Abstract

Background

To compare the solution on the cyclic fatigue resistance of EdgeTaper Platinum (ETP) instruments with that of ProTaper Gold (PTG) in the presence of ethylenediaminetetraacetic acid (EDTA) or sodium hypochlorite (NaOCl) irrigating solutions.

Methods

Sixty PTG and 60 ETP instruments with the same size (#25) and taper (8%) were tested under 17% EDTA, 5.25% NaOCl, or distilled water (n = 20 each). Cyclic fatigue was tested using artificial canals that were milled in stainless steel blocks using a laser micromachining technique. The canals had a curvature angle of 60 and a curvature radius of 5 mm. The center of maximum curvature was set at 5 mm from the instrument tip. The block of artificial canals was stabilized inside a container that was filled with one of the tested solutions. The temperature was fixed at 37 °C with a tolerance limit of 1 °C. The number of cycles to fracture (NCF) was calculated and the fractured surfaces were examined using a scanning electron microscope. All statistical analyses were performed using SPSS software Version 20 (IBM-SPSS Inc., Chicago, IL) at a confidence level of 95%.

Results

ETP showed higher NCF than PTG in any of the tested solutions (P < 0.05). Within each group, NaOCl drastically decreased the NCF compared to water and EDTA (P < 0.05) and changing the solution from distilled water to EDTA did not affect the fatigue resistance (P > 0.05).

Conclusions

ETP showed improved cyclic fatigue performance compared to PTG in all tested irrigating solutions. EDTA can be used in combination with NiTi instruments during canal instrumentation without compromising the cyclic fatigue resistance of PTG and ETP instruments. However, NaOCl drastically decreased the NCF.

Similar content being viewed by others

Background

Endodontics has grown significantly over the past years with the significant development in manufacturing nickel–titanium (NiTi) instruments which led to improved root canal treatment outcomes [1]. These instruments have gained wide popularity ever since due to their superior characteristics derived from inherently super-elastic with excellent shape memory [2]. These properties enable the rotary NiTi instruments to prepare curved canals quicker with fewer procedural errors [3]. However, the risk of instrument separation is still a concern among clinicians which is considered as the most common procedural mishap [4]. There are two identified reasons for instrument separation: torsional overload and cyclic fatigue [5]. Cyclic fatigue develops when a NiTi file undergoes tensile-compressive stresses as a result of repetitive motions during the root canal treatment [5]. Torsional overload may occur from apically directed pressure and wedging the files’ tip into the canal overzealously [5].

The irrigating solution is used in endodontics to serve a variety of chemical, biological, and mechanical functions which are crucial for effective root canal treatment [6]. Canal instrumentation should always be carried out under copious irrigation as it is never advisable to instrument a dry canal [7]. However, the irrigating solution comes in contact with NiTi instruments which might induce instrument corrosion and deformation accelerating instrument's fatigue failure [8, 9]. Previous studies reported that irrigating solutions influence the performance of endodontic files [10,11,12,13,14,15,16,17,18,19]. The most commonly used irrigating solutions are sodium hypochlorite (NaOCl) and ethylenediaminetetraacetic acid (EDTA).

Thermal treatment is a technology used to make the phase transformation temperature close to the intracanal temperature with a high austenite finish temperature approaching 50 °C [20]. The high transformation temperature indicates that the thermally treated instrument will have some degree of martensite at a simulated intracanal temperature, and thus, greater the martensitic behavior with improved resistance to cyclic fatigue [21], flexibility [22], and fatigue crack growth resistance [23]. ProTaper Gold (PTG; Dentsply Sirona, Ballaigues, Switzerland) and EdgeTaper Platinum (ETP; EdgeEndo, Albuquerque, NM, USA) are NiTi instruments which have been manufactured with thermal treatment technology [24]. Both have the same design with a convex triangular cross-section. A previous study concluded that ETP had excellent resistance to cyclic fatigue compared with PTG when tested in distilled water [24].

In clinical practice, the instrument is often used while the canal is flooded with irrigating solutions that could have an effect on the instrument performance as shown previously on other instruments systems [10,11,12,13,14,15,16,17,18,19]. Because no data are available on the effect of irrigating solutions on ETP instrument’s cyclic fatigue resistance, the current study was undertaken to investigate the cyclic fatigue resistance of ETP file instrument in the presence of EDTA, NaOCl, or distilled water and compare it with PTG file instrument. The null hypothesis of the present study was that the tested irrigating solutions has similar effects on the cyclic fatigue resistance difference of ETP and PTG instruments.

Methods

Sixty PTG and 60 ETP instruments were used in this study. All the instruments were F2 (25/0.08) and 25-mm long. All the instruments were inspected for defects and deformities at 13.6X magnification (Zeiss Pico; Carl Zeiss MediTec, Dublin, CA); no instrument was excluded. Each system was divided equally and randomly into three groups (n = 20 per group) based on the used irrigating solution; 17% EDTA, 5.25% NaOCl, or distilled water.

Cyclic fatigue resistance experiment

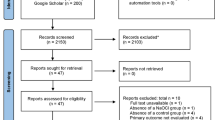

Cyclic fatigue resistance was performed using artificial canals that were milled in stainless steel blocks using a laser micromachining technique (Fig. 1). The canals had a curvature angle of 60° and a curvature radius of 5 mm as described by Pruett et al. [25]. The center of maximum curvature was set at 5 mm from the instrument tip. Dimensions of the canals were larger than the dimensions of the F2 instrument by a 0.1-mm width [26]. A glass bar was used to cover the artificial canal to avoid instrument slippage and to visualize the instruments during rotation until it fractured. The block of artificial canals was stabilized inside a container that was filled with 17% EDTA, 5.25% NaOCl, or distilled water. The solution’s temperature was fixed at 37 with a tolerance limit of 1 °C as evident with a thermometer to simulate the body temperature. The endodontic rotary motor handpiece (TCM Endo III; Nouvag AG, Lake Constance, Switzerland) was mounted on a device that allowed reproducible and fixed positioning of the instrument. Each instrument was inserted inside the canal by 19 mm from its tip. The instrument was rotated at 300 revolutions per minute (rpm) until fracturing occurred. The time to fracture was recorded once the fracture was noticed audibly and visually by the aid of video recording. The number of cycles to fracture (NCF) was calculated using the following formula: NCF = rpm X time to fracture (in minutes). The artificial canal was replaced when any sign of corrosion was noticed. The fractured fragment's length was measured (in mm) using a digital stereomicroscope (Hirox-USA Inc, Hackensack, NJ).

Scanning electron microscopy

From each group, three fractured instruments were randomly selected and cleaned with absolute alcohol in an ultrasonic bath for 3 min to remove debris on the surface. The fractured surfaces were observed under a scanning electron microscope (6360LV Scanning Electron Microscope; JEOL, Tokyo, Japan) to look for the topographic features of the fractured surface at a magnification of 180X.

Statistical analysis

Since the data distribution was normal (Shapiro–Wilk test; P > 0.05), the data were analyzed statistically using one-way analysis of variance (ANOVA) and least significant difference (LSD) tests to compare different solutions within each experimental system. Within each solution, the experimental systems were compared using an independent t-test. The length of the fractured segment was analyzed using the Kruskal–Wallis test. Statistical analyses were conducted by using SPSS 20 software (IBM-SPSS Inc., Chicago, IL) at a confidence level of 95%.

Results

ETP showed higher NCF than PTG in any of the tested solutions (P < 0.05). In each system, LSD tests showed that changing the solution from distilled water to EDTA did not affect the fatigue resistance (P > 0.05). However, NaOCl drastically decreased the NCF, compared to water and EDTA (P < 0.05) (Table 1). The scanning electron microscopy showed common features of cyclic fracture in the fractured surfaces of ETP and PTG instruments tested in different solutions, including the presence of fatigue striations and crack initiation area (Fig. 2). None of the tested surfaces showed any indication of corrosion in 17% EDTA, 5.25% NaOCl, or water (Fig. 2). The lengths of fractured fragments ranged from 4.15 to 4.60 mm (Kruskal–Wallis test; P > 0.05).

Scanning electron microscopic images of the ProTaper Gold (PTG) and EdgeTaper Platinum (ETP) instruments after cyclic fatigue tested in different solutions. A PTG in EDTA, B PTG in NaOCl, C PTG in distilled water, D EPT in EDTA, E EPT in NaOCl, and F EPT in distilled water. "a" corresponds to the fatigue striation area, and "b" corresponds to the fast fracture zone with dimples

Discussion

The current study examined the effect of EDTA and NaOCl on the cyclic fatigue resistance of ETP and PTG instruments when subjected to repetitive cyclic motions in an artificial canal at a temperature of 37 °C. In this study, ETP showed higher cyclic fatigue resistance than PTG in the tested solutions. The negative effect of NaOCl was evident in both groups; however, the fractographic appearance of ETP and PTG instruments cyclically fatigued in EDTA was similar to those fatigued in NaOCl and distilled water.

EDTA is used as a chelating agent and lubricant which comes in contact with the instrument during canal instrumentation [27]. This study showed that it has a negligible effect on the cyclic fatigue resistance of heat-treated instruments. Similarly, previous studies showed that EDTA did not have any effect on the cyclic fatigue resistance of other instruments [11, 14, 19]. However, another study reported that EDTA reduced the cyclic fatigue resistance of instruments studied after 3 min of immersion [13]. Moreover, this study also showed that NaOCl harmed the cyclic fatigue resistance of PTG and ETP instruments. The instrument was in brief contact with NaOCl; however, there was an apparent reduction in the NCF. This might be due to the developed corrosive zones, which could reduce the resistance to cyclic fatigue of the instrument [8, 12, 15, 18]. This is consistent with previous studies [10, 12]. However, other studies revealed that NaOCl did not reduce the cyclic fatigue resistance of other instruments [11, 13, 14, 19, 28]. These contradictory findings could be explained by differences in the implemented study methodology. The previous studies immersed the instruments in NaOCl or EDTA solution for different periods were then subjected to cyclic fatigue testing in canals filled with an oil lubricant. In our study, the instruments were not immersed before the test. Rather, they were subjected to cyclic fatigue by rotating inside an artificial canal which was filled with the tested solution at simulated body temperature. This would be more clinically relevant since it mimics the clinical condition. Besides that, the tested instruments in the abovementioned studies have different characteristics (alloy properties, instrument design, motion kinematics, and rotational speed) which might play a role in the performance of endodontic instruments in these tested solutions [11,12,13,14,15, 18, 19, 28, 29].

The ETP was introduced with a design similar to that of PTG and ProTaper Universal. The PTG was shown to have better resistance to cyclic fatigue and flexibility compared with the ProTaper Universal [20, 21]. However, it did not show improved resistance to torsional fatigue [30]. In this study, the ETP proved to have better cyclic fatigue resistance than PTG by almost 50% in any of the tested solutions. Consistently, a previous study done in water stated that ETP exhibited greater resistance to cyclic fatigue at simulated body temperature [24]. Although the tested systems are manufactured with heat treatment, have the same design and are used in continuous rotation at the same speed, their cyclic fatigue performance was different. This might be explained by differences in the thermo-mechanical properties of the systems as a result of manufacturers' variations and brand specification of heat-treated alloy. Further studies are required to investigate the metallurgical properties of ETP.

Clinically, the alternating use of NaOCl and EDTA is a popular regimen since it enhances the antimicrobial performance [31] and the removal of the smear layer [32]. However, this regimen might show a synergistic effect on the instrument's cyclic fatigue resistance. Conducting studies on NiTi instrument fracture in the presence of commonly used endodontic irrigating solutions would ensure a better imitation of clinical settings. This study used a high concentration of NaOCl which might be responsible for reducing the lifespan of the tested instruments [28]. Testing the instruments at lower concentrations might be more favorable for instrument performance. Therefore, further cyclic fatigue studies are needed to address this issue.

The utilized artificial canals were fabricated accurately using a laser micromachining technology to be similar to the tested instruments and to avoid differences in instrument positioning that might cause a discrepancy in the area of the fracture and consequently affect the cyclic fatigue measurement. It is worth mentioning that our results showed that the instruments fractured at the most curved areas with the range of 4.15–4.60 mm. This is consistent with previous results [10, 24] and confirmed the precise trajectory and positioning of the instruments during the test.

Changes in the transformation and metallurgical behavior are effective for exhibiting improvement in the performance of NiTi instruments [33]. Heat treatment is one of the approaches utilized to improve the fatigue resistance of instruments [33]. To reflect the actual clinical setting, the experimental temperature should be close to the intracanal temperature since it has been shown to have a major influence on the cyclic resistance behavior of conventional austenitic NiTi instruments as well as newly introduced NiTi instruments with special treatments [10, 34]. Moreover, a little decrease in the surrounding temperature or minimal stress application triggers the phase transformation in heat-treated instruments [20, 34]. For that, the current study tested the cyclic fatigue resistance of heat-treated instruments at simulated body temperature [35].

The tested F2 instruments have a variable taper changing over the length of its cutting blades. It shows 8% taper in the apical 3 mm of the instrument and regressively changes as we move upwards. This might not reflect the performance of other instruments with constant taper.

Conclusions

Within the limitations of this laboratory study, ETP showed improved cyclic fatigue performance compared to PTG in all tested irrigating solutions. EDTA can be used in combination with NiTi instruments during canal instrumentation without compromising the cyclic fatigue resistance of PTG and ETP instruments. However, NaOCl drastically decreased the NCF of both systems.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- PTG:

-

ProTaper Gold

- NiTi:

-

Nickel–titanium

- ETP:

-

EdgeTaper Platinum

- NCF:

-

Number of cycles to fracture

- NaOCl:

-

Sodium hypochlorite

- EDTA:

-

Ethylenediaminetetraacetic acid

- LSD:

-

Least significant difference

References

Hülsmann M, Peters OA, Dummer PM. Mechanical preparation of root canals: shaping goals, techniques and means. Endod Top. 2005;10:30.

Walia H, Brantley WA, Gerstein H. An initial investigation of the bending and torsional properties of nitinol root canal files. J Endod. 1988;14:346.

Pettiette MT, Metzger Z, Phillips C, Trope M. Endodontic complications of root canal therapy performed by dental students with stainless-steel K-files and nickel–titanium hand files. J Endod. 1999;25:230.

Spanaki-Voreadi AP, Kerezoudis NP, Zinelis S. Failure mechanism of ProTaper Ni-Ti rotary instruments during clinical use: fractographic analysis. Int Endod J. 2006;39:171.

Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel–titanium files after clinical use. J Endod. 2000;26:161.

Haapasalo M, Shen Y, Qian W, Gao Y. Irrigation in endodontics. Dent Clin North Am. 2010;54:291.

Haapasalo M, Shen Y, Wang Z, Gao Y. Irrigation in endodontics. Braz Dent J. 2014;216:299.

Peters OA, Roehlike JO, Baumann MA. Effect of immersion in sodium hypochlorite on torque and fatigue resistance of nickel–titanium instruments. J Endod. 2007;33:589.

Bonaccorso A, Tripi TR, Rondelli G, Condorelli GG, Cantatore G, Schäfer E. Pitting corrosion resistance of nickel–titanium rotary instruments with different surface treatments in seventeen percent ethylenediaminetetraacetic acid and sodium chloride solutions. J Endod. 2008;34:208.

Alfawaz H, Alqedairi A, Alsharekh H, Almuzaini E, Alzahrani S, Jamleh A. Effects of sodium hypochlorite concentration and temperature on the cyclic fatigue resistance of heat-treated nickel–titanium rotary instruments. J Endod. 2018;44:1563.

Uslu G, Özyürek T, Yılmaz K, Plotino G. Effect of dynamic immersion in sodium hypochlorite and EDTA solutions on cyclic fatigue resistance of waveone and waveone gold reciprocating nickel–titanium files. J Endod. 2018;44:834.

Cheung GSP, Darvell BW. Low-cycle fatigue of rotary NiTi endodontic instruments in hypochlorite solution. Dent Mater. 2008;24:753.

Pedullà E, Franciosi G, Ounsi HF, Tricarico M, Rapisarda E, Grandini S. Cyclic fatigue resistance of nickel–titanium instruments after immersion in irrigant solutions with or without surfactants. J Endod. 2014;40:1245.

Erik CE, Özyürek T. Effects of etidronate, NaOCl, EDTA irrigation solutions and their combinations on cyclic fatigue resistance of nickel–titanium single-file rotary and reciprocating instruments at body temperature. Odontology. 2019;107:190.

Shen SY, Qian W, Abtin H, Gao Y, Haapasalo M. Effect of environment on fatigue failure of controlled memory wire nickel–titanium rotary instruments. J Endod. 2012;38:376.

Pedullà E, Benites A, La Rosa GM, Plotino G, Grande NM, Rapisarda E, et al. Cyclic fatigue resistance of heat-treated nickel–titanium instruments after immersion in sodium hypochlorite and/or sterilization. J Endod. 2018;44:648.

Cheung GS, Shen Y, Darvell BW. Effect of environment on low-cycle fatigue of a nickel–titanium instrument. J Endod. 2007;33:1433.

Pedullà E, Grande NM, Plotino G, Pappalardo A, Rapisarda E. Cyclic fatigue resistance of three different nickel–titanium instruments after immersion in sodium hypochlorite. J Endod. 2011;37:1139.

Cai J, Tang X, Ge J. Effect of irrigation on surface roughness and fatigue resistance of controlled memory wire nickel–titanium instruments. Int Endod J. 2017;50:718.

Hieawy A, Haapasalo M, Zhou H, Wang ZJ, Shen Y. Phase transformation behavior and resistance to bending and cyclic fatigue of ProTaper Gold and ProTaper universal instruments. J Endod. 2015;41:1134.

Elnaghy AM, Elsaka SE. Mechanical properties of ProTaper Gold nickel–titanium rotary instruments. Int Endod J. 2016;49:1073.

Jamleh A, Sadr A, Nomura N, Jamleh A, Sadr A, Nomura N, Ebihara A, Yahata Y, Hanawa T, et al. Endodontic instruments after torsional failure: nanoindentation test. Scanning. 2014;36:437.

De Azevedo Bahia MG, Fonseca Dias R, Buono VT. The influence of high amplitude cyclic straining on the behaviour of superelastic NiTi. Int J Fatigue. 2006;28:1087.

Jamleh A, Alghaihab A, Alfadley A, Alfawaz H, Alqedairi A, Alfouzan K. Cyclic fatigue and torsional failure of EdgeTaper Platinum endodontic files at simulated body temperature. J Endod. 2019;45:611.

Pruett JP, Clement DJ, Carnes DL Jr. Cyclic fatigue testing of nickel–titanium endodontic instruments. J Endod. 1997;23:77.

Alqedairi A, Alfawaz H, Bin Rabba A, Almutairi A, Alnafaiy S, Khan MM. Failure analysis and reliability of Ni–Ti based dental rotary files subjected to cyclic fatigue. Metals. 2018;8:36.

Chandler N, Chellappa D. Lubrication during root canal treatment. Aust Endod J. 2019;45:106.

Huang X, Shen Y, Wei X, Haapasalo M. Fatigue resistance of nickel–titanium instruments exposed to high-concentration hypochlorite. J Endod. 2017;43:1847.

Özyürek T, Gündoğar M, Uslu G, Yılmaz K, Staffoli S, Nm G, et al. Cyclic fatigue resistances of Hyflex EDM, WaveOne gold, reciproc blue and 2shape NiTi rotary files in different artificial canals. Odontology. 2018;106:408.

Alqedairi A, Alfawaz H, Abualjadayel B, Alanazi M, Alkhalifah A, Jamleh A. Torsional resistance of three ProTaper rotary systems. BMC Oral Health. 2019;19:124.

Soares JA, Roque de Carvalho MA, Cunha Santos SM, Mendonça RM, Ribeiro-Sobrinho AP, Brito-Júnior M, et al. Effectiveness of chemomechanical preparation with alternating use of sodium hypochlorite and EDTA in eliminating intracanal Enterococcus faecalis biofilm. J Endod. 2010;36:894.

Silveira LF, Silveira CF, Martos J, de Castro LA. Evaluation of the different irrigation regimens with sodium hypochlorite and EDTA in removing the smear layer during root canal preparation. J Microsc Ultrastruct. 2013;1:51.

Yahata Y, Yoneyama T, Hayashi Y, et al. Effect of heat treatment on transformation temperatures and bending properties of nickel titanium endodontic instruments. Int Endod J. 2009;42:621.

Huang X, Ackland GJ, Rabe KM. Crystal structures and shape-memory behaviour of NiTi. Nat Mater. 2003;2:307.

Jamleh A, Yahata Y, Ebihara A, Atmeh AR, Bakhsh T, Suda H. Performance of NiTi endodontic instrument under different temperatures. Odontology. 2016;104:324.

Acknowledgements

The authors thank College of Dentistry Research Center, King Saud University, for their support in conducting this project (IR0322).

Funding

Not funded.

Author information

Authors and Affiliations

Contributions

HA and AA designed and conducted the experiment, and wrote and edited the manuscript. MA, NA and SA participated in conducting the experiment. AJ analyzed the data statistically and wrote and edited the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Alfawaz, H., Alqedairi, A., Alhamdan, M. et al. Effect of NaOCl and EDTA irrigating solutions on the cyclic fatigue resistance of EdgeTaper Platinum instruments. BMC Oral Health 22, 195 (2022). https://doi.org/10.1186/s12903-022-02215-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12903-022-02215-0