Abstract

A design study, named \({\text {ESS}}\nu {\text {SB}}\) for European Spallation Source neutrino Super Beam, has been carried out during the years 2018–2022 of how the 5 MW proton linear accelerator of the European Spallation Source under construction in Lund, Sweden, can be used to produce the world’s most intense long-baseline neutrino beam. The high beam intensity will allow for measuring the neutrino oscillations near the second oscillation maximum at which the CP violation signal is close to three times higher than at the first maximum, where other experiments measure. This will enable CP violation discovery in the leptonic sector for a wider range of values of the CP violating phase \(\delta _{{\mathrm{CP}}}\) and, in particular, a higher precision measurement of \(\delta _{{\mathrm{CP}}}\). The present Conceptual Design Report describes the results of the design study of the required upgrade of the ESS linac, of the accumulator ring used to compress the linac pulses from 2.86 ms to 1.2 μs, and of the target station, where the 5 MW proton beam is used to produce the intense neutrino beam. It also presents the design of the near detector, which is used to monitor the neutrino beam as well as to measure neutrino cross sections, and of the large underground far detector located 360 km from ESS, where the magnitude of the oscillation appearance of \(\nu _{e }\) from \(\nu _{\mu }\) is measured. The physics performance of the \({\text {ESS}}\nu {\text {SB}}\) research facility has been evaluated demonstrating that after 10 years of data-taking, leptonic CP violation can be detected with more than 5 standard deviation significance over 70% of the range of values that the CP violation phase angle \(\delta _{{\mathrm{CP}}}\) can take and that \(\delta _{{\mathrm{CP}}}\) can be measured with a standard error less than 8° irrespective of the measured value of \(\delta _{{\mathrm{CP}}}\). These results demonstrate the uniquely high physics performance of the proposed \({\text {ESS}}\nu {\text {SB}}\) research facility.

Similar content being viewed by others

1 Executive summary

An EU-supported Design Study has been carried out during the years 2018–2022 of how the \(5\,{{\text {MW}}}\) proton linear accelerator (linac) of the European Spallation Source under construction in Lund, Sweden, can be used to produce the world’s most intense long-baseline neutrino beam for CP violation discovery in the leptonic sector and, in particular, precision measurement of the CP violating phase \(\delta _{{\mathrm{CP}}}\). The project is called the European Spallation Source neutrino Super Beam (\({\text {ESS}}\nu {\text {SB}}\)). This Conceptual Design Report describes the design of:

-

the required upgrade of the ESS linac,

-

the accumulator ring used to compress the linac pulses from \(2.86\,{\text {ms}}\) to \(1.2\,\upmu {\text {s}}\),

-

the target station where the \(5\,{\text {MW}}\) proton beam is used to produce the intense neutrino beam,

-

the near detector which is used to monitor the neutrino beam as well as measure neutrino cross-sections, and

-

the large underground far detector where the magnitude of the oscillation appearance of \(\nu _{e}\) from \(\nu _{\mu }\) is measured.

The report also provides the results of the physics performance study of the neutrino research facility that is proposed.

About a decade ago, results were published of the measurement of the neutrino mass-state mixing angle \(\theta _{13}\) which was found to be \(8.6^{\circ }\), a value that was much higher than that which had until then been presumed. This result made the discovery of leptonic CP violation significantly more viable in practice than previously foreseen, as well as shifting the optimal place for such a measurement from the first neutrino oscillation maximum to the second oscillation maximum where, given the relatively high \(\theta _{13}\) value, the CP violation signal is close to three times larger than at the first. As the second maximum is located further away from the neutrino source, a higher intensity is required when measuring at the second maximum as compared to the first maximum, to obtain the same event statistics.

At about the same time as the results of the measurement of the high \(\theta _{13}\) value became known, the decision was taken to build the European Spallation Source ESS at Lund in southern Sweden. With its \(5\,{\text {MW}}\) proton linear accelerator, ESS will produce the world’s highest flux of slow neutrons for materials science studies, generated by the spallation process. The neutrons will be produced in \(2.86\,{\text {ms}}\) pulses at \(14\,{\text {Hz}}\). The \({\text {ESS}}\nu {\text {SB}}\) conceptual design study has demonstrated that, given the high power and inherent upgrade capacity of the ESS linear accelerator, the linac can be used to produce, in addition to the high-intensity spallation-neutron flux, and concurrently with it, a neutrino beam sufficiently intense to provide a statistically significant number of events at the second oscillation maximum. Thanks to these factors, the evaluated performance of the proposed \({\text {ESS}}\nu {\text {SB}}\) research facility is considerably higher than that of the other proposed neutrino super-beam facilities, which are constrained to make measurements at the first oscillation maximum.

To reach large enough event statistics, an additional requirement is that the far water Cherenkov detector should have an appropriately large mass. For \({\text {ESS}}\nu {\text {SB}}\), the designed mass is 540 kton. To ensure a negligibly small background of neutrinos from cosmic rays, this detector will be installed in a mine \(1000\,{\text {m}}\) underground and the data-collection time-gate for each of the 14 neutrino pulses per second generated by ESS will only be \(1.2\,\upmu {\text {s}}\). The use of this short time-gate will require that the pulses from the ESS linac be compressed from \(2.86\,{\text {ms}}\) to \(1.2\,\upmu {\text {s}}\). To accomplish such a compression, each \(2.86\,{\text {ms}}\) linac pulse will be fed into a \(380\,{\text {m}}\) circumference accumulator ring, located underground on the ESS site, and be extracted in just one turn. This pulse compression is also necessary to be able to operate the target magnetic horns with sufficiently short current pulses. The current required for an efficient focussing of the pions emitted from the target in the forward direction into the decay tunnel is \(350\,{\text {kA}}\). To keep the heating of the horns to a manageable level, the current must be delivered in very short pulses with a flat top that still need to be at least as long as the proton pulses from the accumulator, i.e., \(1.2\,\upmu {\text {s}}\).

The design of the \({\text {ESS}}\nu {\text {SB}}\) research facility is largely conditioned by the above considerations. The doubling of the power of the linac from 5 to \(10\,{\text {MW}}\) is facilitated by the fact that adequate space has already been foreseen in the ESS modulators feeding the accelerating cavities, that can be used to install twice the amount of charging capacitors. To be able to feed the very high charge of \(2.2\times 10^{14}\) protons per pulse into the accumulator, \({\text {H}}^{-}\) ions will be accelerated in the linac and stripped of their two electrons at the injection point into the accumulator. For this, an \({\text {H}}^{-}\) source has to be furnished at the side of the ESS linac proton source. There are several mechanisms that will result in a fraction of the \({\text {H}}^{-}\) ions being stripped of their electrons and therefore lost in the accelerator or the transfer line to the accumulator, causing activation of the accelerator and transfer line components. In order for this activation to be kept at an acceptable level, the beam losses must not exceed \(1\,{\text {W/m}}\). The simulations of the operation of the linac and the transfer line with the selected design have demonstrated that all of these requirements can be fulfilled and that the required \(5\,{\text {MW}}\) \({\text {H}}^{-}\) beam for neutrino production can therefore be produced, concurrently with the \(5\,{\text {MW}}\) proton beam for spallation neutron generation.

The design of the underground accumulator ring and its beam optics must satisfy a number of different conditions. Among these are that the emittance must not exceed \(60\pi\) mm mrad, that the temperature of the carbon electron-stripping foils must not exceed \(2000\,{{\text {K}}}\), and that the beam losses in the accumulator must be kept sufficiently low by sequential collimation to keep the irradiation of the beam line components below \(1\,{\text {W/m}}\). Furthermore, the edges of the \(100\,{\text {ns}}\) gap in the circulating beam, needed for the extraction of the circulating beam and generated by chopping in the low energy part of the accelerator, must be kept sufficiently sharp using radiofrequency cavities to limit the irradiation of the extraction-region components in the ESS linac. The rise time of the current in the extraction magnets must not be longer than \(100\,{\text {ns}}\) in order for the beam extraction to fit within the time gap made available, which is achieved by having the inductance of these magnets sufficiently low. The design of the accumulator ring has been optimised through many iterations and the results of the simulation of the final design show that it will be feasible to deliver the required short and intense proton pulses to the target station.

The underground target station design is conditioned by the requirement that the target must stand the formidable shocks, heat dissipation, and radiation damage of a \(5\,{\text {MW}}\) proton beam delivered in \(1.2\,\upmu {\text {s}}\) short pulses 14 times a second. To manage these severe conditions, the design adopted foresees the chopping of the \(2.86\,{\text {ms}}\) pulse into four sub-pulses in the low energy part of the linac, the compression in sequence of these four sub-pulses in the accumulator ring, and their extraction into a magnet switchyard, which will direct each of the four sub-pulses to one of four separate targets, each of which will thus receive a \(1.25\,{\text {MW}}\) beam. Each of the four targets is designed as a \(78\,{{\text {cm}}}\) long tube, \(3\,{{\text {cm}}}\) in diameter and filled with \(3\,{\text {mm}}\) titanium balls that are cooled by a high-pressure transverse helium-gas flow. The extreme heating, high irradiation and radiation damage of these targets, the surrounding focusing magnetic horns, the walls of the \(50\,{\text {m}}\) long pion decay tunnel, and the water-cooled beam stop at the end of the tunnel have been simulated and found to be within tolerable limits.

The neutrino beam resulting from the decay of the pions produced in the four targets will be directed towards the 1 kton underground near detector located on the ESS site \(250\,{\text {m}}\) from the target station and the 540 kton underground far detector, located at a distance of \(360\,{\text {km}}\) from ESS. The two detectors are based on the water Cherenkov technique. The near detector is in addition equipped with a tracking detector mounted inside a dipole magnet and consisting of 1 million \(1\,{\text {cm}}^{3}\) scintillator cubes read out with wavelength-shifting fibres, and with an emulsion stack detector immersed in water. The excavation of the two cylindrical far detector caverns, each \(78\,{\text {m}}\) high and \(78\,{\text {m}}\) in diameter, at a depth of \(1000\,{\text {m}}\) in the Zinkgruvan mine, represents a unique geotechnical design-challenge, requiring the rock strength and rock pressure to be measured using core drillings before the final design can be certified. About 92,000 \(20''\) single-photon sensitive photomultipliers will be mounted on the walls of these caverns, providing a 30% photocathode coverage.

The physics performance of the \({\text {ESS}}\nu {\text {SB}}\) research facility has been evaluated considering two baselines corresponding to the positions of two active mines, Zinkgruvan at \(360\,{\text {km}}\) and Garpenberg at \({540}\,{\text {km}}\) from ESS in Lund. The result of the evaluation is that, although the CP violation discovery capability is comparable for the two baselines, the accuracy with which \(\delta _{{\mathrm{CP}}}\) can be measured is higher with the far detector being installed at Zinkgruvan. After 10 years of data-taking with the detector located in Zinkgruvan, leptonic CP violation can be detected with more than 5 standard deviation significance over 70% of the range of values that the CP violation phase angle \(\delta _{{\mathrm{CP}}}\) can take, and \(\delta _{{\mathrm{CP}}}\) can be measured with a standard error less than \(8^{\circ }\) irrespective of the measured value of \(\delta _{{\mathrm{CP}}}\). These results demonstrate the uniquely high physics performance of the proposed \({\text {ESS}}\nu {\text {SB}}\) research facility.

The geological conditions of the ESS site allow for that all installations needed for the operation of \({\text {ESS}}\nu {\text {SB}}\) will be located underground at a depth between 10 and 30 m, thereby eliminating all risk for radiation hazard above ground level. It has also been possible to locate the \({\text {ESS}}\nu {\text {SB}}\) installations in such a way that there will be no interference with the existing ESS installations.

The CDR has resulted in a preliminary estimate of the construction cost of \({\text {ESS}}\nu {\text {SB}}\) which is on the level of \(1.4\,{\text {B}}\)€. For more details concerning the costing, see Ref. [1]. The current estimate does not include the cost of the associated civil engineering work on the ESS site, which has not yet been evaluated in detail. The plan is to achieve, after another period of design work, a Technical Design Report, including a more accurate cost estimate, and to seek the necessary support for approval and financing of the \({\text {ESS}}\nu {\text {SB}}\) construction project. The plan for the following period of build-up and commissioning of the facility is such that \({\text {ESS}}\nu {\text {SB}}\) will be ready for start of data-taking operation around year 2035. The operation of the facility is foreseen to continue for several decades, possibly including intermediate upgrades.

Throughout, the Design Study leading up to the present CDR has had the strong support of the ESS management. The international nature of the \({\text {ESS}}\nu {\text {SB}}\) project is demonstrated by the list of the authors’ institutions of the present CDR, which all have, together with the EU Horizon 2020 Frameworks Programme and the European Cooperation in Science and Technology Programme COST, provided the personnel, technical and financial resources for the 4 years of Design Study.

Significant effort has been spent on different outreach activities with the aim of informing the scientific and general public of the goals and achievement of the \({\text {ESS}}\nu {\text {SB}}\) Design Study. One part of this has been the production of two video films, each ca \(6\,{\text {min}}\) long, one intended for the scientifically literate public and the other for the general public and both of which are available at the \({\text {ESS}}\nu {\text {SB}}\) home page https://essnusb.eu/.

2 Introduction

This report gives an account of the results of a 4 year design study of a European neutrino Super Beam facility \({\text {ESS}}\nu {\text {SB}}\) to be based on the use of the ESS linear accelerator (linac), currently under construction in Lund, Sweden. When this linac will have reached its full design performance, it will be the world’s most powerful accelerator, delivering a proton beam of 5 MW average power. The original purpose of creating such a powerful proton beam is to provide the world’s most brilliant neutron spallation source. The linac will deliver the 5 MW by accelerating ca 1015 protons in each of 14 pulses/s of length 2.86 ms, to 2 GeV energy, implying a duty cycle of just 4%. By accelerating additional 14 pulses, interleaved with these 14 pulses, the duty cycle can be raised to 8% and the extra 5 MW used to produce a neutrino Super Beam of world-unique intensity.

The motivation for proposing the European Spallation Source neutrino Super Beam (\({\text {ESS}}\nu {\text {SB}}\)) as a next-generation long-baseline neutrino experiment and the results of the work made on the design of the main components of the \({\text {ESS}}\nu {\text {SB}}\) facility, which are the ESS linac upgraded to produce a 10 MW and 2.5 GeV proton beam, the pulse accumulator ring, the target station, and the near and far neutrino detectors, are described in the following sections of this report. The general layout of the proposed facility is shown in Fig. 1. The results of the evaluation of the physics performance for leptonic CP violation discovery and, in particular, the precision with which it will be possible to measure the CP violation phase \(\delta_{\text {CP}}\) are also included in this report.

3 The motivation for \({\text {ESS}}\nu {\text {SB}}\) as a next-generation long-baseline neutrino experiment

Charge-Parity (CP) symmetry violation in the quark sector was discovered and measured already in the 1960s. The discovery of neutrino oscillations in the 1990s opened the possibility to seek for CP violation in the leptonic sector. To describe how the initial creation of exactly equal amounts of matter and antimatter in the Big Bang did not subsequently lead to a complete annihilation of all matter and antimatter, which would have resulted in a Universe containing only radiation and no matter, CP violation is required. In our Universe, there is on average about a billion photons for each matter particle, the latter constituting the galaxies, stars, planets, and ourselves, that remain from the matter–antimatter annihilation process. Notwithstanding that the relative amount of matter is very small, its presence can be shown to require that there be a sufficient effect of CP violation for which the effect provided by the CP violation measured in the quark sector and described by the Standard model is very far from enough.

There are several different beyond-the-Standard-Model theories proposed, based on flavour symmetries, which include leptonic CP violation and which each predicts a different value of the CP complex phase-angle \(\delta _{{\mathrm{CP}}}\) from the observed matter density in the Universe. Discovering leptonic CP violation will check the validity of this type of theories and the measured value of \(\delta _{{\mathrm{CP}}}\) will be used to discriminate between them. This currently makes the precise measurement of value of the leptonic \(\delta _{{\mathrm{CP}}}\) one of the most urgent research tasks in elementary particle physics and cosmology.

The Neutrino Factory was first proposed in the 1990s as an accelerator-based infrastructure for producing a neutrino beam of sufficiently high intensity for leptonic CP-violation discovery and measurement. In a Neutrino Factory, a very high-power proton accelerator is used to produce a high-intensity pion flux from which, by the decay of the pions, a high-intensity muon beam is derived. This muon beam is subsequently cooled, accelerated, and led into a racetrack storage ring, where the muons decay and produce a beam composed of equal amounts of \(\nu _\mu\) and \(\nu _{\mathrm{e}}\). Building a Neutrino Factory will be a very challenging task, in particular because of the required cooling and acceleration of the very short-lived muons.

The interest and possibility of discovering and measuring leptonic CP violation in the leptonic sector increased even further in 2012 when the first measurements of the till then unknown value of the \(\theta _{13}\) neutrino mixing angle were published. The measured value of ca \(8.3^\circ\) of \(\theta _{13}\) was nearly an order of magnitude higher than what had earlier been expected from general but, as it turned out, incorrect assumptions. This implied that, instead of using the Neutrino Factory technique, it would be possible to measure the effect of CV violation using a beam of the \(\nu _\mu\) created in the classical way, i.e., from the decays of the pions that are produced from the high energy protons delivered by a high-power accelerator, provided that the power of the accelerator is sufficiently high.

The high value found in 2012 for \(\theta _{13}\) furthermore implied that the sensitivity to CP violation is close to three times higher at the second \(\nu _\mu\)-to-\(\nu _{\mathrm{e}}\) oscillation maximum as compared to the first oscillation maximum. For a low value of \(\theta _{13}\), the sensitivity at first maximum would have been higher than that at the second maximum. Several long baseline experiments with the neutrino detector placed at the first oscillation maximum were already in operation around 2012, likeT2K in Japan with which data taking was started in 2011, and NOvA in the US that started in 2014. The next-generation long-baseline experiments, T2HK in Japan and DUNE in the US, were already in the planning stage at that time and are also designed to collect the large majority of the data at the first oscillation maximum.

A difficulty with measuring at the second oscillation maximum is that the neutrino detector will be located 3 times further away from the neutrino source and that, since the neutrino beam is divergent, the neutrino flux-density therefore will be 9 times smaller at the second maximum as compared to the first. This implies that a very high-power proton driver is required for realising an experiment measuring at the second oscillation maximum and thereby profit from the higher sensitivity to \(\delta _{{\mathrm{CP}}}\) there.

In 2009, it was decided to build the European Spallation Source in Lund, Sweden, with a proton driver producing a 5 MW beam, which was close to an order of magnitude higher power than for any accelerator in the world at that time. The purpose was to use the 5 MW proton beam to produce spallation neutrons. It was, however, soon realised that, with a further comparatively limited investment, it would be possible to raise the power of the ESS accelerator to 10 MW by doubling the number of accelerated pulses per second from 14 to 28 with the purpose of using the additional 14 pulses to generate a world-uniquely intense neutrino beam. The ESS neutrino Super Beam project that is described in the present report is designed to perform high-precision neutrino-oscillation measurements using a 540 Mton water Cherenkov detector and this world-uniquely intense ESS neutrino beam, which will allow the detector to be placed at the second maximum and thus to take advantage of the close to 3 times higher \(\delta _{{\mathrm{CP}}}\) signal there.

4 Proton driver

4.1 Introduction

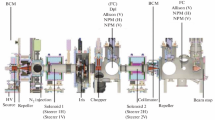

The \({\text {ESS}}\nu {\text {SB}}\) linac upgrade consists of the modifications of the ESS proton linac needed to be able to produce and accelerate interleaved pulses of \({\text {H}}^-\) for the generation of the proposed neutrino super beam, while the acceleration of protons for the production of spallation neutrons continues uninterrupted. This section presents the upgrade requirements for the linac, its auxiliary systems, as well as design considerations for the linac-to-ring (L2R) transfer line. The schematic in Fig. 2 details each of the portions of the linac which must be reviewed for the present upgrade study. The low-energy beam transport (LEBT) and medium-energy beam transport (MEBT) lines have been modelled and simulated in terms of the necessary modifications for transporting both proton and \({\text {H}}^-\) bunches.

A comprehensive study of \({\text {H}}^-\) beam stripping was performed, with simulations of the beam transport and evaluation of the loss magnitude for the baseline beam parameters; this included end-to-end simulations of the upgraded linac and trajectory analysis of ionisation energy deposited from stripped particles (see Sect. 4.10). The upgrade requirements for the superconducting (SC) linac sectors and the linac-to-ring (L2R) transfer line have also been studied both in terms of beam dynamics and stripping.

A detailed study of the modifications needed on the modulators was also performed, showing the possible upgrade paths for the modulators, with an evaluation of the energy efficiency of each option, their cost, and their added footprint on the klystron gallery. This analysis is summarised in Sect. 4.11.

4.2 Pulse structure

Different pulsing schemes of the \({\text {H}}^-\) beam have been considered; see Fig. 3. To accommodate the rise and fall times of the extraction magnet in the accumulator ring, and also owing to space charge and beam instabilities, the full 2.86 ms beam pulses cannot be injected in one filling of the ring. Each beam pulse must instead be split into several sub-pulses or batches. The batch length is limited by the storage time in the accumulator ring—about 1000 turns, corresponding to 1.3 ms—before instabilities are likely to develop [2].

Detailed schematic of the nominal \({\text {ESS}}\nu {\text {SB}}\) pulsing scheme, Option A+ from Fig. 3

A pulsing scheme with an overall 28 Hz macro-pulse structure has been selected as the baseline design, corresponding to Option A+ in Fig. 3. The pulse length in this case is limited by the flat-top length of the present RF modulators (3.35 ms). Since the filling time of the superconducting cavities is about 0.3 ms, and the time to stabilise the radio frequency (RF) regulation is about 0.1 ms, the effective pulse length is limited to about 2.9 ms. If the pulse length from the modulators could be extended, this would decrease the demand of the current. Other pulsing schemes have also been reviewed (Options B and C) where the \({\text {H}}^-\) beam is pulsed at 70 Hz, (4 out of 5 pulses are \({\text {H}}^-\)). Compared with Option A+, these alternatives relax the performance demands on the accumulator ring (in particular, the stripping foil) and the target focusing system, but come with substantial costs due primarily to RF system upgrades and annual electrical running costs.

The total number of particles delivered to the accumulator ring will be \(8.9\times 10^{14}\) per pulse cycle (macro-pulse), divided into four batches of \(2.3\times 10^{14}\), as shown in Fig. 4. Further beam parameters are summarised in Table 1. Each batch is stacked in the accumulator ring, compressing the pulses to \(1.2\,\upmu {\text {s}}\), which are subsequently extracted to the target. By splitting the macro-pulse into four batches, the power on each target is limited to 1.25 MW, and the space charge tune shift [3] in the accumulator ring is limited to an acceptable level [2, 4].

As mentioned above, the disadvantage to a 70 Hz pulsing is a higher total load on the RF system (along with uncertainty on the duty-cycle rating for the nominal ESS superconducting cavity couplers, see Sect. 4.11); this is due to the filling time of the superconducting (SC) cavities of 0.3 ms. Option B, with a pulse length of up to 1.3 ms, has the advantage of allowing for a lower beam current of about 30 mA, relaxing the demands on the ion source requirements and reducing beam stripping losses, particularly intra-beam stripping (IBSt). The impact on the RF modulator systems of the different pulsing options is also discussed in Sect. 4.11, with a detailed analysis available in [5].

4.3 Front-end baseline and overview

The upgrade of the ESS linac for \({\text {ESS}}\nu {\text {SB}}\) requires an additional ion source for delivering \({\text {H}}^-\) ions at the correct energy, and a low energy beam transport (LEBT) to merge this beam and the nominal proton beam into the radiofrequency quadrupole (RFQ) for the first stage of acceleration. Alternatively, the two beams could be merged in the medium-energy beam transport (MEBT), see Fig. 5. This option with separate RFQ units and merging MEBT sections could more straightforward to realise in terms of beam dynamics, since the transport of the two beams is independent.

However, the option with shared RFQ and MEBT would be less expensive and require less downtime for nominal ESS operation. Extensive beam dynamics simulations with this option have shown no prohibitive drawbacks, making it the favoured baseline design. A few key considerations for this design are as follows:

-

The MEBT chopper will need to be redesigned to deflect along both transverse axes due to the opposite charges of the accelerating ion species. Otherwise, the entire linac design is charge-agnostic in terms of transverse dynamics, despite having vertical and horizontal envelope profiles reversed for protons and \({\text {H}}^-\). The chopper will also need to be redesigned to accommodate the fast beam-chopping requirements for creating extraction gaps in the beam.

-

The use of switching magnets (changing sign/magnitude between proton and \({\text {H}}^-\) pulses) is optional, though it may be beneficial in the MEBT for better matching with the drift-tube linac (DTL). Without switching magnets, compromising the matching of both ion species at the MEBT/DTL interface incurs a small overall emittance growth downstream.

-

The RFQ is designed for compatibility with the nominal ESS proton source, and \({\text {H}}^-\) transmission is poorer (especially for the case of injection at 60\(^\circ\), see Fig. 6, right-hand side). This means requiring a substantially greater current from the \({\text {H}}^-\) source. However, as the presently installed RFQ is designed for a maximum 5% duty cycle and the upgraded RF duty cycle would be 10–15%, a redesign of the RFQ would be necessary regardless, and may be more forgiving in terms of H\(^-\) losses. The maximum 5% duty cycle of the present RFQ is imposed by the cooling needed for resistive losses. Thus, the main design issue is allowing for a greater heat load.

For this baseline design with beams merged in the LEBT, two layouts have been studied in terms of source position: a symmetric layout (the \({\pm }\,30^\circ\)) and an asymmetric one (\(+\,60^\circ\) layout), as shown in Fig. 6. In other words, merging the sources requires moving the current proton source and bending both beams at \(30^\circ\), or leaving the proton source and bending the \({\text {H}}^{-}\) beam by \(60^\circ\). This second layout is less costly in terms of equipment and may require less downtime for nominal ESS operation, but increases dispersion dramatically (thus reducing RFQ transmission). Space limitations in the tunnel may also be unavoidable and prohibitive for the second layout, especially in terms of structural requirements, personnel access issues, or wiring and grounding. Specifically, the right-hand solution’s \({\text {H}}^-\) source position makes it difficult to pass and that the drop hatch area has to be used for logistics and included in each search of the tunnel. Meanwhile, left-hand solution means that a realignment of the beam is also required for the proton beam by adjusting the steering magnets.

Both layouts have been simulated in terms of losses and RFQ–DTL transmission. At present, the symmetric layout is taken as the baseline and has been used for end-to-end simulations.

As mentioned above, the total RF duty cycle with both proton and \({\text {H}}^-\) beams will be between 10% and 16%. The maximum 5% duty cycle of the present RFQ is imposed by the cooling needed for resistive losses. Thus, for the nominal case of merging the beams into a single redesigned RFQ, the main design issue is allowing for a greater heat load.

For a more in-depth discussion of the options for the LEBT and MEBT design, see Sects. 4.5 and 4.6.

4.4 Ion source design

The requirements of the \({\text {H}}^-\) source are closely related to the pulsing structure of the beam shown in Fig. 3. For the baseline solution (Option A+), which pulses the \({\text {H}}^-\) source at 14 Hz, a long pulse of 3 ms is needed. For the alternative schemes with 70 Hz, a pulse length of around 1 ms is needed.

There will inevitably be losses along the linac and the cumulative radiative activation from power loss along the linac for the proton and \({\text {H}}^-\) beams must not exceed 1 W/m for safe, hands-on maintenance (or 0.1 W/dm, in terms of machine protection limits [6]). In the high-energy sections of the linac, stripping losses due to intrabeam collisions, which has been identified as a major loss mechanism at the Spallation Neutron Source (SNS), are expected to dominate, along with stripping due to Lorentz-shifted electromagnetic forces [7, 8]. Although though these losses are of great concern in terms of activation, they only involve a small fraction of the accelerated beam.

However, losses in the low-energy sectors can involve significant fractions of the beam being lost; with, for example, the residual gas stripping, intrabeam stripping, and other losses in the LEBT and RFQ estimated to comprise about 25% of the initial bunch population exiting the source.

A large fraction of beam losses are expected to occur in the LEBT and the transmission through the RFQ, where the beam is bunched. Simulations show that roughly 10–15% losses are expected in transport through the LEBT and RFQ, depending on ion source emittance. For the \({\text {H}}^-\) beam, there are also losses expected due to stripping, since the extra electron has a binding energy of only 0.75 eV. The stripping loss mechanisms have been summarised in [8], and will be discussed in detail in Sect. 4.10.

Assuming 25% losses in total, for a 60 mA beam to reach the accumulator ring, a 80 mA beam current is needed from the ion source (required for Option A+ in Fig. 3). The limiting factor for the current is the pulse length of the flat-top of the RF modulators being 3.35 ms in the present design. With a superconducting cavity filling time of about 0.3 ms and the time to stabilise the regulation at 0.1 ms, the effective supported pulse duration is about 2.9 ms. For Options B and C, the beam current requirements from the ion source are more relaxed, since the overall beam current requirements are lower.

The beam from the ion source has to match the acceptance of the RFQ, and therefore, the emittance should ideally be less than 0.25 \(\pi\) mm mrad; higher emittance will lead to higher loss and downstream emittance growth. However, since a new RFQ design will needed, and since the 80 mA required current is at the upper end of conventional \({\text {H}}^-\) source design [9, 10], it can be expected that this emittance requirement will relax. Simulations completed for this report using the present RFQ design show that for source emittances of up to \({\sim }\,0.38\) \(\pi\) mm mrad, the required current can be accelerated through the upgraded 2.5 GeV linac, with emittance growth limited to \({<}\,5\%\) of the ideal case.

The pulse-to-pulse variations in beam current, and the flat-top stability, are also important parameters. These must be managed to avoid field and phase variation in the cavities, which would increase losses in the linac. The variations of the beam current are assumed to be acceptable within \(\pm \, 3\%\). The requirements for the \({\text {H}}^-\) ion source are summarised in Table 2.

4.4.1 Ion source baseline

A variety of \({\text {H}}^-\) ion sources have been studied to meet the linac requirements and there is expertise at leading facilities with ion sources having similar performance as that needed for \({\text {ESS}}\nu {\text {SB}}\). The strongest limitation here is that the \({\text {ESS}}\nu {\text {SB}}\) ion source will require an output current, emittance, and repetition rate roughly matching the limits of technological performance of those currently in operation. For selection of the \({\text {H}}^-\) ion source, recent reviews of various ion source types can be found in [11,12,13]; further reviews are also available [14,15,16]. Additionally, a workshop on the subject was held in 1994, which focused on surveying possible ion sources for SNS [17].

At present, the favoured source design is that of SNS at Oak Ridge National Lab in Tennessee, USA. It is an RF-antenna multicusp (i.e., multipole magnet) volume and surface source; this source operates via inductive excitation of the plasma using a porcelain-coated copper antenna. Caesium is added for enhancing the surface ionisation rate [11, 18] and the beam is injected at an angle to improve electron extraction [19].

Recent experience at SNS shows that such an ion source can be operated routinely, delivering 50–60 mA \({\text {H}}^-\) beams into the RFQ at a 6% duty cycle, with availability of \({\sim }\,99.5\)% [18]. Additional labs in the US have adopted this design for its performance and ease of installation [20]; SNS is also now testing the performance of an external-antenna type source (not pictured) with improvements in efficiency (output current vs. input power) and a smoother beam pulse profile.

The lifetime remains limited for these ion sources before their caesium supply must be replenished, despite improvements in the last few years; it is now on the order of 10 weeks. At Japan’s Particle Accelerator Research Complex (J-PARC) in Tokai, Japan, there has recently been a development of a similar source with \({\sim }\,0.25\) \(\pi\) mm mrad emittance and \({\sim }\,65\) mA beam current [21].

The characterisation of multicusp magnets for plasma confinement may also be a worthy avenue of study, with the influence of pole count [22] and the use of virtual cusps [23] strongly affecting plasma characteristics. The use of pulsed, switching multicusp magnets (e.g., from virtual-cusp to non-virtual-cusp modes) may also be worth investigating, with the goal of leveraging the benefits of various modes. Such technology may be more feasible from an engineering standpoint thanks to recent developments with compact switching multipole magnets [24].

In the following section, more details are provided on this favoured ion-source type, along with other available technologies.

4.4.2 Available ion-source technologies

The production of \({\text {H}}^-\) ion beams is more complex than providing proton beams; and an \({\text {H}}^-\) ion, once formed, can easily be stripped to neutral hydrogen atom, \({\text {H}}^0\), since the binding energy (also termed electron affinity) of the outer electron is only 0.75 eV. This can be compared with, for example, the electron-binding energy of neutral hydrogen at 13.6 eV.

There are essentially two types of ion sources in use at accelerator facilities, one is the surface production type—Penning or magnetron sources—where the plasma discharge is generated by an applied DC voltage. The other main type is the RF volume source, where the plasma discharge is driven by an applied electromagnetic field with a high frequency (MHz range).

In a volume source, the production of ions takes place by first creating highly excited ro-vibrational hydrogen molecules, \({\text {H}}^2\)*, by collision with fast electrons. In a second step, a slow electron (\({\sim }\,1\) eV) is attached to the \({\text {H}}^2\)* which dissociates into \({\text {H}}^-\) and \({\text {H}}^0\). In order for this process to be successful, the fast and slow electrons need to be separated. This is done by a magnetic filter field which separates the plasma into two distinct regions: one with fast electrons and one with slow electrons, where the \({\text {H}}^-\) can be produced [11, 25].

In high-current \({\text {H}}^-\) sources, caesium (Cs) is commonly used for increasing the production rate of \({\text {H}}^-\) in the surface process, since Cs has the lowest work function of all elements at 2.1 eV (and by surface adsorption, it can also reduce the work function of other metals). Molybdenum is also commonly used in ion sources, owing to its low sputtering rate, but has a relatively high work function of 4.2 eV.

Moreover, a variety of metals can be coated with a sub-monolayer of Cs, to reduce the work function further than possible with solid Cs; this yields a theoretical optimum coverage of around 0.6 monolayers, having a work function of about 1.5 eV [26]. The low work function is important for an electron to be easily transferred from the cathode surface toward a hydrogen molecule to form an \({\text {H}}^-\) ion. Maintaining an optimal coverage of Cs throughout the discharge is thus very important.

The most promising ion sources to meet the requirements of the future \({\text {ESS}}\nu {\text {SB}}\) ion source have been identified as follows: the Penning ion source (surface) in use at ISIS, Rutherford Appleton Laboratory (RAL), UK; and the RF volume sources in use at SNS and J-PARC. From this point, the text remains focused on these ion sources and the on-going development at RAL and SNS, with a few comments on other source types.

4.4.2.1 Penning ion sources

The ion source in use at ISIS, RAL, is a surface plasma ion source of Penning type, see Fig. 7 [11]. The Penning source was first developed by Dudnikov [13] and has also been used at Los Alamos National Laboratory (LANL) [27]. The Penning ion source can produce high currents, up to 100 mA, provide high-emission current densities > 1 \({\text {A/cm}}^{2}\) and have a fairly low energy spread of \({<}\,1\) eV. In routine operation, the Penning 1X source at ISIS produces 55 mA in 0.25 ms pulses at 50 Hz (1.5% duty cycle).

Studies pursuing longer pulse lengths are ongoing at RAL. With the Penning 1X source, \({\text {H}}^-\) ion pulses of 6 mA at 1 ms and 50 Hz can be reached with a stable flat-top current. However, for longer pulse-lengths at a pulse frequency of 50 Hz, there is a droop in the beam current [28]. To reach a more stable flat-top current for longer pulses, a research program is underway at the Vessel for Extraction and Source Plasma Analyses (VESPA) test stand [29] and at the Front End Test Stand (FETS). One mitigation that is explored is to have a controlled power supply that can counteract the droop by increasing power in the discharge. Additionally, by improving the stability in the beginning of the discharge, more of the pulse can be used in the extracted beam. Today, about 0.3 ms is required for the discharge to stabilise and noise to reduce before beam is extracted.

Another area of study is to scale up the dimensions of the ion source, which is done in a Penning 2X source [30]. The flat-top droop is believed to be related to thermal variations during the discharge, which causes the Cs coverage of the electrode surfaces to deviate from ideal conditions for \({\text {H}}^-\) production (\(\sim 0.6\) monolayers). By scaling the size of the electrode surfaces, and thereby the plasma volume, the thermal variation of the components is reduced, which will increase the pulse stability and the potential ion current [31, 32]. The aim of the Penning 2X source is to deliver a 60 mA beam at 2 ms and 50 Hz (10% duty cycle).

One disadvantage with the Penning source is its relatively short lifetime of about 4 weeks, limited by sputtering of the anode and cathode. The refurbishing process is also tedious, including mounting new parts to high mechanical precision. The sources routinely in use at ISIS are exchanged every 2 weeks as a preventive maintenance.

Using Cs is an effective way of enhancing \({\text {H}}^-\) ion production, and also reduces co-extracted electrons. However, one needs to ensure that Cs is not transported further through the LEBT to reach the RFQ, or other accelerating structures, where it may cause unwanted electron emission. In the Penning 1X type source, this is done by a cold trap, operated at roughly \(-5\,{^{\circ }}\)C, along with a 90\({^{\circ }}\) bending magnet placed directly after the ion source. In the Penning 2X type source, initial focusing is provided by an Einzel lens, and the Cs is trapped by a carbon gettering system [33, 34]. The extraction voltage used is 18 kV, which is lower than the requirements for the \({\text {ESS}}\nu {\text {SB}}\) ion source. However, the energy can be increased with a post-acceleration gap, which is used at FETS to accelerate the beam to 65 keV [28]. The performance of the Penning ion source comes close to meeting the requirements of the \({\text {ESS}}\nu {\text {SB}}\) ion source (see Table 3). With the development program taking place at RAL, the Penning ion source could potentially reach the long pulse requirements of 3 ms at 14 Hz and 80 mA.

Schematic cross section of a Penning ion source, from [11]

4.4.2.2 RF volume and surface \({\text {H}}^-\) sources

The SNS ion source has an internal RF porcelain-coated copper antenna for inductive excitation of the plasma, and permanent cusp magnets surrounding the plasma chamber to create a magnetic field which confines the plasma, see Fig. 8 [19]. The SNS ion source is based on a design from Lawrence Berkley National Laboratory LBNL [35], with a filter magnetic field separating the fast- and slow-electron regions. This ion source is of volume type; however, it has an additional Cs collar near the outlet, which enhances the ionization rate. This source therefore combines the phenomena of volume and surface ion production. The plasma is excited using 55–65 kW of 2 mHz RF, and the plasma is sustained using a low power 13.56 mHz RF at 200 W. In this way, the plasma is quickly ignited when the high power RF is turned on.

The SNS ion source is operated routinely with 50–60 mA \({\text {H}}^-\) beams directed into the RFQ at a 6% duty cycle (1 mA, 50 Hz). Caesium is added using caesium-chromate cartridges at the outlet collar; the Cs release is adjusted by controlling the temperature. The amount of Cs used is in the order of 10 mg, for one operation cycle, without the need for continuous Cs injection [36]. An updated design places the RF antenna external to the plasma chamber (not pictured); although this technology is much less mature than the internal-antenna design, early results show improvements in efficiency [37].

The LEBT used at SNS is a short electrostatic type, of about 12 cm, without any diagnostic capability (on the test stand, sources are fitted to a false RFQ aperture, beam-current toroid, and Faraday cup for RFQ input-current estimates). The extraction voltage is 65 kV and could potentially be increased to 75 kV to meet the requirements of the \({\text {ESS}}\nu {\text {SB}}\) ion source [38]. Recently, the development of a magnetic LEBT has been studied, which would allow for diagnostics and prevent problems with electric discharges [39].

General schematic of an internal RF negative-ion source (left) and a cross section of the SNS RF ion source (right), both from [11]

At SNS, there has been success in addressing issues limiting the source lifetime and availability. Problems with the insulation of the porcelain-coated antenna were solved by improving the coating procedure and careful selection of the antennas. More recent improvements include increasing the electron dump efficiency and minimizing electrical discharge problems in the electrostatic LEBT. These developments have led to a high power, high duty-cycle RF \({\text {H}}^-\) ion source with a long lifetimes of up to 14 weeks, and availabilities of \({\sim }\,99.5\)% [18, 36].

The performance of the SNS ion source is summarised in Table 3. Its regular operation is with 1 ms pulse length and 60 Hz. It should also be possible to extend the pulse length to 3 ms at 14 Hz to reach \({\text {ESS}}\nu {\text {SB}}\) requirements [38]. Assuming tests with longer pulses prove successful, the SNS RF ion source will stand as the most feasible alternative for the \({\text {ESS}}\nu {\text {SB}}\) ion source. At J-PARC, there has recently been a development of a similar source, with reports of 66 mA ion beam currents [21].

4.4.2.3 Other ion sources

A few other available sources are mentioned here, with some commentary on their performance:

The magnetron surface-plasma ion sources used at Fermi National Laboratory (FNAL) [41] and Brookhaven National Laboratory (BNL) [42] are similar to the Penning source, but use a different geometry. Such ion sources can produce high currents, on the order of 100 mA, with a long lifetime of > 9 months but have a higher noise level, about 10%, and higher energy spread than Penning sources; and have typically been used at relatively low beam duty cycle of about 0.5% [11]. However, recent improvements to the BNL source and its LEBT transport line have resulted in a 120–130 mA current at a 7 Hz repetition rate and 600–1000 \(\upmu {\text {s}}\) pulse length, with an 80 mA beam transmitted through the RFQ [43].

In addition to SNS, RF sources using external antennas have been used at the Deutsches Elektronen-Synchrotron (DESY), reaching 80 mA at a duty cycle of 0.8% [14] and the ion source for Linac 4 at the European Council for Nuclear Research (CERN) is of a similar design, producing 45 mA at a low duty cycle of 0.04% [11].

There is also a development at RAL of a Cs-free RF source. This ion source will have a 30 mA current at a 5% duty cycle. This source is designed to meet the demands of the regular user beam at ISIS, which will be sufficient if the transmission is increased by introducing an MEBT into the linac [44].

4.4.2.4 Summary

Studies have been performed by the authors of this report on the Penning source at RAL and the RF source at SNS closer, since these were identified as being the most promising ion sources to meet the requirements for \({\text {ESS}}\nu {\text {SB}}\). For the pulsing Option A+, with long pulses of 3 ms, the closest to match is the Penning source at RAL. However, this source type is quite service-demanding and requires relatively high amount of Cs. The RF source at SNS has a higher lifetime and uses less Cs. For both ion sources, it remains to be seen whether they can deliver long pulses which can maintain a stable flat-top current of roughly 80 mA over 3 ms at 14 Hz.

For the pulsing Options B and C, with 50–80 mA, \(\sim\)1 ms at 70 Hz, both types of source are feasible. The RF source seems the most promising from the lifetime point of view, and the requirements are nearly met by the state-of-the-art ion sources at SNS and J-PARC.

There are ongoing discussions between \({\text {ESS}}\nu {\text {SB}}\) and both RAL and SNS, to follow their developments and determine if there are any areas of research needing attention to meet the upgrade requirements for \({\text {ESS}}\nu {\text {SB}}\) (since neither of these sources do so as of today). However, steady improvements in performance of the ion sources lead to the expectation that they will meet the requirements within the schedule of the \({\text {ESS}}\nu {\text {SB}}\) project. Moreover, it is worth recalling from the introductory remarks to this section that preliminary simulations with a relaxed emittance limit from the source of 0.38 \(\pi\) mm mrad showed acceptable transmission through the RFQ as well as through the DTL, with total emittance growth at the end of the linac less than 10% versus the nominal 0.25 \(\pi\) mm mrad source emittance.

4.5 Low-energy beam transport (LEBT) design

In studies of the front end, the primary focus has been on finding solutions where a common LEBT, RFQ, and MEBT are used for the proton and \({\text {H}}^-\) beams, as in the left panel in Fig. 5. The alternative, which uses separate front ends, would be more straightforward, but more expensive.

One challenge with the LEBT is that the beam is highly space-charge dominated; this implies the beam tends to “blow up” spatially, has increased emittance, and that the beam transport generally should be kept as short as possible. Space-charge compensation is therefore critical; this involves an injected inert gas or mixture of gases [45]. The process for the space charge compensation is different for protons and \({\text {H}}^-\). For protons, space-charge compensation is largely imparted by electrons, while for \({\text {H}}^-\), it is induced by positively charged ions, which are heavier and alter the underlying dynamics. With an excessive gas pressure, there is also a risk of introducing stripping losses with the \({\text {H}}^-\) ions (see Sect. 4.10), although the required gas concentration is likely to be at least an order of magnitude below the point of problematic stripping, it can cause a non-negligible portion of total losses, and should be simulated carefully in the design stages [45,46,47].

As discussed above, there are two options for how to integrate the ion source with the LEBT, with one option keeping the proton ion source and the beam aligned, and installing the \({\text {H}}^-\) ion source at an angle of 60\({^{\circ }}\), Fig. 6 (left) or with both ion sources displaced by an angle of \({\pm }30^{\circ }\), Fig. 6 (right). It should be noted that the first option requires a switching dipole to be introduced; the second option can use a fixed-field dipole magnet, since the proton and \({\text {H}}^-\) beams have different charge.

Moreover, when merging the beam in the LEBT and using the same RFQ, the energy of the different species should be equal. The platform of the proton ion source is + 75 kV, and so the platform voltage of the \({\text {H}}^-\) source will be − 75 kV relative to ground. The ion sources must therefore lie on two different platforms, with a grounded cage between for shielding. The shortest distance in air at the present proton ion source is about 185 mm, without any discharge problems, so both options in Fig. 6 seem feasible from a high-voltage perspective.

There are physical limitations in the linac tunnel and how accelerator equipment can be added in different directions. From a building design perspective, it is easier to add components in the area to the left of the beam line (eastward, facing the direction of the beam). In the front-end building, the wall to the right in the tunnel is solid and several components are installed in the intervening space, which makes it easier to install equipment on the left-hand side. This makes the 60\({^{\circ }}\) option easier to accommodate.

4.5.1 Simulations of beam transport

Simulations of the beam transport through the LEBT and RFQ have been carried out utilising the TraceWin software [48]. This effort began with 60\({^{\circ }}\) layout, since in this case, the proton beam line would be more or less unchanged. The bending magnet has a bending radius of 0.4 m and edge angles of 20.5\({^{\circ }}\), which balances the focusing effects in horizontal and vertical directions. The first solenoid is kept as close as possible to the ion source.

The dipole bend introduces dispersion, and in principle, the bend could be made achromatic. However, this would require a longer beam line with greater decoherence from space charge forces; this has therefore been avoided. The dispersion introduced is relatively small, about 0.5 m. and considering the limited momentum spread of the beam, in the order of 0.1% determined mostly by the ripple of the power supply for the extraction voltage, this dispersion will not affect the beam significantly.

Simulations with the 60\({^{\circ }}\) layout, assuming a beam from the ion source of emittance 0.14 \(\pi\) mm mrad, and assuming a space charge compensation of 95%, give a transmission of about 93% from the ion source to the end of the RFQ. However, simulations with emittance from the ion source of 0.2 \(\pi\) mm mrad and assuming 85% space charge give a transmission of only 60% from the ion source to the end of the RFQ. This is because the beam envelopes in this case become large and particles at large amplitudes are affected by non-linear fields in the solenoids and fringe fields of the dipole. This result indicates that the beam transport in a LEBT with a 60\({^{\circ }}\) bend is sensitive to both space charge and initial beam distribution from the ion source.

Simulations with a 30\({^{\circ }}\) magnet show that the beam transport becomes much less sensitive to input emittance and space charge compensation (since the envelopes are smaller) and is not influenced by aberration and fringe fields to the same degree. Simulations with a distribution of 0.2 \(\pi\) mm mrad and space charge compensation of 95% show a transmission of about 95%. Using the same input emittance, but space charge compensation of 85%, also gives a transmission of about 95%. A distribution of 0.25 \(\pi\) mm mrad, which is the nominal requirement for the ion source, and space charge compensation of 85%, which is a reasonable assumption for the LEBT [40] gives a transmission of 84%. The beam distribution after the RFQ for this case is shown in Fig. 9, tracking 200 k macroparticles. The output emittance from the RFQ is about 0.25 \(\pi\) mm mrad. A beam density plot in the LEBT is shown in Fig. 10 for this case.

As mentioned in Sect. 4.4.2, further simulations at an upper limit emittance of 0.38 \(\pi\) mm mrad were also carried out for the 30\({^{\circ }}\) case assuming a source capable of delivering \({\sim }\,85\) mA. Here, the transmission through the RFQ is limited to \({\sim }\,70\%\), but the beam is delivered to the end of the linac with a modest emittance growth of \({<}\,10\%\) versus the nominal case.

These simulations demonstrate that the case with a source placement of \({\pm }\,30{^{\circ }}\) is much less sensitive to the initial ion source distribution and the degree of space charge compensation than the 60\({^{\circ }}\) design. However, the impact on ESS operations due to installation is also a significant factor; this is covered in depth in Sect. 4.13. Although both options have serious merits and drawbacks, considering all these aspects discussed here and those discussed in Sect. 4.3, the present baseline is the 30\({^{\circ }}\) option.

4.6 Medium-energy beam transport (MEBT) design

The function of the MEBT is to match the RFQ output beam to the DTL; to characterise the beam with different diagnostics; to clean the head of pulse using a fast chopper (2.86 ms long for the proton beam); and to clean the transverse halo using scrapers, see Fig. 10. The chopper is also part of the machine protection system, which shuts down the linac on detection of any serious faults. Details of the ESS MEBT design and matching can be found in [49, 50].

For the \({\text {H}}^-\) beam, the MEBT will also be used to chop the beam to create extraction gaps for the accumulator ring. The beam envelopes from the RFQ are similar for the proton and \({\text {H}}^-\) beams, but since the DTL has permanent quadrupole magnets, the orientations of the beam envelopes are opposite for \({\text {H}}^-\) and proton beams, see Fig. 9.

As a starting point for the MEBT design, the proton MEBT is used (see Fig. 10). The ESS MEBT contains 11 quadrupoles for transverse focusing and 3 buncher cavities for longitudinal focusing, opposing the space charge forces in the beam. Figure 11 shows the beam envelopes and expected emittance development taken from simulations.

The MEBT must be redesigned to meet the requirements of the \({\text {H}}^-\) beam. The chopper for the standard ESS MEBT is designed to remove the head and tail of the 2.86 ms pulse. It consists of electrostatic plates, and a dump in one plane, with a quadrupole that is used to deflect the beam. This does not work, however, for a beam with the opposite charge (without switching the polarity of the quadrupole). Alternative methods for chopping will be discussed shortly.

Standard proton MEBT, simulations of envelopes (top) and emittance growth for both the MEBT and first DTL tank (bottom), from [50]

The first elements in the MEBT are used to form a beam which is circular at the chopper, both for the proton and \({\text {H}}^-\) beams. The focusing elements after the dump will be used to match the beam to the DTL. Some elements may have to be pulsed between the proton and \({\text {H}}^-\) beams, 28 Hz in the baseline design, but it is desirable to find an MEBT design that switches as few elements as possible. Simulations performed in TraceWin show an emittance growth of \({\,3\%}\) for the case having no switching magnets versus having both beams matched to optimal Twiss parameters at the MEBT-to-DTL interface via switching. The exact design of the quadrupoles will need to be studied further, especially the choice of iron or ferrite-based design.

The critical design criteria for the MEBT are summarised here:

-

Use as few switching magnets and/or focusing elements as possible; these switch the value between p and \({\text {H}}^-\).

-

The longitudinal phase spread should be limited to less than \({\pm }\,25{^{\circ }}\) (rms) to avoid non-linear fields in the buncher cavities, which would lead to halo and/or emittance growth longitudinally.

-

In case one or more cavities fail in the superconducting (SC) section of the linac, parts of the SC linac need to be returned to the order of 10 MeV. This means that no dispersion can be allowed downstream of the MEBT, and that an achromatic solution should be sought as a translation stage.

-

For the option of merging beams in the MEBT, the new RFQ and ion source need to be displaced from the proton RFQ by about 3 m to allow access, and space for installations. It also requires further investigation on whether it is feasible to install a second \({\text {H}}^-\) front end, considering the required waveguides and other auxiliary equipment.

4.6.1 Option for a separate \({\text {H}}^-\) MEBT with a 45\({^{\circ }}\) translation stage

In an alternative design for the \({\text {H}}^-\) MEBT, the standard MEBT design was used, and then split after the diagnostics unit and before the last four quadrupoles, where the translation stage with two 45\({^{\circ }}\) magnets is introduced, see Figs. 12 and 13. The translation section includes three buncher cavities to focus the bunch longitudinally. The quadrupoles and the buncher cavities are matched to create an achromatic section, so that the dispersion and its gradient remains zero at the MEBT exit. As mentioned above, the new RFQ and ion source must be displaced from the proton RFQ by about 3 m to allow access and space for installations; the length of the 45\({^{\circ }}\) translation stage thus becomes 4.2 m.

The proton and \({\text {H}}^-\) beams merge at a second dipole magnet. Thus, for optimal beam conditions, the last four quads and the last buncher cavity need to act in a switching mode, since they require different settings for each of the two beams to provide matching to the DTL. In the DTL, permanent quadrupoles are used for focusing, so no switching can be done between the two beams.

The first section of the MEBT is essentially identical to the nominal proton MEBT, and includes the beam chopper and diagnostics. The chopper cavity is rotated 90\({^{\circ }}\) compared to the proton one, to deflect the beam in x instead of y, and the fifth quadrupole from the MEBT entrance acts as a kick-magnifying element. The quadrupoles in the first section have approximately the same values those in the nominal MEBT.

Table 4 lists the major drawbacks and benefits of this scheme. One additional advantage with merging the beams in the MEBT is that the proton MEBT can be kept more or less intact except for the last section of the MEBT, consisting of four quads and one buncher cavity.

However, the space restrictions, emittance growth, and other listed drawbacks have left this option as a backup, with the design of merging further upstream into a common RFQ being favoured as a baseline, as discussed in Sects. 4.3 and 4.5. Further details on this study can found in [51].

4.6.2 Matching the MEBT to the DTL

Tracking calculations were performed in TraceWin, which does multi-particle tracking with the PICNIC 3D space-charge routine. The beam was tracked in the MEBT and DTL with the input beam distribution provided by tracking an \({\text {H}}^-\) beam through the LEBT and RFQ.

A precision matching of the MEBT was performed using the four final quadrupoles, along with its second and fifth buncher cavities, using multi-particle tracking, to a precision of 2.4e-4 by TraceWin’s optimisation routine. Some oscillations (beat) in the emittances in the DTL can be seen due to imperfect matching; this can probably be improved with further refinement.

It is worth noting in Fig. 14 that there is a noticeable emittance growth. This can be compared to the standard proton MEBT where the emittance growth is about 10% transverse, see Fig. 11. The emittance growth is, to a large extent, taking place in the dipoles, where there is a coupling between x, z and dp/p. In an achromat with two dipoles, this emittance growth will cancel after the second dipole, but this does not take place in this lattice which has a \(3\pi\) phase advance. This issue is discussed further below.

Additional matching studies were performed using the technique described in [49], with a modified solver to accommodate the interleaved pulses of \({\text {H}}^-\) and protons without the use of switching magnets. This results in a modest emittance growth versus the single-species simulations, reaching the end of the linac at roughly 3–10% above the nominal case for both \({\text {H}}^-\) and protons (depending on emittance and current parameters of the ion source). Further optimisation of the matching should be performed to finalise the MEBT chopper design.

4.6.3 Chopping

The chopper in the standard proton MEBT is used for removing the head and tail of the macropulse of 2.86 ms. For the \({\text {H}}^-\) beam, the chopper will also be used to create extraction gaps for the accumulator ring [52].

This means chopping off about \(0.13\,\upmu {\text {s}}\) every \(1.35\,\upmu {\text {s}}\), or 670 kHz, about 2000 times for every macropulse of 3 ms. This is a considerably higher frequency than the standard chopper. It also means that about 10% of the \({\text {H}}^-\) beam will be dumped in the chopper beam dump. With a beam current of 62 mA, this corresponds to a power of 22 kW at 3.62 meV, and with a beam duty cycle of 5%, an average power of 1.1 kW. The chopper and chopper dump will thus have to be redesigned to meet these requirements.

Assuming the same design of the RFQ as for the standard proton MEBT, envelopes are exchanged in x and y between proton and \({\text {H}}^-\) if using the same gradient strengths for the quadrupoles. The chopper must be designed to deflect the beam in x, with the fourth quadrupole used to amplify the kick in x. (For protons, the chopper cavity deflects in the y direction.) The chopping is efficient with a full voltage applied of \({\pm }\,2.5\) kV (the total voltage difference is 5 kV), see Fig. 15.

One of the challenges with 5 kV chopper is to achieve a rise time as fast as the bunch spacing (2.84 ns). The present requirements for the chopper are 4 kV and 10 ns for the ESS MEBT. There will thus be partially chopped bunches that are deflected, but do not feel the full chopper voltage, and thus will be lost in the MEBT or the DTL. For the standard MEBT, such losses are on an acceptable level [49]; but these losses will be roughly 2000 times greater for the \({\text {H}}^-\) case. For the merge-in-MEBT option, these lost particles can probably be handled within the MEBT and not reach higher energies, since the translation stage is situated after the chopper. However, for the baseline option of merging in the front end, this may be more difficult and should be studied further.

4.7 Superconducting linac

The medium-to-high-beta acceleration process is also being studied with the TraceWin program. It is of primary interest that the beam exiting the linac is matched to the accumulator ring to have efficient injection and to avoid losses. The simulations presented in the above sections focused on the first part of the accelerator, from the ion source to the DTL. Simulations of the beam acceleration and transport from the entrance of the DTL to the injection point to the accumulator ring—with and without errors—were performed as well for the \({\text {H}}^-\) beam. The summary of the losses from the machine errors and different \({\text {H}}^-\) stripping sources are reported in [53], with results of a supplementary study also available in [47]; this issue is also discussed in detail in Sect. 4.10.

From the DTL onwards, the settings of the quadrupoles can be identical for the \({\text {H}}^-\) and proton beams, although the trajectory correction for the two species will most likely need to be different. This requires that the steerer magnets operate in pulsed mode, which will mean modifying their corresponding power converters.

The RF power needed for the combined \({\text {ESS}}\nu {\text {SB}}\) and ESS beams is nearly double the current design (although there most subsystems, as well as overall grid power requirements have significant percentages of overhead reserved for contingency and upgrade). This issue has been studied in detail and is reported in [5] and [54]. Such modifications to the RF system were evaluated for different pulsing schemes of the linac; these are discussed further in Sect. 4.11.

In the superconducting cavities, it is a concern that the RF couplers feeding from the waveguides may experience electrical breakdown due to the increased duty cycle. Based on conditioning data, these couplers are rated to handle the required 10% duty cycle for accelerating both the proton and \({\text {H}}^-\) beams. Thus, the risk of their needing to be retrofitted or replaced is considered very low. However, since the scenario of their needing replacement presents a significant disruption risk to ESS operations, a detailed replacement plan is presented in Sect. 4.13.

4.8 Linac-to-ring (L2R) transfer line

The L2R transfer line has been designed to transport the fully accelerated 2.5 GeV \({\text {H}}^-\) beam from the upgraded high-\(\beta\) line (HBL) at the end of the linac to the accumulator ring (AR) [55]. The L2R line bends the beam both horizontally away from the linac and vertically down towards the underground AR as shown in the L2R tunnel engineering drawing in Fig. 16. The beam is horizontal both entering and leaving the L2R line, but at a height difference of 7.864 m.

The transfer line lattice is based on a quadrupole-doublet cell structure, taken from the ESS high-energy beam transport (HEBT) line design. The cell length is 8.52 m long, each quadrupole is 0.35 m long, and the separation of the mid-points of the quadrupoles in each doublet is 1.08 m. The remaining part of a cell constitutes a drift space which is 7.09 m long. It is in these long drifts where the dipole magnets are placed for the transfer line.

In designing the lattice, it is important to stay below the ESS beam-loss limit of 1 W/m [56] which restricts the radioactive activation of the accelerator elements. To this end, the dipole strengths are set to 0.15 T, which limits \({\text {H}}^-\) losses from Lorentz stripping (see Sect. 4.10) to a fractional loss of \(5.7 \times 10^{-8}/{\text {m}}\) [57], corresponding to a stripping loss in the dipole magnets of 0.3 W/m for a 5 MW beam. The 0.15 T field corresponds to a dipole bending radius of 73.5 m, which is used for all horizontal and vertical dipole magnets in the transfer line. All dipole magnets in the L2R line have been taken to be sector dipoles.

Following the tunnel engineering design [58] in Fig. 16, the beam is bent horizontally by \(\theta = 68.75^\circ\), starting from the ESS linac tunnel (point A). For the L2R lattice design, the horizontal bending is performed over 16 lattice cells each of 8.52 m. Each cell therefore bends the beam horizontally by \(4.3^\circ\), and this can be achieved using a single 0.15 T horizontally bending dipole of length 5.512 m per lattice cell.

Layout of the L2R transfer line [58]. Sections are colour-coded according to the presence of horizontal and/or vertical bending

Regarding the vertical bending, the tunnel engineering design calls for a maximum vertical tunnel incline of \(3.38^\circ\). The tunnel incline is progressively increased in section B–C in Fig. 16, from horizontal to \(3.38^\circ\) [58]. After the section of maximum incline (section C–E), the tunnel incline is progressively decreased (section E–F) to return to fully horizontal upon reaching the AR (section F–G). Injection into the AR occurs at, or immediately after, point G in Fig. 16.

Such a design can be achieved by assigning 8 lattice cells in section B–C and 4 lattice cells in section E–F, with an incline change of \(0.42^\circ\) per cell and \(0.84^\circ\) per cell, respectively. This calls for single 0.15 T vertically bending dipole magnets per cell of length 0.542 m and 1.084 m, respectively. It is noted that the longer magnets are not problematic in section E–F as these magnets do not need to share the drift space with horizontally bending magnets.

The dipole and quadrupole distributions within the different 8.52 m lattice cells are shown in Fig. 17. In the section with both horizontal and vertical bending (section B–C in Fig. 16), both the horizontally and vertically bending magnets are distributed to maintain an equal separation of 0.345 m between adjacent dipoles—and between the dipoles and adjacent quadrupoles. In this way, the magnet separations are maximised to minimise cross-talk between magnetic field edge effects.

In the sections with horizontal bending only (sections A–B and C–D in Fig. 16), the location of the horizontally bending dipole magnet is preserved within the lattice cell (see Fig. 17b); this ensures that the beam optics in the horizontal plane is identical throughout sections A–D. For section E–F with vertical bending only, given the freedom of the vertical dipole magnet location, it is placed in the centre of the long drift between quadrupoles, as shown in Fig. 17c.

Quadrupole (Q), horizontally bending dipole (H) and vertically bending dipole (V) distributions within 8.52 m lattice cells for (a)–(c) sections listed in the legend of Fig. 16

Using 16 horizontally bending, 8 vertically down-bending and 4 vertically up-bending dipole magnets, an AR depth of 7.864 m can be achieved. The assignment of the 32 lattice cells is shown in Table 5, and the locations at which the sections of horizontal and vertical bending start and endFootnote 1 are shown in Table 6.

4.8.1 Beam dynamics

Beam dynamics simulations have been performed in TraceWin from the start of the DTL to the end of the L2R transfer line [59]. The L2R quadrupole strengths are optimised to make the L2R line achromatic (that is, with no output horizontal and vertical dispersion) and to limit intra-beam stripping by avoiding beam sizes that are too small (see also Sect. 4.10). A matched beam is also ensured between accelerator sectors by matching the Twiss parameters sector-to-sector.

The optimised choice of phase advance is shown in Fig. 18. The phase advance up to and including the HBL matches closely that used for protons, to allow concurrent operation of protons and \({\text {H}}^-\) ions. There is no step in the transverse phase advance on entering the L2R line to ensure efficient matching; beam matching is performed in TraceWin using the last 2 cells in the HBL section and the phase advance adjustment is minimal, as shown in Fig. 18.

To make the L2R line achromatic, the total phase advance is set to a multiple of \(180^{\circ }\) [60]. A relatively low transverse phase advance of \(22.5^{\circ }/{\text {cell}}\) is used at the beginning of the L2R line, providing relatively weak transverse beam focusing [61] and a large transverse beam size of up to \(\pm \, 4\) mm (root mean square) in the dispersive section. Critically, this large beam size limits the intra-beam stripping losses [62] to under 0.4 W/m, at or below the level observed in the linac (Fig. 19).

The magnitude of intra-beam stripping losses decreases along the L2R line as the longitudinal bunch length increases in the absence of accelerating cavities for longitudinal focusing. Therefore, one can take the opportunity to ramp up the phase advance from \(22.5^{\circ }/{\text {cell}}\) to \(45^{\circ }/{\text {cell}}\) (Fig. 18), increasing the transverse focusing and reducing the transverse beam size to below \(\pm 2\) mm (root mean square). This is beneficial in that the number of cells with vertically up-bending dipole magnets (section E–F in Fig. 16) can be reduced from 8 to 4; thus reducing the number of magnets required for the project, while maintaining the \(180^{\circ }\) requirement for keeping the line achromatic.

In the absence of accelerating cavities in the L2R line, the energy spread grows due to space-charge forces. Figure 20 shows how the energy spread increases from \(\pm \, 0.4\) meV to \(\pm \, 2.3\) meV (1 sigma) along the L2R line. Introducing accelerating cavities towards the end of the L2R line, operated at the zero-crossing (i.e., at an RF phase of \(-\,90^\circ\) from the RF peak), allows bunches to be rotated in the longitudinal phase space to significantly reduce the outgoing energy spread. Figure 20 shows how using four such pi-mode structures (PIMS) with 4 MV/m [63] towards the end of the L2R line brings the energy spread down from \(\pm \, 2.3\) meV to \(\pm \, 0.6\) meV.

4.8.2 Energy collimation

Given the strong horizontal dispersion in the L2R line, its energy acceptance is \(\pm 20\) meV. When the energy error exceeds this limit, the beam is lost in the beam pipe, whose aperture is \(\pm 50\) mm. Therefore, beam energy collimation is necessary for the protection of beam line equipment.

For the results presented here, a multiparticle beam was tracked through an error-free lattice from the start of the DTL to the end of HBL line. This provided the Twiss parameters at the input to the L2R line. To test the energy acceptance of the L2R line, the longitudinal emittance was blown up from 0.446 \(\pi\) mm mrad to 1000 \(\pi\) mm mrad, and a beam distribution with a random longitudinal phase-plane ellipse was adopted in TraceWin.