recombinant strain. Biotechnol Lett 31:1929–1936

Lee HC, Kim JS, Jang W, Kim SY (2010) High NADPH/NADP+ ratio improves thymidine production by a metabolically engineered Escherichia coli strain. J Biotechnol 149:24–32

O’Donovan GA, Neuhard J (1970) Pyrimidine metabolism in microorganisms. Bacteriol Rev 34:278–343

Neuhard J, Nygaard P (1987) Escherichia coli and Salmonella typhimurium. Cellular and molecular biology. American Society of Microbiology, Washington DC

Krogan NJ, Zaharik ML, Neuhard J, Kelln RA (1998) A combination of three mutations, dcd, pyrH, and cdd, establishes thymidine (deoxyuridine) auxotrophy in thyA + strains of Salmonella typhimurium. J Bacteriol 180:5891–5895

Moffatt BA, Ashihara H (2002) Purine and pyrimidine nucleotide synthesis and metabolism. Arabidopsis Book 1:e0018

Proudfoot M, Kuznetsova E, Brown G, Rao NN, Kitagawa M, Mori H et al (2004) General enzymatic screens identify three new nucleotidases in Escherichia coli. Biochemical characterization of SurE, YfbR, and YjjG. J Biol Chem 279:54687–54694

Titz B, Hauser R, Engelbrecher A, Uetz P (2007) The Escherichia coli protein YjjG is a house-cleaning nucleotidase in vivo. FEMS Microbiol Lett 270:49–57

Weiss B (2007) The deoxycytidine pathway for thymidylate synthesis in Escherichia coli. J Bacteriol 189:7922–7926

Zimmerman MD, Proudfoot M, Yakunin A, Minor W (2008) Structural insight into the mechanism of substrate specificity and catalytic activity of an HD-domain phosphohydrolase: the 5′-deoxyribonucleotidase YfbR from Escherichia coli. J Mol Biol 378:215–226

Devroede N, Huysveld N, Charlier D (2006) Mutational analysis of intervening sequences connecting the binding sites for integration host factor, PepA, PurR, and RNA polymerase in the control region of the Escherichia coli carAB operon, encoding carbamoylphosphate synthase. J Bacteriol 188:3236–3245

Devroede N, Thia-Toong TL, Gigot D, Maes D, Charlier D (2004) Purine and pyrimidine-specific repression of the Escherichia coli carAB operon are functionally and structurally coupled. J Mol Biol 336:25–42

Wilson HR, Turnbough CL Jr (1990) Role of the purine repressor in the regulation of pyrimidine gene expression in Escherichia coli K-12. J Bacteriol 172:3208–3213

Canonaco F, Hess TA, Heri S, Wang TT, Szyperski T, Sauer U (2001) Metabolic flux response to phosphoglucose isomerase knock-out in Escherichia coli and impact of overexpression of the soluble transhydrogenase UdhA. FEMS Microbiol Lett 204:247–252

Hua Q, Yang C, Baba T, Mori H, Shimizu K (2003) Responses of the central metabolism in Escherichia coli to phosphoglucose isomerase and glucose-6-phosphate dehydrogenase knockouts. J Bacteriol 185:7053–7067

Murarka A, Dharmadi Y, Yazdani SS, Gonzalez R (2008) Fermentative utilization of glycerol by Escherichia coli and its implications for the production of fuels and chemicals. Appl Environ Microbiol 74:1124–1135

Sauer U, Canonaco F, Heri S, Perrenoud A, Fischer E (2003) The soluble and membrane-bound transhydrogenases UdhA and PntAB have divergent functions in NADPH metabolism of Escherichia coli. J Biol Chem 279:6613–6619

Sanchez AM, Andrews J, Hussein I, Bennett GN, San KY (2006) Effect of overexpression of a soluble pyridine nucleotide transhydrogenase (UdhA) on the production of poly(3-hydroxybutyrate) in Escherichia coli. Biotechnol Prog 22:420–425

Berrios-Rivera SJ, Bennett GN, San KY (2003) Metabolic engineering of Escherichia coli: increase of NADH availability by overexpressing an NAD(+)-dependent formate dehydrogenase. Metab Eng 4:217–229

Petersen C, Moller LB (2001) The RihA, RihB, and RihC ribonucleoside hydrolases of Escherichia coli. Substrate specificity, gene expression, and regulation. J Biol Chem 276:884–894

Bouvier J, Patte JC, Stragier P (1984) Multiple regulatory signals in the control region of the Escherichia coli carAB operon. Proc Natl Acad Sci USA 81:4139–4143

Piette J, Nyunoya H, Lusty CJ, Cunin R, Weyens G, Crabeel M et al (1984) DNA sequence of the carA gene and the control region of carAB: tandem promoters, respectively controlled by arginine and the pyrimidines, regulate the synthesis of carbamoyl-phosphate synthetase in Escherichia coli K-12. Proc Natl Acad Sci USA 81:4134–4138

Donahue JP, Turnbough CL Jr (1990) Characterization of transcriptional initiation from promoters P1 and P2 of the pyrBI operon of Escherichia coli K12. J Biol Chem 265:19091–19099

Caldara M, Charlier D, Cunin R (2006) The arginine regulon of Escherichia coli: whole-system transcriptome analysis discovers new genes and provides an integrated view of arginine regulation. Microbiol 152:3343–3354

Caldara M, Minh PN, Bostoen S, Massant J, Charlier D (2007) ArgR-dependent repression of arginine and histidine transport genes in Escherichia coli K-12. J Mol Biol 373:251–267

Charlier D, Roovers M, Van Vliet F, Boyen A, Cunin R, Nakamura Y et al (1992) Arginine regulon of Escherichia coli K-12. A study of repressor-operator interactions and of in vitro binding affinities versus in vivo repression. J Mol Biol 226:367–386

Turnbough CL Jr, Hicks KL, Donahue JP (1983) Attenuation control of pyrBI operon expression in Escherichia coli K-12. Proc Natl Acad Sci USA 80:368–372

Clemmesen K, Bonekamp F, Karlstrom O, Jensen KF (1985) Role of translation in the UTP-modulated attenuation at the pyrBI operon of Escherichia coli. Mol Gen Genet 201:247–251

Donahue JP, Turnbough CL Jr (1994) Nucleotide-specific transcriptional pausing in the pyrBI leader region of Escherichia coli K-12. J Biol Chem 269:18185–18191

Poulsen P, Jensen KF (1987) Effect of UTP and GTP pools on attenuation at the pyrE gene of Escherichia coli. Mol Gen Genet 208:152–158

Liu C, Heath LS, Turnbough CL Jr (1994) Regulation of pyrBI operon expression in Escherichia coli by UTP-sensitive reiterative RNA synthesis during transcriptional initiation. Genes Dev 8:2904–2912

Liu J, Turnbough CL Jr (1994) Identification of the Shine–Dalgarno sequence required for expression and translational control of the pyrC gene in Escherichia coli K-12. J Bacteriol 176:2513–2516

Liu J, Turnbough CL Jr (1994) Effects of transcriptional start site sequence and position on nucleotide-sensitive selection of alternative start sites at the pyrC promoter in Escherichia coli. J Bacteriol 176:2938–2945

Turnbough CL Jr, Switzer RL (2008) Regulation of pyrimidine biosynthetic gene expression in bacteria: repression without repressors. Microbiol Mol Biol Rev 72:266–300

Datsenko KA, Wanner BL (2000) One-step inactivation of chromosomal genes in Escherichia coli K-12 using PCR products. Proc Natl Acad Sci USA 97:6640–6645

Authors’ contributions

JK performed research, analyzed data, and wrote the paper. BK analyzed data. HH designed research, analyzed data. HL conceptualized project, designed research, analyzed data, and wrote the paper. All authors read and approved the final manuscript.

Acknowledgements

The authors want to thank Dr. Anne Ollis for editing this manuscript. This research was supported by the Converging Research Center Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2011-50210).

Compliance with ethical guidelines

Competing interests The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Additional file

12934_2015_291_MOESM1_ESM.pdf

Additional file 1: In the Supplemental Figure Section results from strain screening experiment and respective SDS-PAGE harboring each plasmid with map as well as HPLC profiles are presented. In the Supplemental Table Section the original data of transcriptome analysis and all primers used in this study are presented.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Kim, JS., Koo, BS., Hyun, HH. et al. Deoxycytidine production by a metabolically engineered Escherichia coli strain. Microb Cell Fact 14, 98 (2015). https://doi.org/10.1186/s12934-015-0291-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12934-015-0291-8