Abstract

A method of iodine-125 deposition on a surface of microsource silver supports for brachytherapy of prostate cancer was reported, which includes preparing the support surface by sequentially treating them with nitric acid and thiourea solutions, followed by chlorination of the support surface with a chlorinating agent to form silver chloride on the support surface, and substitution of chlorine atoms for 125I atoms by placing supports containin silver chloride on the surface in a solution with 125I ions to create a 125I layer on the support surface. The method described allows fixing 125I on supports with a low activity distribution on each activity-carrying support.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Prostate cancer (PC) is one of the most common types of cancer in men. In 2019, 44 706 new cases of PC were detected in the Russian Federation [1].

One of the methods of radical treatment of localized PC is interstitial radiation therapy (brachytherapy) [2, 3]. The technique is based on the implantation into the gland tissue and its immediate surroundings of several dozen closed microsources containing the 125I or 103Pd radionuclide, which remain in the gland tissue throughout the entire life span [4, 5].

125I and 103Pd decay by the electron capture mechanism. The decay is accompanied by low-energy radiation (28 and 21 keV, respectively [6]), which makes it possible to deliver the necessary energy to localized areas and reduce damage to healthy tissues [7].

A site for the production of 125I-based microsources for the treatment of PC was created at the Institute of Physics and Power Ingineering (Obninsk, Russia). The design of the microsources consists of cylindrical silver supports coated with 125I, which are placed in a sealed titanium shell (Fig. 1). This design was first proposed by the Minnesota Mining and Manufacturing Company (USA) [8]. The simplicity and manufacturability of the design also attracts the attention of specialists from other countries [9–11].

Garlands (strands) are made from microsources using a biosoluble material (ESM_1pdf). The strands in transport containers are placed in sterilization bags (ESM_2pdf) and sent to the consumer after sterilization.

One of the operations in the manufacture of microsources is the deposition of 125I on the surface of silver supports. Since there is no direct deposition of 125I on the surface of silver supports, it is proposed to treat this surface with the formation of anions such as Br– [12], N3–, CO32–, C2O42–, AsO43–, PO43– [11, 13, 14], Cl– [8, 15, 16] followed by substitution of anions for 125I. An electrochemical version of 125I deposition on silver supports was also proposed [8, 17].

In Institute of Physics and Power Ingineering (IPPE) a method also was developed for the electrochemical deposition of 125I on the surface of silver supports of microsources [18, 19], but the several years of operation shown its unreliability and the difficulty of operational controlling.

Based on the analysis of the literature and our own experience, a method was proposed for fixing 125I in the surface of silver supports of microsources, including chlorination of the support surface with the help of a chlorinating agent with the formation of silver chloride on the support surface and subsequent replacement of chlorine ions for 125I by contact with a Na125I alkaline solution [20].

Since at depositing 125I on the surface of silver supports, the minimum of the activity distribution on each activity-carrying support is important, which, in turn, depends on the the substrate surface cleanliness, the stages of preparing the support surface were provided by treating with nitric acid to remove silver oxide and also with and thiourea for removal of sulfide compounds.

EXPERIMENTAL

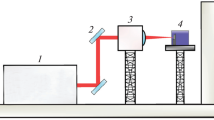

The operational scheme is shown in Fig. 2. When developing the deposition method, a batch of silver wire was used as supports in the amount of 100 pieces (Ср 99.99 Т 0.5 grade, State Standard GOST 7222-2014 [21]) with a diameter of 0.5 and a length of 3 mm. The activity of 125I fixed on each substrate was about 0.4–0.6 mCi, which corresponds to the activity of a single microsource. We used 125I produced by RIAR with the following characteristics: chemical form NaI in 0.015 M NaOH, volumetric activity 1.2 Ci/mL, specific activity ˃17 000 Ci/g (without carrier), 126I content ˂1.3 × 10–7 in terms of activity, radiochemical purity 99.7%, as well as chemical reagents of the analytical grade. Dilute solutions were prepared using distilled water in a quartz vessel.

The batch of supports was placed in a penicillin vial, into which 1 M HNO3 was poured so that the batch of supports was completely immersed in the solution, and the supports were kept therein for 5 min. After the operation completion, the HNO3 solution was removed from the penicillin vial.

Then, a 1 M thiourea solution was poured into a penicillin vial with supports so that the batch of supports was completely immersed in the solution, and the supports were kept therein for 15 min. After the operation completion, the thiourea solution was removed from the penicillin vial, and the supports were washed from thiourea successively with acetone and water.

During chlorinating the support surface, water was poured into the penicillin vial with the batch of supports so that they were completely immersed therein. Then, a chlorinating agent (1.5 mL of 12 M HCl and 10 µL of hydrogen peroxide) was added to the water. The contents of the vial were shaken with a shaker for 15 min, then the supports were sequentially washed with water and acetone.

In order to remove particles of silver chloride, which are weakly bound to the support surface, the supports were shaken for 25 h with a shaker in a vial under a layer of sulfuric acid (pH 4), then the solution was removed from the vial and the supports were washed with water and acetone.

When chlorine atoms on the support surface were replaced by 125I atoms, water was poured into the same penicillin vial with the supports so that they were completely immersed therein, afterwards the vial was sealed with a rubber stopper. In a typical experiment, 50 μL of a 0.05 M alkaline solution of Na125I containing 56 mCi of 125I and 50 μL of 0.1 M H2SO4 (to neutralize the alkali and bring the medium to a slightly acidic state) were introduced through a stopper into the vial with the supports. The penicillin vial with supports was placed on a shaker and shaken for 60 h. Without opening the vial, the solution under study was removed from it and the supports coated with 125I were washed with water. In an open vial, the supports were also washed with water and alcohol, then they were dried.

The activity of silver supports coated with 125I was measured on a Curiementor 3 dose calibrator. Specifications of the dose calibrator: the range of measured 125I activity 0.2 MBq–44 GBq (5.4 × 10–3 mCi–1.2 Ci), measurement error ±5%, reproducibility of activity measurement results no more than ±2%. In the course of the measurement, each support was put into a separate polypropylene ampoule.

RESULTS AND DISCUSSION

Figure 3 shows the results of fixing 125I on the surface of silver supports.

The deposited activity was 53.4 mCi (95.3%) of 125I, the average value of the activity deposited on the surface of one support was 534 μCi, the coefficient of variation was 4.1%. If the coefficient of variation does not exceed 10%, the data dispersion is considered insignificant [22].

Thus, the developed method for fixing 125I on the surface of silver supports of microsources for prostate cancer brachytherapy makes it possible to deposite iodine-125 with a slight deviation from the average value of each activity-carrying support and in the amount necessary for the manufacture of microsources for PC brachytherapy (of the order of 0.4–0.6 mCi per one support).

An effect of the nonuniformity of 125I deposition over the support surface on the distribution of the absorbed dose created by the array of microsources was considered in [23]. It was shown that even with a very uneven distribution of the 125I activity deposited over the support surface, the dose rate distribution created in the vicinity of the tumor by the array of microsources differs little from that obtained in the case of microsources with a uniformly distributed 125I activity.

REFERENCES

Sostoyanie onkologicheskoi pomoshchi naseleniyu Rossii v 2019 godu (The state of Oncological Care for the Population of Russia in 2019), Kaprin, A.D., Starinskii, V.V., and Shakhzadova, A.O., Eds., Moscow: MNIOI im., P.A. Gertsena, FGBU “NMITs Radiologii” Minzdrav Rossii, 2020.

Brakhiterapiya (Brachytherapy), Kaprina, A.D. and Mardynskogo, Yu.S., Eds., Obninsk: MRNTs im., A.F. Tsyba, FGBU “NMITs Radiologii” Minzdrava Rossii, 2017.

Stish, B., Davis, B., Mynderse, L., Deufel, C., and Choo, R., Surg. Oncol. Clin. N. Am., 2017, vol. 26, no. 3, pp. 491–513.

Koutrovelis, P., J. Urol., 1998, vol. 159, no. 1, pp. 142–145.

Koutrovelis, P., Zailas, N., Goldson, A., Bondy, H., Hendricks, F., Katz, S., and Gillenwater, J., J. Brachyther. Int., 1999, vol. 15, no. 1, pp. 65–72.

Selinov, I.P., Izotopy (Isotopes), Moscow: Nauka, 1970, vol. I.

Babakheidari, A.E., Shamsae, M., and Akhmadi, P., Radiokhimiya, 2014, vol. 56, no. 3, pp. 296–301. https://doi.org/10.1134/S1066362214030126

Kubiatowicz, D., US Patent 4323055, 1982.

Rostelato, M.E.C.M., Rela, P.R., Zeituni, C.A., Feher, A., Manzoli, J.E., Moura, J.A., Moura, E.S., and Silva, C.P.G., Nukleonika, 2008, vol. 53, Suppl. 2, pp. S99−S103.

Saxena S., K., Mukherjee, A., Kumar, Y., Ram, R., Tapase, A.S., Anand V., J., and Dash, A., J. Radioanal. Nucl. Chem., 2014, vol. 302, no. 3, pp. 1237–1243.

Lee, J.H., Park, U.J., Son K., J., Choi, K.H., Yu, K.H., Bull. Korean Chem. Soc., 2014, vol. 35, no. 7, pp. 2172–2174.

Kumar, Y., Saxena, S.K., Venkatesh, M., and Dash, A., J. Radioanal. Nucl. Chem., 2011, vol. 290, no. 1, pp. 109–114.

Lee, J.H., Choi, K.H., and Yu, K.H., Appl. Radiat. Isot., 2014, vol. 85, no. 2, pp. 96−100.

Choi, S.J., Son K., J., Lee, J.H. Nam, S.S., and Choi, S.J., US Patent 9421282. 2016.

Ercun, Y., CN Patent 1246042. 2006.

Xiaohai, J., Yuqing, W., and Jinrong, Z., CN Patent 1106860, 2003.

Cieszykowska, I., Piasecki, A., and Mielcarski, M., Nukleonika, 2005, vol. 50, no. 1, pp. 17−22.

Ermolov, N.A., Nerozin, N.A., Podsoblyaev, D.A., Raspopov, A.A., Smetanin E.Ya., Kham’yanov, S.V., and Shapovalov, V.V., Patent RF 2364665, 2009.

Podsoblyaev, D.A., Nerozin, N.A., Shapovalov, V.V., Yakovshchits, Yu.A., Bolonkin, A.S., Dunin, A.V., and Goverdovskii, A.A., Biomed. Photonics, 2015, vol. 4, no. 4, pp. 17–20.

Podsoblyaev, D.A., Shapovalov, V.V., Samsonov, M.D., and Togaeva, N.R., Patent RF 2759441, 2021.

State Standard GOST 7222-2014. Provoloka iz zolota, serebra i splavov na ikh osnove. Tekhnicheskie usloviya (Wire Made of Gold, Silver and Alloys Based on them. Specifications).

Nerozin, N.A., Pyshko, A.P., Shapovalov, V.V., Goverdovskii, A.A., Biomed. Photonics, 2015, vol. 4, no. 3, pp. 10–23.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Additional information

Translated from Radiokhimiya, No. 5, pp. 438–459, October, 2022 https://doi.org/10.31857/S0033831122050021

Supplementary information

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shapovalov, V.V., Artamonov, S.A., Eldashev, N.V. et al. Deposition of Iodine-125 on Silver Supports of Microsources for Prostate Cancer Brachytherapy. Radiochemistry 64, 641–644 (2022). https://doi.org/10.1134/S1066362222050083

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1066362222050083