Abstract

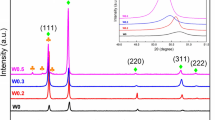

High-entropy alloys (HEAs) consisting of five or more components in an equimolar ratio are attracting increasing attention due to a unique combination of various properties. Doping HEAs with small amounts of certain elements (most often rare earth, trace or noble metals) is a promising way to improve the characteristics of such alloys and to control their properties. This paper reports the results on the microstructure, phase composition, and microhardness of as-cast AgxAl0.5CoCrCuyFeNi HEAs (x = 0, 0.1; y = 0.5, 1.0). The effect of silver addition on the oxidation behavior of the studied HEAs at 700°C was determined. The morphology, phase and chemical composition of the resulting oxide film were studied. It was shown that the introduction of silver improves the mechanical characteristics of the alloys, but deteriorates the oxidation resistance due to the formation of copper-silver eutectic in the alloy microstructure, leading to a change in the morphology and phase composition of the formed oxide layer. Along with the solid solution of (Al, Cr)2O3 oxides and CuCr2O4, NiCr2O4 spinels, the addition of silver leads to the formation of copper oxide CuO and a small amount of silver oxide Ag2O in the surface film.

Similar content being viewed by others

REFERENCES

Cantor, B., Chang, I.T.H., Knight, P., and Vincent, A.J.B., Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A. Struct., 2004, vol. 375–377, pp. 213–218. https://doi.org/10.1016/j.msea.2003.10.257

Yeh, J.W., Chen, S.K., Lin, S.J. Gan, J.Y., Chin, T.S., Shun, T.T., Tsau, C.H., and Chang, S.Y., Nanostructured HEAs with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, vol. 6, no. 5, pp. 299–303. https://doi.org/10.1002/adem.200300567

Li, Z., Pradeep, K.G., Deng, Y., Raabe, D., and Tasan, C.C., Metastable High-Entropy Dual-Phase Alloys Overcome the Strength-Ductility Trade-Off, Nature, 2016, vol. 534, pp. 227–230. https://doi.org/10.1038/nature17981

George, E.P., Curtin, W.A., and Tasan, C.C., High Entropy Alloys: A Focused Review of Mechanical Properties and Deformation Mechanisms, Acta Mater., 2020, vol. 188, pp. 435–474. https://doi.org/10.1016/j.actamat.2019.12.015

Seifi, M., Li, D., Yong, Z., Liaw, P.K., and Lewandowski, J.J., Fracture Toughness and Fatigue Crack Growth Behavior of As-Cast HEAs, JOM, 2015, vol. 67, pp. 2288–2295. https://doi.org/10.1007/s11837-015-1563-9

Hemphill, M.A., Yuan, T., Wang, G.Y., Yeh, J.W., Tsai, C.W., Chuang, A., and Liaw, P.K., Fatigue Behavior of Al0.5CoCrCuFeNi High Entropy Alloys, Acta Mater., 2012, vol. 60, pp. 5723–5734. https://doi.org/10.1016/j.actamat.2012.06.046

Kasar, A.K., Scalaro, K., and Menezes, P.L., Tribological Properties of HEAs under Dry Conditions for a Wide Temperature Range—A Review, Materials, 2021, vol. 14, p. 5814. https://doi.org/10.3390/ma14195814

Jin, B., Zhang, N., Yu, H., Hao, D., and Ma, Y., AlxCoCrFeNiSi High Entropy Alloy Coatings with High Microhardness and Improved Wear Resistance, Surf. Coat. Technol., 2020, vol. 402, p. 126328. https://doi.org/10.1016/j.surfcoat.2020.126328

Xiao, J.K., Wu, Y.Q., Chen, J., and Zhang, C., Microstructure and Tribological Properties of Plasma Sprayed FeCoNiCrSiAlx High Entropy Alloy Coatings, Wear, 2020, vol. 448–449, p. 203209. https://doi.org/10.1016/j.wear.2020.203209

Du, L.M., Lan, L.W., Zhu, S., Yang, H.J., Shi, X.H., Liaw, P.K., and Qiao, J.W., Effects of Temperature on the Tribological Behavior of Al0.25CoCrFeNi HEA, J. Mater. Sci. Technol., 2019, vol. 35, pp. 917–925. https://doi.org/10.1016/j.jmst.2018.11.023

Meghwal, A., Anupam, A., Murty, B.S., Berndt, C.C., Kottada, R.S., and Ang, A.S.M., Thermal Spray HEA Coatings: A Review, J. Therm. Spray Technol., 2020, vol. 29, pp. 857–893. https://doi.org/10.1007/s11666-020-01047-0

Liu, J., Liu, H., Chen, P., and Hao, J., Microstructural Characterization and Corrosion Behaviour of AlCoCrFeNiTix HEA Coatings Fabricated by Laser Cladding, Surf. Coat. Technol., 2019, vol. 361, pp. 63–74. https://doi.org/10.1016/j.surfcoat.2019.01.044

Samoilova, O.V., Yanshina, E.A., Ostovari Moghaddam, A., and Trofimov, E.A., Study of Corrosion Resistance of High Entropy Alloy Al0.5CoCrFeNi1.6Ti0.7 in Sea Water, Vestn. SUSU. Metallurgia, 2022, vol. 22, no. 1, pp. 33–41. https://doi.org/10.14529/met220104

Shi, Y., Yang, B., Xie, X., Brechtl, J., Dahmen, K.A., and Liaw, P.K., Corrosion of AlxCoCrFeNi HEAs: Al-Content and Potential Scan-Rate Dependent Pitting Behavior, Corr. Sci., 2017, vol. 119, pp. 33–45. https://doi.org/10.1016/j.corsci.2017.02.019

Shi, Y., Yang, B., and Liaw, P.K., Corrosion-Resistant HEAs: A Review, Metals, 2017, vol. 7, p. 43. https://doi.org/10.3390/met7020043

Kumar, P., Lam, T.-N., Tripathi, P.K., Singh, S.S., Liaw, P.K., and Huang, E.-W., Recent Progress in Oxidation Behavior of HEAs: A Review, APL Mater., 2022, vol. 10, p. 120701. https://doi.org/10.1063/5.0116605

Butler, T.M. and Weaver, M.L., Oxidation Behavior of Arc Melted AlCoCrFeNi Multi-Component HEAs, J. Alloys Compd, 2016, vol. 674, pp. 229–244. https://doi.org/10.1016/j.jallcom.2016.02.257

Jang, C., Lee, D., and Kim, D., Oxidation Behaviour of an Alloy 617 in Very High-Temperature Air and Helium Environments, Int. J. Pres. Ves. Pip., 2008, vol. 85, no. 6, pp. 368–377. https://doi.org/10.1016/j.ijpvp.2007.11.010

Yang, J.-J., Kuo, C.-M., Lin, P.-T., Liu, H.-C., Huang, C.-Y., Yen, H.-W., and Tsai, C.-W., Improvement in Oxidation Behavior of Al0.2Co1.5CrFeNi1.5Ti0.3 High-Entropy Superalloys by Minor Nb Addition, J. Alloys Compd, 2020, vol. 825, p. 153983. https://doi.org/10.1016/j.jallcom.2020.153983

Lu, J., Chen, Y., Zhang, H., Ni, N., Li, L., He, L., Mu, R., Zhao, X., and Guo, F., Y/Hf-Doped AlCoCrFeNi HEA with Ultra Oxidation and Spallation Resistance, Corros. Sci., 2020, vol. 166, p. 108426. https://doi.org/10.1016/j.corsci.2019.108426

Liu, Y.Y., Chen, Z., Chen, Y.Z., Shi, J.C., Wang, Z.Y., Wang, S., and Liu, F., Effect of Al Content on High Temperature Oxidation Resistance of AlxCoCrCuFeNi High Entropy Alloys (x = 0, 0.5, 1, 1.5, 2), Vacuum, 2019, vol. 169, p. 108837. https://doi.org/10.1016/j.vacuum.2019.108837

Daoud, H.M., Manzoni, A.M., Völkl, R., Wanderka, N., and Glatzel, U., Oxidation Behavior of Al8Co17Cr17Cu8Fe17Ni33, Al23Co15Cr23Cu8Fe15Ni15, and Al17Co17Cr17Cu17Fe17Ni17 Compositionally Complex Alloys (HEAs) at Elevated Temperatures in Air, Adv. Eng. Mater., 2015, vol. 17, no. 8, pp. 1134–1141. https://doi.org/10.1002/adem.201500179

Dąbrowa, J., Cieślak, G., Stygar, M., Mroczka, K., Berent, K., Kulik, T., and Danielewski, M., Influence of Cu Content on High Temperature Oxidation Behavior of AlCoCrCuxFeNi High Entropy Alloys (x = 0; 0.5; 1), Intermetallics, 2017, vol. 84, pp. 52–61. https://doi.org/10.1016/j.intermet.2016.12.015

Abbaszadeh, S., Pakseresht, A., Omidvar, H., and Shafiei, A., Investigation of the High-Temperature Oxidation Behavior of the Al0.5CoCrFeNi High Entropy Alloy, Surf. Interf., 2020, vol. 21, p. 100724. https://doi.org/10.1016/j.surfin.2020.100724

Hsu, U.S., Hung, U.D., Yeh, J.W., Chen, S.K., Huang, Y.S., and Yang, C.C., Alloying Behavior of Iron, Gold and Silver in AlCoCrCuNi-Based Equimolar HEAs, Mater. Sci. Eng. A, 2007, vol. 460–461, pp. 403–408. https://doi.org/10.1016/j.msea.2007.01.122

Klein, L., Zendegani, A., Palumbo, M., Fries, S.G., and Virtanen, S., First Approach for Thermodynamic Modelling of the High Temperature Oxidation Behaviour of Ternary γ′-Strengthened Co–Al–W Superalloys, Corros. Sci., 2014, vol. 89, pp. 1–5. https://doi.org/10.1016/j.corsci.2014.08.016

Shaburova, N.A., Ostovari Moghaddam, A., Veselkov, S.N., Sudarikov, M.V., Samoilova, O.V., and Trofimov, E.A., High-Temperature Oxidation Behavior of AlxCoCrFeNiM (M = Cu, Ti, V) HEAs, Phys. Mesomech., 2021, vol. 24, no. 6, pp. 653–662. https://doi.org/10.1134/S1029959921060035

McAIister, A.J., The Ag-Al (Silver-Aluminum) System, Bull. Alloy Phase Diagrams, 1987, vol. 8, no. 6, pp. 526–533. https://doi.org/10.1007/BF02879428

Karakaya, I. and Thompson, W.T., The Ag-Co (Silver-Cobalt) System, Bull. Alloy Phase Diagrams, 1986, vol. 7, no. 3, pp. 259–263. https://doi.org/10.1007/BF02869002

Venkatraman, M. and Neumann, J.P., The Ag-Cr (Silver-Chromium) System, Bull. Alloy Phase Diagrams, 1990, vol. 11, no. 3, pp. 263–265. https://doi.org/10.1007/BF03029296

Subramanian, P.R. and Perepezko, J.H., The Ag-Cu (Silver-Copper) System, J. Phase Equilib., 1993, vol. 14, no. 1, pp. 62–75. https://doi.org/10.1007/BF02652162

Swartzendruber, L.J., The Ag-Fe (Silver-Iron) System, Bull. Alloy Phase Diagrams, 1984, vol. 5, no. 6, pp. 560–564. https://doi.org/10.1007/BF02868316

Singleton, M. and Nash, P., The Ag-Ni (Silver-Nickel) System, J. Phase Equilib., 1987, vol. 8, no. 2, pp. 119–121. https://doi.org/10.1007/BF02873194

Swalin, R.A., Thermodynamics of Solids, New York: Wiley, 1972.

Ogura, M., Fukushima, T., Zeller, R., and Dederichs, P.H., Structure of the HEA AlxCrFeCoNi: FCC Versus BCC, J. Alloys Compd, 2017, vol. 715, pp. 454–459. https://doi.org/10.1016/j.jallcom.2017.04.318

Rogachev, A.S., Structure, Stability, and Properties of High-Entropy Alloys, PMM, 2020, vol. 121, no. 8, pp. 733–764.

Butler, T.M., Alfano, J.P., Martens, R.L., and Weaver, M.L., High-Temperature Oxidation Behavior of Al-Co-Cr-Ni-(Fe or Si) Multicomponent HEAs, JOM, 2015, vol. 16, no. 1, pp. 246–259. https://doi.org/10.1007/s11837-014-1185-7

Li, B.Y., Peng, K., Hu, A.P., Zhou, L.P., Zhu, J.J., and Li, D.Y., Structure and Properties of FeCoNiCrCu0.5Alx HEA, Trans. Nonferrous Met. Soc. China, 2013, vol. 23, pp. 735−741. https://doi.org/10.1016/S1003-6326(13)62523-6

Wang, Y., Yang, Y., Yang, H., Zhang, M., Ma, S., and Qiao, J., Microstructure and Wear Properties of Nitrided AlCoCrFeNi HEA, Mater. Chem. Phys., 2018, vol. 210, pp. 233–239. https://doi.org/10.1016/j.matchemphys.2017.05.029

Ostovari Moghaddam, A., Shaburova, N.A., Sudarikov, M.V., Veselkov, S.N., Samoilova, O.V., and Trofimov, E.A., High Temperature Oxidation Resistance of Al0.25CoCrFeNiMn and Al0.45CoCrFeNiSi0.45 High Entropy Alloys, Vacuum, 2021, vol. 192, p. 110412. https://doi.org/10.1016/j.vacuum.2021.110412

Samoilova, O.V., Shaburova, N.A., Sudarikov, M.V., and Trofimov, E.A., High-Temperature Oxidation Resistance of Al0.25CoCrFeNiSi0.6 High Entropy Alloy, Chern. Metall. Byull. Nauch. Tekhn. Econ. Inf., 2022, vol. 78, no. 11, pp. 978–986. https://doi.org/10.32339/0135-5910-2022-11-978-986

Holcomb, G.R., Tylczak, J., and Carney, C., Oxidation of CoCrFeMnNi High Entropy Alloys, JOM, 2015, vol. 67, pp. 2326–2339. https://doi.org/10.1007/s11837-015-1517-2

Elhelaly, M.A., ElZomor, M.A., Ahmed, M.H., and Youssef, A.O., Efect of Zirconium Addition on High-Temperature Cyclic Oxidation of Diffusion Chromo-Aluminized Ni-Base Superalloy, Oxid. Met., 2019, vol. 91, pp. 159–175. https://doi.org/10.1007/s11085-018-9871-4

Nechaev, A.V., Electrochemistry and Corrosion of Metals: Educational Textual Electronic Edition, Yekaterinburg: UrFU, 2014.

Wang, W.-R., Wang, W.-L., and Yeh, J.-W., Phases, Microstructure and Mechanical Properties of AlxCoCrFeNi HEAs at Elevated Temperatures, J. Alloys Compd, 2014, vol. 589, pp. 143–152. https://doi.org/10.1016/j.jallcom.2013.11.084

Funding

The study was supported by the Russian Science Foundation, project no. 23-23-00107, https://rscf.ru/en/project/23-23-00107/.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher's Note. Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Samoilova, O.V., Pratskova, S.E., Sudarikov, M.V. et al. Effect of Silver Addition on Microstructure, Phase Composition, Microhardness and Surface Oxide Layer Formation of Al0.5CoCrCu0.5FeNi and Al0.5CoCrCuFeNi High-Entropy Alloys. Phys Mesomech 27, 183–196 (2024). https://doi.org/10.1134/S1029959924020073

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959924020073