Abstract

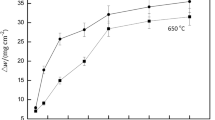

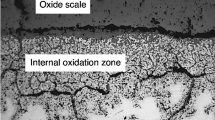

This article investigates the change in the structure of heat-resistant nickel alloys doped with cobalt, chromium, molybdenum, aluminum, niobium, tungsten, and titanium and aluminum, cobalt, rhenium, tantalum, ruthenium, molybdenum, tungsten, and chromium under the influence of a solution of 75%Na2SO4 + 25%NaCl in temperature range 600–750°C. As the results of the study show, a corrosive film of a layer structure based on oxides of chromium, aluminum, nickel and nickel sulfides is formed on the metal surface. It has been established that the nature of corrosion destruction of metal depends on the composition and content of alloying elements in it.

Similar content being viewed by others

REFERENCES

Kablov, E.N., Sidorov, V.V., Kablov, D.E., and Min, P.G., The metallurgical fundamentals for high quality maintenance of single crystal heat-resistant nickel alloys, Aviats. Mater. Tekhnol., 2017, no. S, pp. 55–71. https://doi.org/10.18577/2071-9140-2017-0-S-55-71

Petrushin, N.V., Ospennikova, O.G., and Svetlov, I.L., Single-crystal Ni-based superalloys for turbine blades of advanced gas turbine engines, Aviats. Mater. Tekhnol., 2017, no. S, pp. 72–103. https://doi.org/10.18577/2071-9140-2017-0-S-72-103

Bazyleva, O.A., Arginbaeva, E.G., and Lutskaya, S.A., Ways of increasing corrosion resistance of superalloys (review), Tr. VIAM, 2018, no. 4 (64), pp. 3–8. https://doi.org/10.18577/2307-6046-2018-0-4-3-8. http://www.viam-works.ru. Accessed August 18, 2020.

Kablov, E.N., Startsev, O.V., and Medvedev, I.M., Review of international experience on corrosion and corrosion protection, Aviats. Mater. Tekhnol., 2015, no. 2 (35), pp. 76–87. https://doi.org/10.18577/2071-9140-2015-0-2-76-87

Kablov, E.N., Innovative developments of FSUE “VIAM” SSC of RF on realization of “Strategic directions of the development of materials and technologies of their processing for the period until 2030,” Aviats. Mater. Tekhnol., 2015, no. 1 (34), pp. 3–33. https://doi.org/10.18577/2071-9140-2015-0-1-3-33

Getsov, L.B., Laptev, A.B., Puzanov, A.I., and Shelyapina, N.M., Sulfide oxide corrosion of modern heat-resistant alloys, Russ. Aeronaut., 2019, vol. 62, pp. 689–695. https://doi.org/10.3103/S1068799819040214

Pradhan, D., Mahobia, G.S., Chattopadhyay, K., and Singh, V., Salt induced corrosion behaviour of superalloy IN718, Mater. Today: Proc., 2018, vol. 5, pp. 7047–7054.

Medvedev, I.M., Nikitin, Ya.Yu., Puzanov, A.I., and Laptev, A.B., Hot corrosion testing methods for high-temperature alloys (review), Tr. VIAM, 2018, no. 11 (71), pp. 93–100. https://doi.org/10.18577/2307-6046-2018-0-11-93-100 http://www.viam-works.ru. Accessed August 18, 2020.

Zhang, T.-B., Dong, R.-F., Hu, R., et al., Hot corrosion characteristics of Ni–20Cr–18W superalloy in molten salt, Trans. Nonferrous Met. Soc. China, 2015, vol. 25, pp. 3840–3846.

Kos’min, A.A., Budinovskii, S.A., Matveev, P.V., and Smirnov, A.A., Research of sulfide-oxide corrosion resistance of ZhS36 nickel superalloy with different types of ion-plasma coatings in temperature range 850–900°C, Tr. VIAM, 2015, no. 12, art. ID 5. https://doi.org/10.18577/2307-6046-2015-0-12-5-5. http://www.viam-works.ru. Accessed August 18, 2020.

Cho, S.-H., Hur, J.-M., Seo, C.-S., et al., Hot corrosion behavior of Ni-base alloys in a molten salt under an oxidizing atmosphere, J. Alloys Compd., 2009, vol. 468, nos. 1–2, pp. 263–269.

Lomberg, B.S., Belous, V.Ya., Varlamova, V.E., and Filonova, E.V., Resistance of high-temperature granular disc alloys VV750PD, VV750P, and VV751P to sulfide-oxide corrosion at operating temperatures (650–800°C), Korroz.: Mater., Zashchita, 2014, no. 3, pp. 14–20.

Eliaz, N., Shemesh, G., and Latanision, R.M., Hot corrosion in gas turbine components, Eng. Failure Anal., 2002, vol. 9, no. 1, pp. 31–43.

Fu, G., Qi, Z., Chen, J., Kiu, Q., and Su, Y., Hot corrosion behavior of Ni-base alloys coated with salt film of 75%Na2SO4 + 25%NaCl at 900°C, Rare Met. Mater. Eng., 2015, vol. 44, no. 5, pp. 1112–1115. https://doi.org/10.1016/S1875-5372(15)30077-1

Li, W., Liu, Y., Wang, Y., et al., Hot corrosion behavior of Ni–16Cr–xAl based alloys in mixture of Na2SO4–NaCl at 600°C, Trans. Nonferrous Met. Soc. China, 2011, vol. 21, no. 12, pp. 2617–2625.

Liu, E., Zheng, Z., Guan, X., et al., Influence of pre-oxidation on the hot corrosion of DZ68 superalloy in the mixture of Na2SO4–NaCl, J. Mater. Sci. Technol., 2010, vol. 26, no. 10, pp. 895–899.

Getsov, L.B., Materialy i prochnost’ detalei gazovykh turbin (Materials and Strength of Gas Turbine Parts), Moscow: Nedra, 1996.

Saunders, S.R.J. and Nicholls, J.R., Hot salt corrosion test procedures and coating evaluation, Thin Solid Films, 1984, vol. 119, no. 3, pp. 247–269. https://doi.org/10.1016/0040-6090(84)90010-5

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Drozdova

Rights and permissions

About this article

Cite this article

Movenko, D.A., Laptev, A.B. & Zagorskykh, O.A. Composition and Morphology of Hot-Salt Corrosion in Heat-Resistant Nickel Alloys. Inorg. Mater. Appl. Res. 13, 1652–1657 (2022). https://doi.org/10.1134/S207511332206017X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207511332206017X