Abstract

An effort has been made to develop an equation with the given data for all seasons for a location (Lucknow, India) consisting of composite climate, which is further helpful in developing a relation between difference in efficiencies of module with respect to thicknesses of dust collected on the module. This equation that is developed mathematically is in good correlation with the measured data. Here, data are shown for a whole year (from 2010 to 2011); the study done gives us a broad view of finding out the difference in efficiencies of module when dust collects on it.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

In solar cells, lots of power get lost due to various reasons such as reflection losses at the top surface, incomplete absorption of photon energy due to limited cell thickness, series and shunt resistance loss, curve or fill factor loss, etc. Results obtained show that there is a direct proportionality between solar flux, output current, and efficiency of the photovoltaic module as given by Omubo- Pepple et al. [1].

Dust contributes to as much as 40% degradation in peak power of photovoltaics; there is surprisingly little scientific work done on the subject. Since no information about the type of dust, density, and rate of accumulation of dust was noted, no general understanding of the underlying physical principles could be deduced. Dust accumulation on the photovoltaic (PV) panel surface depends on different parameters such as PV panel inclination and kind of installation as given by Del Cueto [2].

The research done previously include degradation analysis of silicon photovoltaic modules and effective efficiency of PV modules under field conditions as given [3, 4]. Some studies have also been done on corrosion effects in thin film photovoltaic modules as given by Carlson et al. [5]. The airborne particles in the atmosphere affect the amount and properties of the radiation finally reaching the collectors. The accumulation of dust particles on the surface of PV module greatly affects its performance especially in desert areas. Some correlation studies have done direct beam solar radiation received by photovoltaic panel with sand dust accumulated on its surface as given by Al-Hasan [6].

Desert countries are of course best suited to photovoltaic power generation due to the abundant availability of sunlight throughout the year. Nowadays, the ideas of setting up vast solar arrays in desert countries and exporting the power to other countries are being discussed. In a bigger PV solar plant, more work force and machines will be needed to help make the rounds and clean the panels, especially after a stand storm.

Many research results discuss about performance of panel with dust concentration on the surface, but for a common PV user, it is important to know how frequently the panel has been cleaned. In case if frequent cleaning is not possible, it is important to know the performance loss due to dust for additional estimation to compensate the loss.

It has been concluded in many studies that dust accumulation considerably deteriorates the performance of photovoltaic cells. However, in carrying out the investigation on the effect of dust and particulate pollution, the physical characteristics of dust must be determined and correlated to the observed effects [7].

Research done also include characteristic distribution of total, diffuse and direct solar radiation at given locations, qualification testing of modules, etc. [8–11]. Different analysis, performance, and reliability testing of photovoltaic modules and arrays have been done as given [12–14].

As we know that module performance is greatly affected by the amount of dust collected on it [15], sometimes when we want to get the amount of difference value in efficiency of modules, the instruments for measuring it at that instant are not found. The main aim of this paper is to solve these kinds of problems. Here, an attempt has been made to obtain a relation between ‘thicknesses of dust collected and difference in efficiencies’ for all seasons so that difference in efficiencies of modules can be easily estimated by measuring the thicknesses of dust collected using simple devices.

Here, a statistical analysis has been done in finding out the correlation between thicknesses of dust collected on photovoltaic module and the difference in efficiencies of the module for a whole year considering all seasons of a composite climate.

Methods

Instrumentation

The SPV module (number 2007.20.685) which is manufactured in the year 2007 by M/s Rajasthan Electronics and Instruments Ltd, Jaipur, India is studied. The module has been connected to a rheostat ammeter digital multimeter (DT9205A, Agronic Ltd.). Other instruments used are the digital thermometer (SE-221-P-K, Agronic Ltd.) to measure cell temperature, the Thermo-Hygro Clock (288-CTH, Agronic Ltd.) to measure ambient temperature and humidity and digital luxmeter (range 0 to 50,000 lux in three ranges of 0 to 2,000, 0 to 20,000, and 0 to 50,000 lux; accuracy ±5%, ±2 least count) to measure solar flux. Data are taken for one whole year from 2010 to 2011.

The commercial photovoltaic module used has the following components:

-

Solar type is polycrystalline silicon.

-

Cell area = 0.216 m2.

-

Electrical efficiency STP = 12% with a power peak of 36 W.

-

Electrical specifications is at standard test conditions of 100 MW/cm2, AM 1.5, and at 25°C cell temperature within normal production of tolerance ±3%.

-

Area of the panel = 0.340 m2

Development of correlation between thicknesses of dust collected on photovoltaic module and the difference in efficiencies

As stated earlier, we have tried to verify the data taken for the whole year while considering different values, depending on the variation of climate. This fluctuation resulted from different factors affecting the performance of solar photovoltaic module. For example, these factors may be temperature, wind velocity, humidity, cloud cover, and dust.

The aim of this study is to find out the relation of the difference in efficiencies with respect to thicknesses of dust collected. Here, reading is taken three times for each month after every 10 days, and finally, the average of the three readings is taken as measured value of the data for both the variables (difference in efficiencies and thicknesses of dust collected on the module) for that particular month. In this way, each month has its individual reading taken throughout the year. In Table 1, both variables are taken as monthly average value of difference in efficiencies and monthly average value of thicknesses of dust collected on the module.

Thus, the efficiencies of the module and their corresponding thicknesses of dust particles are taken into account. Efficiency of module has been found with the help of the maximum power, solar flux, and area of solar panel. On the other hand, thickness of dust particles collected on the module is calculated using the following the basic formula:

where

The mass of dust collected is measured for every month using a chemical balance. The area of solar panel = 0.340 m2, and the density of dust collected = 3g/cm3.

As we know that density of dust is governed by the diameter of dust particles, dust consists of multiple composite particles ranging from 0.1 to 80 μm in diameter; sand consists of loose siliceous particles whose size range is approximately 0.08 to 1 mm in diameter (full text is found in the handbook [16]); thus, knowing the average characteristic of dust, density is known to be the above given value).

General variation in the difference in efficiencies and thicknesses of dust has been recorded which has been observed to be different for different months. Here, readings have been taken consecutively for 12 months, as given in columns 2 and 3 in Table 1.

Calculation

For calculations of the relation, we have used the process of linear regression as it is given by the method of least squares solved for two variables, as shown in Table 2. Problems involving more than two variables can be treated in a manner analogous to that for two variables.

Substituting the values of ∑t, ∑Δη, ∑t2, and ∑Δη.t in Equations 2 and 3 when n =10, we get the following:

Now, solving Equations 4 and 5 to get the values of ao and a1,

Keeping the value of a1 to find out ao in Equation 6,

Therefore, the equation comes out as follows:

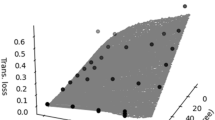

The corresponding relation between the ‘monthly average of thicknesses of dust collected and monthly average of difference in efficiencies’ graph for the data are given in Figure 1.

Here, t and Δη are two variables; t is considered as an independent variable, and Δη is considered as an dependent variable (t = monthly average of thicknesses of dust collected) and (Δη = monthly average of difference in efficiencies). In statistics, linear regression is an approach to model the relationship between the two variables. Problems involving more than two or three variables can be treated in a manner analogous to that for two variables.

To further reconfirm the relation between thicknesses of dust collected and the difference in efficiencies, equations to the lines of regression and regression coefficients have been found with the help of the deviation method using Pearson's formula as given in Table 3. We have taken the estimated value of thicknesses of dust collected as 0 mm and therefore accordingly estimated the value of difference in efficiencies of solar photovoltaic module used as 0%, respectively.

Substituting the above values of Table 3 in the formula, we get the following:

Substituting the above values in the regression equation of t on Δη, we get the following:

Similarly, with the equation of the line of regression of Δη on t, we get the following:

Therefore, the final two equations come out to be as follows:

Using Pearson's formula, coefficient of correlation has been found out as follows:

Note. We have seen that there are two lines of regression (Equations 13 and 14): one of Δη on t and the other of t on Δη. In the first one, Δη is the dependent variable and t is the independent variable, while in the other one, Δη is the independent variable and t is the dependent variable. Since the assumptions for deriving the equations of two lines of regression are different, the two equations are not reversible. In other words, one equation gives the estimate of Δη, while the other gives the estimate of t. However, if r is equal to (±) 1, the two lines of regression can be reduced to the same form, but from the above value of r, it is clear that r = 0, i.e., the estimated value of Δη (or t) is the same for all values of t (or Δη). Thus, the degree of correlation between the two variables is much greater but not perfect; there are other climatic variables influencing the correlation between the two.

Results and discussion

We have made an effort to test the validity of the equation deduced. Table 4 gives the value of Δη measured and calculated from Equation 8 and also from Equation 14.

While keeping manual error in mind, the values obtained (Δη measured and Δη calculated) are quite in agreement with each other as seen from the table and from calculating the error of prediction given as follows:

where the value 0.0950789 signifies the amount of deviation of the predicted value from the observed value, which is considerably very small.

Thus, the equation obtained (Equation 8) may be taken as a valid equation, and using it, Δη (difference in efficiencies of module) can be calculated using the known values of t (thicknesses of dust collected on module) for a location.

Conclusions

Silicon solar cell operating efficiency is at optimum level in the absence of dust which is an ideal condition. Practically, it is seen that there is in average a reduction in output, near 10% to 20%, when heavy layers of dust are accumulated on terrestrial modules [17].

Dust consists of multiple composite particles ranging approximately from 0.1 to 80 μm in diameter. Dust particles may be electrically conducting and are usually soluble in water. Sand dust is most severe in low humidity regions. Dust becomes airborne with slight winds and may remain suspended for hours as dust clouds [16].

During wind storms, dust particles penetrate almost any enclosure which is not hermetically sealed, and it may be hygroscopic. Its presence on metallic surfaces may aggravate corrosion.

It is reported that a small amount of dust on silicon solar photovoltaic module covers has a negligible effect on the sunlight transmission to the silicon photovoltaic module. An attempt has been made to develop an equation to calculate difference in efficiencies from thicknesses of dust particles collected for a whole year. The standard equation obtained is very good to measure the correlation with obtained results for almost every month. This is clear from the calculated percentage error from Table 4. Therefore, the standard equation helps to evaluate the difference in efficiencies of module while knowing thicknesses of dust collected on it for any climatic conditions of the area.

This result has been obtained with a particular module studied the whole year; a combined study can be done by taking different modules with their respective climatic conditions, and difference in output of solar photovoltaic modules can be easily evaluated.

Abbreviations

- Δη:

-

monthly average of difference in efficiencies of solar photovoltaic module (before and after collection of dust) (percentage)

- a o :

-

first constant

- t :

-

monthly average of thicknesses of dust collected (thickness in millimeter)

- u :

-

deviation from the estimated value of thicknesses of dust collected

- v :

-

deviation from the estimated value of difference in efficiencies

- Δη:

-

arithmetic average of the thicknesses of dust collected on module

- Δηmeasured:

-

measured value of difference in efficiencies of module

- Δηcalculated:

-

calculated value of difference in efficiencies of module, bt.Δη, regression coefficient (t on Δη)

- b Δη.t :

-

regression coefficient (Δη on t)

- t :

-

arithmetic average of the difference in efficiencies of photovoltaic module.

References

Omubo-Pepple VB, Israel-Cookey C, Alaminokuma GI: Effects of temperature, solarflux and relative humidity on the efficient conversion of solar energy to electricity. European J Sci Res 2009,35(2):173-180.

Del Cueto JA: Comparison of energy production and performance from flat plate photovoltaic module technologies deployed at fixed tilt. Proceedings of the 29th IEEE Photovoltaic Specialists Conference, Piscataway; 2002.

Meyer EL, Van Dyk EE: Degradation analysis of silicon photovoltaic modules. Proceedings of the 16th European Photovoltaic Solar Energy Conference, Glasgow; 2000.

Topic M, Breel K, Sites J: Effective efficiency of PV modules under field conditions. Progress in Photovoltaics: Res Appl 2007, 15: 19-26. 10.1002/pip.717

Carlson DE, Romero R, Willing F, Meakin DH, Gonzalez L, Murphy R: Corrosion effects in thin film photovoltaic modules. Progress in Photovoltaics: Res Appl 2003, 11: 377. 10.1002/pip.500

Al-Hasan AY: A new correlation for direct beam solar radiation received by photovoltaic panel with sand dust accumulated on its surface. Solar Energy 1998,63(5):323-333. 10.1016/S0038-092X(98)00060-7

Sukhatme SP: Solar Energy: Principles of Thermal Collection and Storage. Tata McGraw-Hill, New Delhi; 2003.

Armstrong S, Hurley WG: A new methodology to optimize solar energy extraction under cloudy conditions. Renew Energy 2010, 35: 780-787. 10.1016/j.renene.2009.10.018

Abentin J, Cueli AB, Diaz J, Moracho J, Lagunas AR: New accredited laboratory for PV module testing. Proceedings of the 20th European Photovoltaic Solar Energy Conference, Barcelona; 2005.

Akpabio LE, Udoimuk AB: Characteristics distribution of total, diffuse and direct solar radiation at Calabar. Glob J Pure Appl Sci 2003,9(1):45-49.

Osterwald CR, McMohan TJ: History of accelerated and qualification testing of terrestrial photovoltaic modules: a literature review. Progress in Photovoltaics: Res Appl 2008,2017(1):11-33.

Malik AQ, Lim Chee M, Tan Kha S, Blundell M: Influence of temperature on the performance of photovoltaic polycrystalline silicon module in the Bruneian climate. AJSTD 2010,26(2):61-72.

Arya RR, Carlson DE: Amorphous silicon PV module manufacturing at BP solar. Progress in Photovoltaics: Res Appl 2002,10(2):69-76. 10.1002/pip.418

Wohlgemuth JH, Conway M, Meakin DH: Reliability and performance testing of photovoltaic modules. 28th IEEE PVSC, Egan Convention Center, Anchorage; 2000:15-22.

Shaharin A, Sulaiman SA, Hussain HH: Nik Leh, NSH, Mohd SI, R: Effects of dust on the performance of PV panels. World Academy of Science, Engineering and Technol 2011, 58: 588-592.

TRW Systems Group, Power Sources Engineering Department, Rauschenbach HS, Jet Propulsion Laboratory, United States National Aeronautics and Space Administration: Solar Cell Array Design Handbook. 1st edition. NASA, Washington, DC; 1976.

Monto M, Rohit P: Impact of dust on solar photovoltaic (PV) performance: research status, challenges and recommendations. Renew Sustain Energy Rev 2010,14(9):3124-3131. 10.1016/j.rser.2010.07.065

Acknowledgments

The authors would like to thank the Ministry of New and Renewable Energy (MNRE), New Delhi, India for providing financial support for current research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

UB supervised the whole work, drafted the manuscript, and corrected the manuscript. RS conducted the experimental analysis, studying the performance of solar photovoltaic module under different climatic parameters, and conducted the calculation according to the instruction provided by the supervisor. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Siddiqui, R., Bajpai, U. Correlation between thicknesses of dust collected on photovoltaic module and difference in efficiencies in composite climate. Int J Energy Environ Eng 3, 26 (2012). https://doi.org/10.1186/2251-6832-3-26

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-6832-3-26