Abstract

ZnO nanoparticles (NPs) were successfully fabricated by simple combustion process, in which Zn(CH3COO)2 precursors migrated with the aid of alcoholic fuel to the top of a burning lampwick and the chemical reactions occurred at the solvent-air interface of the ignited lampwick, yielding ZnO NPs. Ultraviolet-visible spectroscopic analysis and energy-dispersive spectroscopic elemental analysis revealed that the fabricated ZnO NPs are comprised mainly of Zn and O atoms. It was observed that most of the ZnO NPs exhibited an ellipsoidal shape having a particle size of 100 to 200 nm for short-length axes and 100 to 400 nm for long-length axes. To see the effectiveness of the fabricated ZnO NPs, it was employed as photocatalytic agent to degrade the organic dye, viz. Rhodamine B, and catalytic activities under both sunlight and UV light were analyzed and compared with respect to the commercially available ZnO (Fluka). The initial degradation rate in fabricated ZnO NPs was almost double than that of ZnO (Fluka). Furthermore, by exposing to sunlight for 1 h, the fabricated ZnO NPs degraded Rhodamine B dye more than 80%, whereas it was only approximately 35% for ZnO (Fluka). Photocatalytic activities might be attributed to porous structures with larger active surface area of the nanosized ZnO particles. With this advantage, 96% of organic contaminants were degraded by the fabricated ZnO NPs upon exposure to sunlight for 2 h.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Water pollution has been a serious threat to the environment. The major sources of pollutants are from manufacturing processing industries, particularly chemical and textile industries in which organic dyes are widely used. Presently, the perilous effects of organic dyes to the environment are a particular concern. Conventional treatment methods, adsorptions for instance, are not always adequate and/or appropriate to remove organic dyes from wastewater streams in a large scale. Adsorption is a nondestructive method, which simply transfers dyes from one medium to another. In recent years, many researchers are interested in applying the ‘photocatalytic decomposition process’ to degrade the hard-to-biodegrade organic pollutants in industrial wastewater before discharge into mainstream water bodies [1].

Nanostructured semiconductors are a potential candidate for the mineralization of toxic organic compounds, hazardous inorganic constituent [1], and bacteria disinfection [2] owing to its strong oxidizing ability, i.e., hydroxyl radical (). Numerous metal oxides such as zinc oxide (ZnO), titanium dioxide (TiO2) [3], strontium titanate (SrTiO3) [4], tungsten oxide (WO3) [5], silver nanoparticle [6], and hematite (α-Fe2O3) [5] are turned to be potential photocatalysts. ZnO has appeared to be a prominent catalyst as far as water detoxification is concerned; on accounting that, it produces H2O2 more efficiently and shows high reaction and mineralization rates [7]. In addition, it was reported that ZnO showed high surface reactivity due to its higher number of active sites [7]. ZnO has been proven as a superior photocatalyst compared to commercial TiO2 due to its higher initial rates of activities and absorption efficacy of solar radiations [7]. As a result, ZnO has been widely used in the treatment of wastewater owing to its excellent chemical and physical properties. A number of methods have been developed to synthesize ZnO nanoparticles (NPs), such as, the sol-gel method [8], evaporative decomposition of solution [9], hydrothermal [10], wet chemical synthesis [11], and template-assisted growth [12]. These methods are very expensive and usually employed to produce highly pure ZnO with desired shape and crystallinity.

Of these, however, it is still a challenge to find a simple fabrication process to prepare ZnO NPs with a large active surface area. In addition, the use in agricultural and environmental aspect requires a simple, cost-effective fabrication process to synthesize ZnO NPs, which can provide a high yield with reasonable purities. Solution-combustion process is simple and cost-effective, expected to provide extremely porous structure of ZnO NPs [13]. With this advantage, the solution-combustion method has been employed to fabricate ZnO NPs, with a mixture of ethanol and ethyleneglycol (V/V = 60/40) as the solvent and zinc acetate as the zinc source, and explore its photocatalytic degradation effects on organic dye Rhodamine B.

Results and discussion

SEM images of the microstructure ZnO NPs prepared by the combustion method is depicted in Figure 1, showing that most particles exhibited an ellipsoidal shape. Some small particles with a rounded shape and few large particles were also seen. The bigger-sized particles ought to be attributed to the aggregation or overlapping of small particles. The particle size measured from the SEM micrographs was in the range of 100 to 200 nm for short-length axes and 100 to 400 nm for long-length axes. Thus, the topological images suggested that particle sizes were not well defined; it might be resultant of uncontrolled ambient conditions.

Figure 2 shows the EDS scan profile of the fabricated ZnO NPs. The spectrum shows the presence of Zn, O, and K atom in the sample. Highly intense peaks of O and Zn were observed, indicating that the NPs were composed mainly of ZnO along with some impurities. In the scan profile, the K peak was likely to come from the cotton lampwick as cotton lampwick contains K atom. An elemental analysis on the cotton lampwick was performed to further confirm the presence of K atom.

For the characterization of the fabricated ZnO NPs, in the present study, an UV-vis spectrophotometer was employed to record the absorbance spectra in the wavelength range of 200 to 1,100 nm for dispersed ZnO NPs in distilled water. The absorbance spectrum of ZnO NPs is shown in Figure 3. A strong absorption band ranging from 200 to 400 nm was observed for ZnO NPs due to the metal ion [13]. The n → σ* absorption bands appeared at approximately 295 nm. The n → π* transition bands in the ZnO NPs were observed at approximately 312 nm. This spectrum was consistent with previously reported data [13]. An absorption peak centered at 374 nm (3.32 eV) was seen, thus in good agreement with previous work.

ZnO is proven to be a potential photocatalyst and has widely been used in wastewater treatment. The origin of photocatalytic process is related with the generation of electron-hole pairs with the help of bandgap radiation, thus increasing redox reactions with adsorbed species on the catalyst surface [1, 13]. The hydroxyl free radical () is considered as a driving matter, originated from the oxidation process of OH− or H2O by the photogenerated electron-hole pairs in the presence of oxygen. The hydroxyl free radical () is a strong oxidant and can decolorize organic dyes by degrading the conjugated bonds. The possible route of hydroxyl free radical formation is shown here [2, 4]:

To investigate the photocatalytic activities of the fabricated ZnO NPs, an organic dye, Rhodamine B, was employed. Figure 4a shows the UV-vis absorption spectra of Rhodamine B by exposure to sunlight for 30, 60, 90, 120, and 150 min, respectively, in the presence of ZnO NPs. It was seen that after irradiating for 60 min, the absorption peak intensity sharply decreased. After that, it decreased gradually with increasing exposure time. It demonstrated that the fabricated ZnO NPs has good photocatalytic degradation efficiency in sunlight. Figure 4b shows the UV-vis absorption spectra of the Rhodamine dye irradiated by UV light of 365 nm wavelength for several time intervals ranging from 20 to 130 min in the presence of ZnO NPs. A similar trend was found; the intensity of absorbance peak decreased more rapidly until 30 min compared to that with exposure to sunlight, indicating that UV light enhances the catalytic activities of ZnO NPs, which might be due to the bandgap in the ultraviolet region (approximately 3.32 eV) promoting photocatalysis upon illumination with UV radiation. After 30 min, it decreased slowly with increasing exposure time.

The maximum absorbance was observed at approximately 560 nm both in sunlight and UV light, and the percentage of degradation was calculated considering the absorbance maxima, equal to [A i − A t ] × 100, where A i and A t denotes the absorbance of Rhodamine B at time t = 0 and t = t, respectively. In Figure 5, the percentage of degradation with time for degradation reactions, catalyzed by commercial and nanocrystalline ZnO (Fluka) respectively, are shown and compared for both sunlight and UV light exposure. Figure 5a shows the faster degradation rate in the case of the fabricated ZnO NPs compared to that of the commercial ZnO in the early stage of reaction. Approximately 90% of the dye was degraded by the fabricated ZnO NPs, whereas it was only approximately 35% for the commercial ZnO (Fluka) after 80 min. The results of the photodegradation experiments on commercial ZnO and fabricated ZnO NPs catalyst clearly indicated that the fabricated ZnO NPs are more active than the commercial ZnO in degrading Rhodamine B. The photocatalytic activity differences can be attributed to the ZnO NPs' larger surface area with extremely porous structures, providing an elevated active surface for the fabricated ZnO NPs. Moreover, as dimension of NPs are smaller, the photogenerated electron-hole pairs can rapidly reach the catalyst surface, reducing recombination process probability. The reduced activity of ZnO NPs in the whole time course of the catalyzed reaction can be explicated by photocorrosion phenomena. This hypothesis explained that, with decreasing intensity of irradiation, a higher photocatalytic rate of the nanosized ZnO compared to the commercial ZnO was observed, thus omitting an extensive degradation of the catalyst.

Conclusions

A novel, feasible, and cost-effective process of fabricating ZnO NPs was successfully demonstrated, which would be a very promising method for synthesizing other semiconductor NPs. The chemical reactions occurred at the solvent-air interface, yielding ZnO NPs via esterification of alcohol. The NPs exhibited a nonuniform size and shape which might be due to the uncontrolled growth; however, controlled processing parameters might produce a uniform size and shape of the particles. Importantly, the fabricated ZnO NPs exhibited excellent catalytic properties for the degradation of organic dyes in the presence of sunlight and UV-vis light. Porous structures provided a larger surface area with an elevated active surface, thus attributing better catalytic degradation properties of nanosized ZnO particles on the organic dye Rhodamine B over commercial ZnO (Fluka). More than 95% of Rhodamine B was degraded by exposing to sunlight for 2 h in the presence of the fabricated ZnO NPs. Therefore, it is very promising and implementable for the degradation of organic matter for wastewater treatment in small or large scale.

Methods

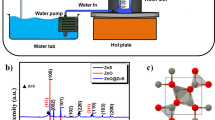

All chemicals were purchased from the market and used as received. In this study, Zn(CH3COO)2.2H2O (0.03 mol) was dissolved in 100 mL of a mixed-solvent system of ethanol-ethyleneglycol in a volume ratio of 60/40. A portion of this mixture was transferred to a spirit lamp including an absorbent cotton lampwick. The spirit lamp was ignited, and after a certain time, a yellowish-colored substance formed around the surface of the ignited lampwick. When the lampwick was quenched, the yellow-colored substance turned white. A schematic diagram of the fabrication process is shown in Figure 6. It has been reported that the interaction between zinc acetate and alcohol under solvothermal conditions follows the esterification reaction, yielding ZnO, ester, and water [13–15], according to the following reaction:

The fabrication process of ZnO NPs by a simple combustion method. (a) A spirit lamp containing Zn(OAc)2 and an ethanol-ethyleneglycol mixture. (b) Yellow-colored ZnO deposited around the burning lampwick. (c) The yellow-colored ZnO turned white, indicating the formation of ZnO NPs. (d) A separated portion of the lampwick with ZnO NPs. (e) ZnO NPs peeled off, dispersed in water, and dried at 500°C.

The resultant white product was repeatedly peeled off and dispersed in distilled water to remove the impurity. For further purification, the synthesized ZnO NPs were dried at 500°C in a muffle furnace for 6 h (5 h) and finally preserved in an airtight desiccator. Scanning electron microscope (SEM) images were taken by a Sirion 200 field emission scanning electron microanalyzer (FEI Co., Hillsboro, OR, USA employing an operating voltage of 25 kV to investigate the particle size and shape. Energy dispersion spectroscopy (EDS) and ultraviolet-visible (UV-vis) spectroscopy using a Hitachi U-4100 spectrophotometer (Tokyo, Japan) were employed to characterize the ZnO NPs. To observe the degradation effects, 1.5 g of ZnO was dispersed in 100-mL aqueous solutions containing Rhodamine B, an organic dye, and exposed to sunlight (at a temperature around 30°C) and UV light for the desired time. Then the decolorization of the dye was measured by UV-vis spectroscopy.

Authors’ information

MAA is an assistant professor at the Department of Agricultural Chemistry at Bangladesh Agricultural University, Bangladesh. Presently, he is on leave and taking a Ph.D. degree at the Centre for Organic Photonics and Electronics (COPE), School of Chemistry and Molecular Biosciences, The University of Queensland, Australia. He has been awarded with an International Postgraduate Research Scholarship and the University of Queensland Centennial Scholarship for Ph.D. study. He achieved his master degree in advanced materials engineering from Kookmin University, South Korea and his bachelor degree in chemistry from the Department of Chemistry, University of Dhaka, Bangladesh. He had obtained a fellowship provided by the Ministry of Science and Technology/Korea Science and Engineering Foundation through the Center for Materials and Processes of Self-Assemble (CMPS) for a 2-year period from September 1, 2008 through August 31, 2010 to support his master degree. His research interest involves the fundamental understanding of the physical properties of optoelectronic materials to implementing the devices. He is credited with more than ten international journal publications and presented his research works in several international conferences.

MRI achieved his B.Sc. in chemistry and M.Sc. degree in physical chemistry from the University of Dhaka, Bangladesh. At present, he involves himself as a lecturer at the Department of Textile Engineering, City University, Bangladesh. He is also taking an M.Phil. degree in physical chemistry at the Department of Chemistry, University of Dhaka. His specialization is on the synthesis, characterization, and applications of nanoparticles.

MEQ is a professor of physical chemistry at the Department of Chemistry, University of Dhaka, Bangladesh. He holds a B.Sc. degree in chemistry, and M.Sc. and Ph.D. in physical chemistry. He has more than 18 years of research experience and 14 years of teaching experience at the graduate and post-graduate level. He is specialized in electrochemistry and materials chemistry. He published more than 20 international journal publications and guided many M.Phil. and Ph.D. students.

References

Curri ML, Comparelli R, Cozzoli PD, Mascolo G, Agostiano A: Colloidal oxide nanoparticles for the photocatalytic degradation of organic dye. Mater Sci Eng C 2003, 23: 285–289. 10.1016/S0928-4931(02)00250-3

Karunakaran C, Abiramasundari G, Gomathisankar P, Manikandan G, Anandi V: Cu-doped TiO 2 nanoparticles for photocatalytic disinfection of bacteria under visible light. J Colloid Interface Sci 2010, 352: 68–74. 10.1016/j.jcis.2010.08.012

Wu MC, Sápi A, Avila A, Szabó M, Hiltunen J, Huuhtanen M, Tóth G, Kukovecz Á, Kónya Z, Keiski R, Su WF, Jantunen H, Kordás K: Enhanced photocatalytic activity of TiO 2 nanofibers and their flexible composite films: decomposition of organic dyes and efficient H 2 generation from ethanol–water mixtures. Nano Res 2011,4(4):360–369. 10.1007/s12274-010-0090-9

Karimi L, Zohoori S: Superior photocatalytic degradation of azo dyes in aqueous solutions using TiO 2 /SrTiO 3 nanocomposite. J Nanostructure Chem 2013, 3: 32. 10.1186/2193-8865-3-32

Bhatkhande DS, Pangarkar DS, Beenackers AACM: Photo catalytic degradation for environmental applications – a review. J Chem Technol 2001, 77: 102–116.

Vanaja M, Gnanajobitha G, Paulkumar K, Rajeshkumar S, Malarkodi C, Annadurai G: Phytosynthesis of silver nanoparticles by Cissus quadrangularis : influence of physicochemical factors. J Nanostructure Chem 2013, 3: 17. 10.1186/2193-8865-3-17

Ullah R, Dutta J: Photocatalytic degradation of organic dyes with manganese-doped ZnO nanoparticles. J Haz Mater 2008, 156: 194–200. 10.1016/j.jhazmat.2007.12.033

Joo J, Kwon SG, Yu JH, Hyeon T: Synthesis of ZnO nanocrystals with cone, hexagonal cone, and rod shapes via non-hydrolytic ester elimination sol–gel reactions. Adv Mater 2005, 17: 1873–1877. 10.1002/adma.200402109

Marci G, Augugliaro V, Lopez-Munoz MJ, Martin C, Palmisano L, Rives V, Schiavello M, Tilley RJD, Venezia AM: Preparation characterization and photocatalytic activity of polycrystalline ZnO/TiO 2 systems. 1. Surface and bulk characterization. J Phys Chem B 2001, 105: 1026–1032. 10.1021/jp003172r

Ni YH, Wei XW, Hong JM, Ye Y: Hydrothermal preparation and optical properties of ZnO nanorods. Mater Sci Eng B 2005, 121: 42–47. 10.1016/j.mseb.2005.02.065

Pal U, Santiago P: Controlling the morphology of ZnO nanostructures in a low-temperature hydrothermal process. J Phys Chem B 2005, 109: 15317–15321. 10.1021/jp052496i

Jie J, Wang G, Wang Q, Chen Y, Han X, Wang X, Hou JG: Synthesis and characterization of aligned ZnO nanorods on porous aluminum oxide template. J Phys Chem B 2004, 108: 11976–11980. 10.1021/jp048974r

Ni Y, Cao X, Wu G, Hu G, Yang Z, Wei X: Preparation, characterization and property study of zinc oxide nanoparticles via a simple solution-combusting method. Nanotechnology 2007, 18: 155603–155608. 10.1088/0957-4484/18/15/155603

Yiamsawas D, Boonpavanitchakul K, Kangwansupamonkon W: Preparation of ZnO nanostructures by solvothermal method. J Micros Soc Thailand 2009,23(1):75–78.

Bell NS: Solvothermal routes for synthesis of zinc oxide nanorods. Symp Pros Mater Res Soc 2005, 878E: Y2.6.1-Y2.6.11.

Acknowledgments

The authors thank the Bangladesh Council of Scientific and Industrial Research (BCSIR), Dhaka, Bangladesh for the SEM images.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

MAA analyzed, interpreted, and organized the data and prepared the manuscript. MRI carried out the experiments. MEQ designed and coordinated the overall project. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Ali, M.A., Idris, M.R. & Quayum, M.E. Fabrication of ZnO nanoparticles by solution-combustion method for the photocatalytic degradation of organic dye. J Nanostruct Chem 3, 36 (2013). https://doi.org/10.1186/2193-8865-3-36

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2193-8865-3-36