Abstract

Nanoparticles of carvedilol are prepared by ultrasonic method. Particle sizes and morphology of nanoparticles are dependent on the power of ultrasound irradiation and sonication time. Results show an increase in the particle size with increasing the power of ultrasound irradiation. The particle size increased with increasing sonication time. The produced carvedilol nanoparticles were characterized by X-ray diffraction, infrared spectroscopy, and scanning electron microscopy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

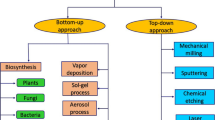

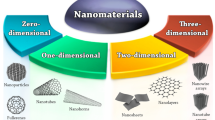

One of the major causes of new drug molecules failing to reach the market is poor bioavailability. Indeed, many of the newly discovered drug candidates suffer from low to extremely low water solubility and hence are prone to limited bioavailability [1–3]. To cope with these issues, drug formulation scientists are developing formulation strategies that enhance the dissolution and thus the bioavailability of these poorly water-soluble drugs [4]. The most important technologies are applied in the formulation development to enhance solubility and dissolution which include particle size reduction, salt formation, and amorphous systems, as well as co-solvents, complexants, surfactants, and lipid formulations. Among these techniques, particle size reduction is highly promising. Micronization of drug crystals by various mechanisms to the lower micron range improves drug dissolution [5]. According to the Noyes-Whitney equation, the dissolution rate increases by increasing the specific surface area. The saturation solubility increases with decreasing particle size according to the Ostwald-Freundlich equation [6, 7]. Therefore, reducing particle size to the nanorange has been investigated through several approaches. Current methods to prepare drug nanocrystals can be divided into top-down and bottom-up methods [8, 9]. At present, most industrially feasible methods are the top-down technologies; all the products on the market are made by size reduction. The major two processes are ball milling and high-pressure homogenization, either in water or in non-aqueous water-reduced media. Disadvantages of the ball milling process are the relatively long milling times in the case of hard drug material, the limited scaling up ability (the weight of the ball mill and the milling material limit maximum size), and potential contamination of the milling material by erosion from the milling pearls [10]. Nanocrystal production by high-pressure homogenization requires typically 10 to 20 homogenization cycles at pressures of, e. g., 1,000 to 1,500 bar. Metal contamination from the homogenizer is obviously not a problem. However, despite when using a high-capacity homogenizer with 1 ton product per hour, the acceleration of production by reduction of the homogenization cycle number would be desirable. Currently, the utilization of ultrasound for material synthesis has been extensively examined over many years, and it is now positioned as one of the most powerful tools in nanostructured material synthesis. Acoustic cavitation provides a unique interaction of energy and matter, and ultrasonic irradiation of liquids causes high-energy chemical reactions to occur, often accompanied by the emission of light [11]. Bubbles generated during sonication can effectively accumulate the diffuse energy of ultrasound, and upon collapse, an enormous concentration of energy is released to heat the contents of the bubble. These transient, localized hot spots with extremely high temperatures and pressures are primarily responsible for the chemical effects of ultrasound [12]. The usefulness of sonochemical synthesis as a synthetic tool resides in its versatility. With a simple modification in the reaction conditions, various forms of nanostructured materials can be synthesized, including metals [13, 14], carbides [15] and sulfides [16] which are nanostructured supported catalysts.

Carvedilol, (+)–1-(Carbazol-4-yloxy)-3-f[2-(o-methoxyphenoxy)ethyl]aminog-2-propanol, is a β-receptor blocker and antihypertensive drug with a multiple-action spectrum [17], and it also has vasodilating properties that are attributed mainly to its blocking activity at α1 receptors. The use of carvedilol has been shown to provide additional morbidity and mortality benefits in severe congestive heart failure [18]. Previously, Varshosaz et al. reported the preparation of carvedilol nanoparticles by emulsification method [19]. Kalimuthu et al. reported the formulation of carvedilol-loaded Eudragit e 100 nanoparticles [20]. In this paper, we have developed a simple ultrasonic method to prepare nanocarvedilol and studied some parameters, such as sonication time and ultrasonic device power in the size and morphology of the carvedilol nanoparticles. The result shows that different particle diameters of carvedilol were prepared, and infrared studies show that the bonds do not change.

Results and discussion

Various conditions for the preparation of carvedilol nanoparticles were summarized in Table 1. In series 1, the reactions were studied in 20 and 40 min. Results show that the particle size in sample 1 (Figure 1B) is smaller than that of 2 (Figure 1A). This point shows that an increase in the sonication time led to an increase in the particle size. In the same way, an increase in the sonication time led to the increase of the particle sizes in sample 4 (Figure 2B). Various ultrasound powers led to different morphologies. Samples 1 and 2 have amorphous structures, but the morphology of samples 3 and 4 changed to spherical structures, and their particle distribution is uniform. Particle size in sample 3 is smaller than that of 4. Therefore, the best morphology with smaller particles and good distribution was obtained from sample 4 with the sonication time of 40 min and the ultrasound device power of 80 W (Figure 2B).

Figure 3 shows the typical Fourier transform-infrared (FTIR) spectrum pattern of the nanocarvedilol in the range of 400 to 4,000 cm−1. The IR spectrum of pure carvedilol showed the peak at 3,344.88 cm–1 (N-H, str), which corresponds to N-H stretching. The hetero-aromatic structure shows the presence of the C-H stretching vibrations in the region 2995.87 cm–1 (C-H, Sp2), also in 2923.56 cm–1, which is the characteristic region for the ready identification of the C-H stretching vibrations. The bands corresponding to the in-plane C-H deformations are observed in the regions 1,000 to 1,300 cm−1. The bands are sharp but of weak to minimum intensity. The medium- and strong-intensity bands are in the regions 1,099.72, 1,119.95, 1,156.24, and 1,177.15 cm−1 in the FT-IR spectrum. A medium experimental peak around 1252 to 1,402 cm−1 in the FT-IR was assigned to the C-C stretching vibrations. The bands in the regions 1,502 to 1,607 cm−1 observed in both FT-IR were assigned to the C = C stretching vibrations. In the present case, the bands observed at 849.50 and 783.90 cm−1 in the FT-IR are assigned to the ring breathing mode. The identification of C-N vibrations is a very difficult task since mixing of several bands is possible in the region assigned for the C-N stretching vibrations which is in the regions 1,347.95 to 1,285.41 cm−1. In the present work, a weak band at 1,402.71 cm−1 and a strong band at 1,453.97 cm−1 were seen in the FT-IR. It is observed that the ultrasonic wave has no effect on nanoscale materials and the structure does not change.

X-ray diffraction (XRD) technique was used to determine the ingredients of the sample. Figure 4 shows the XRD patterns of typical sample 4 prepared by the sonochemical process. The mean size of carvedilol nanoparticles was calculated to be about 96 nm using Scherrer's equation: D = Kλ/(β cos θ), where D is the mean crystalline size (nm), λ is the wavelength of Cu Kα (0.154 nm), β is the full width at half maximum intensity in radian, and θ is the Bragg angle (°) [21].

The differential scanning calorimetry (DSC) curve of carvedilol showed a sharp endothermic peak (Tpeak = 115°C) corresponding to its melting point, indicating its crystalline nature (Figure 5A). In DSC studies, the characteristic endothermic peaks, corresponding to drugs melting point, were shifted toward higher temperature. This could be attributed to the bigger particle sizes and uniform distribution of drugs (Figure 5B). Now, it is found that the melting temperature of carvedilol nanoparticles decreases with decreasing their particle size. The melting temperature increases as its size increases. In other words, their melting temperature is lower than the corresponding bulk materials.

It is also noteworthy that one of the problems of carvedilol is its very low aqueous solubility. The importance of solubility enhancement is for the absorption of drug from the site of absorption. The size of the solid particle influences the solubility because as a particle becomes smaller, the surface area-to-volume ratio of the particle increases. The larger surface area allows a greater interaction with the solvent. Increase aqueous solubility with the nanoparticle size increases the efficiency and/or reduces the side effects for certain drugs.

Conclusions

The described method for preparing carvedilol nanoparticles can potentially be used at industrial scale because it does not need special conditions, such as high temperature, long times, or high-temperature and high-pressure controlling. The advantage of using ultrasound radiation is that it yields smaller particles. The same results have been shown for recent reports too. This approach can be used to improve the therapeutic efficacy of poorly soluble drugs.

Methods

Material and methods

Carvedilol was purchased from Alborz Darou Pharmaceutical Company in Tehran, Iran. A multiwave ultrasonic generator (Sonicator_3000, Misonix, Inc., Farmingdale, NY, USA), equipped with a converter/transducer and titanium oscillator (horn), 12.5 mm in diameter, operating at 20 kHz with a maximum power output of 600 W, was employed. The morphology of synthesized samples was studied using scanning electron microscopes (KYKY-EM3200, KYKY Technology Development Ltd., Beijing, China; Philips XL 30 and S-4160, Philips, Amsterdam, The Netherlands) and by a sputtering technique with gold as covering contrast material. The thermal analysis was carried out on DSC Q10 V9.4 Build 287 (TA Instruments, New Castle, DE, USA). The XRD measurements of synthesized samples were carried out using a Philips X-pert PRO powder diffractometer (Philips, Amsterdam, The Netherlands) with Cu Kα radiation (λ = 1.54 Å) in the scan range of 0° to 100°. The IR spectra were recorded using a Bruker spectrometer (Bruker AXS, Inc., Madison, WI, USA) with KBr pellets in the range of 400 to 4,000 cm−1.

Synthesis of nanoparticles

Carvedilol and carbon tetrachloride were mixed to prepare nanoparticles by ultrasonic method. The sonochemical reactions were carried in the sonochemical probe, as shown in Figure 6. The ultrasonic device power and sonication time were the parameters which were changed to reach the optimum condition.

Then, the suspension was ultrasonically irradiated with a high-density ultrasonic probe immersed directly into the solution under various conditions (Table 1). The precipitate was separated from the mother liquor by a centrifuge at 4,000 rpm for 3 min. The final product was dried at 50°C in a vacuum system.

References

Alsenz J, Kansy M: High throughput solubility measurement in drug discovery and development. Adv. Drug Deliv. Rev. 2007, 59: 546–567. 10.1016/j.addr.2007.05.007

Li P, Zhao LW: Developing early formulations: practice and perspective. Int. J. Pharmaceut. 2007, 341: 1–19. 10.1016/j.ijpharm.2007.05.049

Gardner CR, Walsh CT, Almarsson O: Drugs as materials: valuing physical form in drug discovery. Nat. Rev. Drug Discov. 2004, 3: 926–934. 10.1038/nrd1550

Horn D, Rieger J: Organic nanoparticles in the aqueous phase-theory, experiment, and use. Angew. Chem. Int. Ed Engl. 2001, 40: 4331–4361.

Patravale VB, Date AA, Kulkarni RM: Nanosuspensions: a promising drug delivery strategy. J. Pharm. Pharmacol. 2004, 56: 827–840. 10.1211/0022357023691

Pillay V, Fassihi R: A new method for dissolution studies of lipid-filled capsules employing nifedipine as model drug. Pharm. Res. 1999, 16: 333–337. 10.1023/A:1011959914706

Müller RH, Peters K: Nanosuspensions for the formulation of poorly soluble drugs: I. Preparation by a size-reduction technique. Int. J. Pharm. 1998, 160: 229–237. 10.1016/S0378-5173(97)00311-6

Merisko-Liversidge E, Liversidge GG, Cooper ER: Nanosizing: a formulation approach for poorly-water-soluble compounds. Eur. J. Pharm. Sci. 2003, 18: 113–120. 10.1016/S0928-0987(02)00251-8

Chen X, Young TJ, Sarkari M, Williams RO 3rd, Johnston KP: Enhanced drug dissolution using evaporative precipitation into aqueous solution. Int. J. Pharm. 2002, 242: 3–14. 10.1016/S0378-5173(02)00147-3

Bang JH, Suslick KS: Applications of ultrasound to the synthesis of nanostructured. Materials Adv. Mater. 2010, 22: 1039–1059. 10.1002/adma.200904093

Suslick KS: in Kirk-Othmer Encyclopedia of Chemical Technology, 26, 4th edn. New York: Wiley; 1998:517–541.

Koltypin Y, Katabi G, Prozorov R, Gedanken A: Sonochemical preparation of amorphous nickel. J. Non-Cryst. Solids 1996, 201: 159. 10.1016/0022-3093(96)00184-6

Okitsu K, Mizukoshi Y, Bandow H, Maeda Y, Yamamoto T, Nagata Y: Formation of noble metal particles by ultrasonic irradiation. Sonochem 1996, 3: 249. 10.1016/S1350-4177(96)00033-8

Hyeon T, Fang M, Suslick KS: Nanostructured molybdenum carbide: sonochemical synthesis and catalytic properties. J. Am. Chem. Soc. 1996, 118: 5492. 10.1021/ja9538187

Wu GS, Yuan XY: A simple synthesis route to CdS nanomaterials with different morphologies by sonochemical reduction. J. Mat. Lett. 2004, 58: 794–797. 10.1016/j.matlet.2003.07.014

Wu GS, Yuan XY, Xie T, Xu GC, Zhang LD, Zhuang YL: A simple synthesis route to CdS nanomaterials with different morphologies by sonochemical reduction. Mater. Lett. 2004, 58: 794. 10.1016/j.matlet.2003.07.014

Ruffolo RR Jr, Feuestein GZ: Pharmacology of carvedilol: rationale for use in hypertension, coronary artery disease, and congestive heart failure. Cardiovasc. Drugs Ther. 1997, 11: 247–256. 10.1023/A:1007735729121

Packer M, Fowler MB, Roecker EB, Coats AJ, Katus HA, Krum H, Mohacsi P, Rouleau JL, Tendera M, Staiger C, Holcslaw TL, Amann-Zalan I, DeMets DL: Carvedilol Prospective Randomized Cumulative Survival (COPERNICUS) Study Group. Effect of carvedilol on the morbidity of patients with severe chronic heart failure: results of the carvedilol prospective randomized cumulative survival (COPERNICUS) study. Circulation 2002,106(17):2194–2199. 10.1161/01.CIR.0000035653.72855.BF

Varshosaz J, Moazen E, Fathi M: Preparation of carvedilol nanoparticles by emulsification method and optimization of drug release: surface response design versus genetic algorithm. J. Dispersion Sci. Tech. 2012, 33: 1480–1491. 10.1080/01932691.2011.620847

Kalimuthu S, Yadav AV: Formulation and evaluation of carvedilol loaded udragit e 100 nanoparticles. Int. J. Pharm. Res. 2009,1(2):179–183.

Darezereshki E: Synthesis of maghemite (α-Fe 2 O 3 ) nanoparticles by wet chemical method at room temperature. Mater. Lett. 2010, 64: 1471–1472. 10.1016/j.matlet.2010.03.064

Acknowledgements

We acknowledge Dr. Ali Afshar from Alborz Darou Pharmaceutical Company, who supported this study through a grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

Both authors participated in writing the manuscript. Both authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Sadr, M.H., Nabipour, H. Synthesis and identification of carvedilol nanoparticles by ultrasound method. J Nanostruct Chem 3, 26 (2013). https://doi.org/10.1186/2193-8865-3-26

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2193-8865-3-26