Abstract

Background

Manganese-oxides are one of the most important minerals in soil due to their widespread distribution and high reactivity. Despite their invaluable role in cycling many redox sensitive elements, numerous unknowns remain about the reactivity of different manganese-oxide minerals under varying conditions in natural systems. By altering temperature, pH, and concentration of arsenite we were able to determine how manganese-oxide reactivity changes with simulated environmental conditions. The interaction between manganese-oxides and arsenic is particularly important because manganese can oxidize mobile and toxic arsenite into more easily sorbed and less toxic arsenate. This redox reaction is essential in understanding how to address the global issue of arsenic contamination in drinking water.

Results

The reactivity of manganese-oxides in ascending order is random stacked birnessite, hexagonal birnessite, biogenic manganese-oxide, acid birnessite, and δ-MnO2. Increasing temperature raised the rate of oxidation. pH had a variable effect on the production of arsenate and mainly impacted the sorption of arsenate on δ-MnO2, which decreased with increasing pH. Acid birnessite oxidized the most arsenic at alkaline and acidic pHs, with decreased reactivity towards neutral pH. The δ-MnO2 showed a decline in reactivity with increasing arsenite concentration, while the acid birnessite had greater oxidation capacity under higher concentrations of arsenite. The batch reactions used in this study quantify the impact of environmental variances on different manganese-oxides’ reactivity and provide insight to their roles in governing chemical cycles in the Critical Zone.

Conclusions

The reactivity of manganese-oxides investigated was closely linked to each mineral’s crystallinity, surface area, and presence of vacancy sites. δ-MnO2 and acid birnessite are thought to be synthetic representatives of naturally occurring biogenic manganese-oxides; however, the biogenic manganese-oxide exhibited a lag time in oxidation compared to these two minerals. Reactivity was clearly linked to temperature, which provides important information on how these minerals react in the subsurface environment. The pH affected oxidation rate, which is essential in understanding how manganese-oxides react differently in the environment and their potential role in remediating contaminated areas. Moreover, the contrasting oxidative capacity of seemingly similar manganese-oxides under varying arsenite concentrations reinforces the importance of each manganese-oxide mineral’s unique properties.

Similar content being viewed by others

Background

Manganese (Mn)-oxides are important minerals in the environment because of their abundance and high reactivity. They are among the strongest oxidants in soils and sediments, and generally have high sorption capacities. These characteristics make Mn-oxides’ role paramount in sequestering both naturally occurring and anthropogenic toxins in the environment. The structure, crystallinity, and particle size of Mn-oxides are important factors which determine reactivity and thus the relative rate of Mn oxidation in the subsurface environment.

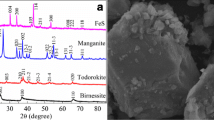

Manganese-oxide minerals are composed of MnO6 octahedra, which can be arranged in numerous ways. Subtle variations in the arrangement of these octahedra give rise to a multitude of minerals with nearly the same crystalline structure. Many naturally occurring Mn-oxides are difficult to characterize because they are small and exhibit poorly crystalline structure. Generally, Mn-oxides fit into two broad structural groups: tunnel structures and layer structures. Layered structures are characterized by stacked sheets of Mn octahedra with cations or water molecules integrated into the region between octahedral layers. Tunnel structures differ by consisting of a sequence of edge-sharing Mn octahedra which link corners to make tunnels with a rectangular or square cross section. Manganese-oxides exhibiting layered structure tend to be more reactive than those with tunnel structure due to the impact of the mineral configuration on surface area, vacancy and edge sites, and Mn(III) substitution. Some variations of the layered structure exhibit a triclinic configuration, including random stacked birnessite. However, among Mn-oxides with layered structure, those with configurations similar to hexagonal birnessite tend to be the most reactive and important in the environment [1].

Acid birnessite, biogenic Mn-oxide, hexagonal birnessite, and hydrous δ-MnO2 are Mn-oxides that exhibit a similar hexagonal structure. Two kinds of reactive sites exist in birnessite type minerals with hexagonal structure: vacancy and edge sites [2, 3]. Vacancy sites are areas where Mn is missing within the Mn(IV) octahedral sheets, while edge sites are found on the edges of the octahedral sheets. Mn-oxides with this configuration derive some of their negative charge and reactivity from the presence of vacancy sites [4]. Differences in reactivity between minerals sharing the hexagonal birnessite structure can be partially attributed to variances in the amount of these vacancy and edge sites [4]. Based on scanning and transmission electron microscopy, hexagonal birnessite and acid birnessite have a more ordered crystalline structure compared to δ-MnO2 and biogenic Mn-oxide. A more ordered structure tends to indicate a lower surface area and fewer reactive vacancy and edge sites, leading to decreased reactivity. Accordingly, acid birnessite is reported to have a surface area of 36 m2 g−1 and 12.0 % vacancies, while δ-MnO2 was found to have a surface area of 121 m2 g−1 and 6.0 % vacancies [5]. The greatly increased surface area of δ-MnO2 leads to a high reactivity as also seen in the biogenic Mn-oxide with 16.7 % vacancies and similar amorphous structure [5]. While vacancy sites are important for sorption of many cations, the influence of edge sites on the reactivity of these Mn-oxides should not be overlooked [6]. Reaction products, such as Mn(II), can also fill vacancy sites, or sorb on edge sites, blocking sorption and reactions with other compounds. Accordingly, edge sites can lead to higher reactivity in a mineral like acid birnessite, even though it has a greater proportion of total vacancy sites. In addition to structure, origin can greatly influence Mn reactivity. Many of the Mn-oxide minerals found in the environment are created by soil microorganisms and exhibit a layered structure similar to hexagonal birnessite [3, 4, 6].

Even over a large range of pHs, Mn-oxides play an important role in oxidizing many redox sensitive metals in the environment [7]. For example, they are one of the main agents that oxidize toxic and mobile arsenite [As(III)], to arsenate [As(V)], which is less mobile and less toxic [8]. After this reaction, As(V) can be readily removed through precipitation or adsorption to minerals such as Mn-oxides and Fe-oxides [9]. As the reaction between As(III) and Mn-oxides continues, the surface of some Mn-oxides may become passivated, resulting in a biphasic kinetic reaction [9–11]. Initially, the reaction proceeds rapidly; however, as the As(III) oxidation continues, intermediates including Mn(II) and Mn(III) along with As(V) may sorb to the Mn-oxide surface or replace surficial Mn(IV), which leads to a decrease in the oxidation rate during the later phase of the reaction [10].

The toxic impacts of As contamination are a global issue that affects the health and wellbeing of many diverse populations. It is estimated that over 150 million people worldwide are endangered by As contamination [12]. Arsenite has the greatest impact on human health in a few critical developing countries where natural geological formations contain hazardous levels of As. The World Health Organization deemed Bangladesh “the largest mass poisoning of a population in history,” due to the installation of wells in naturally As contaminated areas [13, 14]. These shallow wells often tap into alluvial sediments that are nearly devoid of oxidizing agents such as Mn and Fe and are rich in As(III) accumulated from weathering of upstream rocks. The pH of these soils also impacts As transport, with older deposits ranging from pH 6.0–6.5 and more recent alluvium having a pH of 7.0–8.5 [15].

Understanding the structure of different Mn-oxides can provide critical insight to their predicted reactivity. However, it is still unclear how many of the Mn-oxides behave under changing environmental conditions. Very few studies have examined the effects of variations in concentration of reactants and temperature on Mn-oxides reactivity. Even pH studies have only encompassed a limited selection of the many Mn-oxides. This study seeks to provide critical information on the reactivities of several Mn-oxides in oxidizing As(III) under varying pH, temperature, and As(III) concentration. Such information will provide important insights on fate and transport of toxic As(III) in the soil environment.

Results and discussion

Effect of Mn-oxide structure on As(III) oxidation kinetics

Based on structural assumptions, the predicted reactivity of the Mn-oxides investigated in this study in descending order should be δ-MnO2 ~ biogenic Mn-oxide > acid birnessite > hexagonal birnessite > random stacked birnessite. However, this is solely based on structure (i.e. particle size, surface area, and percentage of vacancy sites) and does not encompass the full scope of factors contributing to Mn-oxide reactivity. Batch reactions with 100 μM As(III) and 1.82 mM Mn-oxide at pH 7.2 are shown in Fig. 1. These data confirm that δ-MnO2 was the most reactive of the Mn-oxides studied and it oxidized ~100 % of the As(III) in the first 5 min. The δ-MnO2 sorbed on average ~30 % of the produced As(V) over the course of the experiment. In the first 4 h, acid birnessite was the second most reactive, followed by hexagonal birnessite, and finally biogenic Mn-oxide. Between 3 and 6 h the reactivity of biogenic Mn-oxide greatly increased and most of the As(III) in solution was oxidized. This initial delay in reactivity for the biogenic Mn-oxide was unexpected and may be attributed to the presence of remnant bacterial cell fragments interfering with the reactive sites on the Mn-oxide, as was found for iron oxides by Franzblau et al. [16]. Additionally, extracellular polymeric substances (EPS) may be present, further delaying the initial As(III) oxidation [17]. Remnant bacterial cells and EPS may also make the biogenic Mn-oxide more thermodynamically stable and cause increased persistence of the mineral phase. After this preliminary period of reacting slowly, the biogenic Mn-oxide proceeded to oxidize ~99 % of the As(III), releasing more oxidized As into solution than any of the other Mn-oxides studied. The δ-MnO2 reaction stopped in <5 min, while with acid birnessite the reaction finished in <15 min and oxidized 86 % of the total As in solution. All reactions containing Mn-oxides with hexagonal structure were complete after 1 day, except for hexagonal birnessite.

The rate constants of As(III) oxidation on the Mn-oxides were determined by fitting data to different kinetic models. All Mn-oxides tested fit well to a first-order kinetic model as demonstrated in Table 1. However, the δ-MnO2 reaction was completed in <5 min and the data were fit to a first-order model. The observed rate coefficients for the Mn-oxides show that δ-MnO2 oxidized As(III) about ten times more quickly than the next most reactive mineral, acid birnessite. The three remaining Mn-oxides were much less reactive as demonstrated by their significantly smaller kobserved. However, from 90 to 180 min the biogenic Mn-oxide completely oxidized most of the As(III) solution. Due to the temporal distance between these two sample times it is probable that the oxidation occurred in much <90 min and that biogenic Mn-oxide is more reactive in a small time window than indicated by the reported kobserved. Our results agree with the scientific literature in that reactions and back reactions of Mn and As have previously been linked to pseudo-first or pseudo-second-order kinetics [18–20].

Only δ-MnO2 and biogenic Mn-oxide appeared to sorb a noticeable amount of As(V) during the oxidation reaction. This was determined by the total As(III) and As(V) in solution compared to the total concentration of As added initially. The δ-MnO2 initially sorbed approximately 37 % of the total As, which steadily decreased to 21 % over the course of the 2 days experiment. The biogenic Mn-oxide initially showed 5 % sorption after 5 min. During the highest rate of reaction at 3 h, approximately 13 % of the total As was sorbed. A larger number of edge sites in δ-MnO2 may be responsible for sorbing As(V) and thus removing it from solution [2].

Random stacked birnessite was the only Mn-oxide with triclinic structure, which has been shown to have decreased reactivity compared to layered Mn-oxides with hexagonal structure [21]. Triclinic birnessite is different from hexagonal birnessite in that the triclinic form has a minute lengthening of one of the unit cell planes, most likely resulting from an increase in Mn(III) [22–24]. Random stacked birnessite showed the slowest overall As(III) oxidation kinetics of all minerals studied and also has fewer edge sites compared to the minerals with hexagonal structure. The random stacked birnessite reaction fit best to a first-order kinetic model as seen in Table 1. The production of As(V) was still occurring at a slow rate when the experiment ended after 2 days. Additionally, the amount of total As [As(V) and As(III) combined] in solution was always equal to the initial concentration, indicating there was little to no sorption of the As(V) produced during the experiments.

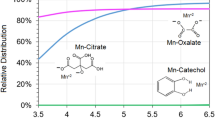

Effect of pH on manganese reactivity and arsenic(III) oxidation

The pH of an environment plays a critical role in the reaction of Mn-oxides with As due to the importance of H+ in reactions governing the oxidation of As. Two of the most reactive Mn-oxides, δ-MnO2 and acid birnessite, were reacted with 100 μM As(III) at pH 4.5, 7.2, and 9.0 (Fig. 2). The influence of pH on As(III) oxidation of Mn-oxides is described by Feng et al. [25] in the following reactions. In acidic pH conditions, the reaction is represented as:

Effect of pH on manganese As(III) oxidation: the influence of pH on the oxidation of 100 μM arsenite by 1.82 mM Mn δ-manganese-oxide (left) and acid birnessite (middle and right). The minerals were reacted with As(III) at pH 4.5, 7.2, and 9.0. The oxidation of As(III) by the manganese-oxide produces As(V)

In this reaction, an H+ atom is consumed during the oxidation of As. In alkaline pH conditions, the result is the production of an H+ atom as seen in the reaction below:

Thus, at a more alkaline pH this reaction will proceed quickly toward the products in order to produce more H+ ions in an effort to reach equilibrium. The species of As present also changes within the pH range. Based on the pKa of As species, at pH 4.5 As(III) is present as H3AsO3° and As(V) as H2AsO4 −. At pH 7.2 the As(III) species is the same; however, As(V) is a nearly equal mixture of H2AsO4 − and HAsO3 2−. When the pH is increased to 9.0, As(III) exists as approximately 40 % H2AsO3 − and 60 % H3AsO3°, while As(V) is completely HAsO3 2−. Manganese-oxides also experience changes in chemical properties with pH alterations. As pH increases, the surface charge of Mn-oxides becomes increasingly negative. The point of zero charge for δ-MnO2 and acid birnessite occurs at pH 2.8 and 3.14, respectively, indicating the zeta potential of these minerals becomes increasingly negative as pH increases from 4.5 to 9.0 [1, 26]. These charge characteristics tend to promote oxidation of As(III) due to enhanced favorability of desorption of oxidized As(V) from reactive sites back into the solution [25]. However, this increased negative surface charge may result in more sorption of Mn(II) intermediates on the Mn-oxide surface, resulting in surface passivation and reduced As(III) oxidation.

The δ-MnO2 data in this study follow some of these assumptions as demonstrated in Fig. 2. The δ-MnO2 oxidized ~99 % of the As(III) in the first 5 min under all pHs. However, pH dependent differences were seen in the amount of sorbed As(V). The δ-MnO2 at pH 4.5 and pH 7.2 sorbed ~ 37 % of the As(V) before 5 min, while the δ-MnO2 at pH 9.0 sorbed ~20 % of the As(V) within 5 min. δ-MnO2 at pH 4.5 and 7.2 initially sorbed similar amounts of As(V); however, after 10 min the reaction at pH 4.5 had released ~9 % more As(V) into solution than the pH 7.2. The hypothesis that less sorption of As(V) would occur at higher pH was confirmed by the amount of total As in solution over the range of pHs in the δ-MnO2 experiments. The pH 4.5, 7.2, and 9.0 reactions had ~26, ~21, and ~6 % sorption of As(V), respectively, after 2 days. This was presumably caused by the increase in Mn(II) adsorption at higher pH, which Stone and Ulrich [27] also found.

The acid birnessite oxidized As(III) differently over the range of pH investigated. Within the first 5 min, the acid birnessite at pH 4.5 produced the most As(V), followed by the pH 7.2, and pH 9.0. However, between 15 and 30 min the reaction at pH 9.0 continued to increase and equaled the amount of As(V) produced by acid birnessite at pH 4.5. Despite the initially slow reaction at pH 9.0, the data mimic the typical trend in oxidation kinetics for acid birnessite. The lower overall reactivity of acid birnessite at pH 7.2 is expected because most Mn-oxides experience a dip in reactivity somewhere in the pH range. This point of lowest reactivity is related to the redox half reactions (H3AsO4 + H+) and (MnO2 + H+)/Mn2+ in acidic conditions with redox potentials of 0.56 and 1.23 V, respectively; and under alkaline conditions MnO2/(Mn(OH)2 + OH−) and AsO4 3−/(AsO2 − + OH−) with standard potentials of 0.1 and −0.71 V, respectively [25]. The pH where the lowest potentials of these two reactions is met determines the point where the Mn-oxides produce the least As(V). Additionally, in the acid birnessite reaction at pH 7.2 the As(III) was never completely oxidized and after 15 min–2 days ~ 1 ppm As(III) remained in solution. Unlike δ-MnO2, acid birnessite did not show significant As(V) sorption, and thus it reacted following the previous assumptions, with the reactions at pH 4.5 and 9.0 oxidizing all As(III) in solution to As(V). The data from each reaction fit well to a first-order kinetic model with r2 values >0.91 (Table 2). The observed rate coefficients for pH 4.5, 7.2, and 9.0 were 0.4326, 0.1326, and 0.2456 s−1, respectively, as demonstrated by the linear fitting of the natural log of As(III) concentration in Fig. 3. These data reinforce the idea of lowered Mn-oxide reactivity over the middle range of pH. The reaction was initially slower at pH 9.0, than pH 4.5, but eventually both reactions completely oxidized the As(III) in solution.

Effect of temperature on arsenic(III) oxidation kinetics on manganese-oxides

The kinetics of As(III) oxidation by δ-MnO2 and acid birnessite relative to temperature were determined by reacting the minerals with 1 mM As(III) at 10, 25, and 40 °C as seen in Fig. 4. The As(III) oxidation by δ-MnO2, with respect to varying temperature, appeared to be intuitively linked, with increasing temperature resulting in a faster oxidation of As(III). Additionally, a ~10 % increase in As(V) sorption by δ-MnO2 was seen by increasing the temperature from 10 or 25–40 °C. The 10, 25, and 40 °C reactions with 1 mM As all fit first-order reaction kinetics (Table 2). With the kobserved = 0.0026, 0.0027, and 0.0037 s−1, respectively. The fast step of this reaction occurs within the first 5 min, making it challenging to define with a limited temporal scale. Thus, the first 5 min were excluded for these calculations and the reported coefficients represent the second and slower step of the reaction [11]. As discussed previously, there are several reactions occurring during the oxidation of As(III) by δ-MnO2 and it truly fits a pseudo first-order kinetic model.

Effect of temperature on arsenic(III) oxidation by manganese-oxides: the influence of temperature on the oxidation of 1 mM arsenite by 1.82 mM δ-manganese-oxide (top) and acid birnessite (bottom). The minerals were reacted at 10, 25, and 40 °C at pH 7.2. The oxidation of As(III) (right) by a manganese-oxide produces As(V) (left)

The acid birnessite initially followed a similar trend, with increasing temperature the rate of reaction also increased. However, after 30 min the 25 and 40 °C reactions had produced the same amount of As(V). This may be due to the 40 °C reaction quickly proceeding with the first and fast step of As(III) oxidation and then slowly oxidizing the remaining As(III). All of the acid birnessite data fit well to a first-order kinetic model. The kobserved for the 10, 25, and 40 °C acid birnessite reactions based on the first-order model are 0.0043, 0.0131, and 0.0441 s−1, respectively (Table 2). The increase in reactivity with a higher temperature may be partially explained by the fact that with a rise in temperature the point of zero charge of the Mn-oxide’s surface decreases [28, 29]. This causes the surface of the Mn-oxide to become more negatively charged and in turn promotes the oxidation of As(III).

Effect of As(III) concentration on oxidation kinetics

Acid birnessite and δ-MnO2 were reacted with 100 μM, 1, and 10 mM As(III) to determine the minerals’ oxidative capacity and the rate of reaction under varying As concentrations (Fig. 5). With increasing As(III) concentration in solution the two Mn-oxides reacted somewhat differently. The δ-MnO2 was much more sensitive to increases in As(III) than the acid birnessite, but both minerals were able to oxidize less of the total As(III) in solution with increasing As(III) concentration. It is possible that there is much more surface passivation on δ-MnO2 with the byproducts Mn(II), Mn(III), and perhaps As(V) during the course of the As(III) oxidation reaction compared to acid birnessite [10]. At 100 μM and 1 mM As(III) concentrations, oxidation by δ-MnO2 initially produces more As(V) in solution than acid birnessite, but after 10 and 15 min, respectively, acid birnessite releases more As(V) into solution. After 30 min at 1 mM As(III), the acid birnessite generated more As(V) than δ-MnO2. At 10 mM As(III) acid birnessite produced much more As(V) than δ-MnO2 for the entire course of the reaction. The greatest difference in the amount of 10 mM As(III) oxidized is reached at 30 min when the δ-MnO2 and acid birnessite have reacted with ~8 and ~19 % of the As(III), respectively. Acid birnessite oxidation of 100 μM, 1, and 10 mM As(III) fit first-order kinetic models with kobserved of 0.1326, 0.0131, and 0.0143 s−1 respectively (Table 2). With increasing As(III) concentration the rate coefficient of the acid birnessite reaction rose from 100 μM to 1 mM As(III) and then stayed somewhat constant between 1 and 10 mM As(III) indicating the reaction may proceed faster with greater As(III) concentration up to a limit. The δ-MnO2 fast reaction reached near completion in <5 min for the 100 μM As(III) reaction, which was fitted to a first-order kinetic model with kobserved equal to 1.3684. The 1 mM and 10 mM As(III) reactions fit first-kinetic models from 5–90 to 5–60 min, respectively, with kobserved equal to 0.00234 and 0.0011 s−1, sequentially. The δ-MnO2, at 1.82 mM, may have reached its upper limit in oxidation between 10 and 1 mM As(III), as little increase in As(V) production was observed with a tenfold increase in As(III).

Experimental

Manganese-oxide synthesis

The δ-MnO2 was chosen for this study due to its high reactivity and structural similarity to biogenic Mn-oxides [4]. The low degree of stacking in the layered structure of δ-MnO2 is the signature of this type of hexagonal birnessite [30–34]. Synthesis procedures followed an altered method of Murray found in Zhu [34]. 250 mL of 0.15 M Mn(NO3)2·4H2O were added at 20 mL min−1 into a 250 mL solution of 0.1 M KMnO4 in 0.2 M NaOH [34]. The reaction was mixed well during the addition of Mn(NO3)2. The Mn solid was obtained through centrifugation and then washed with DI water to ensure purity. Only fresh δ-MnO2 was used.

Acid birnessite was synthesized by following the procedures in Zhu [34]. First, a concentrated solution of HCl totaling 65.4 mL was added at 1 mL per min into a 1 L 0.4 M solution of boiling KMnO−4. The reaction was stirred well during the addition of acid. The Mn solid was collected through centrifugation and washed with DI water several times, until the remaining KMnO4 was removed as indicated by a clear supernatant.

Hexagonal birnessite was synthesized through a modified procedure described by Zhu [34]. 1 g of random stacked birnessite was added to 100 mL of 0.1 M NaNO3. The pH of the solution was adjusted to 5.0 through the addition of 0.5 M HNO3 −. The pH was held constant through the use of a Metrohm pH stat. After 36 h of equilibrium, the Mn solid was centrifuged and washed several times to ensure purity.

Synthesis of random stacked birnessite was carried out using the procedure of Zhu [34], which was modified to exclude post-hydrothermal aging. Initially, 250 mL of 8 M NaOH and 250 mL of 0.4 M MnCl2 solutions were created using anoxic DI water and nitrogen gas was used to purge the solutions. The two solutions were cooled in a water bath to 0 °C before and during their mixing. The mixture of the two solutions was purged with nitrogen gas for the first half hour of the reaction, then a white pyrochroite [Mn(OH)2] suspension formed. After half an hour, the solution was vigorously mixed and aerated with oxygen gas for 5 h to oxidize the pyrochroite into random stacked birnessite, denoted by the formation of a black suspension. The suspension was then washed several times with DI water and stored.

Biogenic Mn-oxide was synthesized following the procedure of Zhu [34]. Pseudomonas putida strain GB-1 was cultured in 500 mL of Leptothrix discophora media in 2 L Erlenmeyer flasks at 30 °C and agitated at 200 rpm in a thermostatic shaker. Bacteria inoculums were created by culturing P. putida in media containing trace elements, mineral salts, and glucose for 12 h at 30 °C. After 36 h of cultivation, the Biogenic Mn-oxide was collected and centrifuged at 12,000 rpm, decanted and washed with DI water multiple times.

Batch reactions

The reactivity of Mn-oxides for As(III) was investigated with a series of batch reactions. All experiments were run with a background electrolyte of 10 mM NaCl, and unless otherwise indicated, were buffered to pH 7.2 with 5 mM 3-(N-morpholino)propanesulfonic acid (MOPS). The background electrolyte, MOPS buffer, Mn-oxide solution, and DI water were added to a volume of 250 mL in a 500 mL flask. All Mn-oxides were used at a final concentration of 1.82 mM. The experiments were started with the addition of As(III). The flasks were shaken at 120 rpm to facilitate constant mixing of the solution. Samples were taken in 4.5 mL aliquots and filtered with 0.20 μm sterile syringe filters upon collection. After the start of the reaction, samples were collected at 5, 10, 30 min, 1, 1.5, 3, 6, 12, 24, and up to 48 h. All reactions were simultaneously run in triplicate to ensure reproducibility.

Initially, acid birnessite, hexagonal birnessite, random stacked birnessite, δ-MnO2, and biogenic Mn-oxide were reacted under the parameters described above, with the addition of 100 μM As(III). The two most reactive Mn-oxides, acid birnessite and δ-MnO2, were selected for further experimentation. δ-MnO2 and acid birnessite reactions with As(III) concentrations of 1 and 10 mM, were also investigated. A series of temperature controlled experiments with these two Mn-oxides were completed utilizing a temperature controlled chamber under 10, 25, and 40 °C with 1 mM As(III). Further experimentation controlling pH of the reaction at 25 °C was done with a Metrohm pH stat titrator at pH of 4.5, 7.2, and 9.0 with 100 μM As(III). The As(III) data from each experiment were fit to zero-order, first-order, and second-order kinetic models and the model with the best fit was chosen to represent the reaction as shown in Fig. 3.

As analysis

The collected As(V) and As(III) from the batch reactions were filtered with 0.20 μm sterile syringe filters, diluted to an acceptable concentration, and then analyzed with liquid chromatography inductively coupled plasma mass spectrometry (LC-ICP-MS) for As(III) and As(V) in solution.

Conclusions

All five Mn-oxides were capable of oxidizing a substantial amount of As(III) into As(V) within 2 days and Mn-oxide reactivity was closely related to structure and vacancy site differences. Experiments with δ-MnO2 and acid birnessite showed the importance of pH, temperature, and As(III) concentration in affecting the kinetics of As(III) oxidation. These results have critical implications for understanding and predicting the reactivity of Mn-oxides and mobility of As in the environment.

The effect of temperature on the kinetics of As(III) oxidation is especially relevant and important for soil systems because of the temperature difference between the ambient environment and subsurface. The long term reactivity of Mn-oxides should be much lower in soil than under many experimental conditions because of decreased temperatures in soil relative to most laboratory experiments. A primary environmental concern of As is contamination in groundwater and understanding the kinetics of As oxidation under these conditions is essential to fully comprehend the potential for this contamination under different subsurface conditions. Groundwater temperature is innately linked to surface temperature, and thus the climate of the region will have a significant impact on the subsurface reactivity of Mn-oxides. In the tropics, Mn-oxides will be more reactive because the underground temperature is close to 25 °C, while the same reaction will proceed more slowly in the 10 °C conditions found along the Mid-Atlantic United States and in other temperate regions. Similarly, As fate and mobility in the environment can be predicted based on soil pH. In Bangladesh, the older alluvial sediments have a lower pH than the more recent deposits. Knowing As sorption on Mn-oxides is greater in acidic conditions than in alkaline environments indicates the older sediments will sorb more As from the contaminated groundwater. Wells can then be drilled strategically into regions with older sediment deposits to mediate the risk of arsenic imbibition. As discussed previously, Mn minerals experience a dip in reactivity under certain pHs and reactivity can be enhanced by adjusting pH. Remediation strategies for sites contaminated with redox sensitive metals can benefit from the results of this study by realizing that the oxidation capacity of Mn-oxides can be bolstered by adding sulfur or lime amendments to adjust soil pH. Finally, varying the concentration of As(III) showed that concentration can greatly impact a Mn-oxide’s ability to react. Some Mn-oxides have greater total oxidation capacities and can produce more As(V) under higher concentrations of As(III), such as acid birnessite. While other Mn-oxides can react much more rapidly and oxidize nearly all As(III) into As(V) in short times at lower Mn to As(III) concentrations. Manganese-oxides are one of the most important minerals in the soil environment with respect to reactivity. This study provides insight into their chemical behavior under varying environmental conditions and its impacts on redox sensitive compounds.

References

Sparks DL (2003) Environmental soil chemistry. Academic Press, San Diego

Lafferty BJ, Ginder-Vogel M, Sparks DL (2011) Arsenite oxidation by a poorly-crystalline manganese oxide. 3. Arsenic and manganese desorption. Environ Sci Technol 45:9218–9223

Tebo BM, Bargar JR, Clement BG, Dick GJ, Murray KJ, Verity R, Webb SM (2004) Biogenic manganese oxides: properties and mechanisms of formation. Annu Rev Earth Planet Sci 32:287–328

Villalobos M, Toner B, Bargar J, Sposito G (2003) Characterization of the manganese oxide produced by Pseudomonas putida strain MnB1. Geochim Cosmochim Acta 67:2649–2662

Toner B, Manceau A, Webb SM, Sposito G (2006) Zinc sorption to biogenic hexagonal-birnessite particles within a hydrated bacterial biofilm. Geochim Cosmochim Acta 70:27–43

Lafferty BJ, Ginder-Vogel M, Zhu M, Livi KJT, Sparks DL (2011) Arsenite oxidation by a poorly crystalline manganese oxide. 2. Results from X-ray absorption spectroscopy and X-ray diffraction. Environ Sci Technol 44:8467–8472

Scott MJ, Morgan JJ (1995) Reactions at oxide surfaces. 1. Oxidation of As(III) by synthetic birnessite. Environ Sci Technol 29:1898–1905

Dixit S, Hering JG (2003) Comparison of arsenic(V) and arsenic(III) sorption onto iron oxide minerals: implications for arsenic mobility. Environ Sci Technol 37:4182–4189

Tournassat C, Charlet L, Bosbach D, Manceau A (2002) Arsenic(III) oxidation by birnessite and precipitation of manganese(II) arsenate. Environ Sci Technol 36:493–500

Lafferty BJ, Ginder-Vogel M, Zhu M, Sparks DL (2010) Arsenite oxidation by a poorly crystalline manganese oxide. 1. Stirred flow experiments. Environ Sci Technol 44:8460–8466

Manning BA, Fendorf SE, Bostick B, Suarez DL (2002) Arsenic(III) oxidation and arsenic(V) adsorption reactions on synthetic birnessite. Environ Sci Technol 36:976–981

Ravenscroft P, Brammer H, Richards K (2009) Arsenic pollution: a global synthesis. Wiley, West Sussex

Singh R, Singh S, Parihar P, Singh VP, Prasad SM (2015) Arsenic contamination, consequences and remediation techniques: a review. Ecotoxicol Environ Saf 112:247–270

Argos M, Kalra T, Rathouz PJ, Chen Y, Pierce B, Parvez F, Islam T, Ahmed A, Rakibuz-Zaman M, Hasan R, Sarwar G, Slavkovich V, van Geen A, Graziano J, Ahsan H (2010) Arsenic exposure from drinking water, and all-cause and chronic-disease mortalities in Bangladesh (HEALS): a prospective cohort study. Lancet 376:252–258

Gerrard J (1992) Soil geomorphology. Chapman & Hall, London

Franzblau RE, Weisener CG, Daughney CJ (2013) Selenate sorption onto bacteria-mineral composites during the progressive addition of Fe(II). Gldschmdt 23:1107

Jones LC, Lafferty BJ, Sparks DL (2012) Additive and competitive effects of bacteria and Mn oxides on arsenite oxidation kinetics. Environ Sci Technol 46:6548–6555

Ginder-Vogel M, Landrot G, Fischel JS, Sparks DL (2009) Quantification of rapid environmental redoxprocesses with quick-scanning X-ray absorption spectroscopy (Q-XAS). Proc Natl Acad Sci USA 106:16124–16128

Zhang W, Singh P, Issa TB (2011) Arsenic(III) remediation from contaminated water by oxidation and Fe/Al Co-precipitation. JWARP 3:655–660

Chen JP (2012) Decontamination of heavy metals: processes, mechanisms, and applications. CRC Press, Boca Raton

Tang Y, Webb SM, Estes ER, Hansel CM (2014) Chromium(III) oxidation by biogenic manganese oxides with varying structural ripening. Environ Sci Process Impacts 16:2127–2136

Learman DR, Wankel SD, Webb SM, Martinez N, Madden AS, Hansel CM (2011) Coupled biotic-abiotic Mn(II) oxidation pathway mediates the formation and structural evolution of biogenic Mn oxides. Geochim Cosmochim Acta 75:6048–6063

Bargar JR, Tebo BM, Bergamann U, Webb SM, Glaetzel P, Chiu VQ, Villalobos M (2005) Biotic and abiotic products of Mn(II) oxidation by spores of the marine bacillus sp. strain SG-1. Am Miner 90:143–154

Webb SM, Tebo BM, Bargar JR (2005) Structural influences of sodium and calcium ions on biogenic manganese oxides produced by the marine bacillus sp., strain SG-1. Geomicrobiol J 22:181–193

Feng X, Zu Y, Tan W, Liu F (2006) Arsenite Oxidation by three types of manganese oxides. J Environ Sci 18:292–298

Puppa LD, Bordas F, Komarek M, Bollinger JC, Jous-sein E (2013) Adsorption of copper, cadmium, lead and zinc onto a synthetic manganese oxide. J Colloid Interface Sci 399:99–106

Stone AT, Ulrich HJ (1989) Kinetics and reaction stoichiometry in the reductive dissolution of manganese(IV) dioxide and co(III) oxide by hydroquinone. J Colloid Interface Sci 132:509–522

Scott MJ (1991) Kinetics of adsorption and redox processes on iron and manganese oxides: reaction of As(III) and Se(IV) at goethite and birnessite surfaces. Environmental Quality Laboratory California Institute of Technology, Pasadena

Machesky ML (1990) Influence of temperature on ion adsorption by hydrous metal oxides. In: Melchior DC, Bassett RL (eds) Chemical modeling of aqueous systems II, vol 416. American Chemical Society, Washinton, DC, pp 282–292

Silvester E, Manceau A, Drits VA (1997) Structure of synthetic monoclinic Na-rich birnessite and hexagonal birnessite 2. Results from chemical studies and EXAFS spectroscopy. Am Miner 82:962–978

Morgan JJ, Stumm W (1964) Colloid-chemical properties of manganese dioxide. J Colloid Sci 19:347–359

Tan W, Lu S, Liu F, Feng X, He J, Koopal LK (2008) Determination of the point-of-zero charge of manganese oxides with different methods including an improved salt titration method. Soil Sci 173:277–286

Drits VA, Silvester E, Gorshkov AI, Manceau A (1997) Structure of synthetic monoclinic Na-rich birnessite and hexagonal birnessite. 1. Results from X-ray diffraction and selected area electron diffraction. Am Miner 82:946–961

Mengqiang Zhu (2010) Sturcture and reactivity study of biotic and abiotic poorly crystalline manganese oxides. PhD thesis. University of Delaware, Department of Plant and Soil Sciences

Authors’ contributions

MHHF conducted each set of batch reactions, analyzed the samples, and was the primary author of all sections of the manuscript. JSF assisted in approximately one-third of the batch reactions and in writing the abstract section of the manuscript. BJL helped to formulate the ideas behind this project and gave intellectual assistance, support, and provided oversight throughout the experimental process. DLS oversaw the development of this project and assisted in formulating the ideas behind the experiments. All authors read and approved the final manuscript.

Acknowledgements

The authors thank Caroline Golt and Gerald Hendricks for laboratory assistance. We also extend our gratitude to the three reviewers for their critical critique of the paper and suggestions. MHHF and JSF thank Mike Zhu (University of Wyoming) for teaching essential skills required to culture Pseudomonas putida strain GB-1 and form biogenic manganese-oxide. Support for this manuscript was provided by Delaware EPSCoR with funds from the National Science Foundation Grant EPS-0814251 and the State of Delaware.

Compliance with ethical guidelines

Competing interests The authors declare they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Fischel, M.H.H., Fischel, J.S., Lafferty, B.J. et al. The influence of environmental conditions on kinetics of arsenite oxidation by manganese-oxides. Geochem Trans 16, 15 (2015). https://doi.org/10.1186/s12932-015-0030-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12932-015-0030-4