Abstract

The Jiangmen Underground Neutrino Observatory is constructing the world’s largest liquid scintillator detector, with a 20 kt target mass and approximately 700 m of overburden. The total underground space of civil construction is around 300,000 m\(^3\), with the main hall comprising about 120,000 m\(^3\), making it the largest experimental hall in the world. Maintaining a low radon concentration in the underground air is crucial for both human health and the accuracy of experiments involving rare decay detection, such as neutrino and dark matter experiments. To ensure human health and the integrity of neutrino physics experiments, the nominal radon concentration in the main hall must be kept below 200 Bq/m\(^3\) with a maximum value below 400 Bq/m\(^3\). Introduction of fresh air from above ground can significantly lower radon concentration. A benchmark experiment conducted in the refuge room near the main hall revealed that the radon emanating from underground water is a significant source of radon in the underground air. The total underground ventilation rate is approximately 160,000 m\(^3\)/h of fresh air with about 30 Bq/m\(^3\) \(^{222}\)Rn from the bottom of the vertical tunnel after the installation of powerful fans. Of this, 55,000 m\(^3\)/h is used for ventilation in the main hall. As a result of these measures, the radon concentration inside the main hall has decreased from 1600 Bq/m\(^3\) to below 200 Bq/m\(^3\) under stable working conditions, with exceptions during rare adverse weather events or fan failures. The employed strategies to control radon concentration in the underground air are described in this paper.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Radon (\(^{222}\)Rn) is a well-known radioactive noble gas with a half-life of 3.8 days, produced by the alpha decay of \(^{226}\)Ra in the natural uranium chain. Outdoor radon concentration is typically around 10 Bq/m\(^3\) [1], while it can reach several thousand Bq/m\(^3\) in underground locations without special ventilation conditions. Radon in the atmosphere is the most significant contributor to human exposure from natural sources, as it is inhaled and its short-lived decay products are deposited along the walls of the respiratory tract. Additionally, radon and its daughters are significant radioactive backgrounds for experiments with very low signal rates, such as JUNO [2], Borexino [3], SNO+ [4], nEXO [5], PandaX [6], and DEAP-3600 [7], which all utilize liquid detector media. To reduce the background component due to cosmic radiation, experiments of this nature are typically situated in underground laboratories, where radon concentration can be a serious issue.

Numerous underground laboratories worldwide are dedicated to rare event searches, with SNOLAB in Canada and the Gran Sasso Underground Laboratory (LNGS) in Italy being notable for their relatively larger volumes compared to others [8]. Both facilities have well-designed ventilation systems in place to achieve low radon environments. SNOLAB situated in the active Creighton nickel mine at a depth of 6,000 meters of water equivalent (m.w.e.) near Sudbury, Ontario boasts a total volume of 47,000 m\(^3\). With a ventilation rate of 180,000 m\(^3\)/h, the underground radon concentration was reduced to 130 Bq/m\(^3\), allowing 10 air volume exchanges per hour in the smaller laboratory areas and 5 air volume exchanges per hour in the three main detector cavities [9]. Meanwhile, LNGS is located beneath the Gran Sasso mountain in the central region of Italy (not far from Rome), with a rock coverage of 3,800 m.w.e. Its total volume stands at 180,000 m\(^3\), with a ventilation rate of 40,000 m\(^3\)/h. In Halls A and B, the radon concentration in the underground air was lowered to 20 Bq/m\(^3\) as of 1995 through the implementation of enhanced ventilation measures. However, in Hall C and the connecting tunnels, where ventilation was poorer, the radon concentration ranged from 250 to 400 Bq/m\(^3\) [10]. Subsequent efforts were made to improve ventilation in Hall C, resulting in a radon concentration of around 50 Bq/m\(^3\) [11].

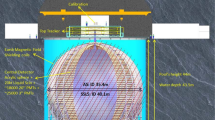

The Jiangmen Underground Neutrino Observatory (JUNO) is set to become the largest liquid scintillator experiment dedicated to neutrino physics. The detector comprises 20 kt of liquid scintillator (LS) contained within a 35.4 m diameter acrylic vessel, which is supported by a 40.1 m diameter stainless steel truss. The scintillation light resulting from energy deposition in the detector will be detected by 17,612 20-inch photomultiplier tubes (PMTs) and 25,600 3-inch PMTs. The detector, PMTs, and connected electronics will be immersed in a 41 m diameter and 41.5 m high water pool, which will also function as a water Cherenkov detector, equipped with an additional 2,400 20-inch PMTs. A comprehensive description of the experimental facility can be found in [2] and its references. The primary objective of JUNO is to determine the neutrino mass ordering by studying the oscillated antineutrino flux originating from the Yangjiang and Taishan nuclear power plants, both located at an optimized distance of approximately 53 km. With its substantial dimensions and projected performance, JUNO is poised to deliver a vast and distinctive physics program [2].

The JUNO underground laboratory is situated in Jinji town, 43 km southwest of the city of Kaiping, in Guangdong province, China at a geographic location of 112\(^{\circ }\)31\('\)05\(''\) E and 22\(^{\circ }\)07\('\)05\(''\) N. Civil construction was completed at the end of 2021, resulting in a total underground volume of approximately 300,000 m\(^3\). The facility features two accesses: a 564 m deep vertical shaft and a 1266 m long tunnel with a slope of 42.5% (refer to Fig. 1). The surrounding rock consists of granite with a measured average density of 2.61 g/cm\(^3\). The detector is positioned within a cylindrical pit inside the main experimental hall, which measures 45.6 m \(\times \) 45.6 m \(\times \) 71.9 m (height) with an arched top, resulting in a total volume of about 120,000 m\(^3\). The vertical overburden at the center of the JUNO detector is 693.35 m (\(\sim \)1800 m.w.e.). There are two entrances to the main hall: one provides access to the area around the top of the pit, while the other serves as a gateway to the bottom of the water pool, which was necessary during the construction phase. Both accesses provide an air shower to individuals and goods in a 3.5 m \(\times \) 4.1 m \(\times \) 13.0 m enclosed space for 20 s before entering the detector area. Several rooms are situated around the top level of the main experimental hall, some of which are directly connected to it and can be accessed both from inside the hall and through the respective entry doors facing the various connection tunnels (refer to Fig. 1). The room hosting all pipes and tanks required for the LS filling and overflow control (FOC room), the two rooms with the electronic modules (Electronics #1 and Electronics #2), and the two rooms with the fresh air cabinets (Cabinet #1 and Cabinet #2) are all linked to the main hall and accessible from the top level of the experimental hall. The LS purification room (LS room) and a refuge room, on the other hand, can only be accessed through the connection tunnel. A 3-D layout of the underground facility is depicted in Fig. 1. As per the design, the fresh air for the entire underground facility will be drawn in from above ground through dedicated cabinets at the top of the vertical shaft and then exhausted through the slope tunnel. However, the above-ground infrastructure was not ready before July 2023. Since the installation of the JUNO detector commenced at the beginning of 2022, powerful fans were temporarily used to draw fresh air from the bottom of the vertical shaft during the initial months of activities in the underground laboratory. For ventilation within the main experimental hall, there are two fresh air inlet cabinets on the upper level, while air is exhausted through dedicated orifices at the bottom of the hall.

The National Occupational Health standards for underground facilities in China (WS/T 668-2019) stipulate that the radon content to be less than 400 Bq/m\(^3\) [12]. Workers at JUNO underground facility are required to work for 8-14 h per day. As a conservative measure, the nominal environmental radon concentration in the main hall during the JUNO detector construction should be kept below 200 Bq/m\(^3\) for human health, with a maximum value of less than 400 Bq/m\(^3\). Additionally, for the neutrino physics, the \(^{210}\)Pb in LS should not exceed the level of 10\(^{-23}\) g/g [13]. As the LS is contained within the acrylic vessel, the deposition of radon daughters (\(^{210}\)Pb, \(^{210}\)Po) on the acrylic surface can lead to LS contamination. All acrylic panels were individually manufactured by the company and then transported to the JUNO site, where they were bonded together layer by layer in the main hall. During the transportation and construction, the surface of the acrylic panels is protected by a film. However, there are still potential instances where some areas may not be adequately protected, such as film detachment during the transportation. Additionally, the bonded areas of the acrylic panels are cleaned during the bonding process, and the acrylic surface is re-covered with a new film after cleaning. Considering the potential exposure, we have estimated that the risk of radon daughter deposition on the inner surface of acrylic in a 200 Bq/m\(^3\) radon environment is acceptable.

The main hall at JUNO is the largest in the world. Due to the limited size of the vertical shaft pipes, the upper limit for the ventilation capacity of fresh air in the JUNO experimental hall is approximately 40,000 m\(^3\)/h. Therefore, achieving a low radon environment through ventilation is more challenging at JUNO. At the start of the underground operations, the radon concentration in the experimental hall reached 1,600 Bq/m\(^3\). In order to effectively address this situation, careful investigations of the underground radon sources were conducted.

The structure of this paper is as follows: Sect. 2 describes the study of underground radon sources through benchmark experiments in the refuge room. Section 3 discusses the optimization of the ventilation system in the underground tunnel and the main hall. Section 4 reviews the identification of radon sources in the main hall under steady-state conditions. Finally, Sect. 5 summarized the main conclusions.

2 Study of underground radon sources in the refuge room

The concentration of \(^{238}\)U in the rock at the JUNO site was measured to be approximately 120 Bq/kg [2], which is significantly higher (1–2 orders of magnitude) than at SNOLAB [14] and LNGS [15]. Additionally, \(^{222}\)Rn, as a daughter product, can emanate from the rock surface. The JUNO laboratory is situated near a rich aquifer, with water outflow reaching 450 m\(^3\)/h. A substantial amount of radon from \(^{226}\)Ra decay accumulates in the water. The partition factor of radon between water and air is approximately 0.25 at 20\(^{\circ }\)C [16], indicating that radon in water can also diffuse into the air. In order to gain a better understanding of the primary radon sources in the underground air, tests were conducted in the refuge room (4.5 m \(\times \) 9 m \(\times \) 4.7 m (height) with an arched top) near the main hall. As depicted in Fig. 2, the refuge room features rock walls, a concrete floor, water outflow, drainage ditch, and fresh air inlet, in a configuration similar to that of the main hall.

The refuge room’s air radon content is constantly supplied by the emanations from rock and water, while the ventilation system’s inlet of fresh air with low radon content dilutes it. Therefore, the radon emanation rate can be expressed in kBq/h as:

where \(E_{\textrm{rock}}\) and \(E_{\textrm{water}}\) represent the radon emanation rates from the rock and the water outflow, respectively. \(\varPhi \) is the rate of fresh air inlet in m\(^3\)/h, and \(C_\textrm{fresh}\) is the radon concentration in the fresh air.

Due to the imperfect sealing of the refuge room, radon diffuses from inside to outside, and vice versa. The net diffusion is dependent on the variance in radon concentration on the two sides of the door. Additionally, radon decay reduces its concentration with a half-life of 3.8 days. The differential function of the radon concentration in the air, \(C_{\textrm{air}}\), can be described as:

where L is the radon net diffusion rate in m\(^3\)/h, V = 175 m\(^3\) is the volume of the refuge room, \(\lambda \) = \(7.6\times 10^{-3}\) h\(^{-1}\) is the decay constant of \(^{222}\)Rn. The solution of Eq. (2) is obtained as

where \(C_0\) is the initial concentration of radon. The radon concentration in air at equilibrium is obtained as:

The radon emanation from the rock of the refuge room was measured using the RAD7 instrumentFootnote 1 [16]: it was found to be 3.6 ± 0.5 Bq/m\(^2\)/h for the 114 m\(^2\) wall surface, and 1.9 ± 0.5 Bq/m\(^2\)/h for the 60 m\(^2\) concrete floor. Consequently, the total radon emanation rate from the rock, \(E_{rock}\), is 0.52 ± 0.06 kBq/h. This would result in an estimated radon concentration of about 400 Bq/m\(^3\) in the air of the refuge room at steady state equilibrium, as calculated by Eq. (4) assuming no ventilation and no air leakage (\(\varPhi =L=0\) in Eq. 4). The measurement of radon in water can be conducted using the accessory RAD AQUA [16]. The sucked-in water is sprayed by AQUA, thereby increasing the efficiency of radon emanation from water; then, the radon gas is pumped to the RAD7 for measurement. To obtain a reliable result, several hours are required to reach the equilibrium condition. The radon concentration in water can be calculated from the radon partition factor a between water and gas, which is a function of temperature T [16]:

We observed a temperature difference of about 1\(^{\circ }\) between RAD AQUA and RAD7, resulting in a fluctuation of approximately 2.3% in the partition factor a. To account for this temperature uncertainty, we conservatively consider 3% as the systematic error for the measurement of the radon concentration in water. The radon content in the water exiting the rock was measured to be 75.0 ± 0.7 kBq/m\(^3\), while the radon concentration in the drainage ditch water was 22.3 ± 0.6 kBq/m\(^3\). A substantial amount of radon from the water quickly emanated into the air after the outflow.

The initial radon concentration \(C_0\) was measured as \(36.0\pm 6.6~\textrm{Bq}/\mathrm m^3\) with a fresh air flow rate of 600 m\(^3\)/h. Subsequently, several actions were taken, and the radon concentration in the air was recorded every three hours with the RAD7:

-

The fresh air was turned off (thus \(\varPhi =0\) in Eqs. 3 and 4) and all the known exits of the refuge room, including spaces around the door, a drainage ditch and fresh air pipes, were blocked. The measured radon concentration in the refuge room air as a function of time is shown in Fig. 3 and it reached the equilibrium value of about 2700 Bq/m\(^3\) after \(\sim \)100 h. The model described in Eq. (3) was used to fit the data points, with radon emanation from the water outflow and radon net diffusion rate as free parameters. The uncertainties on the measurements of radon emanations from rock and water were used as the systematics of this fit. The best fits resulted in \(E_{\textrm{water}}\) = 16.6 ± 0.3 kBq/h and L = 4.8 ± 0.1 m\(^3\)/h, including the systematics, indicating that the radon emanated from the water outflow is approximately 30 times larger than the radon emanated from the rock. The decreasing rate of the radon concentration in air due to radon diffusion out of the refuge room is about four times larger than the decay constant, shortening the time to reach equilibrium four times.

-

The gap (about 0.02 m\(^2\)) at the bottom of the refuge room door was unblocked to quantify the relationship between the radon diffusion rate and the dimension of the leak area. The radon concentration in air decreased to a new equilibrium value of 1258 ± 45 Bq/m\(^3\) after 30 h, shown in the red curve of Fig. 4. Since the total radon emanation from rock and water outflow remained unchanged, the radon diffusion rate was calculated as 12.3 ± 0.6 m\(^3\)/h according to Eq. (4).

-

One of the most significant water outflows was directed outside the refuge room via a flexible tube through the opening at the bottom of the entrance door. This method allowed for quantifying the contribution from water outflow. We observed a fluctuation of about 20% in the water flow from the same outlet at different times. The water outflow from this point was measured to be 0.12 ± 0.03 m\(^3\)/h, with the uncertainty including the flowmeter precision and flow rate fluctuation. The radon concentration in the air of the refuge room decreased to 403 ± 35 Bq/m\(^3\) after approximately 20 h, as shown in the blue curve of Fig. 4. The residual radon emanation from water was calculated as 5.0 ± 0.5 kBq/h according to Eq. (4). Therefore, the radon emanation from this water point amounted to 11.6 ± 0.6 kBq/h. Considering the radon concentration in the fresh water and the ditch, the expected radon emanation from this water point was calculated to be 6.3 ± 2.0 kBq/h, which is approximately 46% lower than the measured value.

-

The rock serves as a heat source inside the refuge room, and the air convection within the room volume is quite complex. To study the radon concentration uniformity, we measured the radon concentration in different areas of the room, including those near the water source (169 ± 23 Bq/m\(^3\)), near the ditch (129 ± 35 Bq/m\(^3\)), and a drier place in the center of the room (64 ± 17 Bq/m\(^3\)). The radon concentration uniformity was assumed to be around 60%. The radon monitoring setup was positioned at the center of the room to acquire the data points of Fig. 4, so the radon concentration around the RAD7 can be affected by convection. Therefore, the 46% difference between the measurement and the calculation of the radon emanation from water is considered acceptable.

The radon concentration in the refuge room air has reached the equilibrium state of about 2700 Bq/m\(^3\) after \(\sim \)100 h. The model described in Eq. (3) is used to fit the data points, while radon emanation from water outflow and the radon diffusion rate are two free parameters. The uncertainties for the best fits are only statistical

In summary, in addition to the well-known surface of the rock, radon emanated from the water was identified as one of the main radon sources in the underground air. It could even play a dominant role, as in this refuge room experiment, depending on the water outflow rate and the radon concentration in the water. Additionally, it is challenging to seal a room, and thus radon diffusion can be significant. The radon concentration in the refuge room decreased by a factor of two due to a 0.02 m\(^2\) leak area, while diffusion had the opposite effect in the main experimental hall due to the reversed concentration of radon, which will be discussed in the next section. Finally, ventilation is the most effective way to reduce radon not only from the rock but also from the water. Therefore, it is important and complicated to design a good and effective ventilation system in such a large underground laboratory.

3 Underground ventilation design

3.1 Ventilation in the tunnel

A robust ventilation system is essential to maintain control over radon concentration in underground air. Given that all the fresh air was temporarily drawn from the bottom of the vertical shaft, powerful fans are required to enhance the flow of fresh air. Figure 5 presents a diagram of the top level of the underground laboratory. Twelve fans were strategically placed in the tunnels of the JUNO laboratory to optimize underground ventilation. The final layout of the airflow direction and capacity is illustrated in Fig. 5, and the airflow outlet can reach 160,000 m\(^3\)/h. Through this measure alone, the radon concentration in the main hall decreased to below 800 Bq/m\(^3\).

A distinct oscillation in radon concentration from day to night was observed, as depicted in Fig. 6. The radon concentration peaks during the day (with a maximum in the afternoon), decreases during the night (with a minimum in the early morning). This phenomenon is contrary to what is observed above ground, where hourly concentrations tend to decrease during the day to a minimum in the late afternoon and then increase to a maximum concentration in the early morning [17]. The explanation for the oscillation observed above ground is that the higher daily temperature leads to a maximum extension of the atmospheric mixing layer, thus lowering the radon concentration at a height of about 2.5 m from the ground.

The monitoring of radon concentration in the air of the JUNO underground experimental hall is shown as the black data points, and a clear oscillation from day to night is observed. The variation of airflow speed underground is represented as the red line, demonstrating a negative correlation between radon concentration in the main hall and the airflow speed

At the JUNO underground site, there is a natural wind from the vertical shaft to the slope tunnel due to the different altitude of entrances on the ground, while the air blower can help to enhance the airflow underground. To understand the radon oscillation phenomenon from day to night, two weather monitoring setups at the top and bottom of the vertical shaft were installed. The variation of airflow speed, temperature, and pressure on the ground and underground is depicted in Figs. 6 and 7. The fluctuation of temperature from day to night is more significant above ground than underground, with the variation of temperature at a depth of \(\sim \)700 m being about 1–2 \(^{\circ }\)C. According to Eq. (5), a 1–2 \(^{\circ }\)C variation in temperature will lead to 4% difference in the partition factor of radon emanation from water. Therefore, the variation of temperature from day to night underground is not the crucial reason for the observed oscillation of radon. An inverse relationship exists between the airflow speed above ground and underground. Based on the weather information, it was observed that higher temperature above ground corresponded to lower airflow speed underground, resulting in higher radon concentration underground. No significant relationship with pressure was identified, consistent with the conclusions in Ref. [18]. The weather setups were installed in August 2022, and the weather information from August was plotted alongside the radon oscillation recorded during the preceding month (July 2022) in Fig. 6. The strong inverse correlation between radon concentration and airflow speed underground is clearly evident. The airflow speed underground oscillated between 0.5 and 1.5 m/s from day to night, impacting the efficiency of radon exhaust in the tunnel and, consequently, the radon concentration in the air. The reduction of radon content from atmospheric mixing related to daytime activities by the staff appears to be minimal. The natural ventilation underground is influenced by the weather conditions above ground, which therefore represent a critical factor for the radon concentration in the underground air.

a A negative correlation exists between the airflow speed above ground and underground. b There is a negative correlation between the airflow speed underground and the temperature above ground, with the variation of temperature underground being much smaller than that above ground. c There is no obvious correlation between the airflow speed underground and the pressure. The three dips in pressure readouts are data taking artefacts

We conducted a thorough screening of the radon concentration at various positions along the underground laboratory to identify the radon source. The radon concentration near the bottom of the vertical shaft was approximately 30 Bq/m\(^3\), indicating good quality fresh air. However, at a distance of about 100 m from the bottom of the vertical shaft, radon accumulated in Tunnel #1, which had inadequate ventilation. It was discovered that the airflow direction in this area was slightly from the slope tunnel towards the vertical tunnel, causing radon-rich air from Tunnel #1 to be blown into the vertical shaft tunnel and then into the experimental hall. Continuous monitoring of radon in Tunnel #1 over a 24-h period revealed the same oscillation phenomena from day to night, with radon concentration varying between 600 and 1100 Bq/m\(^3\), consistent with the measurements in the main hall. Consequently, we optimized the deployment of ventilation fans inside and outside Tunnel #1 to redirect the airflow from the vertical shaft towards the slope tunnel. Following this optimization, the radon concentration in the air of the tunnel area between the vertical shaft and the LS room decreased to below 100 Bq/m\(^3\) without day-night oscillation, while the radon concentration inside the main hall reached values below 400 Bq/m\(^3\). The subsequent step to further decrease these radon concentrations was to optimize the ventilation inside the main hall, as discussed in Sect. 3.2.

3.2 Ventilation in the main hall

On the top of the main hall, there are two fresh air cabinets labeled as Cabinet #1 and Cabinet #2 in Fig. 5, which are used to introduce fresh air. Additionally, there are four temporary cabinets equipped with three stages of filters to facilitate air circulation within the hall, enhancing the cleanliness level in the detector area. The temperature inside the main hall is maintained at a stable level of (21 ± 1)\(^{\circ }\)C through the use of cooling water inside the cabinets. Consequently, the radon emanations from rock and water inside the main hall should remain almost stable due to the consistent temperature maintenance.

The initial design placed the inlet for the two fresh air cabinets above ground, with the fresh air transported underground through a long steel pipe along the vertical shaft. However, the construction of this infrastructure was completed in June 2023. Before this date, the fresh air intake was located underground near the bottom of the vertical shaft, which was not an ideal condition. The lack of suction power at the inlet of the pipe installed at the bottom of the vertical shaft meant that the fresh air was drawn into the main hall only by the cabinets. However, the length of the pipe from the intake at the bottom of the vertical shaft to the cabinets near the main hall was about 200 m, making the cabinets insufficient to draw fresh air. To address this issue, a fan with 85,000 m\(^3\)/h air displacement was added at the inlet of this pipe to increase the fresh air stream, along with a primary filter to improve the air quality. The final amount of fresh air supplied by the two cabinets is 35,000 m\(^3\)/h, with 10% directed towards the LS room.

A significant amount of water with a flow rate of 70 m\(^3\)/h is continuously discharged from the rock at the bottom of the water pool, leading to the emanation of radon, which is a significant source of contamination inside the experimental hall. To mitigate this issue, a fan was installed outside the bottom of the hall to assist in the exhaust of air from inside, with a flow rate of up to 22,000 m\(^3\)/h. This not only helps to remove the significant radon emanation from the water but also improves ventilation in the main hall, which has a height of 71.9 m.

Compared to the total volume of 120,000 m\(^3\) of the experimental hall, the net air flow rate of 10,000 m\(^3\)/h introduced into the hall (inlet 32,000 m\(^3\)/h, outlet 22,000 m\(^3\)/h) may not be sufficient to maintain overpressure with respect to the outside, which is essential to prevent contaminated air from leaking into the experimental area. The presence of drainage ditches and rooms around the main hall, coupled with the complex airflow direction inside the main hall, makes it challenging to measure the overall pressure in the main hall. Evidence of a slight underpressure is observed at the location of the plastic curtain sealing off Electronic #1. To guarantee overpressure inside the main hall, one circulation cabinet (indicated as Temporary Cabinet in Fig. 5) has been converted to provide an additional 20,000 m\(^3\)/h of fresh air to the hall. Unfortunately, the air intake of this cabinet is in Tunnel #2, where a large amount of water is discharged from the rock walls at a flow rate of 150 m\(^3\)/h, constituting approximately one-third of the total water outflow underground. Consequently, there is a significant accumulation of radon in this area. To address this, two fans with 34,000 m\(^3\)/h air displacement were positioned in this gallery, resulting in improved ventilation and a decrease in radon concentration from 2000 to 350 Bq/m\(^3\) in the air close to the water source. This measure also helps to prevent high radon leakage into the hall. Additionally, the intake of the temporary cabinet was extended to the tunnel with low radon fresh air using a stainless steel pipe to further enhance the fresh air quality.

In summary, approximately 52,000 m\(^3\)/h of fresh air is being pumped into the main hall and shared with the FOC and the two electronic rooms, all of which are directly connected to the main hall. Considering the 22,000 m\(^3\)/h outlet from the bottom of the main hall, there remains a residual flow of 30,000 m\(^3\)/h to maintain a overpressure inside the main hall and prevent the leakage of radon-rich air from Tunnel #2 into the experimental area.

3.3 Long time monitoring of radon concentration

Figures characterising the final design of the ventilation system underground are summarized in Table 1, while the radon concentrations measured at different locations are listed in Table 2. Within the main hall and its connected adjacent rooms, the radon concentration averages around 100 Bq/m\(^3\). However, in areas with significant underground water and poor ventilation outside the experimental hall, the radon concentration can range from 140 to 450 Bq/m\(^3\).

The results of the long-time monitoring of radon levels inside the main hall are depicted in Fig. 8, with the main operations described in the previous sections labeled in the figure. Despite these efforts, the radon concentration inside the experimental hall remained relatively stable around 100 Bq/m\(^3\) from October 2022 to March 2023, well below our specified requirement. The radon concentration in the FOC room, which is connected to the main hall, mirrors that of the main hall. During the initial stage of installing the purification plants in the LS room, the door separating this area from the tunnel was not installed to facilitate the transportation of materials, resulting in a similar radon concentration in the LS room and the tunnel, as indicated in Table 2. Subsequent to the installation of the door, a constant supply of 3000 m\(^3\)/h of fresh air has been maintained since December 2022. Consequently, the radon concentration in the LS room reached approximately 150 Bq/m\(^3\), primarily due to the larger ratio of water outflow to the volume of the room when compared to the main hall.

Unfortunately, the situation worsened in April 2023 due to the transition to summer and the construction of above-ground infrastructure. The ventilation system was impacted by the variation in airflow speed between summer (averaging 1.5 m/s in June) and winter (averaging 3.0 m/s in February). Additionally, the consistently sunny weather resulted in underground airflow speed mostly remaining below 1 m/s, as indicated by the spikes in Fig. 8. The radon concentration consistently decreased abruptly during heavy rainfall, coinciding with a decrease in temperature, which affected the underground airflow speed. Furthermore, construction of the cabinet room above ground at the vertical shaft commenced in April 2023. This room, located directly above the vertical shaft, could potentially impact the efficiency of downward airflow due to the presence of scaffolding and the room itself. The radon concentration in the installation room, utilized for pre-assembly of stainless steel supporting bars and storage of acrylic panels outside the main hall, even rose to 1,000 Bq/m\(^3\). We have two layers of film protection on the acrylic panels, and the films will be removed for cleaning after bonding together inside the main hall. Therefore, the high radon in the installation room will not contaminate the acrylic panel but pose a risk to the personnel working there. Situated at the exit of the Tunnel #2, the installation room experiences a significant water flow, and despite optimized fan configurations, the improvement in radon concentration in the installation room is limited.

The fans above ground at the vertical shaft infrastructure were ready on June 13, 2023. Despite the cabinet not being fully operational, we initiated the supply of fresh air through those fans via pipes installed along the vertical shaft to the tunnel underground. As a result, the radon concentration in the tunnel decreased from 200 Bq/m\(^3\) to approximately 50 Bq/m\(^3\), while fresh air for the main hall continued to be drawn from the bottom of the vertical shaft. The radon concentration in the main hall decreased from 300 Bq/m\(^3\) to 100–200 Bq/m\(^3\), while it remained at 300–400 Bq/m\(^3\) in the installation room. Two weeks later, the pipes from the vertical shaft were connected to the pipes supplying fresh air to the main hall, enabling the direct transportation of 40,000 m\(^3\)/h of fresh air at 24 \(^{\circ }\)C from the above-ground cabinet to the main hall. However, fresh air for the tunnel continued to be drawn from the bottom of the vertical shaft with the assistance of fans, which was subject to weather conditions. Due to the unstable radon content in the tunnel air, we ceased the intake of fresh air from the tunnel through the Temporary Cabinet, as depicted in Fig. 5. Since July 2023, the radon concentration in the main hall has remained below 200 Bq/m\(^3\) for the most part, except during special typhoon periods. This indicates that extreme weather can still impact ventilation and radon concentration in underground air; fortunately, such extreme weather events are rare. For the installation room, we have extended a pipe from the main hall to the working area, resulting in a radon content similar to that of the main hall.

4 Identification of the radon sources in the main hall

The experimental hall contains four sources of radon: radon emanation from rock and water, radon diffusion from outside, and radon from fresh air. The measurements for all the sources inside the main hall are consolidated in Table 3, while the radon emanation rate is calculated using Eq. (1).

We have a strong air circulation inside the main hall, with approximately 200,000 m\(^3\)/h at the top and about 20,000 m\(^3\)/h in the pool, ensuring good uniformity of the radon concentration throughout the hall volume. Radon content has been monitored at the top, bottom, and the platform used for acrylic sphere installation, and the results are consistent within the measurement uncertainty. The radon emanation rate from rock and water at the top hall is calculated to be 67 kBq/h. Given the substantial amount of fresh air (net air inlet 30,000 m\(^3\)/h) with low-radon air introduced into the main hall, the radon diffusion from outside to inside can be disregarded in the calculation. Therefore, the radon concentration in the air at equilibrium can be estimated to be approximately 30 Bq/m\(^3\) using Eq. (4), primarily influenced by the fresh air.

However, the average radon concentration inside the main hall is approximately 100 Bq/m\(^3\), indicating that the contribution from the bottom radon source must be non-negligible. The sidewalls of the pool are hardened with 50 cm of concrete and covered with 5 mm HDPE (high density polyethylene) film, rendering the radon emanation from the sidewalls negligible. In contrast, the HDPE on the pool floor is not fixed to the ground, and there are drains under the HDPE film. Furthermore, there is a gap between the HDPE film on the sidewalls and the floor. During the detector construction phase, drains often become clogged due to precipitations from saliferous underground water, necessitating regular cleaning, and the film is not affixed to the ground. Following the installation of the entire detector, all the film will be welded together. The water flow rate at the bottom of the hall is 70 m\(^3\)/h, more than two orders of magnitude higher than that at the top, and all this water is discharged through pipes into a drainage ditch near the exit door. Radon from the water under the HDPE film can diffuse into the air at the edges and through holes in the film, circulating to the top. The installation of a fan outside the bottom door can exhaust 22,000 m\(^3\)/h of air from the main hall, most of the radon-rich air near the door.

5 Summary

At the JUNO site, the underground water exhibits a high radon concentration of 120 kBq/m\(^3\), while the \(^{238}\)U content in the rock is approximately 120 Bq/kg. The water outflow at the JUNO site can reach 450 m\(^3\)/h. Experimental findings indicate that the radon emanation from water is a primary source of radon in underground air.

A ventilation is mandatory for controlling radon concentration levels underground. It is crucial to ensure comprehensive ventilation and verify the correct airflow direction. The airflow speed underground is influenced by the airflow speed and temperature on the ground, resulting in varying ventilation capacities between winter and summer. At the JUNO site, a ventilation capacity of 160,000 m\(^3\) with powerful fans in the tunnel effectively maintains a low radon environment of less than 200 Bq/m\(^3\). All rooms around the main hall are sealed by doors, and the introduction of 40,000–50,000 m\(^3\) of fresh air helps maintain radon levels below 200 Bq/m\(^3\) in the laboratory. For the experimental hall, an effective drainage system with proper isolation is more beneficial than an open ditch in maintaining a low radon environment. In areas where isolation is challenging, it is advisable to establish adequate ventilation directed towards the outside. The findings of this study are applicable to other underground experiments and mine construction projects.

Data Availability Statement

This manuscript has no associated data or the data will not be deposited. [Authors’ comment: There is no associated data.]

Notes

Details about this measurement are discussed in the appendix.

References

United Nations. Sources and effects of ionizing radiation. United Nations Scientific Committee on the Effects of Atomic Radiation (UNSCEAR) 2000 Report to the General Assembly, with Scientific Annexes. United Nations sales publication E.00.IX.3 (United Nations, New York, 2000)

A. Abusleme et al., JUNO physics and detector. Prog. Part. Nucl. Phys. 123, 103927 (2022)

M. Agostini et al., Search for low-energy neutrinos from astrophysical sources with Borexino. Astropart. Phys. 125, 102509 (2021)

A. Allega et al., Evidence of antineutrinos from distant reactors using pure water at SNO+. Phys. Rev. Lett. 130(9), 091801 (2023)

G. Adhikari et al., nEXO: neutrinoless double beta decay search beyond 10\(^{28}\) year half-life sensitivity. J. Phys. G 49(1), 015104 (2022)

X. Ning et al., Search for light dark matter from the atmosphere in PandaX-4T. Phys. Rev. Lett. 131(4), 041001 (2023)

R. Ajaj et al., Search for dark matter with a 231-day exposure of liquid argon using DEAP-3600 at SNOLAB. Phys. Rev. D 100(2), 022004 (2019)

L. Baudis, J. Hall, K.T. Lesko, J.L. Orrell, Snowmass 2021 Underground Facilities and Infrastructure Overview Topical Report. 12 (2022)

N.J.T. Smith, The SNOLAB deep underground facility. Eur. Phys. J. Plus 127(108) (2012)

A. Bassignani, B.B. Bam, G. Colombo, H. Dekhissi, C. Sartorio, Review of long term radon studies at the gran sasso underground laboratory. Radiat Meas 25(1), 557–560 (1995)

C. Bucci, private communication

The National Occupational Health standards of the People’s Republic of China. http://www.nhc.gov.cn/wjw/pcrb/202003/56f16201a75d4ae0974ea71de5728b00.shtml

A. Abusleme et al., JUNO sensitivity to \(^{7}\)Be, pep, and CNO solar neutrinos. JCAP 10, 022 (2023)

V. Strati, S.A. Wipperfurth, M. Baldoncini, W.F. McDonough, F. Mantovani, Perceiving the crust in 3D: a model integrating geological, geochemical, and geophysical data. Geochem. Geophys. Geosyst. 18, 4326 (2017)

M. Coltorti et al., U and Th content in the Central Apennines continental crust: a contribution to the determination of the geo-neutrinos flux at LNGS. Geochim. Cosmochim. Acta 75, 2271–2294 (2011)

DURRIDGE Company Inc. https://durridge.com/products/rad-aqua/

L. Sesana, E. Caprioli, G.M. Marcazzan, Long period study of outdoor radon concentration in Milan and correlation between its temporal variations and dispersion properties of atmosphere. J. Environ. Radioact. 65(2), 147–160 (2003)

L. Kamra, Seasonal emanation of radon at Ghuttu, northwest Himalaya: differentiation of atmospheric temperature and pressure influences. Appl. Radiat. Isot. 105, 170–175 (2015)

Acknowledgements

This work is supported by the Youth Innovation Promotion Association of the Chinese Academy of Sciences (Grant no. 2021013), and the Strategic Priority Research Program of the Chinese Academy of Sciences (Grant no. XDA10000000). The authors would like to acknowledge Professor Frédéric Perrot from University of Bordeaux and Jose Busto from Aix-Marseille University for their useful discussions. The authors would like to acknowledge Mr. Jian Wang for producing Fig. 5.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

In this appendix, we outline the method for measuring radon emanation from rock.

The radon emanation from the rock is assessed using the RAD7 instrument. A plastic basin is used to cover a small section of the rock surface, and the edge is sealed with plasticene. The basin features two holes through which two tubes are used to connect it with the RAD7. This setup allows for the circulation of air inside the basin, enabling the radon concentration to accumulate and reach an equilibrium state. The time required for a single measurement is approximately two hours, denoted as T. The relationship between radon concentration at neighbouring data points can be calculated using Eq. (3):

By defining \(a=\frac{E(1-e^{-\lambda _eT})}{V\lambda _e}\) and \(b=e^{-\lambda _eT}\), both a and b are constant. So the radon concentration between neighbouring data points follows a linear function of \(C_n=a+bC_{n-1}\).

The plot in Fig. 9 displays consecutive measurements \(C_{n-1}\) and \(C_n\) of radon concentration (at times \(t-T\) and T, respectively), with a linear curve fitted to the data points. The best fit yields a radon concentration value at time zero of 133 ± 67 Bq/m\(^3\) and a slope of 0.9 ± 0.1.

The radon emanation rate E can be calculated as \(\frac{-aVln(b)}{T(1-b)}\), where V = 2.2 L represents the volume of the basin. Based on the best fit results presented in Fig. 9, the calculated radon emanation rate E from this rock point is 3.8 ± 0.5 Bq/m\(^2\)/h.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

Funded by SCOAP3.

About this article

Cite this article

Cui, C., Zhao, J., Li, G. et al. Environmental radon control in the 700 m underground laboratory at JUNO. Eur. Phys. J. C 84, 120 (2024). https://doi.org/10.1140/epjc/s10052-024-12474-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjc/s10052-024-12474-6