Abstract

Ferrous block metals are used frequently in large quantities in various sectors of industry for making automotive, furniture, electrical and mechanical items, body parts for consumables, and so forth. During the manufacturing stage, the block metals are subjected to some form of material removal process either through turning, grinding, milling, or drilling operations to obtain the final product. Wastes are generated from the machining process in the form of effluent waste, solid waste, atmospheric emission, and energy emission. These wastes, if not recycled or treated properly before disposal, will have a detrimental impact on the environment through air, water, and soil pollution. The purpose of this paper is to determine the impact of the effluent waste from the machining process on the environment through water analysis. A twofold study is carried out to determine the impact of the effluent waste on the water stream. The preliminary study consists of a scenario analysis where five scenarios are drawn out using substances such as spent coolant, tramp oil, solvent, powdered chips, and sludge, which are commonly found in the effluent waste. The wastes are prepared according to the scenarios and are disposed through the Institute of Product Design and Manufacturing (IPROM) storm water drain. Samples of effluent waste are collected at specific locations according to the APHA method and are tested for parameters such as pH, ammoniacal nitrogen, dissolved oxygen, biochemical oxygen demand, chemical oxygen demand, and total suspended solids. A subsequent study is done by collecting 30 samples of the effluent waste from the machining operations from two small- and medium-scale enterprise locations and the IPROM workshop to test the quality of water. The results obtained from the tests showed high values of chemical oxygen demand, ammoniacal nitrogen, and total suspended solids when compared with the Standard B specification for inland water bodies as specified by the Department of Environment, Malaysia.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

The rapid deterioration of the world's environment in the name of development is a major cause of concern for every human being on this planet. Both individuals and businesses have a social and environmental responsibility to keep this planet clean. With the rapid development in today's industrialized world, the issue of preserving and managing our environment has become crucial. The need for a good environmental management system is evidenced by the amendments made to the Environmental Quality Act 1974 and other environmental regulations, which serve to ensure stricter compliance of environmental standards in Malaysia. Malaysia also adopted the National Environment Policy in 2002 as a means of addressing environmental issues in an integrated manner, while more and more companies are striving to attain the MS14001 EMS certification [1].

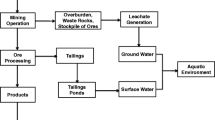

Small- and medium-scale enterprises (SMEs) are the backbone of industrialization in many developed and developing countries and play a crucial role in the growth of the country's economy. While most SMEs are in the service sector, approximately one quarter or so that are engaged in manufacturing contributes to a major portion of industrial waste [2]. Most of the SMEs that are in the metal industry and engaged in the manufacturing sector utilize one form of machining or another for material removal process. During the machining operation, any material or energy generated in addition to the final product is termed as waste. The waste generated due to machining process is a major environmental concern for manufacturers. With the emergence of new manufacturing industries, a large amount of block metals and other ferrous metals are subjected to machining process, resulting in a considerable amount of machining waste generated in the form of effluent and solid waste, and atmospheric and energy emission, as shown in Figure 1.

The cutting oil, coolant, lubricants, solvents, and additives used in the metal working processes helps to improve machinability, increase productivity, and extend tool life. They are also used to reduce friction and wear, to flush away the chips from the cutting zone, and to protect the machined surface from environmental corrosion. When performing these functions, they become contaminated with foreign organisms, causing coolants to lose effectiveness and develop foul odors. Hence, coolants are used only for a short time and then discarded. The practice of discarding and recycling coolants can be costly and troublesome. Many small- and medium-scale enterprises often dispose the used coolant and cutting fluids in an improper manner into the environment, often neglecting the consequences of such behavior. The wastes, if not recycled or treated properly before disposal, have negative impacts on the environment in terms of water, soil, and sediment pollution [3]. People, the flora and fauna, and the living environment in general are therefore affected adversely. The effluent wastes from the industries are classified as scheduled wastes and are hazardous to nature. In view of the problem above, the Department of Environment (DOE) has made it mandatory for the manufacturers to comply with the Malaysian Environmental Quality (Industrial Effluent) Regulations 2009 (PU (A) 434).

The hazardous waste in Malaysia has been gradually increasing over the years, as shown in Figure 2, a response to a survey from United Nations Statistical Division (UNSD) and United Nations Environment Programme (UNEP).This paper investigates the potential impact of effluent waste from the machining processes on the environment through water analysis.

Hazardous waste generation in Malaysia. Source: UNSD/UNEP Questionnaires on Environment Statistics [4].

Numerous studies have been carried out in Malaysia and abroad on the environmental performance assessment among the SMEs. The impact of machining waste on the environment is an area that has to be considered in view of the machines used widely among the manufacturing companies in Malaysia. The machines under consideration are the lathe machines, drilling machines, boring machines, and the milling machines. Work was conducted on field exposures of grade 304 and 316 stainless steels and a laboratory percolation study simulating 20 to 25 years of chromium- and nickel-containing runoff water interaction with soil [5]. Total metal annual release rates varied between 0.2 and 0.7 mg/m2/year for Cr, between 0.1 and 0.8 mg/m2/year for Ni, and between 10 and 200 mg/m2/year for Fe. Soil extractions showed Cr and Ni to be very strongly retained within the soil. This confirms that the corrosion from the metals can enter the nearby field and pollute the environment through the runoff water [5].

Continuous monitoring and assessment of the physical, chemical, and biological parameters of water is an essential part of the water quality control program. The disposal of machining waste through the water stream affects the aquatic organisms living in the water. Most countries practice the water quality index (WQI) method, which is similar to the existing DOE index [6]. The concept of WQI is based on the comparison of the water quality parameter with respective regulatory standards [7].

According to the DOE, the WQI is defined by six parameters, namely the biochemical oxygen demand (BOD), chemical oxygen demand (COD), dissolved oxygen (DO), pH, total suspended solids (TSS), and ammoniacal nitrogen. BOD is the most commonly used parameter for determining the oxygen demand on the receiving water of a municipal or industrial discharge. High BOD is an indication of poor water quality, while COD is an indicator of organics in the water, usually used in conjunction with BOD. COD test is commonly used to measure the amount of organic and inorganic oxydizable compounds in the water [8]. Generally, the BOD/COD ratio should be equal to or less than 1.0 [9]. The BOD/COD ratios for industrial waste water can be lower than 0.5 [10]. Oxygen is essential for all plants and animals to survive, whether they live on land or in water. Aquatic organisms rely on oxygen that is dissolved in the water. A low DO (less than 2 mg/l) indicates poor water quality and, thus, is not conducive for sustaining many sensitive aquatic lives. DO also depends on physiochemical parameters such as temperature, salinity, and pH [11]. The ammonia molecule is a nutrient required for life, but excess ammonia accumulates in the organism and causes alteration of metabolism or increase in body pH. TSS refers to the particles in the water that are larger than 0.45 μm. TSS includes pollutants such as minute metal swarfs, filings, and powdered chips [12], high concentrations of which can damage the habitats of fish and other aquatic organisms [13]. The presence of synthetic organic chemicals like solvents, paints, and detergents can impart offensive tastes, odors, and colors to fish and aquatic plants even if present in low concentrations [14]. Oil in the water also affects the lives of the aquatic beings by inhibiting the atmospheric oxygen from dissolving in the water. Free oil found in the effluent waste rises to the surface of the water and prevents the sunlight from reaching the depths of the water. Oil and grease also become chemically emulsified, primarily through the use of detergents and other alkalis [15]. pH is an indicator of the existence of biological life as most of them thrive in a quite narrow and critical pH range. The discharge of industrial effluents and urban wastes into the river water causes an increase in BOD, COD, and TSS [14, 15].

Methods

A twofold study was conducted to determine the impact of the effluent waste on the water stream. The preliminary study consisted of a scenario analysis where five scenarios were drawn out using substances which included spent coolant, tramp oil, solvent, powdered chips, and sludge [16]. These substances are used for preparing the scenarios as they are commonly found in the effluent wastes which are disposed from the manufacturer's premises. Of all the life cycle stages directly influenced by metal working fluids, the disposal stage has the largest impact on the environment as it impacts the environment through hazardous metal carry-off, hazardous chemical constituents, oxygen depletion, oil content, and nutrient loading [16]. The reaction of the coolant between the fluids, additives, and the metals being machined may cause spent fluid to become hazardous even if the ‘clean’ product was not hazardous [17]. Table 1 shows the most commonly found combinations of effluent waste confined to machining process, taken from the preliminary survey among the SMEs in Malaysia.

A scenario analysis was chosen because the effluent waste from the manufacturers may contain different combinations of the above mentioned substances depending upon the usage during the machining process. The variations in the effluent waste can cause varying impact on the water body if the waste reaches the water stream without any prior treatment or separation. The purpose of conducting this study is to determine the scenario of effluent waste that can cause the greatest impact on the water stream if it were to be disposed in an inappropriate manner.

Scenario 1 consists of the basic coolant obtained from a lathe machine after 6 months of usage. Scenario 2 consists of the basic coolant mixed with 10% of tramp oil. The amount of tramp oil in the effluent waste was found to be between 1% and 16% [18]. Tramp oil originates as lubrication oil seeping out from the slideways and washing into the coolant mixture, as the protective film with which the steel supplier coats the bar stock to prevent rusting, or as hydraulic oil leaks. In extreme cases, it can be seen as a film or skin on the surface of the coolant or as floating specks of oil. A tramp oil level above 2% could cause health issues due to emulsification [18]. Scenario 3 consists of the basic coolant mixed with 10% oil and around 10 g of ferrous material chips in near-powdered form [19]. Generally the effluent waste from a grinding machine includes minute particles of iron and worn-out or burnt-out abrasives from the wheel, which are difficult to segregate from the used coolant. The complexity of the fluid is compounded by contamination from a combination of substances from the manufacturing process, such as tramp oils, hydraulic fluids, and particulate matter from the machining operations [19]. Scenario 4 consists of 10% sludge mixed with the basic coolant. Sludge is a heavy residue that lies at the bottom of the sump or in a drum where the used coolants are stored before disposal. Microorganisms such as bacteria tend to multiply and grow in the sludge that is present in the effluent waste. Scenario 5 consists of the basic coolant mixed with 10% sludge and 2% solvent. Solvents are used to clean and degrease the finished goods and even certain machine parts after the machining operation. The effluents, in combination with oil and grease, can form a toxic substance for the aquatic organisms [8].

These wastes are then diluted with 20% of water from the Institute of Product Design and Manufacturing (IPROM) workshop to simulate the type of effluent waste which is disposed by manufacturers into the water stream. These wastes are disposed into the storm water drain in the IPROM; from there, the effluent waste flows into a bigger drain which runs along the periphery of the campus.

The experiments are conducted on three different occasions, and on each occasion, the experiments are repeated thrice for reliability. Samples of effluent waste are collected for each of the simulated scenarios from the IPROM storm water drain according to APHA methods. A bar chart is plotted using the mean values to assess the WQI parameters against the Standard B specification from the DOE, Malaysia.

The second part of the research consists of a comparative study where 30 samples of effluent wastes were collected from the machining workshops of two SMEs and the IPROM. The samples were diluted and tested for the WQI parameters. A statistical analysis was conducted using the SPSS software to determine the homogeneity of variance, the mean between the samples, and the effect of covariance among the samples of effluent waste collected from the SMEs and from the IPROM.

Results and discussion

The effluent quality of any discharge from a point of source to an inland body of water should meet the minimum requirements of the Environmental Quality Act 1974, and the limits set down by the Environmental Quality Act are the Standard A and Standard B specification in accordance with the Sewage and Industrial Effluent Regulations, 1979. Standard A criteria applies to catchment areas located upstream of drinking water supply offtakes, while Standard B specification refers to areas downstream from the point of discharge.

Scenario analysis

Figure 3 shows the BOD values for different scenarios of effluent waste. The maximum BOD is between 15 to 16 mg/l, which is below the Standard B specification for inland bodies of water and is within the permissible range by the DOE. However, this would place the BOD limit above category 4 according to the Interim National Water Quality Standard (INWQS). The increase in values of the BOD for scenario 4 can be due to the presence of microorganisms in the sludge generated during the storage of the waste coolant before disposal. The untreated or partially treated sewage from the outlets into the drain can also cause the BOD to go high [15].

Figure 4 shows the COD values for different scenarios of effluent waste. The maximum COD is around 31 mg/l, which is below the Standard B specification, and it can be placed in category 3 according to the INWQS. Sample1 shows a higher COD limit due to the presence of anaerobic microbes generated in the stored effluent waste before disposal. A higher COD results in a reduced oxygen level in the water.

Figure 5 shows the DO values for different scenarios of effluent waste. The minimum DO is around 1 mg/l, which is very low for aquatic beings and indicates poor water quality according to Standard B specification. This would place the DO limit to category 4 according to the INWQS. Scenarios 1, 2, and 3 show the presence of greater amount of oxygen in the water. However, for scenarios 4 and 5, the amount of DO is below 2 mg/l in samples 2 and 3. Scenarios 4 and 5 constitute one part of sludge, which is a thick viscous liquid where microorganisms such as bacteria can easily multiply and grow. These microorganisms take in the dissolved oxygen, consequently reducing the overall level of DO in the water. The low water level in the drain, together with high atmospheric temperature, can also reduce the level of DO in water.

Figure 6 shows the values of ammoniacal nitrogen (AN) for different scenarios of effluent waste. The maximum AN is between 8 and 9 mg/l, which is higher than the Standard B specification limit and places the AN limit in category 5 according to the INWQS. Ammonia is produced from the decay of organic matter and animal waste. The bacteria break down the organic matter into nitrate. The sources of AN can also be from the domestic sewage that is resident in the drain. Excess ammonia accumulates in the organism and causes alteration of metabolism or increase in body pH.

Figure 7 shows the pH values for different scenarios of effluent waste. The samples containing the effluent waste appear to be mildly alkaline as they exceed 7 on the pH scale. The levels are within the range of Standard B specification and can be placed in category 2 according to the INWQS.

Figure 8 shows the values for TSS for different scenarios of effluent waste. The maximum limit of TSS obtained from the samples is between 50,000 and 60,000 mg/l.

This is much higher than the Standard B specification limit. It places the TSS limit to category 5 as specified by the INWQS. The TSS limits are very high during the third sampling conducted with scenario 4 of the effluent waste. The effluent waste from the IPROM containing sludge and small particles of iron chips contributes to this effect. High suspended solids also prevent the sunlight from penetrating into the water [8].

The Water Quality Index for the five scenarios is shown in Figure 9. According to the DOE standards, a range from 0 to 59 indicates a high pollution level, while a range from 60 to 80 indicates slight pollution, and any value higher than 81 indicates no pollution. The results of the experiment show that when the effluent waste is disposed into the water stream, the water can be polluted. However, the level of pollution will be minimized when there is a heavy flow of water in the drain.

Comparative study

A comparative study through water analysis was also conducted among the SMEs on the impact of effluent waste on the environment. Thirty samples of effluent waste derived from the machining process were collected from two SMEs and the IPROM for the comparative study. A statistical analysis was done on the data obtained through experimentation.

The data from the samples indicate a positive correlation to that obtained from the IPROM during the scenario analysis. An ANOVA was performed on the data obtained from the two SME premises and the IPROM. The BOD analysis shows that the test of homogeneity of variance is not significant at the 5% significance level according to Levene's statistic (as P value > 0.05). Thus, the null hypothesis of homogeneity of variances cannot be rejected. The estimated F statistics is 9.413 and significant at the 5% level (as P value 0.00 < 0.05). Hence, the decision was to reject the null hypothesis of equal means at the 5% level of significance. This shows that the mean of the BOD between the groups of samples are different from each other in a significant manner. The post hoc comparison test shows that the SME1 samples indicate a higher BOD compared to the SME2 and IPROM samples, as shown in Figure 10.

The COD analysis shows that the test of homogeneity of variance is not significant at the 5% significance level (as P value > 0.05). Thus, the null hypothesis of homogeneity of variances cannot be rejected. The estimated F statistics is 0.538 and is not significant at the 5% level of significance (as P value 0.586 > 0.05). Hence, the decision was not to reject the null hypothesis of equal means at the 5% level of significance. This proves that the mean COD between the groups of samples is not significantly different from each other. The post hoc comparison test shows that the SME1 samples indicate a higher COD compared to the SME2 and IPROM samples, as shown in Figure 11.

The DO present among the three samples was also subjected to an ANOVA test. The test of homogeneity of variance shows that Levene's statistic is not significant at the 5% significance level (as P value > 0.05). Thus, the null hypothesis of homogeneity of variances is not rejected. The estimated F statistics is 15.970 and significant at the 5% level of significance (as P value 0.00 < 0.05). Hence, the decision was to reject the null hypothesis of equal means at the 5% level of significance. This proves that the mean of the DO between the groups of samples are different from each other in a significant manner. The post hoc comparison test with honestly significant difference (HSD) test shows that the SME1 samples indicate a higher DO compared to the SME 2 and IPROM samples, as shown in Figure 12.

In the analysis for TSS, the test of homogeneity of variance shows that Levene's statistic is not significant at the 5% significance level (as P value > 0.05). Thus, the null hypothesis of homogeneity of variances cannot be rejected. The estimated F statistics is 0.021 and is not significant at the 5% level of significance (as P value 0.979 > 0.05). Hence, the decision was not to reject the null hypothesis of equal means at the 5% level of significance. This proves that the mean TSS values of SME1, SME2, and the IPROM are not significantly different from each other. The post hoc comparison test shows that the SME1 samples indicate a higher TSS compared to the SME2 and IPROM samples, as shown in Figure 13.

The AN present among the three samples was also subjected to an ANOVA test. The test of homogeneity of variance shows that Levene's statistic is not significant at the 5% significance level (as P value > 0.05). Thus, the null hypothesis of homogeneity of variances cannot be rejected. The estimated F statistics is 1.657 and not significant at the 5% level of significance (as P value 0.197 < 0.05). Hence, the decision was not to reject the null hypothesis of equal means at the 5% level of significance. This proves that the mean AN values of the SME1, SME2, and IPROM samples are not significantly different from each other. The post hoc comparison test with HSD shows that the SME2 samples indicate a higher AN compared to the SME1 and IPROM samples, as show in Figure 14.

The statistical analysis indicate that the mean of the samples may or may not be different from each other, depending upon several factors such as the age of the effluent waste that was disposed, the nature of the effluent waste, the scenario of waste disposal, and the amount of waste disposed.

An analysis of covariance (ANCOVA) was also conducted based on the samples to determine the effect of the independent variables on the dependent variables sub-index value of BOD (QBOD) and sub-index value of COD (QCOD) without the existence of any extraneous variables. The possible effect of any extraneous variables such as temperature and turbidity (covariates) on the dependent variable is statistically controlled in the analysis of covariance.

When an ANCOVA is performed on QBOD with turbidity as the covariate, Levene's test of equality of error variances shows that there is no significant difference between the variances of the QBOD values of the three samples (as P value 0.174 > 0.05). As the probability value obtained from SPSS (0.662 for the sample comprised of the IPROM, SME1, and SME2) is higher than the predetermined value (0.05), the null hypothesis was not rejected. Hence, there exists adequate evidence to show that there is no significant difference in the mean score of QBOD between the different samples when turbidity is statistically controlled. As the probability value obtained from SPSS (0.730 for turbidity) is higher than the predetermined value (0.05), the null hypothesis was not rejected. There exists adequate evidence to show that there is no significant difference in the mean score of QBOD due to turbidity. When the ANCOVA was performed on QBOD with temperature as the covariate, Levene's test of equality of error variances shows that there is no significant difference between the variances of the QBOD values of the three samples (as P value 0.153 > 0.05). As the probability value obtained from SPSS (0.006 for the samples comprised of the IPROM, SME1, and SME2) is lower than the predetermined value (0.05), the null hypothesis is rejected. Hence, there exists adequate evidence to show that there is a significant difference in the mean score of QBOD between the different samples when temperature is statistically controlled.

The ANCOVA was also conducted on QCOD with turbidity as the covariate. Levene's test of equality of error variances shows that there is no significant difference between the variances of the QCOD values of the three samples (as P value 0.365 > 0.05). As the probability value obtained from SPSS (0.388 for the sample comprised of the IPROM, SME1, and SME2) is higher than the predetermined value (0.05), the null hypothesis was not rejected. Hence, there exists adequate evidence to show that there is no significant difference in the mean score of QCOD between the different samples when turbidity is statistically controlled. As the probability value obtained from SPSS (0.294 for turbidity) is higher than the predetermined value (0.05), the null hypothesis was not rejected. There exists adequate evidence to show that there is no significant difference in the mean score of QCOD due to turbidity. When the ANCOVA was conducted with temperature as the covariance, Levene's test of equality of error variances shows that there is no significant difference between the variances of the QCOD values of the three samples (as P value 0.311 > 0.05). As the probability value obtained from SPSS (0.576 for the sample comprised of the IPROM, SME1, and SME2) is higher than the predetermined value (0.05), the null hypothesis was not rejected. Hence, there exists adequate evidence to show that there is no significant difference in the mean score of QCOD between the different samples when temperature is statistically controlled. As the probability value obtained from SPSS (0.591 for Temperature) is higher than the predetermined value (0.05), the null hypothesis was not rejected. There exists adequate evidence to show that there is no significant difference in the mean score of QCOD due to temperature.

The ANCOVA is used to minimize the possible errors by individual differences in the samples. The results for the ANCOVA show that the covariates considered in this study, turbidity and temperature, do not have significant influence on the dependent variable, apart from the case when temperature causes a fluctuation in the QBOD. The temperature of the water causes the DO to fluctuate, and colder water can hold more oxygen compared to warmer waters [20].

Conclusions

Numerous studies through water analysis have been made on the impact of effluent waste on the environment, a few of which are compiled in Table 2. Most of these experiments show high amounts of BOD and COD in combination with low DO in the presence of effluent waste. The resident waste in the channel, wastes flowing down from upstream, wastes from sewages, and waste due to the influx of the effluents from the industries can be the source of contamination. The current study showed that the BOD and COD are within the Standard B specification, while TSS and ammoniacal nitrogen are high compared to the Standard B specification for inland waters. The WQI parameters may show a different result, depending upon several factors. These factors can be broadly classified as internal factors and external factors. The internal factors consist of the nature of the effluent waste that is disposed from the SME, the amount of waste disposed on one occasion, the treatment done on the effluent waste before disposal, the frequency of disposal, and the time of disposal. These factors are within the control of the company, while the external factors lie outside the control of the company. The external factors consist of the amount of water flowing down the drain at the point of disposal, the flow of water in the drain, the slope of the drain towards the merging river, and upstream pollution. Adequate measures must be taken on the internal factors to comply with the Malaysian environmental law before the effluent waste is released into the drain. Subsequent to this research, an acute test with LC50 as the end point is recommended to determine the degree of toxicity of the effluent waste.

Authors' information

PPK is a senior lecturer at Universiti Kuala Lumpur, Malaysia, currently doing his PhD study with IPROM, Universiti Kuala Lumpur. This research paper is a part of his PhD program. MRI is an associate professor and Deputy Dean for IPROM and is also the PhD supervisor for PPK. MHH is a senior professor of University Malaya and Co-supervisor for PPK. TFTY is a Senior Lecturer with MICET, Universiti Kuala Lumpur, and is also the Head of Section for the Environmental Engineering Department.

Abbreviations

- AN:

-

Ammoniacal nitrogen

- BOD:

-

Biochemical oxygen demand

- COD:

-

Chemical oxygen demand

- DO:

-

Dissolved oxygen

- DOE:

-

Department of Environment

- INWQS:

-

Interim National Water Quality Standard

- IPROM:

-

Institute of Product Design and Manufacturing

- QBOD:

-

Sub-index value of BOD

- QCOD:

-

Sub-index value of COD

- SME:

-

Small- and medium-scale enterprises

- TSS:

-

Total suspended solids

- UNSD:

-

United Nations Statistical Division

- WQI:

-

Water quality index.

References

Ensearch: Environmental management for SMIs/SMEs. SMI/SME Business Directory, SMI/SME Editorial. (2008) http://www.smibusinessdirectory.com.my/smisme-editorial/more/safetyhealthenvironmentalissues/389-environmental-management-for-smissmes.html (2008)

UNEP: Industry and Environment. 2003., 26: No. 4

Amin A, Ahmad T, Ehsanullah M, Irfanullah , Khatak , Khan MA: Evaluation of industrial and city effluent quality using physicochemical and biological parameters. EJEAFChe 2010,9(5):931–939.

The United Nations Statistics Division: UNSD/UNEP questionnaires on environment statistics, waste section. . (2011) http://unstats.un.org/unsd/environment/hazardous.htm . (2011)

Wallinder IO, Bertling S, Kleja B, Leygraf C: Corrosion-induced release and environmental interaction of chromium, nickel and iron from stainless steel. Water, Air, and Soil Pollution 2006, 170: 17–35. 10.1007/s11270-006-2238-5

Department of Environment: Classification of Malaysian rivers, final report on development of water quality criteria and standards of Malaysia, (Phase IV-River classification). 1994. Department of Environment Malaysia, Ministry of Science, Technology and the Environment

Khan S, Noor M: Investigation of pollutants in waste water of Hayatabad Industrial Estate Peshawar. Pakistan Journal of Agriculture Sciences 2002, 2: 457–461.

Ministry of Natural Resources and Environment Malaysia: Study on the river water quality trends and indexes in peninsular Malaysia. Water Resources Publication No. 21, Water Resources Management and Hydrology Division, Department of Irrigation and Drainage. 2009.

Samudro G, Mangkoedihardjo S: Review on BOD, COD and BOD/COD ratio: a triangle zone for toxic, biodegradable and stable levels. International Journal of Academic Research. 2010, 2: 4.

Mangkoedihardjo S: Biodegradability improvement of industrial wastewater using hyacinth. Journal of Applied Sciences. 2006,6(6):1409–1414.

Jack PJ, Abdsalam AT, Khalifa NS: Assessment of dissolved oxygen in coastal waters of Benghazi. Libya. J. Black Sea/Mediterranean Environment 2009, 15: 135–150.

Said A, Stevens DK, Sehlke G: An innovative index for evaluating water quality in streams. Environ Manage 2004,34(3):406–414. 10.1007/s00267-004-0210-y

Avvannavar SM, Shrihari S: Evaluation of water quality index for drinking purposes for river Netravathi. South India, Environmental Monitoring and Assessment, Mangalore; 2007.

Sisodia R, Chaturbhuj M: Assessment of water quality index of wetland Kalakho Lake, Rajasthan. India. Journal of Environmental Hydrology. 2006, 14: 23.

Tariq M, Ali M, Shah Z: Characteristics of industrial effluents and their possible impacts on quality of underground water. Soil & Environ. 2006,25(1):64–69.

Handbook of Environmentally Conscious Mechanical Design: Environmentally Conscious Manufacturing. Prevention of Metalworking Fluid Pollution: Environmentally Conscious Manufacturing at the Machine Tool. 2nd edition. Wiley, New York ; 2000.

USEPA: Pollution prevention in machining and metal fabrication: a manual for technical assistance providers. NEWMOA (2001). http://www.newmoa.org/prevention/topichub/23/newmoamanual.pdf NEWMOA (2001).

Gauthier SL: Metalworking fluids: oil mist and beyond. Appl Occup Environ Hyg 2003, 18: 818–824. 10.1080/10473220390237313

National Institute for Occupational Safety and Health (NIOSH): Metalworking Fluids. Centers for Disease Control and Prevention. Atlanta; . Accessed January 2012 http://www.cdcinfo@cdc.gov . Accessed January 2012

Phiri O: Assessment of the impact of industrial effluents on water quality of receiving rivers in urban areas of Malawi. Int. J. Environ. Sci. Tech. 2005,2(3):237–244.

Ogedengbe K, Akinbile CO: Comparative analysis of the impact of industrial and agricultural effluent on Ona Stream in Ibadan. Nigeria. New York Science Journal. 2010, 3: 7.

Kanu I, Jeoma P, Achi OK: Industrial effluents and their impact on water quality of receiving rivers in Nigeria. Journal of Applied Technology in Environmental Sanitation 2011,1(1):75–86.

Kumara P, Kumar S, Agarwal A: Impact of industrial effluents on water quality of Behgul River at Bareilly. Advances in Bioresearch. 2010,1(2):127–130.

Acknowledgments

The current research is funded by the Short Term Research Grant (STRG) from Universiti Kuala Lumpur to carry out studies in manufacturing and on the environment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

PPK was involved in the design of the study, carried out the experimentations, collected the samples, performed the graphical and statistical analyses, and drafted the manuscript. MRI guided the whole study. MHH was involved in the design of the study. TFTY carried out the water analysis test at the MICET environmental laboratory. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Kovoor, P.P., Idris, M.R., Hassan, M.H. et al. A study conducted on the impact of effluent waste from machining process on the environment by water analysis. Int J Energy Environ Eng 3, 21 (2012). https://doi.org/10.1186/2251-6832-3-21

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-6832-3-21