Abstract

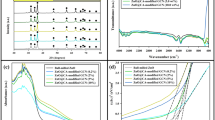

Graphite-like carbon nitride (g-C3N4) nanopowders were synthesized by heat treatment of urea in air at a temperature of 450–550°С for 30 min and studied by X-ray diffraction and infrared spectroscopy. The main processes resulting in the formation of g-C3N4 from urea under the above conditions was established using the method of simultaneous thermal analysis. It was found that with an increase in the processing temperature of urea from 450 to 550°C, a rise in the specific surface of the powders occurs from 43.3 to 58.6 m2 g–1, as well as an increase in the crystallite sizes of graphite-like carbon nitride in the crystallographic direction (002) from 2.8 to 4.1 nm. According to the results of scanning electron microscopy and low-temperature nitrogen adsorption, the obtained graphite-like carbon nitride powders have a mesoporous structure and are characterized by an average pore size of 6.6–13.8 nm and porosity of 0.07–0.20 cm3 g–1. According to the results of diffuse reflectance spectroscopy, it was found that g-C3N4 nanopowders absorb radiation in the visible region and have a band gap of 2.9 eV. The photocatalytic activity of the obtained graphite-like carbon nitride during the oxidation of an aqueous murexide solution under the influence of visible light was analyzed and it was shown that the obtained g-C3N4 nanopowders have activity close to that of the commercial TiO2 photocatalyst (AEROXIDE P25). In view of the high activity and low cost, the obtained powders of graphite-like carbon nitride can be used as the substrate for new photocatalytic materials.

Similar content being viewed by others

REFERENCES

Spasiano, D., Marotta, R., Malato, S., Fernandez-Ibanez, P., and Di Somma, I., Appl. Catal. B: Environmental, 2015, vol. 170–171, pp. 90–123. https://doi.org/10.1016/j.apcatb.2014.12.050

Vasilevskaia, A.K., Popkov, V.I., Valeeva, A.A., Rempel, A.A., Russ. J. Appl. Chem., 2016, vol. 89, no. 8, pp. 1211–1220. https://doi.org/10.1134/S1070427216080012

Fagan, R., McCormack, D.E., Dionysiou, D.D., and Pillai, S.C., Mater. Sci. Semiconductor Processing, 2016, vol. 42, pp. 2–14. https://doi.org/10.1016/j.mssp.2015.07.052

Ilkaeva, M., Krivtsov, I., Bartashevich, E., Khainakov, S.A., García, J.R., Díaz, E., and Ordónez, S., Green Chem. Lett. and Reviews, 2017, vol. 19, no. 18, pp. 4299–4304. https://doi.org/10.1039/C7GC01588G

Kadi, M.W., Mohamed, R.M., Ismail, A.A., and Bahnemann, D.W., Appl. Nanosci., 2018, vol. 8, no. 6, pp. 1587–1596. https://doi.org/10.1007/s13204-018-0835-4

Schaber, P.M., Colson, J., Higgins, S., Thielen, D., Anspach, B., and Brauer, J., Thermochim. Acta, 2004, vol. 424, nos. 1–2, pp. 131–142. https://doi.org/10.1016/j.tca.2004.05.018

Mo, Z., She, X., Li, Y., Liu, L., Huang, L., Chen, Z., Zhang, Q., Xu, H., Li, H., RSC Advances—Royal Soc. Chem., 2015, vol. 5, no. 123, pp. 101552–101562. https://doi.org/10.1039/C5RA19586A

Wen, J., Xie, J., Chen, X., Li, X., Appl. Surface Sci., 2017, vol. 391, pp. 72–123. https://doi.org/10.1016/j.apsusc.2016.07.030

Zhang, J.-H., Hou, Y.-J., Wang, S.-J., Zhu, X., Zhu, Ch.-Y., Wang, Zh., Li, Ch.-J., Jiang, J.-J., Wang, H.-P., Pan, M., and Sua, C-Y., J. Mater. Chem. A, 2018, vol. 6, no. 37, pp. 18252–18257. https://doi.org/10.1039/C8TA06726K

Ming, L., Yue, H., Xu, L., and Chen, F., J. Mater. Chem. A., 2014, vol. 2, no. 45, pp. 19145–19149. https://doi.org/10.1039/C4TA04041D

Khan, A., Alama, U., Razaa, W., Bahnemannbc, D., and Muneer, M., J. Phys. Chem. Solids, 2018, vol. 115, pp. 59–68. https://doi.org/10.1016/j.jpcs.2017.10.032

Kharlamov, A., Bondarenko, M., Kharlamova, G., and Gubareni, N., Diamond and Related Mater., 2016, vol. 66, pp. 16–22. https://doi.org/10.1016/j.diamond.2016.03.012

Chidhambaram, N. and Ravichandran, K., Mater. Lett., 2017, vol. 207, pp. 44–48. https://doi.org/10.1016/j.matlet.2017.07.040

Dong, F., Wang, Zh., Sun, Y., Hob, W.-K., and Zhang, H., J. Colloid Interface Sci., 2013, vol. 401, pp. 70–79. https://doi.org/10.1016/j.jcis.2013.03.034

Dong, F., Liwen Wu, L., Sun, Y., Fu, M., Wu, Zh., and Lee, S.C., J. Mater. Chem., 2011, vol. 21, no. 39, pp. 15171–15174. https://doi.org/10.1039/c1jm12844b

Xu, J., Li, Y., Peng, Sh., Lu, G., and Li, Sh., Phys. Chem. Chem. Phys., 2013, vol. 15, no. 20, pp. 7657. https://doi.org/10.1039/c3cp44687e

Lotsch, B.V. and Schnick, W., Chem. Mater., 2005, vol. 17, pp. 3976–3982. https://doi.org/10.1021/cm050350q

Zhang, Y., Liu, J., Wua, G., and Chen, W., Nanoscale, 2012, vol. 4, pp. 5300–5303. https://doi.org/10.1039/C2NR30948C

Ye, S., Wang, R., Wu, M.-Z., and Yuan, Y.-P., Appl. Surface Sci., 2015, vol. 358, pp. 15–27. https://doi.org/10.1016/j.apsusc.2015.08.173

Sosnov, E.A., Malkov, A.A., and Malygin, A.A., Russ. J. Phys. Chem. A, 2009, vol. 83, no. 4, pp. 642–648. https://doi.org/10.1134/s0036024409040219

ACKNOWLEDGMENTS

The studies were performed using the analytical equipment of the Engineering Center of the St. Petersburg State Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

N.V. Zakharova declares that she is the executive secretary of the Journal of Applied Chemistry, the remaining authors have no conflict of interest that requires disclosure in this article.

Rights and permissions

About this article

Cite this article

Chebanenko, M.I., Zakharova, N.V. & Popkov, V.I. Synthesis and Visible-Light Photocatalytic Activity of Graphite-like Carbon Nitride Nanopowders. Russ J Appl Chem 93, 494–501 (2020). https://doi.org/10.1134/S1070427220040035

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427220040035