Abstract

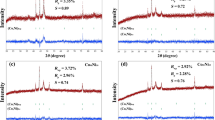

Two samples of TiO2/Cr2O3 composites are synthesized in the form of spherical grains via the stagewise thermal treatment of ion-exchange resins preliminarily saturated with chromium Cr3+ cations and dichromate \({\text{C}}{{{\text{r}}}_{{\text{2}}}}{\text{O}}_{7}^{{2 - }}\) anions, and then coated with a film-forming titania-based solution. Calcination temperature regimes are set on the basis of a thermal analysis and determined by the type of ion-exchange resin selected as a template. The synthesized composites are generally composed of the α-Cr2O3 phase, and the content of the TiO2 phase is less than 4%. The composites replicate the spherical shape of grains for the initial ion-exchange resins with sizes of 370 to 660 µm. The grains of the sample based on kaolinite adsorbing Cr3+ ions have a porous structure with bulbs and cavities. The anion-exchange resin-based sample grains have kinks and cracks over their surfaces due to a nonuniform distribution of adsorbed \({\text{C}}{{{\text{r}}}_{{\text{2}}}}{\text{O}}_{7}^{{2 - }}\) anions in the initial anion-exchange resin. The composites exhibit catalytic activity in the deep p-xylene oxidation reaction. The cation-exchange resin-based sample is more active, due apparently to the smaller accessible titania surfaces in the anion-exchange resin-based sample as a result of the formation of a solid Ti3+ solution in α-Cr2O3.

Similar content being viewed by others

REFERENCES

Alkhazov, T.G and Margolis, L.Ya., Glubokoe kataliticheskoe okislenie organicheskikh veshchestv (Deep Catalytic Oxidation of Organic Compounds), Moscow: Khimiya, 1985.

Krylov, O.V., Geterogennyi kataliz (Heterogeneous Catalysis), Moscow: Akademkniga, 2004.

SU Patent 1563015, 1998.

Porsin, A.V., Kulikov, A.V., Dalyuk, I.K., Rogozhnikov, V.N., and Kochergin, V.I., Chem. Eng. J., 2015, vol. 282, pp. 233–240. https://doi.org/10.1016/j.cej.2015.02.028

Zheksenbaeva, Z.T., Tungatarova, S.A., Baizhumanova, T.S., and Shaizada, E., Chem. Eng. Trans., 2015, vol. 45, pp. 1213–1218. https://doi.org/10.3303/CET1545203

Goodman, E.D., Dai, Sh., Yang, An-Ch., Wrasman, C.J., Gallo, A., Bare, S.R., Hoffman, A.S., Jaramillo, T.F., Graham, G.W., Pan, X., and Cargnello, M., ACS Catal., 2017, vol. 7, no. 7, pp. 4372–4380. https://doi.org/10.1021/acscatal.7b00393

Lokhande, S., Doggali, P., Rayalu, S., Devotta, S., and Labhsetwar, N., Atmos. Pollut. Res., 2015, vol. 6, no. 4, pp. 589–595. https://doi.org/10.5094/APR.2015.066

Tidahy, H.L., Siffert, S., Wyrwalski, F., Lamonier, J.-F., and Aboukaïs, A., Catal. Today, 2007, vol. 119, nos. 1–4, pp. 317–320. https://doi.org/10.1016/j.cattod.2006.08.023

Barbato, P.S., Colussi, S., Benedetto, A.D., Landi, G., Lisi, L., Llorca, J., and Trovarelli, A., J. Phys. Chem. C, 2016, vol. 120, no. 24, pp. 13039–13048. https://doi.org/10.1021/acs.jpcc.6b02433

Baidya, T., Murayama, T., Bera, P., Safonova, O.V., Steiger, P., Katiyar, N.K., Biswas, K., and Haruta, M., J. Phys. Chem. C, 2017, vol. 121, no. 28, pp. 15256–15265. https://doi.org/10.1021/acs.jpcc.7b04348

Albert, J.J., John, F., Ronald, M., Arora, A., Sharma, H., Hamilton, A., and Wessley, J.J., Int. J. Comput. Sci. Eng., 2017, vol. 5, no. 2, pp. 19–26. https://www.researchgate.net/profile/Anurag-Hamilton-2/publication/327932813_Design_Fabrication_and_Testing_of_a_MnO_2_based_Catalytic_Converter/links/5bae0b-2845851574f7ec4421/Design-Fabrication-and-Testing-of-a-MnO-2-based-Catalytic-Converter.pdf. Cited June 11, 2023.

Yim, S.D. and Nam, I.-S., J. Catal., 2004, vol. 221, no. 2, pp. 601–611. https://doi.org/10.1016/j.jcat.2003.09.026

Yim, S.D., Chang, K.-H., Koh, D.J., Nam, I.-S., and Kim, Y.G., Catal. Today, 2000, vol. 63, nos. 2–4, pp. 215–222. https://doi.org/10.1016/S0920-5861(00)00462-4

Padilla, A.M., Corella, J., and Toledo, J.M., Appl. Catal., B, 1999, vol. 22, no. 2, pp. 107–121. https://doi.org/10.1016/S0926-3373(99)00043-0

Yates, J.G. and Lettieri, P., Fluidized-Bed Reactors: Processes and Operating Conditions, Cham: Springer, 2016, vol. 26, https://doi.org/10.1007/978-3-319-39593-7

Campanati, M., Fornasari, G., and Vaccari, A., Catal. Today, 2003, vol. 77, no. 4, pp. 299–314. https://doi.org/10.1016/S0920-5861(02)00375-9

Islam, A., Taufiq-Yap, Y.H., Chu, C.-M., Ravindra, P., and Chan, E.-S., Renewable Energy, 2013, vol. 59, pp. 23–29. https://doi.org/10.1016/j.renene.2013.01.051

Fajardo, H.V. and Probst, L.F.D., Appl. Catal., A, 2006, vol. 306, pp. 134–141. https://doi.org/10.1016/j.apcata.2006.03.043

Pimneva, L.A. and Nesterova, E.L., Fundam. Issled.: Khim. Nauki, 2011, no. 4, pp. 150–153. https://s.fundamental-research.ru/pdf/2011/4/27.pdf. Cited June 11, 2023.

Pimneva, L.A. and Nesterova, E.L., Sovrem. Naukoemkie Technol.: Fiz.-Mat. Nauki, 2010, no. 1, pp. 21–26. https://s.top-technologies.ru/pdf/2010/1/3.pdf. Cited June 11, 2023.

Rogacheva, A., Shamsutdinova, A., Brichkov, A., Larina, T., Paukshtis, E., and Kozik, V., AIP Conf. Proc., 2017, vol. 1899, no. 1, article no. 020007. https://doi.org/10.1063/1.5009832

Zharkova, V., Bobkova, L., Brichkov, A., and Kozik, V., AIP Conf. Proc., 2017, vol. 1899, no. 1, article no. 020011. https://doi.org/10.1063/1.5009836

RF Patent 2608125, 2017.

Rudometkina, T.M. and Ivanov, V.M., Vestn. Mosk. Univ., Ser. 2: Khim., 2013, vol. 54, pp. 164–167. http://www.chem.msu.su/rus/vmgu/133/164.pdf. Cited June 11, 2023.

Shvartsenbakh, G., Kompleksometricheskoe titrovanie (Complexometric Titration), Moscow: Khimiya, 1970.

Shamsutdinova, A.N., Brichkov, A.S., Paukshtis, E.A., Larina, T.V., Cherepanova, S.V., Glazneva, T.S., and Kozik, V.V., Catal. Commun., 2017, vol. 89, pp. 64–68. https://doi.org/10.1016/j.catcom.2016.10.018

Drozdov, A.A., Zlomanov, V.P., Mazo, G.N., Spiridonov, F.M., and Tret’yakov, Yu.D., Neorgani-cheskaya khimiya (Inorganic Chemisry), Moscow: Akademiya, 2007.

Korchagin, V.I., Izv. Vyssh. Uchebn. Zaved., Khim. Khim. Tekhnol., 2006, vol. 49, no. 11, pp. 59–63.

Pimneva, L.A., Fundam. Issled.: Khim. Nauki, 2014, no. 8, part 3, pp. 614–619. https://s.fundamental-research.ru/pdf/2014/8-3/34603.pdf. Cited June 11, 2023.

Yakovishin, V.A. and Savenkov, A.S., Visn. Nats. Tekh. Univ. “KhPI”, 2009, vol. 40, pp. 59–64. http://repository.kpi.kharkov.ua/handle/KhPI-Press/32186. Cited June 11, 2023.

Zherebtsov, D.A., Viktorov, V.V., Kulikovskikh, S.A., Belaya, E.A., and Galimov, D.M., Inorg. Mater., 2016, vol. 52, no. 1, pp. 33–37. https://doi.org/10.1134/S0020168516010167

Shannon, R.D., Acta Crystallogr., 1976, vol. A32, part 5, pp. 751–767. https://doi.org/10.1107/S0567739476001551

Nemykina, E.I., Pakhomov, N.A., Danilevich, V.V., Rogov, V.A., Zaikovskii, V.I., Larina, T.V., and Mol-chanov, V.V., Kinet. Catal., 2010, vol. 51, no. 6, pp. 898–906. https://doi.org/10.1134/S0023158410060169

Funding

This work was performed as part of a State Task from the RF Ministry of Science and Higher Education for the Bores-kov Institute of Catalysis, project nos. FSWM-2020-0037 and AAAA-A21-121011390054-1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Buzaev, A.A., Rogacheva, A.O., Larina, T.V. et al. Spherical TiO2/Cr2O3 Composites Synthesized with the Use of Ion-Exchange Resins as a Template. Catal. Ind. 15, 313–322 (2023). https://doi.org/10.1134/S2070050423030029

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070050423030029