Abstract

Beam steering performance of bent silicon crystals irradiated with high-intensity and high-energy protons has been studied. In particular, crystals of the type used for collimation and extraction purposes in the Large Hadron Collider and the Super Proton Synchrotron at CERN have been irradiated at the HiRadMat CERN facility with \(2.5 \times 10^{13}\) 440 GeV/c protons, with a pulse length of 7.2 \(\upmu \)s. The purpose is to study possible changes in bending angle and channeling efficiency due to thermo-mechanical stresses in case of accidental irradiation during accelerator operations. A comparison between measurements performed before and after the irradiation does not show any appreciable performance reduction in either crystal.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the last decades, bent crystals have been used and developed to steer high-energy particle beams using the planar channeling process realized between crystal atomic planes [1]. In particular, since 2008, the UA9 Collaboration at CERN has been studying how to apply silicon bent crystals for an upgrade of the Large Hadron Collider (LHC) collimation [2] and the Super Proton Synchrotron (SPS) extraction [3, 4] systems. These crystals must be reliable in operation, also in case of accidental fast irradiation in the machine, in particular during beam injection or dump procedures in the LHC. In the past, several tests have been performed to verify the crystal robustness to a high doses of high energy hadrons [5,6,7], but a crystal has never been exposed to the maximum beam intensity and energy circulating in the SPS and in the LHC at injection. A first study of the consequences in case of a fast crystal irradiation has been carried out in 2012 at CERN by UA9. No visual damage was observed on the crystal after the irradiation with several 7.8 \(\upmu \)s pulses of \(3.2 \times 10^{13}\) protons in the extracted 440 GeV beam. The High-Radiation to Materials (HiRadMat) facility was used for the test [8]. The channeling efficiency was not measured after the irradiation [9]. In 2017, with the purpose to complete this important study, two different crystals have been irradiated in HiRadMat with the same beam intensity and energy used to fill the LHC and that circulates in the SPS during the slow extraction procedures. Then, the two samples were tested at the H8 SPS extraction line before and after the irradiation, looking for possible variation of beam steering performance induced by thermo-mechanical stresses and atomic lattice damage. The results of this test are reported in this manuscript. Section 2 contains a description of the HiRadMat test, including the main characteristics of the crystals. The UA9 experimental apparatus at the H8 SPS extraction line, the measurement procedures and the results on the crystal performance before and after the irradiation are reported in Sect. 3.

2 Irradiation of bent crystals

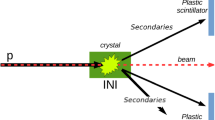

HiRadMat is a CERN facility able to provide high-intensity and high-energy pulsed beams to test accelerator component assemblies and material samples. The facility can use an SPS beam made of up to 288 bunches of \(10^{11}\) protons at 440 GeV/c, with a pulse length of 7.2 \(\upmu \)s, for a maximum pulse energy of 3.4 MJ. The beam size is \(\sim (0.3 \times 0.3) \,\hbox {mm}^{2}\) (1 \(\sigma \)) and can reproduce a real accidental irradiation of a component both during the SPS extraction that an asynchronous injection or dump in the LHC would cause. Since in a 4 mm thick silicon crystal the energy deposition of 440 GeV/c protons is only \(10\%\) less than the 7 TeV case, this test is significant also at the LHC maximum energy [9]. The two crystals have been irradiated at the same time with four-batch injections: three with 216 bunches and one with 288 bunches of \(\sim 10^{11}\) protons. In Table 1 the irradiation parameters are listed. The beam impact points have been chosen inside the beam steering area of the crystals and are shown in Fig. 1.

The alignment procedure consisted of performing vertical and horizontal scans around the beam position by moving a copper mask, in turn precisely aligned with the crystals, and measuring the losses by Beam Loss Monitors (BLM) located downstream. The minimum of the loss rate corresponds to the best alignment of the mask, and therefore of the crystal samples (beam based alignment). A cross-check has been performed using three Gafchromic foils, one upstream, one just before and one downstream of the samples. After the test, these foils report precise markers of the beam position and, by very precise metrology measurements, it was possible to confirm that the particle pulses crossed the crystals at the expected positions.

The HiRadMat setup is shown in Fig. 2: the copper mask used for the beam based alignment, the two crystals with their bending holders and the Gafchromic foils, are mounted on a single mechanical support that can be moved horizontally and vertically with respect to the beam axis.

The QMP33 is a quasi-mosaic silicon crystal of the same kind already installed and tested in LHC between 2014 and 2018 for collimation purposes [2], produced and bent as described in [10]. The STF103 is a strip silicon crystal that has the same bending angle of a typical LHC strip crystal, produced and bent as described in [11,12,13,14], but with half of the thickness along the beam direction and the quadruple in the transverse direction. The transverse size was chosen to simplify the irradiation procedure in HiRadMat. The thickness was reduced to test a crystal with higher mechanical stresses induced by the bending holder with respect to a standard LHC strip crystal, avoiding a more challenging test. In fact, to produce the same bending angle on a shorter crystal, higher mechanical stresses on the silicon are needed. This test is significant, for example, for crystal-assisted beam extraction in the SPS, where crystals with greater curvature could be used. In Table 2 the main crystal parameters are reported.

3 Experimental measurements

The first visual inspection of the two crystal samples after the HiRadMat test does not demonstrate any macroscopic damage such as cracks, deformations or surface vitrification. In Figs. 3 and 4 there are respectively the pictures of both crystals before and after the irradiation.

The best quantitative way to understand if the crystal has suffered structural damage is to check its bending angle and its channeling efficiency. To that end, both crystals were characterized at the H8 SPS extraction line before and after the irradiation, in the same experimental conditions, and the results obtained were analyzed . The standard UA9 procedure to test bent crystals in H8 implies the use of a dedicated tracker to reconstruct individually the tracks of particles before and after the interaction with the crystal. In this way, it is possible to measure precisely the deflection angle and the efficiency of the channeling process. The tracker is composed of 5 planes, 2 upstream and 3 downstream of the crystal position, and it reconstructs the tracks over a 10 m arm for both incoming and outgoing particles. Each plane is composed of 2 microstrip silicon sensors. For 400 GeV/c protons, the system has an excellent angular resolution for both incoming and outgoing tracks, with a cumulative resolution for a single deflection event of 5.2 \(\upmu \)rad. Instead, for 180 GeV/c hadrons, this resolution is 12.3 \(\upmu \)rad. This is mainly due to multiple scattering in the sensor layers [15, 16]. The crystal is precisely oriented with respect to the beam using a goniometer with a \(\sim 1 \upmu \)rad of repeatability.

The channeling process is possible if the incoming particle enter the crystal within an angle \(\theta _{c}=(2U_{o}/pv)^{1/2}\) around the atomic plane orientation, where \(U_{o}\) is the depth of the planar potential well, p and v are the particle momentum and velocity [1]. The number of particles channeled divided by the number of particles with an incoming angle within \(\theta _{c}/2\), provides the crystal channeling efficiency reported in this study, using a relative and conservative approach. In Table 3 the measurements of bending angle and efficiency before and after the HiRadMat test are reported.

For the QMP33, it was possible to perform both measurements with 180 GeV/c positive hadron beam (\(\sim 70\%\) of protons and \(\sim 30\%\) of pions) and the crystal does not show any variation of channeling angle and efficiency within the error bars. For the STF103 the test before the irradiation was possible only with 400 GeV/c pure proton beam and has to be compared with the 180 GeV/c test performed after.

As a reference, the 400 GeV/c proton beam available in H8 has a divergence equal to the critical angle at this energy (\(\sim \)10 \(\upmu \)rad). Alternatively, the 180 GeV/c positive hadron beam has a divergence two times larger than the respective critical angle (\(\sim \)15 \(\upmu \)rad). The wider angular distribution of the 180 GeV/c beam, despite the incoming angular cut applied is always \(\theta _{c}/2\), leads to a selection of incoming particles that have a higher probability of dechanneling, consequently the channeling efficiency is lower (\(\sim 5 \%\)). This happens for all the crystals tested with both types of beams, as for example the QMP33 (Table 3), and is independent of whether the crystal has been irradiated or not in HiRadMat. With the purpose to provide a further complementary proof of the crystal integrity, the efficiency of the two crystals after the HiRadMat test has been studied by dividing the surface into intervals of 0.2 \(\times \) 0.2 mm\(^{2}\). In Figs. 5 and 6 the channeling efficiency maps of the QMP33 and STF103 surfaces, perpendicular to the beam direction, are shown. Efficiency is computed individually for each interval with respect to the optimal impact angle within the bin itself. Left and right sides of the plot are aligned with edges of the crystal and the area of the HiRadMat beam impacts is delimited by the green dashed line. It is clearly visible that the crystal surfaces have a very homogeneous efficiency within the impact area, proving that the HiRadMat irradiations (Fig. 1) affected the quality of the crystal atomic structure, and consequently its channeling efficiency, in a negligible way (within an error bar of ± 2%).

4 Conclusions

The experimental results reported here clearly show that a bent silicon crystal optimised for LHC collimation does not suffer any macroscopic damage, as cracks, verification or deformations in case of accidental beam impact at injection from the SPS, or due to an asynchronous beam dump at maximum energy. The same has been proved for a crystal that could be used in SPS beam extraction operations.

Moreover, the crystals preserve its beam steering performance in terms of channeling angle and efficiency, ensuring its operational stability. It is also indirectly confirmed that the number of dislocations produced by \(\sim 10^{14}/{\text {cm}}^{2}\) 400 GeV/c protons is not enough to change appreciably the channeling performance. In the near future, a deeper and quantitative investigation of the irradiated crystal structure, using techniques like the Etch Pit Density, Rutherford Backscattering Spectrometry and Scanning Electron Microscopy, will be carried out.

In conclusion, it is established that this innovative technology is reliable in case of a fast irradiation of the crystal, both from the point of view of machine protection as well as that of beam collimation and extraction performance.

Data Availability Statement

This manuscript has no associated data or the data will not be deposited. [Authors’ comment: The datasets generated during and/or analysed during the current study available from the corresponding author on reasonable request.]

References

V. Biryukov, V.I. Kotov, Y.A. Chesnokov, Steering of high-energy charged-particle beams by bent single crystals. Phys. Uspekhi 37(10), 937 (1994)

W. Scandale et al., Observation of channeling for 6500 GeV/c protons in the crystal assisted collimation setup for LHC. Phys. Lett. B 758, 129–133 (2016)

W. Scandale, A. Kovalenko, A. Taratin, Possibility of high efficient beam extraction from the cern sps with a bent crystal. Simulation results. NIM A 848, 166–169 (2017)

M. Fraser et al., Experimental results of crystal-assisted slow extraction at the SPS. in Proceedings of the International Particle Accelerator Conference (2017)

Y.A. Chesnokov et al., Proc. of the XV Int. Conf. on High Energy Accelerators, Hamburg (1992)

S. Baker, R. Carrigan Jr., V. Cupps II, J. Forster, W. Gibson, C. Sun, Effects on channeling of radiation damage due to 28 GeV protons. NIM B 90(1–4), 119–123 (1994)

A. Baurichter et al., Channeling of high-energy particles in bent crystals: experiments at the cern sps. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 164, 27–43 (2000)

F. Harden, A. Bouvard, N. Charitonidis, Y. Kadi, et al., Hiradmat: A facility beyond the realms of materials testing, in 10th Int. Partile Accelerator Conf. (IPAC’19), Melbourne, Australia, 19-24 May 2019 (JACOW Publishing, Geneva, Switzerland, 2019), pp. 4016–4019

A. Lechner, M. Calviani, M. Di Castro, J. Lendaro, F. Loprete, R. Losito, C. Maglioni, A. Masi, S. Montesano, A. Perillo-Marcone, P.S. Roguet, D. Wollmann, J.B. Sancho, F. Burkart, W. Scandale, Y. Gavrikov, V. Guidi, and A. Mazzolari, “Robustness test of a silicon strip crystal for crystal-assisted collimation studies in the LHC,” Conf. Proc., vol. C130512, p. THPFI059, May 2013

Y.M. Ivanov, A. Petrunin, V.V. Skorobogatov, Observation of the elastic quasi-mosaicity effect in bent silicon single crystals. JETP Lett. 81(3), 99–101 (2005)

V. Guidi, A. Antonini, S. Baricordi, F. Logallo, C. Malagù, E. Milan, A. Ronzoni, M. Stefancich, G. Martinelli, A. Vomiero, Tailoring of silicon crystals for relativistic-particle channeling. Nucl. Instrum. Methods Phys. Res. B 234(1), 40–46 (2005)

S. Baricordi, V. Guidi, A. Mazzolari, D. Vincenzi, M. Ferroni, Shaping of silicon crystals for channelling experiments through anisotropic chemical etching. J. Phys. D Appl. Phys. 41(24), 245501 (2008)

V. Guidi, L. Lanzoni, A. Mazzolari, Study of anticlastic deformation in a silicon crystal for channeling experiments. J. Appl. Phys. 107(11), 113534 (2010)

A. Afonin, V. Biryukov, V. Gavrilushkin, B. Zelenov, V. Kotov, V. Maisheev, A. Minchenko, V. Terekhov, E. Troyanov, Y.A. Chesnokov et al., First results of experiments on high-efficiency single-crystal extraction of protons from the u-70 accelerator. J. Exp. Theor. Phys. Lett. 67(10), 781–785 (1998)

M. Pesaresi et al., Design and performance of a high rate, high angular resolution beam telescope used for crystal channeling studies. J. Instrum. 6(04), P04006 (2011)

G. Hall et al., A high angular resolution silicon microstrip telescope for crystal channeling studies. NIM A 924, 175–180 (2019)

Acknowledgements

We wish to acknowledge the CERN EN-EA team in charge of setting-up the H8 beam line during the data taking and the CERN EN-STI group for strong support provided. The Imperial College group thanks the UK Science and Technology Facilities Council for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

A. Natochii: On leave from Taras Shevchenko National University of Kyiv (TSNUK).

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Funded by SCOAP3

About this article

Cite this article

Scandale, W., Calviani, M., D’Andrea, M. et al. Beam steering performance of bent silicon crystals irradiated with high-intensity and high-energy protons. Eur. Phys. J. C 79, 933 (2019). https://doi.org/10.1140/epjc/s10052-019-7448-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjc/s10052-019-7448-2