Abstract

Potable water is always a need of every human being in the world. Only one third of water is potable water, and two thirds of water is saline water, which is not used for drinking purposes. Solar still is a device, which converts the saline or brackish water into drinkable water. Here, in place of saline water, industrial wastewater is used to convert potable water. In this research work, three solar stills have developed by locally available materials and tested in climate conditions of Mehsana (latitude of 23°59′ and the longitude of 72°38′). Among three solar stills, two solar stills are consist of floating plates like aluminum and galvanized iron. Third solar still that is used as a reference solar still is called a conventional solar still. Three-month research showed that solar still, consists of aluminum floating plate, gave considerable daily distillate as well as cumulative output compared with galvanized iron floating plate solar still as well as conventional solar still. Hence, the performance of solar still could increase by the use of aluminum floating plate, which can be used as an energy absorbing plate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

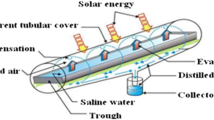

Solar desalination is a process of separation of pure water from saline water by the use of solar energy. The use of solar still is a simple and cheap method to obtain potable water. A conventional solar still has consisted of a black painted basin for holding the saline water and receiving solar radiation. Phase equilibrium has existed between the saline water and the air over it. Hence, the air over the water surface has been in saturated condition. Increasing of saline water temperature has caused the increase of partial pressure of water vapor at the water surface. The partial pressure of water vapor at the bottom of the glass cover has been very low as the temperature at the bottom of the glass cover has been lower than that of the water surface. The temperature difference between the water and glass cover is the partial pressure of water vapor transferring water vapor from the saline water surface to the glass cover. The still has been insulated with insulating material to reduce heat losses from the bottom as well as on the sides of the solar still. The rate of evaporation of water vapor from the water surface depends on the rate of condensation of water vapor in the glass cover and temperature difference between the saline water and glass cover.

Solar radiation can be used to distill and collect the drinking water, which is essential for the daily survival both at sea and in the deserts. It is light weight, compact, and easy to use. Also, this important and necessary piece of survival equipment has been used by the military for many years. The high increase of the earth’s population by years has resulted in a large rise demand for potable water [1]. Added to that, problems of industrial and sewage pollutants to rivers, lakes, and groundwater exist. Solar distillation system will be one of the beneficial options for a short term solution for the needy arid communications facing shortage of potable water. Solar still is dependant on the level of solar radiation available. This level is in turn dependent on the location, season, and weather conditions [2].

Solar stills have two important features: technological simplicity and exploitation of a free heat source such as the sun. However, their productivity is relatively small, and throughout their operational history, various attempts even via relatively complex structures have been made to enhance their performance [3–7].

There are many different designs of solar stills that have been used by different researchers. They can be categorized in two systems: passive solar still and active solar still [7–12]. Many researchers concentrated on the factors affecting the still productivity, using the experimental techniques such as Al-Hayek and Bardan [5], Naim et.al. [8], Tripathi and Tiwari [9], Meukam et.al. [10], Nafey et.al. [11], Voropolus et.al. [12], and Madani and Zaki [13]. The effect of different designs of solar stills on yield has been conducted by Al-Hayek and Bardan [5]. They found that the productivity of asymmetric greenhouse-type solar still is more efficient. The output from the asymmetric-type solar still is 20 % more than the symmetric-type solar still. Also, they concluded that the water depth and solar radiations are major factors of the solar still to improve the productivity.

Naimet.al. [8] proved that the used of charcoal particles bed increases the productivity by 15 % over the wick-type solar stills. Nafeyet.al. [11] concluded that their experimental work using black rubber and black gravels within a single-sloped solar still as a storage medium, the black gravel, absorbs and releases the incident solar radiation faster than the black rubber; and also, they concluded that the black gravel of 20 to 30 mm increases the productivity by 19 % at conditions of 20 L of saline water and glass cover of 15°. Madaniand Zaki [13] used soot powder as absorber material instead of black painted concrete base to reduce the cost of productivity. They found that removing the basin’s insulation reduced the productivity by 13 % to 17 %. Voropoluset.al. [12] experimentally investigated that the behavior of a solar still is coupled with hot water storage tank. They showed that the coupling system led to higher distilled output. Tripathi and Tiwari [9] studied that the effect of different water depths in the basin in the heat and mass transfer coefficient between water and condensing cover depends significantly on the water depth in the basin.

From the above literature reviews, it confirms that solar still is a very important device to convert brackish water into drinkable water. Main aim of this present study is to evaluate the effect of various energy absorbing plates in order to improve the distillate output of solar still through improvement in thermal conductivity. These plates are aluminum and copper plates in climate conditions of Mehsana Gujarat.

Experimental setup

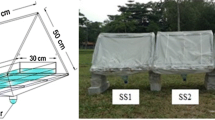

In this research work, three solar stills were designed and fabricated to study and compare the performance of the solar stills, as shown in Figure 1. The first one is a solar still having aluminum plate, and the second is a solar still having galvanized iron plate, while the third is a conventional solar still. The conventional still (a single basin) has a basin area of 1 m2 (50 × 200 cm). The still is made of iron sheets (2.5-mm thick). The whole basin surfaces are coated with black paint from inside to increase the absorptivity. Also, the still is insulated from the bottom to the sidewalls with sawdust 5-cm thick to reduce the heat loss from the still to the atmosphere. The insulation layer is supported by a wooden frame. The basin is covered with a glass sheet of 3-mm thick inclined at nearly 30° horizontally. Solar stills put on the terrace of ‘GeetanjaliSociety’, Mehsana. It has a latitude and longitude of Egypt (23°43′N,72°37′E) to maximize the amount of incident solar radiation and increases distillate output. The whole experimental setup is kept in the south direction to receive maximum solar radiation throughout the year.

Feed water tank of 50 × 50 × 50 cm3 is used to feed water to all solar stills. The feed water tank is connected to the mainline which is divided into three feed waterlines. A flow control valve is integrated at each line inlet in order to regulate the flow rate of water. The experimental setup is suitably instrumented to measure the temperatures at different points of the still (brine, absorber, and glass cover temperatures), total solar radiation, and the amount of distillate water. The temperatures have been measured using calibrated copper constantan-type thermocouples which were integrated with a modeler programmable logic control to measure all temperatures of the solar stills at the same time. The solar radiation intensity is measured instantaneously by a solarimeter. The digital airflow/volume meter is used to measure the wind velocity. Table 1 shows the different instruments as well as their accuracies used in experiment with solar stills.

Procedure

Experiments of solar stills were conducted at Geetanjali Society, Mehsana, Gujarat and carried out from 9 a.m. to 8 p.m. during July 2011. The solar radiation, atmospheric temperature, basin temperature, glass temperature, and distillate water were measured every 1 h for maintaining steady state conditions. However, the accumulated productivity during the 24 h is also measured in each experiment. All measurements were performed to evaluate the performance of the stills under the climate conditions of Mehsana. During the experiments, the ambient climatic conditions (solar radiation, ambient temperature, and wind velocity) were also measured.

Saline water in still is heated by solar radiation. The water vapor formed is condensed at the inner glass surface, and the water droplets are glided along the glass. The condensed water is collected in a calibrated flask. The depth of the saline water in the solar stills is maintained constant manually using the feed water tank and control valves. The present experimental study aims to study the effect of still surface area variation on fresh water productivity and the efficiency of single-slope basin solar stills.

Results & discussion

Depending upon the weather conditions of Mehsana, Gujarat, the wind speed is varied from 4.5 to 7 m/s during the month of March as well as April, and 1.5 to 4.5 m/s at different days of June. Variation of solar insolation versus time (hour) is shown in Figure 2. It remains the same for all solar stills because the solar insolation incident on all solar stills is equal. Figure 3 shows the basin water temperatures of all solar stills versus time (hour). It is shown that temperatures at all points increased as the time increases until at maximum value during the afternoon (because maximum solar radiation falls on earth surface during the afternoon, hence, the maximum value is reached in the afternoon).It is also observed that the maximum value in basin temperature is reached during the period of 3:00 p.m. to 4 p.m. for all solar still due to great availability of solar radiation as well as warming of solar still from early morning to afternoon. It also shows that highest temperature is gained by solar still having aluminum plate compared with solar still having a GI plate as well as conventional solar still. It is increased due to its higher thermal conductivity.

Figure 4 shows comparison between hourly distillate outputs gained in all three solar stills like solar still having aluminum plate, GI plate as well as conventional solar still. It shows that maximum distillate output is gained in the afternoon. Also, it is observed that during the starting of readings, all the readings have an initial output of zero at 9:00 a.m., then they increased up to 3 p.m., and then decrease gradually. Here, the highest distillate output quantity is 29.50 L. From the quantity of brackish water inside the solar stills, it is shown that due to large amount of brackish water inside the conventional solar still, it requires highest time for evaporation as well as condensation; hence, the quantity of distillate output produced from conventional solar still is least and highest for solar still having aluminum plate. Figure 5 shows comparison of cumulative distillate water versus the time for all solar stills. Cumulative distillate output means total distillate output starting from 9:00 a.m. It is obtained by adding the distillate output from 9:00 a.m. to 10:00 a.m. and 10:00 a.m. to 11:00 a.m. and continues up to 8:00 p.m. It means that the cumulative output will be highest at 8:00 p.m. Also, it reaches its maximum of suspended aluminum plate solar still due to higher hourly distillate output. Table 2 shows the comparison of distillate output achieved by all solar stills during the month of April, May, and June 2011. Here, clear sky conditions are considered. Results show that the highest average distillate output is gained during the month of June 2011 compared with the month of April as well as May 2011.

Conclusions

Solar still is a very simple device to obtain potable water. It can also somewhat reduce the demand of potable water, but due to its lower distillate output, it cannot be used in wider applications. Present work gave the following points in conclusion:

-

Solar intensity is directly proportional to the distillate output of solar still.

-

Suspended aluminum plate in solar still enhances distillate output compared with the suspended galvanized iron plate. It increased daily distillate output as well as cumulative distillate output.

-

Highest distillate output is obtained in the month of June 2011. It was 3,703 by solar still having aluminum suspended plate and least obtained in the month of April; it was 2,300 by conventional solar still.

-

Suspended aluminum plate is a good material to enhance the distillate output of solar still. It is cheap and easily available.

Authors’ information

HP is a research scholar and PhD student of KSV University, Gandhinagar, Gujarat and assistant professor in the Department of Mechanical Engineering, Gujarat Power Engineering & Research Institute, Mehsana, Gujarat, India, and PKS is a principal at Silver Oak College of Engineering & Technology, Ahmedabad, Gujarat, India.

References

Tiwari GN, Singh HN: Present status of solar distillation. Sol Energy. 2003, 75: 367-373. 10.1016/j.solener.2003.07.005

Rustam Mamrook OmarBarden: Fuzzy sets implementation for the evaluation of factors affecting on solar still production. Desalination 2007, 203: 394-402. 10.1016/j.desal.2006.02.024

UNICEF: The state of world’s children. Oxford UniversityPressm, UK; 1995.

Malik MAS, Kumar A, Sodha MS: Solar distillation. Pergamon Press, Oxford, UK; 1982.

Al Hayek, Badran OO: The effect of using different designs of solar still on water distillation. Desalination 2004, 169: 121-127.

Kalogirou S: Survey of desalination systems and system selection. Energy. 1997, 22: 121-127. 10.1016/S0360-5442(96)00132-6

Singh AK, Tiwari GN: Thermal evaluation of regenerative active solar distillation under thermosyphon mode. Energy. Conv. Manag. 1993,34(8):697-706. 10.1016/0196-8904(93)90105-J

Kawi AM: Non conventional solar stills Part1. Non conventioanl solar still with charcoal as absorber medium. Desalination 2002, 153: 55-64.

Tripathi R, Tiwari GN: Effect of water depth on internal heat and mass transfer for active solar distillation sytem. Desalination. 2004, 170: 251-262. 10.1016/j.desa1.2004.03.019

Meukam P, Nijomo D, Gbane A, Toure S: Experimental optimization of solar still: application to alchoholic distillation. Chem. Engg. Proc. 2004, 43: 1569-1577. 10.1016/j.cep.2004.02.007

Nafey AS, Abdelkadar M, Andelmotalip AA: MabroukAA: Solar still productivity enhancement. Energy Conv. Manag. 2001, 42: 1401-1408. 10.1016/S0196-8904(00)00107-2

Voropolus K, Mathioulakis E, Belessiotis V: Experimental investigation of a behaviour of a solar still coupled with hot water storage tank. Desalination. 2003, 156: 315-322. 10.1016/S0011-9164(03)00362-X

MadaniAA Z: GM: Experimental and theoretical study of single basin solar still with porous basin. Applied. Energy. 1995,52(2–3):273-281.

Acknowledgments

I am very thankful to the management of Gujarat Power Corporation Limited (GPCL), Dr. AJ Mehta, Director of Gujarat Power Engineering & Research Institute for supporting me in the entire research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

HP made the experimental set up and readings of solar stills. PS checked the equations as well as updated the revised manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Panchal, H., Shah, P.K. Investigation on solar stills having floating plates. Int J Energy Environ Eng 3, 8 (2012). https://doi.org/10.1186/2251-6832-3-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-6832-3-8