Abstract

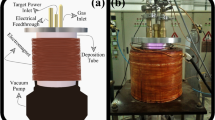

In this investigation, the feasibility of direct synthesis and production of ultrafine tungsten carbide in a high-speed jet of tungsten carbon electric discharge plasma is shown. According to X-ray diffraction and electron microscopy, the plasmadynamic synthesis product consists of the cubic modification of tungsten carbide mostly, the structure of which is closest to the structural model of WC1 − x . Furthermore, the powder contains crystalline tungsten W, tungsten carbon W2C, and graphite C, the total weight of that amount being about 2.0 wt %. The particles of the tungsten material have a two-layer carbon shell.

Similar content being viewed by others

References

A. S. Kurlov and A. I. Gusev, “Phase equilibriums in W-C system and wolfram carbides,” Usp. Khim. 75(7), 687–708 (2006).

K. Abdelouahdi, C. Sant, C. Legrand-Buscema, P. Aubert, J. Perrière, G. Renou, and P. Houdy, “Microstructural and mechanical investigations of tungsten carbide films deposited by reactive RF sputtering,” Surf. Coat. Technol., No. 200, 6469–6473 (2006).

S. Aravinth, B. Sankar, M. Kamaraj, S. R. Chakravarthy, and R. Sarathi, “Synthesis and characterization of hexagonal nano tungsten carbide powder using multi walled carbon nanotubes,” Int. J. Refract. Met. Hard Mater., No. 33, 53–57 (2012).

D. J. Ham, R. Ganesan, and J. S. Lee, “Tungsten carbide microsphere as an electrode for cathodic hydrogen evolution from water,” Int. J. Hydrogen Energy, No. 33, 6865–6872 (2008).

A. V. Samokhin, N. V. Alekseev, and Yu. V. Tsvetkov, “Plasmochemical processes for synthesizing nanodispersed powders,” Khim. Vys. Energii 40(2), 120–126 (2006).

A. A. Sivkov and A. Ya. Pak, “On the possibility of dynamic synthesis of ultradispersed crystalline phases of the B-C-N system in a hyperhigh-speed plasma jet,” Journal of Superhard Materials 32(1), 21 (2010).

A. A. Sivkov and A. Ya. Pak, “On possible synthesis and crystalline structure of nanodisperse C3N4 carbon nitride,” Tech. Phys. Lett. 37(7), 654 (2011).

A. A. Sivkov, D. S. Nikitin, A. Ya. Pak, and I. A. Rakhmatullin, “Direct plasmadynamic synthesis of ultradisperse silicon carbide,” Tech. Phys. Lett. 39(1), 105 (2013).

A. A. Sivkov, E. P. Naiden, and D. Yu. Gerasimov, “Direct dynamical synthesis of nanodispersed titanium nitride in high speed pulse jet of electroerosion plasma,” Sverkhtverd. Mater. 30(5), 33–39 (2008).

A. A. Sivkov and A. Ya. Pak, RF Patent No. 2431947, H05H 11/00, F41B 6/00, Byull. Izobret., No. 29 (2011).

S. S. Gorelik, L. N. Rastorguev, and Yu. A. Skakov, X-Ray and Electron-Optical Analysis (Metallurgiya, Moscow, 1970) [in Russian].

E. Krainer and J. Robitsch, “Zur Frage des kubischen Wolframkarbids,” Planseeber, Pulvermetall 15(3), 179–180 (1967).

Ming-Hong Lin, “Synthesis of nanophase tungsten carbide by electrical discharge machining,” Ceram. Int., No. 31, 1109–1115 (2005).

Hua Jun Zheng, Ai Mei Yu, and Chun An Ma, “Polyporous C@WC1 − x composite and its electrocatalic activity for p-nitrophenol reduction,” Chinese Chem. Lett., No. 22, 497–500 (2011).

F. G. Zhang, X. P. Zhu, and M. K. Lei, “Microstructural evolution and its correlation with hardening of WC-Ni cemented carbides irradiated by high-intensity pulsed ion beam,” Surf. Coat. Technol., No. 206, 4146–4155 (2012).

J. Y. Howe, C. J. Rawn, L. E. Jones, and H. Ow, “Improved crystallographic data for graphite,” Powder Diffr. 18(2), 150–154 (2003).

J. Leciejewicz, “A note on the structure of tungsten carbide,” Acta Cristallogr, No. 14, 200 (1961).

T. Epicier, J. Dubois, C. Esnouf, G. Fantozzi, and P. Convert, “Neutron powder diffraction studies of transition metal hemicarbides M2C1 − x — II. In situ high temperature study on W2C1 − x and Mo2C1 − x ,” Acta Metall. 36(8), 1903–1921 (1988).

H. E. Swanson and E. Tatge, Standard X-Ray Diffraction Powder Patterns (National Bureau of Standards, 1953).

R. G. Rakov, Nanotubes and Fullerens (Lotos, Moscow, 2006) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. Sivkov, A.Ya. Pak, I.A. Rakhmatullin, K.N. Shatrova, 2014, published in Rossiiskie Nanotekhnologii, 2014, Vol. 9, Nos. 11–12.

Rights and permissions

About this article

Cite this article

Sivkov, A.A., Pak, A.Y., Rakhmatullin, I.A. et al. Production of ultrafine tungsten carbide in a discharge plasma jet. Nanotechnol Russia 9, 682–687 (2014). https://doi.org/10.1134/S1995078014060147

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995078014060147