Abstract

The regional differences and environmental challenges are key factors in measuring the efficiency of renewable systems. The loss of transmittance due to weather events, such as dust, clouds/rain, extreme heat, and humidity, is one of the main factors causing reduction in energy generation from photovoltaic (PV) systems’ ideal energy production potentials. Existing literature analysed the impact of transmittance loss due to dust on PV systems’ performances, recommending frequent system cleaning to maintain the highest energy production level. In this paper we build a mathematical model to quantify the effect of dust accumulation on the transmittance losses. The model predicts the transmittance losses of PVs at tilts between 0° and 90°, exposed to Kuwait’s climate with and without cleaning. We use the model to analyse the performance of recommended tilts for optimum energy production (overall and seasonal) based on Kuwait’s geographical location. The results demonstrate that the recommended regional optimum tilt (30°) for maximum energy generation is applicable only if the system is cleaned at least once a week. Tilts of 50° and higher can perform better when the frequency of cleaning is once every two weeks or less. This is an important observation that can guide the design, installation, and maintenance (frequency of cleaning) of the PV systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction and background

Arid regions are typically characterised with a dry and hot weather and frequent winds, carrying particles in various size and chemical composition [1]. In such regions, the climate influences the way energy is consumed to control the indoor thermal conditions and buildings design [2]. In addition, it has impact on energy production systems that rely in renewable resource; different researchers in different regions analysed PVs’ productivity to explain the impact of regional climatic characteristics on the systems’ performance [3]. The key elements with direct impact on dust accumulation levels on PV systems designs are the tilt of the PVs [4], the cover material of the PV [5] and the duration of exposure to the natural environment without cleaning the panels [6]. The dust impact on PV systems’ efficiency is a direct result of the loss in transmittance from its surface. This loss in transmittance is caused by solid particles obstructing the solar radiation from penetrating the panel’s surface of the PV collector. In this paper, we include the dust effect as a factor in the selection criteria of alternative PV positions, which in most cases was only governed by the solar incidence angle particular to the region and location of installation.

In Kuwait, according to the 2020 statistical yearbook issued by the ministry of electricity and water, the government is targeting to increase the capacity and production of electricity from renewable resources up to 15% by 2030 [7]. The report includes details of one power plant (Al-Shygaya Power Plant) that operates using renewable resources to produce electricity, recording only 0.02% of the total electricity generated in Kuwait (mostly relying on hydrocarbon fuels). Furthermore, the report mentions five new future projects, all of which consider solar energy as a renewable resource to generate electricity. With such major investments in Kuwait and considering solar power as a renewable resource, the recommended approach in literature for sustaining optimum energy production rates against dust is to increase the frequency of cleaning. There is still a gap in literature in support of alternative adaptive methods rather than recommending intensive cleaning and maintenance requirements. The objective of this paper is to investigate an alternative adaptive approach by quantifying the effect of dust, while taking the frequency of cleaning as a decision factor. By modelling the relationship between PV tilts and the duration of their exposure without cleaning, we trade-off between alternative tilts (to the theoretical optimum tilts) and the frequency of cleaning while achieving optimum energy production rates.

The effect of dust on systems relying on solar power, as a renewable source, to generate energy has been the focus of many studies [7,8,9,10,11]. Dust accumulation can differ based on the technology used; the performance of focused lenses [12], mirrors [13] and flat PVs [4] has been investigated with the purpose of identifying the effect of dust and the frequency of maintenance and cleaning required. Furthermore, the effect of dust accumulation also differs based on the location of the study [6]. Manufacturer’s specifications of similar technologies can also impact the rate of dust accumulation [14], based on the material of surfaces (PV covers) exposed to the environment [15] and their positioning (tilt and orientation) [16].

In regions where dust events are more frequent, analyses detailing the effect of dust on the transparent covers of flat plate solar energy collectors was reported [17]. The study took place in India and the duration of exposure was a month. The surfaces were set at different tilts (from 0֯ to 90֯ at 10֯ increments). Within that duration, the corresponding loss in transmittance was at its highest on a horizontal plate (69%) and at its lowest on the vertical plate (12%), being exposed to the natural conditions without cleaning. One key observation is that the loss in transmittance becomes significantly higher when the tilts of plates are less than 40֯. All plates tilted at 40֯ and beyond had a loss in transmittance of less than 23%.

One of the earlier studies, specific to PVs performance in Kuwait’s region, evaluated the performance of solar systems and their power generation potentials [18]. The reported loss in efficiency due to dust was significant; 17% drop in efficiency was recorded after only 6 days of exposure to the natural conditions. Also in Kuwait, the performance of flat-surface solar devices was analysed [19]. The panels were exposed to the natural conditions for 38 days at tits between 0° and 60°; The corresponding transmittance losses were between 64 and 17%, respectively. It is also noted that the horizontally placed panel (0° tilt) registered a 30% loss in transmittance after only 3 days. Both [18, 19] indicate that significant losses in efficiency/transmittance are expected within a period that is less than a week, especially for panels placed at tilts closer to (or are) horizontal.

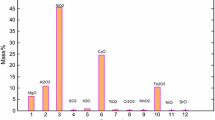

In a comparison between the results reported based on the weather conditions in India and Kuwait [17, 19], an experiment was designed to evaluate the regional effect of dust on the transmittance in Egypt; In a study specific to panels with a glass cover, the experiment analysed the effect of dust on the transmittance of surfaces tilted between 0° and 90° [24]. The panels were exposed to the natural conditions close to agricultural fields for a year. They reported losses in transmittance (averaged for each 30 days of exposure) between 27% for PVs at 0֯ tilt and 3.5% for PVs at 90֯ tilt.

The comparison showed that Egypt and India data are closer in transmittance loss values when the tilts of surfaces are more than 50° Kuwait’s data did not investigate tilts larger than 60°. Furthermore, based on the three different set of data, it was suggested that panels with tilts less than 60° will require a minimum cleaning frequency of once a week in order to maintain the loss in transmittance at low levels.

Further, the effect of dust on transparent covers of solar collectors with respect to different orientations and tilts was investigated [16]. The experiment took place in Egypt using 100 glass samples positioned at eight orientations (at increments of 45°starting from the true North orientation) and 7 tilts between 0° and 90°. The transmittance of the glass samples was measured periodically and after every rain event for a period of 7 months. Some of the glass samples were cleaned every month, after measuring the effect of dust on the transmittance. Other glass samples were kept uncleaned during the whole testing period (7 months). Also, the dust disposition did not vary in significant amounts between the different orientations at each tilt. The average of transmittance losses after 30 days of exposure range from 28% for a horizontally positioned surface, and 6% for the vertically positioned surfaces. While the total transmittance losses after the 7 months of exposure without cleaning range from 53% for a horizontally positioned surface, and 14% for the vertically positioned surfaces.

Also in Egypt, data were collected from two sets of polycrystalline silicon PV modules tilted at 15°, 20°, 30° and 45° [9]. One set was cleaned weekly and the second set was kept uncleaned for 10 months. The study did not focus on measuring the loss in transmittance, it was specific in measuring the impact of dust on the output power of the tested PV module. The maximum difference recorded in output power between the uncleaned set of panels and the weekly cleaned set, tilted at 15°, is 40%; while, the maximum difference in output power between the uncleaned set of panels and the weekly cleaned set, tilted at 45°, is 25%. For the weekly cleaned set during summer and autumn seasons, the panels at 15° tilt yielded more energy than the other tilts; while during winter seasons, the panels at 30° tilt yielded more energy than the other tilts. As for the uncleaned set, the optimum tilt for energy production throughout the year is 30°. It is unfortunate that the experiment was limited to PVs tilted only between 15° and 45°. Furthermore, the analysis does not quantify the losses due to dust within the week prior to the scheduled cleaning, measured in the earlier literature to be of significance.

Controlled conditions laboratory-based experiments have also been reported in literature to analyse the effect of dust on the transmittance of surfaces [1, 10, 20, 21]. In these studies, the transparent surfaces are subject to wind and dust for a period of time, using fans to distribute the dust particles and lights to simulate the sun radiation. In those cases, the results are useful to understand a specific parameter’s influence in the relationship between the dust and the loss in transmittance, eliminating all other environmental factors. However, in order to model a prediction of transmittance loss, the effect of all the environmental/regional influences that can control or limit the effect of dust are to be considered.

Most of the studies, specific to arid regions, recommend the earliest removal of dust particles from the collector’s surfaces to bring back the energy production to the optimum rates [22]. An experimental setup was used to evaluate and compare monocrystalline PV modules outputs at different tilts in Kuwait [23]. The results argued that panels installed at 50° tilt can yield to a yearly power output close to the panels installed at the optimum tilt of 30°. However, their analysis comes short to discuss if the relationship between the dust and tilts of surfaces was the reason that PVs with higher tilts generated energy close to rates produced by PVs tilted at optimum position. Furthermore, there was no mention of the frequency of cleaning that took place, before or after recording the system’s output. In this paper, we re-evaluate the optimum tilt positioning of PVs in consideration of the regional (Kuwait’s) dust factor. By creating a prediction model for the transmittance losses at different tilts, the daily PV energy generation data are recalculated with the inclusion of a dust reduction factor. The total yearly energy generation rates are then evaluated at different tilts and for different cleaning scenarios (cleaning frequency) to explore alternative tilts that achieve better performance. The novelty in our approach is that our model recommends an adaptive method to the regional impact of dust, recognising the cleaning scenarios as a key factor while deciding on the tilt of PVs.

Methodology

To model the transmittance losses due to dust, parameters such as the climate/location, positioning of PVs (tilt/orientation), the material of PV covers, the duration of exposure and the cleaning schedules must be identified. To predict the amount of loss in transmittance from PV covers, the climate characteristics where the system is installed must be specified. The prediction model is built using data of PV panels installed at tilts between 0° and 90°, with measurements of dust accumulation on their uncleaned surfaces span from one day to 210 days of exposure in Kuwait. The positioning of PVs’ tilt and orientation are key installation elements for maximum energy generation. However, by comparing the results of dust accumulation rates at different orientations, in most cases the difference is less than 2% [16, 24]. Hence, our prediction of the transmittance losses within the days of exposure at tilts between 0֯ and 90֯ is assumed to be at the same rate at every orientation.

The data used in the prediction model are from losses reported for PVs with glass covers, being the most commonly used/productive cover material in the region. First, we group the data available from studies conducted based on experiments specific to Kuwait’s environment [8, 18, 19, 25]. We collect the data associated with transmittance losses of surfaces that were not cleaned during the period of the experiment or consider the reported losses before cleaning, and when it took place. Second, we take into account the data available from regions with similar climate and environmental conditions (in Egypt and India) [5, 16, 17, 25] to increase the reliability and the accuracy of the model. Based on the data, the model predicts the transmittance loss percentage within 40 days of exposure, at any tilt between 0° and 90°.

For the prediction model we use Kriging method due to the nature of our regional geographical specific data [26]. Kriging is specifically useful as predicting model for data at different spatial location while capturing the regional variabilities of each data set [27]. We use different data sets from multiple studies with similar regional/environmental characteristics to strengthen the model’s reliability. Kriging method uses covariate information to accurately capture the relationship between multi-variables data sets and is made of two components: the regression model \(f\left( . \right)\) and the correlation model \({\mathcal{R}}\left( . \right)\). In our case, the Kriging predictor looks like,

as a function of two variables, the tilt (\(t\)) and the days of exposure \(\left( d \right)\). \(\varepsilon\) have zero mean and covariance related to the correlation function \({\mathcal{R}}\left( . \right)\) as

where \(\theta\) is the correlation parameter and \(x\) are the data value at set j. As a rule of thumb, the Gaussian, or the spline functions are fit better when the function is continuously differentiable, likely showing a parabolic behaviour near the origin. A linear, or exponential perform better if the prediction displays a linear behaviour near the origin. \(\theta\) is optimally found using the variance of data set and the determinant of \({\mathcal{R}}\) [26].

In our model we use linear regression for \(f\left( {t,d} \right)\) and Gaussian correlation function \(\exp \left( { - \theta x^{2} } \right)\) at tilts between 0° and 90° and within days of exposure up to 40 days. In the regression models the shape and the structure of the model is pre-defined within the polynomial class of functions, which is not always an accurate shape for a given data set. However, the Kriging interpolation adapts itself nonlinearly to the data set given the extra component in Eq. (1) using the covariance of data in a Gaussian process [28].

In the module we assume that the prediction of dust accumulation follows the same trajectory and reset once the PVs are cleaned. In reality, dust events cannot be accurately predicted nor follow the same occurrence frequency every month. However, the data used in building the prediction model are from different seasons/years, representing the yearly impact of dust on the performance of PVs.

We assess the accuracy of our prediction by calculating the coefficient of determination (R2), the mean absolute error (MAE) and the mean squared error (MSE), indicating the strength (goodness of fit) of the model. R2 is function of the regression sum of squares (SSR) and the total sum of squares (SST):

where SST can also be calculated by the summation of SSR and the sum of squares of errors (SSE). Accordingly, the value of R2 is between one and zero. The closer the value of R2 to 1, the stronger the prediction is (as the value of SSE will be closer to zero).

The MAE is calculated by averaging the summation of the absolute values of the model’s errors:

while the MSE is calculated by averaging the summation of the model’s error squared values:

The MAE and the MSE values range between one and zero as well. The closer their values to zero, the better competency in prediction the model has.

Results and discussion

The multivariable prediction model estimates the transmittance losses, at any given tilt between 0° and 90° and within 40 days of exposure (Fig. 1). Transmittance losses are at their lowest when the tilts are closer to 90°. At each tilt, the transmittance losses increase with time. However, as the tilts increase, the rate of loss in transmittance gets lower. The two-dimensional views highlight the transmittance loss data versus prediction against the days of exposure (Fig. 2a) and against the different tilts (Fig. 2b). One key observation is the difference between the transmittance loss at tilt 0° and tilt 90° by day 30, reaching almost 50%. Figures 1 and 2 indicate that the prediction model converges with most of the data point, and the strength of the prediction is determined by calculating the R2, the MAE and the MSE (Table 1).

The value of R2 is 0.928 (very close to 1), indicating a strong fit between the data points and the prediction model. As for the MAE and the MSE, their values are 0.026 and 0.002, respectively. Both MAE and MSE are close to zero, indicating that the errors between the data points and the predictions are very minor.

To show the impact of dust and tilt selection, we need to apply the dust reduction/prediction model to the solar energy generation potentials in Kuwait. Using GIS solar modelling technology,Footnote 1 Kuwait’s optimum tilt, providing the highest yearly energy generation potential is 29°. GIS models rely on satellite solar radiation measurements which are considered an alternative to ground/on-site measurements. The GIS model we have used has been the subject of analysis and validation, and was reportedly providing the best statistics for all of irradiance components identified in six different models [29]. The energy production varies at different seasons (within a year), and greater energy generation potentials can be achieved at different tilts in some months more than others. The optimum summer energy production tilt is 6° and the optimum winter energy production tilt is 52°.

Using a solar energy simulation model,Footnote 2 we calculate the daily potential solar energy output of a 1 MWh system based on the regional conditions on Kuwait. Within a year, Fig. 3 breaks down the monthly values of energy that can be generated from a 1 KWh PV system. It is important to mention that the solar energy simulation platform uses hourly recorded satellite measurements at any selected location within a full year. Accordingly, the energy values consider the fluctuation in energy generation due to any detected environmental factors that can affect the amount of solar radiation measured, that being clouds or dust.

By comparing the yearly energy production rates between the different tilts, the summer optimum tilt generated 5% less energy than the overall optimum tilt, while the winter optimum tilt generated 6% less energy than the overall optimum tilt. To identify the pattern of yearly energy generation potential corresponding to different PV tilts, we increase the data points by simulating the yearly solar energy generation potential from four more tilts. The pattern of yearly energy generation potential at different PV tilts is presented in Fig. 4.

Since all of these measurements assume clean surfaces of the solar system at all time, our dust prediction model is needed to account for the accumulation of dust due to the surfaces’ exposure to the environment (in Kuwait) until a cleaning event takes place. However, before applying the transmittance loss factor, the relationship between transmittance losses in a PV system and the corresponding energy losses must be quantified. The loss in transmittance can impact the energy output differently, based on the specifications of the solar/PV systems used. In this particular example, recorded data estimating the factor at which the transmittance losses influences the energy performance of a solar desalination plant is used [30].

We use three cleaning scenarios as explain below. In the first one, we assume that the PV panels are being cleaned once by the end of each month. This means that our daily predictions for transmittance loss are factored in the daily energy generation values, in consideration of the relationship between energy losses and transmittance losses for each month. Then, reset the daily predictions for transmittance losses at beginning of the next month.

The monthly energy generation is summed up at each tilt and the monthly patterns are shown in Fig. 5. Given the trend of the reduction in the transmittance loss prediction model, the patterns of yearly energy corresponding to optimum tilts have changed. With higher tilts, there will be lower impact due to dust on the optimum energy generation values.

The percentage of yearly energy losses from the optimum values, due to dust, is 43%, 30% and 17% corresponding to 6°, 29° and 52°, respectively. With higher tilts (winter optimum), the solar system is estimated to outperform the summer optimum and the overall optimum. The difference in the total yearly energy production between the winter optimum and the summer and overall optimums is 31% and 11%, respectively.

The second scenario assumes that the surfaces are being cleaned twice in a month, once at the middle of the month and a second time at the end on the month. Being applied in the model, the daily energy generated is factored by the prediction of transmittance/energy daily loss up to day 15. Then, the transmittance/energy daily loss prediction model is reset to start again on day 16 up to the end of the month. The percentage of yearly energy losses from the optimum values is 28%, 19% and 11% corresponding to 6°, 29° and 52°, respectively. The difference in the total yearly energy production between the winter optimum (which remained being the highest producing tilt as in the first scenario) and the summer and overall optimums are 17% and 2%, respectively.

The Third scenario considers that the cleaning is being done by the end of every week. With this scenario a change happens to the order of which tilt can generate more energy from the previous scenarios. The percentage of yearly energy losses from the optimum values is 13%, 9% and 5% corresponding to 6°, 29° and 52°, respectively. The overall optimum tilt (29°) in this scenario has the most yearly energy generation value. The difference in the total yearly energy production between the overall optimum and the summer and winter optimums are 9% and 2%, respectively.

Figure 6 summaries the yearly energy generated for PVs at tilt 6°, 29° and 52°. The first set of columns on the left represents the yearly energy generated without the consideration of dust (or daily cleaning). The next set from the left considers system cleaning by the end of every month. The set follows, represents system cleaning at day 15 and the last day of every month. The last set on the right considers cleaning by the end of every week.

To understand the effect of the cleaning frequency on the energy losses, Fig. 7 shows the patterns of yearly energy generated, corresponding to different tilts, for every scenario simulated and compared with the optimum values.

From Fig. 6, the amount of energy that can be generated by PVs positioned at the optimum summer tilt (6°) and cleaned once a week will produce energy almost equal to the energy produced by PVs tilted at the winter optimum tilt (52°) but clean twice a month. Furthermore, the winter optimum tilt (52°), cleaned once a week preforms better than the PVs positioned at the optimum tilt being cleaned once or twice a month. Figure 7 shows the effect of the frequency of PV cleaning, and how the dust effect on the transmittance becomes less as the tilt increases.

Those results indicated that the dust accumulation and the frequency of cleaning can influence the tilt position of PVs and the objective of maximising their energy production. The module is useful in suggesting alternative tilts that are not only based on the regional-optimum angle of solar radiance. Due to dust and its varying accumulation rate at different tilts, the optimum tilt for producing energy becomes a function of the days of exposure and the frequency of cleaning that can be decided by the user. The model can be the basis for cost–benefit analysis, taking into account the amounts of resources required (water and manpower) to clean the PV’s and their associated costs, as well as the potential damage from the accumulating dust particles on the PV surfaces, in deciding the optimum tilt for energy production.

Future research

While our model can be limited to the relationship between the transmittance loss, PV tilt and the duration of exposure in Kuwait and regions with similar climate/dust-fall rates, the same approach can be adapted to study the performance of PV’s in other regions. Our methodology can be applied to analyse the performance of PVs against snow fall and its accumulation rate in regions where snow is common with a long winter season. Furthermore, more on-site experiments to test the output of PV systems within a full year, using different set of panels, at different tilts and cleaned at different durations are needed. While such experiments might be lengthy and time consuming, the output will provide detailed data of the seasonal impact of dust, as well as the possible transmittance recovery/deterioration from the rare rainfall events.

Conclusion

The impact of dust accumulation on PV systems’ efficiency has been addressed in several studies. Regional data and laboratory experiments were used to quantify the amount of dust on the systems’ surfaces, evaluate the losses in efficiency and determine the frequency of cleaning required. The optimum PV tilt is theoretically calculated based on the regional angle of solar radiance, to give the highest amount of yearly energy generation potential. As the amount of dust accumulating on a surface is highly associated with its tilt, we have built a prediction model to assess the performance of PVs at different tilts. Instead of recommending the frequency of cleaning needed to sustain the performance of that optimum position, we use the prediction model to assess the most efficient tilt for energy production, while considering different scenarios for the frequency of cleaning.

We model the relationship between the loss in transmittance from a PV cover and its tilt, being exposed to the environmental conditions in Kuwait. Given the regional nature of dust events, the prediction model is built using the Kriging method, based on data specific to Kuwait and regions with similar climate characteristics. The results from the prediction model indicate that the transmittance loss can reach more than 50% within a month of exposure in Kuwait due to dust. The closer the surfaces tilt to being horizontal, the rate of loss in transmittance becomes higher.

The optimum tilt for yearly energy generation based on solar radiation calculations for Kuwait is 29֯, and based on our prediction model, will only produce the highest amount of energy if cleaned at least once a week. The optimum tilt for energy generation changes based on the frequency of cleaning, and higher tilts become more efficient when the duration of exposure without cleaning increases. With weekly cleaning, the losses in energy production (compared to energy production rates without factoring in the dust prediction model) are 9% and 5% corresponding 29° and 52°, respectively. The difference in yearly energy between PVs at 29° and 52° tilts becomes only 2%. Every other scenario, with cleaning frequency of less than once a week, disputes the recommended tilt of 29°, as it no longer remains the optimum yearly energy generation tilt.

Notes

GIS model provided by www.solargis.com.

Renewables calculation model provided by www.renewables.ninja.

References

Hassan, A.H., Rahoma, U.A., Elminir, H.K.: Effect of airborne dust concentration on the performance of PV modules. J. Astron. Soc. Egypt 13, 24–38 (2005)

Almufarrej, A.M., Erfani, T.: Climate, buildings’ envelope design and energy patterns: improving energy performance of new buildings in Kuwait. Eng. Constr. Archit. Manag. (2021). https://doi.org/10.1108/ecam-04-2021-0360

Al-Otaibi, A., Al-Qattan, A., Fairouz, F., Al-Mulla, A.: Performance evaluation of photovoltaic systems on Kuwaiti schools’ rooftop. Energy Convers. Manag. 95, 110–119 (2015). https://doi.org/10.1016/j.enconman.2015.02.039

Asl-Soleimani, E., Farhangi, S., Zabihi, M.S.: The effect of tilt angle, air pollution on performance of photovoltaic systems in Tehran. Renew. Energy 24, 459–468 (2001). https://doi.org/10.1016/S0960-1481(01)00029-5

Nahar, N.M., Gupta, J.P.: Effect of dust on transmittance of glazing materials for solar collectors under arid zone conditions of India. Sol. Wind Technol. 7, 237–243 (1990). https://doi.org/10.1016/0741-983X(90)90092-G

Kazem, H.A., Chaichan, M.T.: The effect of dust accumulation and cleaning methods on PV panels’ outcomes based on an experimental study of six locations in Northern Oman. Sol. Energy 187, 30–38 (2019). https://doi.org/10.1016/j.solener.2019.05.036

Sarver, T., Al-Qaraghuli, A., Kazmerski, L.L.: A comprehensive review of the impact of dust on the use of solar energy: history, investigations, results, literature, and mitigation approaches. Renew. Sustain. Energy Rev. 22, 698–733 (2013). https://doi.org/10.1016/j.rser.2012.12.065

AlBusairi, H.A., Möller, H.J.: Performance evaluation of CdTe PV modules under natural outdoor conditions in KUWAIT. In: 5th World Conf. Photovolt. Energy Convers., 25th European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, pp. 29–36 (2010)

Abdeen, E., Orabi, M., Hasaneen, E.S.: Optimum tilt angle for photovoltaic system in desert environment. Sol. Energy 155, 267–280 (2017). https://doi.org/10.1016/j.solener.2017.06.031

Jiang, H., Lu, L., Sun, K.: Experimental investigation of the impact of airborne dust deposition on the performance of solar photovoltaic (PV) modules. Atmos. Environ. 45, 4299–4304 (2011). https://doi.org/10.1016/j.atmosenv.2011.04.084

Goossens, D., Van Kerschaever, E.: Aeolian dust deposition on photovoltaic solar cells: the effects of wind velocity and airborne dust concentration on cell performance. Sol. Energy 66, 277–289 (1999). https://doi.org/10.1016/S0038-092X(99)00028-6

Miller, D.C., Kurtz, S.R.: Durability of Fresnel lenses: a review specific to the concentrating photovoltaic application. Sol. Energy Mater. Sol. Cells 95, 2037–2068 (2011). https://doi.org/10.1016/j.solmat.2011.01.031

Roth, R.B., Pettit, E.P.: Effect of soiling on solar mirrors and techniques used to maintain high reflectivity. Sol. Mater. Sci. (1980). https://doi.org/10.2172/5249717

Alamoud, A.R.M.: Performance evaluation of various flat plate photovoltaic modules in hot and arid environment. J. King Saud Univ. Eng. Sci. 12, 235–242 (2000). https://doi.org/10.1016/S1018-3639(18)30716-5

Ali, H.M., Zafar, M.A., Bashir, M.A., Nasir, M.A., Ali, M., Siddiqui, A.M.: Effect of dust deposition on the performance of photovoltaic modules in city of taxila, Pakistan. Therm. Sci. 21, 915–923 (2017). https://doi.org/10.2298/TSCI140515046A

Elminir, H.K., Ghitas, A.E., Hamid, R.H., El-Hussainy, F., Beheary, M.M., Abdel-Moneim, K.M.: Effect of dust on the transparent cover of solar collectors. Energy Convers. Manag. 47, 3192–3203 (2006). https://doi.org/10.1016/j.enconman.2006.02.014

Garg, H.P.: Effect of dirt on transparent covers in flat-plate solar energy collectors. Sol. Energy 15, 299–302 (1974)

Wakim, F.: Introduction of PV Power Generation to Kuwait. Kuwait Institute for Scientific Researchers (1981)

Sayigh, A.A.M., Al-Jandal, S., Ahmed, H.: Dust effect on solar flat surfaces devices in Kuwait (1985)

Al-Hasan, A.Y.: A new correlation for direct beam solar radiation received by photovoltaic panel with sand dust accumulated on its surface. Sol. Energy 63, 323–333 (1998). https://doi.org/10.1016/S0038-092X(98)00060-7

Sulaiman, S.A., Hussain, H.H., Siti, N., Leh, H.N., Razali, M.S.I.: Effects of dust on the performance of PV panels. World Acad. Sci. Eng. Technol. 5, 2028–2033 (2011)

Alshebani, M.: A critical review of solar energy and dust in Gulf Countries. Int. J. Eng. Res. Appl. 11, 43–73 (2021). https://doi.org/10.9790/9622-1101044373

Bunyan, H., Ali, W.: Investigating of proper photovoltaic panel tilt angle to be used as shading device in Kuwait. J. Eng. Res. Appl. 5, 1–8 (2015)

Kimber, A., Mitchell, L., Nogradi, S., Wenger, H.: The effect of soiling on large grid-connected photovoltaic systems in California and the Southwest Region of the United States. In: Conf. Rec. 2006 IEEE 4th World Conf. Photovolt. Energy Conversion, WCPEC-4, vol 2, pp. 2391–2395 (2006). https://doi.org/10.1109/WCPEC.2006.279690

Hegazy, A.A.: Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew. Energy 22, 525–540 (2001). https://doi.org/10.1016/S0960-1481(00)00093-8

Sacks, J., Welch, W.J., Mitchell, T.J., Wynn, H.P.: Design and analysis of computer experiments. Stat. Sci. 4, 15–51 (1989). https://doi.org/10.1214/ss/1177012413

Cressie, N.: Spatial prediction and ordinary kriging. Math. Geol. 20, 405–421 (1988). https://doi.org/10.1007/BF00892986

Lophaven, S.N., Søndergaard, J., Nielsen, H.B.: Kriging Toolbox Dace (2002)

Ineichen, P.: Long term satellite hourly, daily and monthly global, beam and diffuse irradiance validation. In: Interannual Variability Analysis. (Adapted to CM-SAF product from the IEA 2013 report), C. SAF Clim. Monit. 4th User Work. Adapted to CM-SAF product from the IEA 2013 report. http://www.cuepe.ch/archives/annexes-iae/ineichen-2014_long-term-saf-validation.pdf (2014)

El-nashar, A.M.: Seasonal effect of dust deposition on a field of evacuated tube collectors on the performance of a solar desalination plant. Desalination 239, 66–81 (2009). https://doi.org/10.1016/j.desal.2008.03.007

Acknowledgements

We acknowledge the support of Kuwait Petroleum Corporation (KPC) and its subsidiary Kuwait Oil Company (KOC).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Almufarrej, A., Erfani, T. Modelling the regional effect of transmittance loss on photovoltaic systems due to dust. Int J Energy Environ Eng 14, 379–386 (2023). https://doi.org/10.1007/s40095-022-00510-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-022-00510-8