Abstract

A quantitative study of the biodegradability of polymer soil conditioners is necessary for a reasonable prediction of their stability and functioning in soils. For this purpose, a new methodological approach based on PASCO (USA) equipment was proposed. This approach allows recording continuous kinetic curves of CO2 emission in laboratory experiments based on incubation of composite gel-forming soil conditioners. Several characteristic types of respiration curves have been identified, and new physically based models have been proposed for their description with subsequent calculation of the half-lives of composite hydrogels. For the traditionally considered non-biodegradable acrylic superabsorbents of soil water, the possibility of rapid biodegradation was shown for the first time in the case of the addition of a biologically active compost extract into their liquid phase. With this treatment, which brings laboratory experiments closer to real soil conditions, the half-lives of both the well-known European Aquasorb and Zeba superabsorbents and the Russian Aquapastus hydrogel decreased by an order of magnitude from the initial values of 2–6 years to 0.1–0.3 years. In practice, this can negatively affect the profitability of using such materials for soil conditioning due to their rapid destruction and loss of functionality. The addition of silver ions into innovative Aquapastus composite superabsorbents at a dose of 0.1% or 10 ppm in swollen gel structures effectively reduces their biodegradability, prolonging the half-life to 10 years or more, which is twice the German standard DüMV 05.12.12 of the stability of polymer ameliorants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Synthetic and combined gel-forming soil conditioners are successfully used in modern agriculture and landscaping to optimize the water-holding capacity and hydraulic conductivity of soils, create a water-stable aggregate structure, protect against water and wind erosion, and also as agents for controlled release systems of agrochemicals and plant protection products in the rhizosphere [4, 9–11, 28, 30, 39–41, 53]. Small effective doses of such conditioners (0.05–0.3%) are 10 or even 100 times lower compared to traditional soil ameliorants, ensuring their high potential profitability not only in direct application, but also in logistics [5, 6, 15, 34, 40]. Such doses can increase the water-holding capacity of soils by 3–5 times, the range of available moisture by 1.5–2 times, reduce physical evaporation by 1.3–3 times and unproductive losses during infiltration by up to 2–10 times [5, 6, 8, 15, 34, 40–42, 48, 51]. Similar and smaller doses of gel-forming polymer materials firmly aggregate soil particles and protect them from water and wind erosion [25, 34, 51].

However, most of these assessments are given for laboratory tests of gel-forming soil conditioners, whereas in a real biologically and biochemically active soil environment there are factors that can limit the efficiency of such materials. The most serious and not adequately taken into account factor is the biodegradation of polymer superabsorbents [3, 25, 27, 37, 38, 43, 45, 47, 52]. Previously [37], based on a thermodynamic analysis of the dynamics of water retention of sandy soils under the influence of radiation-crosslinked polyacrylamide (PAA), a significant (from 30–50% or more) reduction in the water capacity of samples was revealed in the water pressure range of 0–1000 kPa (centrifugation method) during six-month-long incubation experiment at different temperatures from 20 to 37°C. In fact, similar results were obtained for the Iranian acrylic Super AB, A-200 superabsorbent in field lysimetric experiments followed by thermodynamic analysis of water retention curves in the range of 0–1600 kPa (membrane press method) in the study [8]. However, the authors, apparently guided by the traditional point of view about the resistance of such materials to biodegradation, did not associate losses in water retention with the biodegradation of the superabsorbent, limiting themselves to the broad concept of “aging” of the material and the suppression of its swelling under the influence of external (lithological) pressure or osmotic stress from the electrolytes of the pore solution. Meantime, currently, more and more researchers are inclined to the conventionality of the traditional division of superabsorbents into “biodegradable” (usually biopolymers–polysaccharides and composite gels based on them) and resistant to biodegradation (usually synthetic acrylic, acrylamide, acrylonitrile and other polymers) substances, emphasizing the potential significance of biodegradation in the behavior of both classes of gel-forming superabsorbents in soils [4, 9, 11, 28, 30, 37, 38, 43].

The purpose of our study was an instrumental assessment of the biodegradation of composite gel-forming soil conditioners with an acrylic polymer matrix in a fully automated incubation experiment based on PASCO equipment (USA) for monitoring carbon dioxide emissions. This methodological study continues the previous development based on the kinetic assessment of biological oxygen demand (BOD) during long-term incubation of hydrogels using the Velp Respirometric Sensor System 6 for Soils from the Italian company VELP [43]. The main tasks included adapting new equipment to studies of biodegradation of gel-forming soil conditioners, obtaining and typing experimental kinetic curves of CO2 emission during the incubation of gels, developing their physically based models for an adequate description of experimental data, and calculating basic biodegradation parameters as the half-lives of the studied materials, as well as conducting a comparative assessment of the resistance of gels to biodegradation depending on their composition and incubation conditions.

OBJECTS AND METHODS

Polymer composite gel-forming materials for soil conditioning, synthesized in the Russian Federation (patents RU No. 2726561, RU 2639789) of Aquapastus trademark [39] were studied. They included acrylic copolymers based on acrylamide and acrylic acid salts, as well as various fillers of the synthetic polymer matrix in the form of waste from the biocatalytic production of acrylamide, dispersed peat, salts of humic acids, and various technological additives, such as microelements, growth stimulants, or biocides. Methylene bis-acrylamide was used as a crosslinking agent. The water absorption of innovative products during freely swelling in distilled water varied from 340 to 500 kg/kg for granules with a size of about 1 mm. Hydrogel Aquapastus-11 (A11) is a base copolymer of acrylamide and ammonium acrylate, filled (28%) with solid waste from the biocatalytic production of acrylamide as a mixture of microbial cells, cell agglomerates, and perlite filter. Its modification consists of the addition of 0.1% of silver ions (A11-Ag gel) with the presumable purpose to inhibit the biodegradation of the composite. Two other experimental A22 and A22-Ag materials from the trade line of innovative Russian Aquapastus hydrogels, along with acrylamide copolymer and sodium acrylate, contained fine peat as a filler (23.5%) and 0.1% ionic silver embedded in the polymer matrix. Information on their hygroscopicity and carbon content obtained by the standard gravimetric method and combustion in an oxygen mixture using an AN-7529 C-analyzer and required for a quantitative assessment of the biodegradation of gels is presented in Table 1.

Innovative Russian soil conditioners, as well as well-known international brands of superabsorbents, namely Aquasorb (SNF-group, https://www.snf-group.com) and Zeba (UPL-group, https://www.upl-ltd.com) based on polyacrylamide, acrylic acid, and starch were compared. Detailed descriptions of the synthesis, composition, and results of preliminary laboratory tests of Aquapastus composites in comparison with Aquasorb and other foreign brands for soil conditioning are presented in previous publications [39, 41] and patents RU No. 2726561, RU 2639789.

Before incubation experiments, swollen gel structures were obtained from air-dried preparations weighing 400 mg in a ratio of 1 : 100 of the mass of absolutely dry gel and liquid phase. Two types of liquid phase were used, namely pure distilled water and distilled water with an aqueous extract from compost consisting of rotting vegetables and fruits (potatoes, onions, apples, grapes, oranges) with soil humus. The gel structures were placed into sealed incubation vials with a free volume of 200 mL and a built-in wireless digital carbon dioxide sensor PS-3208 (PASCO Scientific, USA, https://www.pasco.com), allowing continuous monitoring of CO2 emission during the incubation experiment. Closed vials with gels and PS-3208 sensors configured to take readings every 5 min were installed in a Binder ED023-230V thermostat (Germany) and exposed for 24–72 hours at a constant temperature of 30°C optimal for aerobic biodegradation.

Upon completion of the experiment, the sensor was connected to the computer via a USB port and, using PASCO software, data on CO2 dynamics were read from the sensor memory and exported to MS Excel spreadsheets for further mathematical and statistical processing, as well as preparation of illustrative material. The approximation of experimental curves by the physically based models of the kinetics of microbial growth and CO2 emission proposed in the study with the necessary statistical assessment of the approximation parameters was carried out in the S-Plot 11 program based on the “Regression Wizard” application for nonlinear regression.

RESULTS AND DISCUSSION

Types of kinetic curves and their physically based modeling. The main types of curves for the carbon dioxide concentration dynamics during the incubation of gel-forming soil conditioners are shown in Fig. 1. The most common type 1 is represented by a convex curve with a rapid increase in CO2 concentration at the initial stage of incubation and a subsequent gradual slowdown reaching a constant (quasilinear) small increase at the end of the experiment. This form can be explained by the inhibition of biodegradation by a lack of oxygen when it is consumed in a bottle closed for gas exchange [23, 32, 43].

A more complex shape of the kinetic curves was observed in type 2 with a change from a concave segment to a convex segment as CO2 accumulated over time. The initial segment with a slow rate of CO2 growth is often interpreted as a lag phase in the development of a microbial population decomposing the organic substrate [2, 23]. After the lag phase, active growth of the colony begins with rapid destruction of the organic substrate and CO2 emission. Limitation by oxygen and possibly synchronous inhibition of microorganisms by excess CO2 slow down their growth and biodegradation of the substrate, so the kinetic curve takes on a convex shape with a quasilinear small increase in CO2 concentration at the final stage of the experiment, by analogy with type 1 curves.

The rarest type 3 was characterized by a constant (quasilinear) increase in the CO2 concentration in the incubator throughout the entire experiment. It can be explained both by the short duration of the experiment and by the susceptibility to biodegradation of the studied organic substrate with intense CO2 release without a significant effect of inhibiting this process.

The above types of kinetic curves are known in the literature on biodegradation modeling, and a number of empirical models have been proposed for their quantitative description [7, 23]. The most well-known model [23] is capable of quite adequately approximating both the first and second types of kinetic curves:

where C(t) is the CO2 concentration in the incubator depending on time (t), t0 is the delay time before the start of intense CO2 release (lag phase), a is the asymptote of the kinetic curve or the maximum possible amount of CO2 that can be achieved with a long incubation of material capable of biodegradation. This model describes only the convex shape of biodegradation curves, completely ignoring the lag phase range; thus, for curves of type 2, its application is very conditional. Also, in contrast to the prediction from model (1), the actually observed kinetic curves of all three types had, at the last stage of incubation, instead of the asymptotic final a value, a clearly defined quasilinear range with a constant rate of increase in CO2. This specificity of the experimental data and the shortcomings of the known empirical equations for their description required the development of new physically based kinetic models of the biodegradation of organic gel-forming substrates in relation to the isothermal incubation in a mass-transfer-closed system.

The key idea of the development was to divide the biodegradation curve into two segments reflectingfast (nonlinear) and slow (quasilinear) stages with a conventional time boundary between them (ta) and a stage-by-stage kinetic description of the modeled curve using a linear combination of the most adequate kinetic models for each segment. To describe the curves of the first type in the initial segment (t ≤ ta), we will use the results of previous work on the kinetics of BOD in similar incubation experiments to assess the biodegradation of gel-forming soil conditioners [43]. Since the rate of BOD and CO2 release are linearly related through the molar ratio of these gases and the reaction of aerobic biodegradation of organic material, the kinetic model of BOD dynamics [43] can be adapted to CO2 release in a closed bottle in the following form:

where C, K, are the current and maximum CO2 concentrations in the closed volume of the incubation bottle, g/m3; k is the kinetic constant of the biodegradation at the fast stage, h–1. Differential Eq. (2) models a gradual slowdown in the rate of biodegradation of organic material and CO2 release down to zero when the limiting level of carbon dioxide (K) or, accordingly, the maximum BOD is reached, according to [43]. The solution to (2), assuming an insignificant (close to zero) initial CO2 concentration in the incubator atmosphere, is an exponential function (3), which describes the dynamics of CO2 accumulation in a closed incubator:

From a mathematical point of view, Eq. (3) is obviously identical to the empirical model (1) [23] in the absence of a lag phase (t0 = 0).

A more complex shape of the curve of the second type suggests the presence of a slowdown (lag phase) followed by a rapid increase in CO2 emission in the initial segment (t ≤ ta). Typically, such an S-shaped curve is a consequence of 2nd-order kinetics with the growth of decomposing microorganisms limited by the environmental “capacity of the environment” according to the classical Verhulst–Pearl model [19]:

where K is the “medium capacity” in terms of the limiting carbon dioxide concentration, g/m3; r is Malthusian growth parameter (kinetic constant), h–1. The analytical solution to this model gives a logistic function of the following form:

where Q is a dimensionless parameter associated with the initial growth conditions of a colony of microorganisms. Checking the adequacy of Eq. (5) for describing type 2 curves in the range (t ≤ ta) revealed discrepancies between experimental and model data (Fig. 2, Table 2). However, a slight modification of the classical Verhulst–Perl model led to a qualitatively new type of sigmoid, which turned out to be more adequate for describing experimental curves of type 2. This modification implied an additional slowdown in the growth rate of destructor microorganisms in inverse proportion to the time of the experiment:

A physical explanation of such nonlinear kinetics for the biodegradation of organic substrates is given in [1] by the power-law link between the kinetic constant and the substrate concentration in the original autonomous equation (classical Moser model [1]). The analytical solution of model (6) gives a family of sigmoids, among which function (7) turned out to be the most suitable for describing experimental kinetic curves of type 2:

where Q is the integration constant in the range t > 0. In Fig. 2 and Table 2, an example of approximation of the type 2 curve for the Aquasorb soil conditioner by sigmoids (5) and (7) in the area (t ≤ ta) is shown. Based on this, it can be seen that function (7) matches the experimental data better, with a higher determination coefficient (R2) and three-fold reduction in the standard error of approximation (s).

The slow (quasilinear) part of the kinetic curves at t > ta is adequately approximated by a straight-line equation with a constant slope coefficient, reflecting the rate of increase in the carbon dioxide concentration in the incubation bottle. Since functions (3) and (7) have a limit of a K constant, to combine the nonlinear (fast at t ≤ ta) and quasilinear (slow at t > ta) parts of the kinetic curves, it is convenient to use the algebraic sum of these functions with the equation of the straight line. At the same time, to compare curves that differ in time scales and levels of accumulated CO2, they were scaled with the introduction of dimensionless variables of CO2 concentration (y = C/Cmax) and time (x = t/tmax), where Cmax, tmax are the maximum values of the CO2 concentration and duration of the experiment, respectively. In this case, to describe curves of type 1 over the entire range, the combination of Eq. (3) with the equation of a straight line in dimensionless form gives function (8):

where a = K/Cmax, b = tmax k are the dimensionless concentration and kinetic parameters of the model.

By analogy, for type 2 scaling kinetic curves we obtain the approximating model (9):

where a = K/Cmax, x0 = Q–(1 + r)/tmax are dimensionless constants.

New models (8), (9) are convenient to use not only for describing the kinetic curves of CO2 dynamics in incubation experiments but also for assessing the biodegradation capacity of the gel-forming materials under study. Traditionally, a parameter of the intensity of biodegradation is the half-life (T0.5) of an organic substance or the time of decomposition of half of its original amount [32]. To a first (linear) approximation, the half-life can be calculated from data on the percentage of decomposition (mass loss) of organic material (D%) over a known incubation time (TD) using the following formula [38]:

If the dimensionless parameter (a) in models (8) and (9) is estimated from the kinetic curves, it is easy to convert it into the specific rate of carbon dioxide emission (A, g CO2/(m3 day)) at the last (quasilinear) stage of biodegradation with a constant intensity established after the development of a microbial population of destructor organisms:

where K, gCO2/m3; tmax is normalizing characteristics of the maximum carbon dioxide concentration and duration of the incubation experiment, h; 24 is conversion factor of hour to day. The K value (gCO2/m3) is estimated from the law of state of an ideal gas according to the formula [38]:

where Xppm is the maximum volumetric CO2 concentration in the incubator determined by the PASCO gas analyzer, expressed in ppm, P is atmospheric pressure, Pa; T is incubation temperature, K; R = 8.314 J/(mol K) is the universal gas constant, M = 44 g/mol is the molar mass of carbon dioxide.

Then, the percentage of material decomposition at the steady-state slow stage of biodegradation is found as:

where V is the volume of the air space of the bottle, m3; Corg is percentage of organic carbon in the incubated material, %; m0 is mass of air-dry sample of material, g; Wh is the percentage of hygroscopic moisture in it, %; 12/44 is conversion factor taking into account the mass fraction of carbon in CO2. Substituting the value of D% into formula (10) and taking into account that for it the TD = 1 day, the half-life of the material under study can be found. Note that taking into account hygroscopic moisture content in calculating the D% and T0.5 values is extremely important for superabsorbents, since they are highly hygroscopic materials with Wh values of 30% and higher [42].

Along with the above assessment using models (8), (9), additional options for determining T0.5 were used in the form of a potential \(T_{{0.5}}^{{{\text{min}}}}\) – \(T_{{0.5}}^{{{\text{fin}}}}\)range of this value. The lower limit of this range (\(T_{{0.5}}^{{{\text{min}}}}\)) was determined by the mass of CO2 released over the entire period of the experiment, including the fast stage (t ≤ ta), which gives the following formula for calculating the percentage of decomposition:

where С0, Cmax are the initial (atmospheric) and final (maximum) concentrations of CO2 in the incubator, g CO2/m3. Substituting D% determined by Eq. (14), along with the value of the experiment time TD = tmax, into formula (10) allows us to estimate \(T_{{0.5}}^{{{\text{min}}}}\).

The upper limit of the considered range (\(T_{{0.5}}^{{{\text{fin}}}}\) ) is determined using direct linear approximation of the C(t) experimental data at the final stage of the experiment (t \( \gg \) ta) with the slowest emission rate by the straight line equation:

where СK is g СО2/m3; d is approximation parameters, g CO2/(m3 h). Substituting the 24d value instead of A into formula (13) gives the minimum possible estimate of D% for the incubation experiment and, accordingly, the maximum \(T_{{0.5}}^{{{\text{fin}}}}\) value according to formula (10).

Almost all studied gel-forming soil conditioners were characterized in incubation experiments by kinetic curves of types 1 or 2. The only exception was the Zeba composite material, which included an easily degradable starch component [41]. For this hydrogel, the kinetic curve was represented by a straight-line dependence C(t) throughout the experiment (type 3 in Fig. 1). Accordingly, to approximate it, it was possible to equally successfully use both model (8) (at a \( \ll \) 1) and Eq. (15) with subsequent calculation of the half-life of the material using formulas (11), (13) and (10).

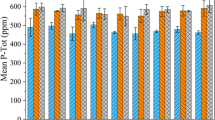

Comparative analysis of the results obtained for different hydrogels and incubation conditions. Figure 3a shows the scaling kinetic curves of CO2 emission for gel-forming soil conditioners, pre-swollen to a water content of 100 g/g in distilled water (hereinafter referred to as pure gels). All hydrogels, with the exception of the Zeba composite material, were characterized by type 1 curves of a convex shape with a rapid increase in CO2 concentration (up to 60–80% of the maximum) at the initial stages of incubation (0.2–0.4 tmax) and a subsequent rather slow stage of steady-state biodegradation with an almost constant (quasi-linear) increase in CO2 concentration. The fastest exit to the quasi-equilibrium stage was observed for the Aquasorb gel (<0.2 tmax). The kinetic curve for the Zeba material belonged to type 3 and was characterized by a constant increase in CO2 throughout the experiment (Fig. 3a). The introduction of innovative A11-Ag and A22-Ag materials—biocides in the form of silver ions—into the polymer matrix did not greatly affect the shape of the kinetic curves of CO2 emission, which became only slightly flatter, i.e., with a slower exit to the quasilinear section (Fig. 3b).

The parameters for approximating experimental data for pure gels and composites with silver by model (8) varied in the ranges 0.5 < a < 0.8, 10 < b < 69, with the exception of the Zeba material, where the use of model (8) was possible only at very low values of a, b is about 10–3 (Table 3). All parameters were statistically significant with a p-value in the range of 0.0013–0.0001, which, along with high determination coefficients (R2 = 0.955–0.999) and small standard errors of approximation (s = 0.01–0.04), indicated the adequacy of the new model (Table 3).

Sharp changes in the kinetic curves of CO2 emission occurred for variants of hydrogels swelling in distilled water with the addition of compost extract (Fig. 4a). This processing led to a change in the shape of the curves from the first type to the second one. For all gel-forming soil conditioners, without exception, a lag phase with a duration of 0.3 to 0.4 tmax appeared on the kinetic curves of biodegradation. The intensity of CO2 emission in this area did not exceed 0.2 Cmax (Fig. 4a). Subsequently, the lag phase gave way to a stage of very rapid growth (CO2 generation) with a maximum relative slope of the curves of the order of 3/2 in the interval 0.4–0.6 (up to 0.8) tmax. This stage, in turn, was replaced by a quasilinear range at the final phase of the incubation experiment.

Approximation of experimental curves of type 2 by model (9) showed its adequacy (R2 = 0.996–0.998, s = 0.01–0.02) with parameters statistically significant at the p-value < 0.0001 level, varying in the ranges: 0.4 ≤ a < 0.8, 9 < r < 14, 0.4 < x0 < 0.7. The introduction of silver ions into the polymer matrix of innovative A11-Ag and A22-Ag composites was reflected in the kinetic patterns of their biodegradation by changing the type of curve from 2 to 1 (Fig. 4b). Therefore, for these biocide-embedded materials, incubation conditions involving swelling of the gels in pure distilled water or with the addition of compost extract did not affect the shape of the kinetic curve, which belonged to type 1 in both cases.

The patterns noted above were characteristic to the scaling curves and they described the relative changes in the biodegradation kinetics of the compared materials. The absolute values of CO2 emission intensities and biodegradation rates of the studied gel-forming soil conditioners are estimated by the Сmax and tmax normalizing indicators as well as half-life indicators calculated from the parameters of models (8), (9) using theoretical formulas (10)–(15) (Table 4). The Сmax value varied from 1.8 to 135 g CO2/m3 and was highest in experiments with the addition of compost extract, which stimulates biodegradation. The experimental time usually did not exceed three days (tmax = 60–72 h), which distinguishes the new methodology favorably in comparison with BOD, where a similar assessment of biodegradation requires incubation of gel-forming soil conditioners for 1–3 months [43]. Such differences are primarily due to the low accuracy of manometric BOD analyzers (0.3–1 g O2/m3) compared to PASCO IFC gas analyzers (0.0–0.02 g CO2/m3).

The half-lives of the studied gels varied widely from 0.1–0.2 to 10–14 years. The highest T0.5 values, reflecting maximum resistance to biodegradation, as expected, were found in innovative composites A11-Ag and A22-Ag with silver biocides. The assessment \(T_{{0.5}}^{{{\text{min}}}}\) – \(T_{{0.5}}^{{{\text{fin}}}}\)intervals were 3.2–10.9 and 6.6–13.9 years, and the calculation according to model (8) T0.5 = 13.8 ± 0.5 and 12.3 ± 0.3 years for gels A11-Ag and A22-Ag, respectively. Such characteristics significantly (2–4 times or more) exceeded the half-lives for materials without biocidal additives, both in the A11 and A22 original prototypes, and in similar Aquasorb and Zeba foreign composites. Among them, the Zeba composite material based on polyacrylamide and starch had the minimum stability (T0.5 ≈ 0.6 years), and the A22 composite with an acrylic matrix filled with mechanically activated peat had the maximum stability (T0.5 = 3.5–6.1 years). A11 and Aquasorb materials occupied an intermediate position with T0.5 = 0.7–2.7 and 1.9–3.5 years, respectively.

The addition of compost extract to the liquid phase to swell the gels sharply increases the intensity of their biodegradation. The T0.5 values of gels in such incubation options are reduced to 0.1–0.3 (0.6) years, i.e., by 6–10 times or more compared to pure samples. This result seems extremely important from a technological point of view, since it calls into question the traditional ideas about the high resistance to biodegradation of synthetic polymer superabsorbents in real soil conditions, where instead of almost sterile distilled water, natural solid-phase components and solutions with degrading organisms and exoenzymes are present. Obviously, the reduction in the actual working life and functionality of rather expensive soil conditioners from several years to 0.5–1 year may well be the reason for abandoning their use due to lack of profitability. In this regard, technological developments of composite materials that combine the properties of superabsorbents with increased resistance to biodegradation are promising for soil conditioning [41].

Thus, the introduction of silver ions into the polymer matrix of composite acrylic gels, originally proposed to control potato pathogens, including late blight [39], allows simultaneously increasing their resistance to biodegradation. The T0.5 values in the innovative A11-Ag and A22-Ag composites when they were swollen in a liquid with a compost extract increased to 2.4–3.4 years, that is, by 5–10 times, actually returning to such materials the stability characteristic of the original pure state when swelling in distillate.

The results obtained made it possible to clarify the existing rather contradictory information about the biodegradability of polymer synthetic superabsorbent hydrogels. Such materials are traditionally believed to be very resistant to biodegradation and can be classified as resistant to biodegradation, in contrast to well-degradable environmentally friendly polysaccharide gels based on starch, cellulose, chitosan and other biopolymers of natural origin [3, 9–11, 28–30, 47]. At the same time, it is obvious that there are no polymers that are completely resistant to decomposition, and the only question is to characterize the rate of their decomposition (characteristic lifetime) under certain conditions [32]. Formally, this issue was resolved in the foreign examination of polymer materials by two standards of resistance to biodegradation, namely European EN 13432 and American ASTM 6400 [29]. For the American standard, a material that loses 60% in 180 days is considered biodegradable, and for the more strict European standard, it is 90% of its original mass or carbon content [29]. Using Eq. (10), it is easy to determine that the conventional boundary for dividing materials into resistant and non-resistant to biodegradation according to American and European standards will be the standard half-lives of 136 and 54 days or 0.15–0.37 years, respectively.

Comparing the data obtained (Table 4) with these criteria, it is easy to verify that pure acrylic gels that swell in distilled water are indeed stable, since their half-lives of 2–3.5 years or more significantly exceed the limits of EN 13432 standards and ASTM 6400 in 0.15–0.37 years. And only the Zeba composite material with an easily degradable biopolymer component (starch) and the corresponding characteristic T0.5 = 0.11–0.24 years can be conditionally classified as a class of polymers that are not resistant to biodegradation, especially according to the American standard. Most of the known data on the decomposition of acrylic superabsorbents is consistent with this information [24, 25, 28]. Thus, study [24] reports that 10% destruction of polyacrylamide (PAA) per year, which, translated into half-life according to formula (10), gives T0.5 = 6.5 years. Similar estimates of T0.5 of 5–7 years for synthetic polymer superabsorbents are given in [28]. In [25], the degree of mineralization of PAA in soil is estimated at 22.5% over 2 years or a half-life of 5.5 years.

At the same time, a number of publications contain information about the possibility of rapid decomposition of acrylamide and PAA with half-lives of only a few days, that is, significantly lower than the standards EN 13432 and ASTM 6400 [3, 13, 21, 35, 44, 49, 52]. The authors of [21] estimated the decomposition rate of acrylamide at doses of 25–500 mg/kg in agricultural soils with a T0.5 = 1–4 days at a temperature of 20–22°C. Data [3] on 71–95% decomposition of acrylamide in soils in 14 days correspond to half-lives of 3–8 days. Similar data with T0.5 = 2–3 days were obtained for acrylamide in water bodies [13]. In [44], PAA was almost completely decomposed within 5 days after adding 0.05% to garden soil. Many microorganisms are capable of generating extracellular amidases that successfully utilize the amide groups of polyacrylamide [25, 49]. Aliphatic amidase (cd07565) from Pseudomonas putida leads to PAA degradation by 46% after 7 days at 39°C, which, according to formula (10), corresponds to a half-life of no more than 8 days [49].

The study [52] presents the kinetic constants of PAA biodegradation. Based on them, T0.5 equals from 37 to 80 days in the experimental temperature range of 25–37°C. Researchers [27] provide data on the biodegradation of a superabsorbent based on copolymers of acrylamide and potassium acrylate by soil bacteria, from which it follows that the half-life of such a hydrogel varies from 0.13 to 1.31 years. The authors mention a strong (about 25%) loss of water-holding capacity of such material during the 8-month biodegradation. This is consistent with previously obtained experimental data for radiation-crosslinked PAA with T0.5 = 0.4–1.7 years and losses of water retention of hydrogel-treated soil (silty–sandy Arenosol of Karakum) of 50% or more during a five-month incubation experiment with a temperature range of 20–37°С [37].

The main reason for such a strong variation in the estimates of the intensity of biodegradation of acrylic gel-forming polymers known in the literature may be clarified by comparing the results of incubation of these materials in their pure form and with the addition of a compost extract to the liquid phase for swelling. It is the presence of biodestructor organisms and their enzymes necessary for biodegradation that causes a sharp increase in the intensity of decomposition of these synthetic polymers, which are a priori stable due to chemical cross-linking and high molecular weight. This conclusion is confirmed by recent studies [45] assessing the biodegradation of gel-forming soil conditioners depending on synthesis parameters (degree of swelling and chemical composition), as well as environmental conditions. The results of [45] showed that the degree of swelling, composition of the composites, and synthesis parameters had little effect on the stability of hydrogels compared to environmental parameters, which seem to be the main factors influencing their biodegradation. If the untreated control (clean gels) remained stable during 8 days of the incubation experiment (mass loss up to 3–5%, not statistically significantly different from zero), then contact with forest soil led to losses of 30–40%, and with agricultural soil, to losses of 60–70% of polymer composites due to biodegradation. Such losses in terms of half-life are T0.5 = 6–15 days or significantly less than 1 month. The main factor for a significant increase in biodegradation after direct contact with soils and plants or after the addition of aqueous extracts from them are, of course, soil microorganisms–bio-destructors and exoenzymes present there. Additionally, the priming effect can be assumed, which is well known in soil biochemistry [16].

In this regard, the conventionality of dividing gel-forming soil conditioners into biodegradable (mainly polysaccharide gels) and resistant to biodegradation becomes obvious. The review [4] summarizes the data of 22 modern publications on the biodegradation of polymer hydrogels, expressed as a percentage of decomposition over a certain time interval, which made it possible, using Eq. (10), to estimate their half-lives. For the entire data set presented in [4] (n = 33), T0.5 varied in a wide range from 2 days to 285 years. Using the limits of EN 13432 and ASTM 6400 standards of 54 or 136 days, we estimated the probability that a particular hydrogel would be in the class of polymers not resistant to biodegradation. Of the entire data set [4], 61% of materials were conditionally biodegradable according to the American standard and 33%, according to the European classification. If we analyze only composite superabsorbents with acrylic components (acrylates and PAA in various combinations with each other and natural biopolymers), then the probability of them being biodegradable was 57% according to the American standard and 24% according to the European standard. For other, mainly biopolymer gel-forming composites based on polysaccharides without the addition of acrylic copolymers, such probabilities of biodegradability were slightly higher (67 and 58%, respectively). Consequently, according to the American standard ASTM 6400, more than half of the gel-forming superabsorbents given in the review [4] are biodegradable, and the presence of acrylic copolymers in their composition has little effect on this parameter, reducing the likelihood of biodegradability by only 10%.

Obviously, for soil gel-forming conditioners, rapid biodegradation with loss of functionality is a significant reason for their potential unprofitability. According to the [17], a German quality standard requiring that synthetic polymers, when added to the soil, are decomposed by no more than 20% over a 2-year period (half-life of about 6 years). As can be seen from Table 4, in reality, none of the biocide-free acrylic composites, including the famous Aquasorb brand, pass this stringent test. A similar result is given by an analysis of literature information [4, 18, 28, 37, 38, 43, 45, 47], according to which no more than 10% of superabsorbents are in this standard, and 60% of materials lose half of their mass (and, therefore, functionality) within 1 year of use. This serious problem leads to the challenge of further improving gel-forming composite materials for conditioning soils and soils with higher resistance to biodegradation.

A promising way to increase the resistance of polymer materials to biodegradation may be the adding of biocidal components into their composition [12, 38]. In the present study and in previous works [38–41], apparently, for the first time, it was proposed to use silver ions and nanoparticles for soil conditioners for this purpose. Known similar developments with silver biocides mainly concern medications and antiseptics [12, 33]. Silver biocides effectively increase the resistance of hydrogels to biodegradation, which is confirmed by both previously published data of laboratory [38, 40, 43] and field [39, 41] tests, and new results based on PASCO equipment. The results obtained are fully consistent with data on the high efficiency of silver biocides in relatively small doses (1–100 ppm) [14, 20, 22, 31]. When the innovative A11-Ag and A22-Ag gels swell to a degree of 100 g/g, the initial silver content of 0.1% will be equivalent to its working concentration in the gel structure of 10 ppm. This dose, as can be seen from Table 4, is sufficient to give the soil conditioner the stability required according to the German quality standard [17] (T0.5 is more than 6 years), and, at the same time, it is not dangerous for plants and soil zoocenosis, including earthworms with effective concentrations of biocidal suppression of 250–500 ppm or more [22, 36, 38]. However, due to the relatively high cost of silver, future studies should be directed to the search for alternative biocidal additives, for example, based on copper, antimony, ammonium, phosphonium or sulfonium salts, titanium oxide, as well as organic antimicrobials [12, 30, 50].

At the end of the paper, we will discuss the methodological issue of comparing the results obtained with the data of BOD analysis based on the automatic equipment Velp Respirometric Sensor System 6 for the same composite materials from previous work [43]. European Aquasorb gel and Russian Aquapastus (A11, A22) in pure form were characterized by a range of half-lives estimated by BOD from 0.5 to 4.0 years, decreasing by 5–20 times after adding compost extract to values T0.5 = 0.1–0.2 years. Innovative A11-Ag and A22-Ag composites with 0.1% silver biocide in a polymer matrix, according to BOD assessment, had half-lives of 3.5–8.8 years in pure form and 1.1–2.6 years when swollen in a distillate with compost extract. These quantitative results and patterns of gel biodegradation response to the addition of compost extract or the use of biocides are generally close to the data obtained in the present study. However, the mean half-lives of gel-forming soil conditioners based on BOD assessment were in most cases lower than those assessed based on CO2 emissions. It is difficult to name the reason for this discrepancy. The incubation time of materials in BOD and VELP CO2 analyzers differs by 10–30 times. It is possible that the kinetic curves of CO2 analysis with a quasi-linear final range (Fig. 1) with longer incubation would change their shape with corresponding consequences for calculating the T0.5 based on them. Although the assumption of accelerated rates of decomposition of materials at longer stages of incubation, necessary to obtain lower T0.5 values close to BOD analysis, seems unlikely. Another hypothesis is the interfacial interactions of the gases studied in incubation experiments [38]. Carbon dioxide has 20–30 times, and in alkaline solutions up to 1000 times, greater solubility compared to oxygen. This means that there is a possibility of accumulation of a certain part of the CO2 released during the decomposition of the material in the gel structure itself. Since this amount is not taken into account by direct monitoring of CO2 in the air phase of the incubator, there may be a strong underestimation of the rate of biodegradation of gels and, accordingly, an overestimation of their half-lives compared to BOD analysis. An indisputable advantage of both types of analysis is a fully automated incubation experiment with continuous gasometric monitoring of the intensity of biodegradation, and future methodological studies will have to establish the true reason for their discrepancies in order to clarify the estimated T0.5.

CONCLUSIONS

(1) A methodology has been developed for quantitative assessment of the biodegradation ability of gel-forming soil conditioners in laboratory incubation experiments based on PASCO equipment with automated control of CO2 emissions.

(2) Three characteristic types of kinetic curves of CO2 emission from incubated gels have been identified and physically based models have been proposed. They allow making their adequate approximation with subsequent calculation of the half-lives of gel-forming soil conditioners as a basic indicator of their biodegradation

(3) The half-lives of the gel structures from the studied acrylic composites, swollen in distilled water, were in the range of 0.6–6.6 years with the minimum values for the Zeba composite with a starch filler and the maximum for the A22 material with a peat filler of the polymer matrix.

(4) Adding compost extract to the liquid phase to swell hydrogels sharply (up to 10 times) stimulates their biodegradation with a corresponding reduction in their half-life to 0.1–0.3 years.

(5) The introduction of silver ions in a dose of 0.1% into the acrylic polymer matrix of gel-forming soil conditioners is an effective means of controlling their resistance to biodegradation. This fact allows achieving the European standard for the stability of synthetic polymers in soils with a decomposition period of more than 6 years.

(6) Traditional views on synthetic superabsorbents of soil moisture as resistant to biodegradation are controversial, since they correspond only to close to sterile laboratory conditions for testing such materials. In more realistic conditions, with the presence of the necessary microorganisms–bio-destructors and enzymes, such materials can decompose by 50% in a few months, i.e. be biodegradable according to existing European and American standards for the biodegradation of polymers.

REFERENCES

B. M. Dolgonosov, Nonlinear Dynamics of Ecological and Hydrological Processes (Knizhnyi Dom LIBROKOM, Moscow, 2009) [in Russian].

Methods of Soil Microbiology and Biochemistry (Mosk. Univ., Moscow, 1991) [in Russian].

H. M. Abdelmagid and M. A. Tabatabai, “Decomposition of acrylamide in soils,” J. Environ Qual. 11, 701–704 (1982).

T. A. Adjuik, S. E. Nokes, and M. D. Montross, “Biodegradability of bio-based and synthetic hydrogels as sustainable soil amendments: a review,” J. Appl. Polym. Sci., e53655 (2023). https://doi.org/10.1002/app.53655

A. M. Al-Darby, “The hydraulic properties of a sandy soil treated with gel-forming soil conditioner,” Soil Technol. 9, 15–28 (1996).

A. M. Al-Darby, S. I. Al-Asfoor, and Y. Z. El-Shafei, “Effect of soil gel-conditioner on the hydrophysical properties of sandy soil,” J. Saudi Soc. Agric. Sci. 1, 14–40 (2002).

Y. Baldera-Moreno, V. Pino, A. Farres, A. Banerjee, F. Gordillo, and R. Andler, “Biotechnological aspects and mathematical modeling of the biodegradation of plastics under controlled conditions,” Polymers 14, 375 (2022). https://doi.org/10.3390/polym14030375

S. Banedjschafie and W. Durner, “Water retention properties of a sandy soil with superabsorbent polymers as affected by aging and water quality,” J. Plant Nutr. Soil Sci. 178, 798–806 (2015).

S. Behera and P. A. Mahanwar, “Superabsorbent polymers in agriculture and other applications: a review,” Polym.-Plast. Technol. Mater. 59, 341–356 (2020). https://doi.org/10.1080/25740881.2019.1647239

E. V. R. Campos, J. L. de Oliveira, and L. F. Fraceto, “Applications of controlled release systems for fungicides, herbicides, acaricides, nutrients, and plant growth hormones: a review,” Adv. Sci. Eng. Med. 6, 373–387 (2014). https://doi.org/10.1166/asem.2014.1538

E. V. R. Campos, J. L. de Oliveira, L. F. Fraceto, and B. Singh, “Polysaccharides as safer release systems for agrochemicals,” Agron. Sustainable Dev. 35, 47–66 (2015).

M. Cloutier, D. Mantovani, and F. Rosei, “Antibacterial coatings: challenges, perspectives, and opportunities,” Trends Biotechnol. 33, 637–651 (2015). https://doi.org/10.1016/j.tibtech.2015.09.002

B. T. Croll, G. M. Arkell, and R. P. J. Hodge, “Residues of acrylamide in water,” Water Res. 8 (11), 989–993 (1974).

J. De Lucca, S. Boue, T. Sien, T. E. Cleveland, and T. J. Walsh, “Silver enhances the in vitro antifungal activity of the saponin, CAY-1,” Mycoses 54, e1–e8 (2011).

H. A. A. El-Rehim, E. S. A. Hegazy, and H. L. A. El-Mohdy, “Radiation synthesis of hydrogels to enhance sandy soils water retention and increase plant performance,” J. Appl. Polym. Sci. 93, 1360–1371 (2004).

S. Fontaine, A. Mariotti, and L. Abbadie, “The priming effect of organic matter: a question of microbial competition?,” Soil Biol. Biochem. 35, 837–843 (2003).

D. Hennecke, A. Bauer, M. Herrchen, E. Wischerhoff, and F. Gores, “Cationic polyacrylamide copolymers (PAMs): environmental half-life determination in sludge-treated soil,” Environ. Sci. Eur. 30, 16 (2018). https://doi.org/10.1186/s12302-018-0143-3

A. Hiroki, P. T. T. Hong, N. Nagasawa, and M. Tamada, “Biodegradability of blend hydrogels based on carboxymethyl cellullose and carboxymethyl starch,” Trans. Mater. Res. Soc. 36, 397–400 (2011).

S. Kingsland, “The RefractoryModel: the logistic curve and the history of population ecology,” Q. Rev. Biol. 57, 29–52 (1982).

S. W. Kim, J. H. Jung, K. Lamsal, Y. S. Kim, J. S. Min, and Y. S. Lee, “Antifungal effect of silver nanoparticles (AgNPs) against various plant pathogenic fungi,” Mycobiology 40, 53–58 (2012).

S. S. Lande, S. J. Bosch, and P. H. Howard, “Degradation and leaching of acrylamide in soil,” J. Environ. Qual. 8, 133–137 (1979).

K. A. Langdon, M. J. McLaughlin, J. K. Kirby, and G. Merrington, “Influence of soil properties and soil leaching on the toxicity of ionic silver to plants,” Environ. Toxicol. Chem. 34, 2503–2512 (2015). https://doi.org/10.1002/etc.3067

R. L. Larson, “Estimation of biodegradation potential of xenobiotic organic chemicals,” Appl. Environ. Microbiol. 38 (6), 1153—1161 (1979).

R. D. Lentz, F. F. Andrawes, F. W. Barvenik, and A. C. Koehn, “Acrylamide Monomer leaching from polyacrylamide-treated irrigation furrows,” J. Environ. Qual. 37, 2293–2298 (2008). https://doi.org/10.2134/jeq2007.0574

A. Nyyssola and J. Ahlgren, “Microbial degradation of polyacrylamide and the deamination product polyacrylate,” Int. Biodeterior. Biodegrad. 139, 24–33 (2019). https://doi.org/10.1016/j.ibiod.2019.02.005

O. A. Novoskoltseva, I. G. Panova, N. G. Loiko, Y. A. Nikolaev, E. A. Litmanovich, and A. A. Yaroslavov, “Polyelectrolytes and polycomplexes for stabilizing sandy grounds,” Polym. Sci., Ser. B. 63, 488–495 (2021). https://doi.org/10.1134/S1560090421050092

M. P. Oksinska, E. G. Magnucka, K. Lejcus, and S. J. Pietr, “Biodegradation of the cross-linked copolymer of acrylamide and potassium acrylate by soil bacteria,” Environ. Sci. Pollut. Res. Int. 23 (6), 5969 (2016). https://doi.org/10.1007/s11356-016-6130-6

M. S. Ostrand, T. M. DeSutter, A. L. M. Daigh, R. F. Limb, and D. D. Steele, “Superabsorbent polymer characteristics, properties, and applications,” Agrosyst., Geosci. Environ. 3, e20074 (2020). https://doi.org/10.1002/agg2.20074

P. N. Patel, Kh. G. Parmar, A. N. Nakum, M. N. Patel, P. R. Patel, V. R. Patel, and D. J. Sen, “Biodegradable polymers: an ecofriendly approach in newer millenium,” Asian J. Biomed. Pharm. Sci. 1 (3), 23–39 (2011).

F. Puoci, F. Iemma, U. G. Spizzirri, G. Cirillo, M. Curcio, and N. Picci, “Polymer in agriculture: a review,” Am. J. Agric. Biol. Sci. 3, 299–314 (2008). https://doi.org/10.3844/ajabssp.2008.299.314

M. K. Rai, S. D. Deshmukh, A. P. Ingle, and A. K. Gade, “Silver nanoparticles: the powerful nanoweapon against multidrug-resistant bacteria,” J. Appl. Microbiol. 112, 841–852 (2012). https://doi.org/10.1111/j.13652672.2012.05253.x

Biodegradation—Life of Science, Ed. by F. Rosenkranz and R. Chamy (Pontificial Catholic University of Valparaiso Publ., Chile, 2013). https://doi.org/10.5772/56222

A. Sannino, Ch. Demitri, and M. Madaghiele, “Biodegradable cellulose-based hydrogels: design and applications,” Materials 2, 353–373 (2009). https://doi.org/10.3390/ma2020353

S. A. Shahid, A. A. Qidwai, F. Anwar, I. Ullah, and U. Rashid, “Improvement in the water retention characteristics of sandy loam soil using a newly synthesized poly(acrylamide-co-acrylic acid)/AlZnFe2O4 superabsorbent hydrogel nanocomposite material,” Molecules 17, 9397–9412 (2012). https://doi.org/10.3390/molecules17089397

R. Shanker, C. Ramakrishna, and P. K. Seth, “Microbial degradation of acrylamide monomer,” Arch. Microbiol. 154, 192–198 (1990).

K. Schlich, Th. Klawonn, K. Terytze, and K. Hund-Rinke, “Effects of silver nanoparticles and silver nitrate in the earthworm reproduction test,” Environ. Toxicol. Chem. 32, 181–187 (2013). https://doi.org/10.1002/etc.2030

A. V. Smagin, N. B. Sadovnikova, and M. V. Smagina, “Biodestruction of strongly swelling polymer hydrogels and its effect on the water retention capacity of soils,” Eurasian Soil Sci. 47 (6), 591–597 (2014). https://doi.org/10.1134/S1064229314060088

A. V. Smagin, N. B. Sadovnikova, V. I. Vasenev, and M. V. Smagina, “Biodegradation of some organic materials in soils and soil constructions: experiments, modeling and prevention,” Materials 11, 1889 (2018). https://doi.org/10.3390/ma11101889

A. Smagin, N. Sadovnikova, and M. Smagina, “Synthetic gel structures in soils for sustainable potato farming,” Sci. Rep. 9, 8588 (2019). https://doi.org/10.1038/s41598-019-55205-8

A. V. Smagin, V. I. Budnikov, N. B. Sadovnikova, A. V. Kirichenko, E. A. Belyaeva, and V. N. Krivtsova, “Gel-forming soil conditioners of combined action: laboratory tests for functionality and stability,” Polymers 14, 4665 (2022). https://doi.org/10.3390/polym14214665

A. V. Smagin, N. B. Sadovnikova, E. A. Belyaeva, V. N. Krivtsova, S. A. Shoba, and M. V. Smagina, “Gel-forming soil conditioners of combined action: field trials in agriculture and urban landscaping,” Polymers 14, 5131 (2022). https://doi.org/10.3390/polym14235131

A. V. Smagin, N. B. Sadovnikova, and E. A. Belyaeva, “Hygroscopicity of gel-forming composite materials: thermodynamic assessment and technological significance,” J. Compos. Sci. 6, 269 (2022). https://doi.org/10.3390/jcs6090269

A. V. Smagin, N. B. Sadovnikova, and V. I. Budnikov, “Biodegradation of aqueous superabsorbents: kinetic assessment using biological oxygen demand analysis,” J. Compos. Sci. 7, 164 (2022). https://doi.org/10.3390/jcs7040164

R. E. Sojka and J. A. Entry, “Influence of polyacrylamide application to soil on movement of microorganisms in runoff water,” Environ. Pollut. 108, 405–412 (2000).

C. Turioni, G. Guerrini, A. Squartini, F. Morari, M. Maggini, and S. Gross, “Biodegradable hydrogels: evaluation of degradation as a function of synthesis parameters and environmental conditions,” Soil Syst. 5, 47 (2021). https://doi.org/10.3390/soilsystems5030047

D. Venkatachalam and S. Kaliappa, “Superabsorbent polymers: a state-of-art review on their classification, synthesis, physicochemical properties, and applications,” Rev. Chem. Eng. 39, 1–45 (2021). https://doi.org/10.1515/revce-2020-0102

B. Wilske, M. Bai, B. Lindenstruth, M. Bach, Z. Rezaie, H.-G. Frede, and L. Breuer, “Biodegradability of a polyacrylate superabsorbent in agricultural soil,” Environ. Sci. Pollut. Res. 21 (16), 9453–9460 (2014). https://doi.org/10.1007/s11356-013-2103-1

L. Wu, M. Liu, and R. L. Rui-Liang, “Preparation and properties of a double-coated slow-release NPK compound fertilizer with superabsorbent and water-retention,” Bioresour. Technol. 99, 547–554 (2008). https://doi.org/10.1016/j.biortech.2006.12.027

B. Xiong, R. D. Loss, D. Shields, T. Pawlik, R. Hochreiter, A. L. Zydney, and M. Kumar, “Polyacrylamide degradation and its implications in environmental systems,” Clean Water 1, 1–9 (2018). https://doi.org/10.1038/s41545-018-0016-8

Y. Xue, H. Xiao, and Y. Zhang, “Antimicrobial polymeric materials with quaternary ammonium and phosphonium salts,” Int. J. Mol. Sci. 16, 3626–3655 (2015). https://doi.org/10.3390/ijms16023626

L. Yang, Y. Yang, and Z. Chen, “Influence of super absorbent polymer on soil water retention, seed germination and plant survivals for rocky slopes eco-engineering,” Ecol. Eng. 62, 27–32 (2014). https://doi.org/10.1016/j.ecoleng.2013.10.019

L. Zhao, M. Bao, M. Yan, and J. Lu, “Kinetics and thermodynamics of biodegradation of hydrolyzed polyacrylamide under anaerobic and aerobic conditions,” Bioresour. Technol. 216, 95–104 (2016). https://doi.org/10.1016/j.biortech.2016.05.054

M. J. Zohuriaan-Mehr and K. Kabiri, “Superabsorbent polymer materials: a review,” Iran. Polym. J. 17, 451–477 (2008).

Funding

This work was supported by the Russian Science Foundation, interdisciplinary project no. 23-64-10002 (synthesis of hydrogels, their experimental studies on precision equipment, development of mathematical models and methodology for assessing biodegradation). The analysis of literature sources, statistical processes and comparative analysis of the results were supported by the Lomonosov Moscow State University, grant nos. 121040800146-3 and 122041900020-1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

CONFLICT OF INTEREST

The authors have no conflicts of interest to declare that are relevant to the content of this article.

CONSENT TO PARTICIPATE

Informed consent was obtained from all individual participants included in the study.

Additional information

Translated by V. Klyueva

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Smagin, A.V., Sadovnikova, N.B., Belyaeva, E.A. et al. Kinetic Assessment of the Biodegradability of Gel-Forming Soil Conditioners in Incubation Experiments with Instrumental Monitoring of Carbon Dioxide. Eurasian Soil Sc. 56, 1963–1977 (2023). https://doi.org/10.1134/S1064229323602056

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1064229323602056