Abstract

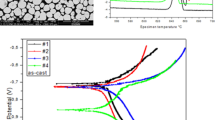

Effects of niobium content on the microstructure and corrosion were investigated on various Al‒x% Nb alloys (x: 10, 20, 25, 30, 40, and 50 wt %) prepared by high-frequency electromagnetic fusion melting and solidification at room temperature. Microstructural characterization was carried out by X-ray diffraction (XRD), differential scanning calorimetry (DSC), Vickers microhardness, and scanning electron microscopy (SEM). Electrochemical tests in 3.5 wt % NaCl solution, via potentiodynamic polarization curves and impedance spectroscopy (EIS) was accomplished on both as-cast and annealed alloys. All of the results highlight the role played by the intermetallic trialuminide compound Al3Nb dispersed within the matrix consisting of α-Al solid solution. The volume fraction of the Al3Nb intermetallic phase controls the mechanical properties through the microhardness acting as reinforcement of the α-Al matrix in the manner of a composite material. It also acts as a precaution against corrosion by the pitting of aluminum. This effect naturally varies according to the niobium content and the distribution of the intermetallic phase.

Similar content being viewed by others

REFERENCES

Audebert, F., Galano, M., and Saporiti, F., The use of Nb in rapid solidified Al alloys and composites, J. Alloys Compd., 2014, vol. 615, p. 621.

Schwarz, H.G., Briem, S., and Zapp, P., Future carbon dioxide emissions in the global material flow of primary aluminium, Energy, 2001, vol. 26, p. 775.

Hirsch, J., Aluminium in innovative light-weight car design, Mater. Trans., 2011, vol. 52, p. 818.

Toros, S., Ozturk, F., and Kacar, I., Review of warm forming of aluminum–magnesium alloys, J. Mater. Process. Technol., 2008, vol. 207, p. 1.

Yasakau, K.A., Zheludkevich, M.L., and Ferreira, M.G.S., Role of intermetallics in corrosion of aluminum alloys. Smart corrosion protection, in Intermetallic Matrix Composites, Mitra, R., Ed., Woodhead Publ., 2018, p. 425.

Ujah, C.O., Popoola, A.P.I., Popoola, O.M., and Aigbodion, V.S., Electrical conductivity, mechanical strength and corrosion characteristics of spark plasma sintered Al–Nb nanocomposite, Int. J. Adv. Manufact. Technol., 2019, vol. 101, p. 2275.

Pramod, S.L., Bakshi, S.R., and Murty, B.S., Aluminum-based cast in situ composites: a review, J. Mater. Eng. Perform., 2015, vol. 24, p. 2185.

Di Franco, F., Santamaria, M., Di Quarto, F., La Mantia, F., de Sá, A.I., and Rangel, C.M., Dielectric properties of Al–Nb amorphous mixed oxides, ECS J. Solid State Sci. Technol., 2013, vol. 2, p. 205.

Saidman, S.B., Garcia, S.G., and Bessone, J.B., Electrochemical behaviour of Al–In alloys in chloride solutions, J. Appl. Electrochem., 1995, vol. 25, p. 252.

Salinas, D.R., Influence of alloying elements and microstructure on aluminium sacrificial anode performance: case of Al±Zn, J. Appl. Electrochem., 1999, vol. 29, p. 1063.

Shayeb, H.A.E., Effect of gallium ions on the electrochemical behaviour of Al, Al±Sn, Al±Zn and Al±Zn±Sn alloys in chloride solutions, Corros. Sci., 2001, vol. 43, p. 643.

Gudić, S., Smoljko, I., and Kliškić, M., Electrochemical behaviour of aluminium alloys containing indium and tin in NaCl solution, Mater. Chem. Phys., 2010, vol. 121, p. 561.

Shibli, S.M.A., Jabeera, B., and Manu, R., Development of high performance aluminium alloy sacrificial anodes reinforced with metal oxides, Mater. Lett., 2007, vol. 61, p. 3000.

Mostaan, H., Karimzadeh F., and Abbasi, M.H., Thermodynamic analysis of nanocrystalline and amorphous phase formation in Nb–Al system during mechanical alloying, Powder Metall., 2012, vol. 55, p. 142.

Gauthier, V., Bernard, F., Gaffet, E., Vrel, D., Gailhanou, M., and Larpin, J.P., Investigations of the formation mechanism of nanostructured NbAl3 via MASHS reaction, Intermetallics, 2002, vol. 10, p. 377.

Almeida, A., Petrov, P., Nogueir I., and Vilar, R., Structure and properties of Al–Nb alloys produced by laser surface alloying, Mater. Sci. Eng. A, 2001, vol. 303, p. 273.

Vilar, R., Conde, O., and Franco, S., Crystallographic structure of Al3Nb in laser-processed Al–Nb alloys, Intermetallics, 1999, vol. 7, p. 1227.

Baumann, J.R., Liebemann, E.K., Simon, M., and Bucher, E., Growth, structural study, and thermal stability of metallic Al/Nb superlattices, Phys. Rev. B, 1992, vol. 45, p. 3778.

Wang, N., Chao, D., Hou, J., Zhang, Y., Huang, K., Jiao, S., and Zhu, H., Direct synthesis of Nb–Al intermetallic nanoparticles by sodiothermic homogeneous reduction in molten salts, Intermetallics, 2013, vol. 43, p. 45.

Miao, W., Tao, K., Liu, B.X., and Li, B., Formation of NbAl3 by Nb ion implantation using metal vapor vacuum arc ion source, Nucl. Instrum. Methods Phys. Res. Sect. B: Beam Interact. Mater. Atoms, 2000, vol. 160, p. 343.

Santamaria, M., Di Franco, F., Di Quarto, F., Skeldon, P., and Thompson, G.E., Tailoring of the solid state properties of Al–Nb mixed oxides: a photoelectrochemical study, J. Phys. Chem. C, 2013, vol. 117, p. 4201.

De Sá, A.I., Rangel, C.M., Smith, C.J.E., Skeldon, P., and Thompson, G.E., Growth of anodic oxides on sputtered Al–Nb alloys, Key Eng. Mater., 2002, vol. 230, p. 44.

Wang, F., Liang, Y.F., Shang, S.L., Liu, Z.K., and Lin, J.P., Nb–Al diffusion reaction in high Nb containing TiAl porous alloys, Mater. Sci. Technol., 2015, vol. 31, p. 1388.

Peng, L.M., Synthesis and mechanical properties of niobium aluminide-based composites, Mater. Sci. Eng. A, 2008, vol. 480, p. 232.

De Lazzari, C.P., Danielle Goya Simões, D., and Trani Capocchi, J.D., Study of the aluminothermic reduction of niobium pentoxide through thermal analysis experiments and high energy milling processing, Mater. Res., 2007, vol. 10, p. 215.

Yeh, C.L. and Wang, H.J., Effects of sample stoichiometry of thermite-based SHS reactions on formation of Nb–Al intermetallics, J. Alloys Compd., 2009, vol. 485, p. 280.

Sina, H. and Iyengar, S., Studies on the formation of aluminides in heated Nb–Al powder mixtures, J. Alloys Compd., 2015, vol. 628, p. 19.

Fleischer, R.L., Field, R.D., Denike, K.K., and Zabala, R.J., Mechanical properties of alloys of IrNb and other high-temperature intermetallic compounds, Metallurg. Trans. A, 1990, vol. 21, p. 306.

Jiao, Z., Li, C., Bai, Y., Zhang, M., Liu, Q., Ling, X., Gong, Y., Liu, F., and Liu, Z., A comparative study of NbAl3 and Nb3Al itermetallic compounds under pressure, Comput. Mater. Sci., 2017, vol. 126, p. 280.

Khireche, S., Boughrara, D., Kadri, A., Hamadou L., and Benbrahim, N., Corrosion mechanism of Al, Al–Zn and Al–Zn–Sn alloys in 3 wt % NaCl solution, Corros. Sci., 2014, vol. 87, p. 504.

Gupta, R.K., Fabijanic, D., Zhang, R., and Birbilis, N., Corrosion behaviour and hardness of in situ consolidated nanostructured Al and Al–Cr alloys produced via high-energy ball milling, Corros. Sci., 2015, vol. 98, p. 643.

Oladijo, O.P., Obadele, B.A., Venter, A.M., and Cornish, L.A., Investigating the effect of porosity on corrosion resistance and hardness of WC–Co coatings on metal substrates, Afr. Corros. J., 2016, vol. 2, p. 37.

Decheng, K., Chaofang, D., Xiaoqing, N., Liang, Z., Cheng, M., Jizheng, Y., Yucheng, J., Yupeng, Y., Kui, X., Xuequn, C., and Xiaogang, Li, High-throughput fabrication of nickel-based alloys with different Nb contents via a dual-feed additive manufacturing system: effect of Nb content on microstructural and mechanical properties, J. Alloys Compd., 2019, vol. 785, p. 826.

Okamoto, H., Supplemental literature review of binary phase diagrams: Ag–Nd, Ag–Zr, Al–Nb, B–Re, B–Si, In–Pt, Ir–Y, Na–Si, Na–Zn, Nb–P, Nd–Pt, and Th–Zr, J. Phase Equilib. Diffus., 2014, vol. 35, p. 636.

Witusiewicz, V.T., Bondar, A.A., Hecht, U., Rex, S., and Velikanova, T.Y., The Al–B–Nb–Ti system: III. Thermodynamic re-evaluation of the constituent binary system Al–Ti, J. Alloys Compd., 2008, vol. 465, p. 64.

He, C., Stein, F., and Palm, M., Thermodynamic description of the systems Co–Nb, Al–Nb and Co–Al–Nb, J. Alloys Compd., 2015, vol. 637, p. 36.

Carvalho Coelho, G., Angelo Nunes, C., Fiorani, J.M., David, N., and Vilasi, M., Mat. Res., 2019, vol. 22, p. 1.

Jorda, J.L., lükiger, R.F., and Muller, J., A New metallurgical investigation of the niobium–aluminium system, J. Less Common. Met., 1980, vol. 75, p. 227.

Ribaud, G., La théorie du chauffage par courants induits de haute fréquence, J. Phys. Radium, 1932, vol. 3, p. 537.

Souilah, Y., Boutouta, A., Boulkhessaim, S., Bedboudi, H., Bourbia, A., and Draissia, M., Correlation of hardness and corrosion characteristics with crystalline structures of Al–Mg alloys, Phys. Scr., 2013, vol. 88, p. 06560.

Knipling, K.E., Dunand, D.C., and Seidman, D.N., Criteria for developing castable, creep-resistant aluminum-based alloys—a review, Z. Metallkd., 2006, vol. 97, no. 3, p. 246.

George, E., Totten, D., and MacKenzie, S., Handbook of Aluminum, vol. 2: Alloy Production and Materials Manufacturing, CRC Press, 2003, p. 736

Prach, O., Trudonoshyn, O., and Puchnin, M., Effects of chemical composition on mechanical properties of Al–Mg–Si–Mn based alloys materials engineering, Mater. Inž., 2017, vol. 24, p. 11.

Car, T., Radić, N., Panjan, P., and Tonejc, A., Mehanical properties of Al–(Nb, Mo, Ta, W) thin films, Strojarstvo, 2011, vol. 53, p. 429.

Osório, W.R., Freire, C.M., and Garcia, A., The effect of the dendritic microstructure on the corrosion resistance of Zn–Al alloys, J. Alloys Compd., 2005, vol. 397, p. 179.

Osório, W.R., Santos, C.A., Quaresma, J.M.V., and Garcia, A., Mechanical properties as a function of thermal parameters and microstructure of Zn–Al castings, J. Mater. Process. Technol., 2003, vol. 143-144, p. 703.

Donelan, P., Modelling microstructural and mechanical properties of ferritic ductile cast iron, Mater. Sci. Technol., 2000, vol. 16, p. 261.

Quaresma, J.M.V., Santos, C.A., and Garcia, A., Correlation between unsteady-state solidification conditions, dendrite spacings, and mechanical properties of Al–Cu alloys, Metall. Mater. Trans. A, 2000, vol. 31, p. 3167.

Khun, N.W. and Liu, E., Effect of substrate temperature on corrosion performance of nitrogen doped amorphous carbon thin films in NaCl solution, Thin Solid Films, 2009, vol. 517, p. 4762.

Benzarouk, H., Drici, A., Mekhnache, M., Amara, A., Guerioune, M., Bernède, J.C., and Bendjffal, H., Effect of different dopant elements (Al, Mg, and Ni) on microstructural, optical and electrochemical properties of ZnO thin films deposited by spray pyrolysis (SP), Superlattices Microstruct., 2012, vol. 52, p. 594.

Enos, D.G., The potentiodynamic polarization scan, Tech. Rep. no. 33, Center for Electrochemical Science & Engineering. Department of Materials, 1997.

Wong, L.L., Martin, S.I., and Rebak, R.B., Methods to calculate corrosion rates for alloy from polarization resistance experiments, Proc. ASME 2006 Pressure Vessels and Piping/ICPVT-11 Conf., Vancouver, 2006.

Shi, Y.Z., Yang, B., Xie, X., Brechtl, J., Dahmen, K.A., and Liaw, P.K., Corrosion of AlxCoCrFeNi high-entropy alloys: Al content and potential scan-rate dependent pitting behavior, Corros. Sci., 2017, vol. 33, p. 119.

Singh, D., Dhayal, V., and Chandra, D.A., Corrosion performance of nano-alumina coatings over anodized aluminum alloy by dip coating method, Surf. Eng. Appl. Electrochem., 2019, vol. 55, p. 436.

Toloei, A. and Stoilov, V.D., Northwood Proc. ASME 2013 Int. Mechanical Engineering Congress & Exposition IMECE2013, San Diego, CA, Nov. 13–21, 2013.

Chen, Y. and Jepson, W.P., EIS measurement for corrosion monitoring under multiphase flow conditions, Electrochim. Acta, 1999, vol. 44, no. 24, p. 4453.

Prakashaiah, B.G., Vinaya Kumara, D., Anup Pandith, A., Nityananda Shetty, A., and Amitha Rani, B.E., Corrosion inhibition of 2024-T3 aluminum alloy in 3.5% NaCl by thiosemicarbazone derivatives, Corros. Sci., 2018, vol. 136, p. 326.

Arthanari, S., Jang, J.C., and Shin, K.S., Corrosion performance of high pressure die-cast Al–Si–Mg–Zn alloys in 3.5 wt % NaCl solution, J. Alloys Compd., 2019, vol. 783, p. 494.

Song, G.L. and Liu, M., Corrosion and electrochemical evaluation of an Al–Si–Cu aluminum alloy in ethanol solutions, Corros. Sci., 2013, vol. 72, p. 73.

Wen, J., Cui, H., Wei Na, Song, X., Zhang, G., Wang, C., and Song, Q., Effect of phase composition and microstructure on the corrosion resistance of Ni–Al intermetallic compounds, J. Alloys Compd., 2017, vol. 695, p. 2424.

Gupta, R.K., Murty, B.S., and Birbilis, N., Corrosion behaviour of high-energy ball milled, anocrystalline Al alloys, in An Overview of High-Energy Ball Milled Nanocrystalline Aluminum Alloys, Cham: Springer Int. Publ., 2017.

Kharitonov, D.S., Sommertunec, J., Örneka, C., Ryld, J., Kuriloe, I., Claessona, P.M., and Pana, J., Corrosion inhibition of aluminum alloy AA6063-T5 by vanadates: microstructure characterization and corrosion analysis, J. Electrochem. Soc., 2018, vol. 165, p. 116.

ACKNOWLEDGMENTS

This work was carried out with the help of the Directorate General of Scientific Research and Technological Development DGRSDT. The authors are grateful to researchers at the ENSMM Annaba for SEM observations and Digital surf MountainlabPremium8 Software Company.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Authors announce that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Layachi, F., Debili, M.Y. & Bedboudi, H. Structure and Corrosion Behaviour of Al–Nb Alloys. Russ J Electrochem 58, 360–380 (2022). https://doi.org/10.1134/S1023193522050081

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193522050081