Abstract

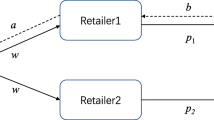

A closed-loop supply chain includes the forward supply chain and the reverse supply chain. In a reverse supply chain, the used products are collected from the end-customers. Hence, the return rate of used products is affected by the end-customer's willingness, and the end-customer's willingness is affected by the collecting price. In a forward supply chain, the wholesale price and the retail price will be affected by the collecting price. In this paper, we focus on the managements of the collecting price, the wholesale price and the retail price for the closed-loop supply chain. On the assumption that the return rate of the used products is an increasing function of the collecting price, we obtain the optimal collecting price, the optimal wholesale price and the optimal retail price based on the following models: Model CMRC (The manufacturer for collecting), Model CRMRC (The retailer for collecting) and Model CTMRC (The third party for collecting). By comparing the optimal pricing and the profits of the models, we find that the manufacturer for collecting is the best choice, and the retailer for collecting is another choice if the manufacturer has decided to transfer all its cost saving to the retailer. At the end of the paper, a numerical example is given to illustrate the optimal results.

Similar content being viewed by others

References

Coates, J. F. (2000) ‘Manufacturing in the 21 century’, International Journal of Manufacturing Technology and Management, 1, 1, 42–59.

Dennis, W. K. and Sheu, C. (2002) ‘A model for reverse logistics entry by third-party providers’, Omega, 30, 5, 325–333.

Daniel, V., Guide Jr, R. and Van Wasssenhove, L. N. (2002) ‘The reverse supply chain’, Harvard Business Review, 80, 2, 25–26.

Donohue, K. (2000) ‘Efficient supply contracts for fashion goods with forecast updating and two production modes’, Management Science, 46, 11, 1397–1411.

Emmons, H. and Gilbert, S. (1998) ‘The role of return policies in pricing and inventory decisions for catalogue goods’, Management Science, 44, 2, 276–283.

Fleischmann, M., Bloemhof-Ruwaard, J., Dekker, R., van der Laan, E., van Nunen, J. and Van Wassenhove, L. (1997) ‘Quantitative models for reverse logistics: a review’, European Journal of Operational Research, 103, 1, 1–17.

Gu, Q. L., Gao, T. G. and Shi, L. S. (2005) ‘Price decision analysis for reverse supply chain based on game theory’, Systems Engineering — Theory & Practice, 25, 3, 20–25 (in Chinese).

Gu, Q. L. and Ji, J. H. (2005) ‘Research on price decision for reverse supply chain based on fixed lowest quantitative demand’, Computer Integrated Manufacturing Systems, 11, 12, 1751–1757 (in Chinese).

Gu, Q. L. and Ji, J. H. (2006) ‘Research on the stochastic optimal control of inventory integrating remanufacturing and manufacturing system for the market’, Systems Engineering — Theory & Practice, 26, 1, 53–59 (in Chinese).

Hu, T. -L., Sheu, J. B. and Huang, K. H. (2002) ‘A reverse logistics cost minimization model for the treatment of hazardous wastes’, Transportation Research Part E, 38, 6, 457–473.

Inderfurth, K. (2004) ‘Optimal policies in hybrid manufacturing/remanufacturing systems with product substitution’, International Journal of Production Economics, 90, 3, 325–343.

Jahre, M. (1995) ‘Household waste collection as a reverse logistics channel: a theoretical perspective’, International Journal of Physical Distribution and Logistics Management, 25, 2, 39–55.

Johnson, M. R. and Wang, M. H. (1995) ‘Planning product disassembly for material recovery opportunities’, International Journal of Production Research, 33, 11, 3119–3142.

Kroon, L. and Vrijens, G. (1995) ‘Returnable containers: an example of reverse logistics’, International Journal of Physical Distribution and Logistics Management, 25, 2, 56–68.

KiesmÄuller, G. P. (2003) ‘A new approach for controlling a hybrid stochastic manufacturing/remanufacturing system with inventories and different lead times’, European Journal of Operational Research, 147, 2, 62–71.

Lund, R. (1996) ‘The Remanufacturing Industry: Hidden Giant’, Research Report, Manufacturing Engineering Department, Boston University, Boston.

Mabini, M. C. and Gelders, L. F. (1991) ‘Repairable item inventory system: a literature review’, Belgian Journal of Operations Research, Statistics and Computer Science, 30, 4, 57–69.

Nagurney, A. and Toyasaki, F. (2005) ‘Reverse supply chain management and electronic waste recycling: a multitiered network equilibrium framework for e-cycling’, Transportation Research Part E, 41, 1, 1–28.

Padmanabhan, V. and Png, I. P. L. (1997) ‘Manufacturer's return policies and retail competition’, Marketing Science, 16, 1, 81–94.

Pasternack, B. A. (1985) ‘Optimal pricing policies for perishable commodities’, Marketing Science, 4, 2, 166–176.

Pohlen, T. L. and Farris II, M. T. (1992) ‘Reverse logistics in plastics recycling’, International Journal of Physical Distribution and Logistics Management, 22, 7, 35–47.

Savaskan, R. C., Bhattacharya, S. and Van Wassenhove, L. N. (2004) ‘Closed-loop supply chain models with product remanufacturing’, Management science, 50, 2, 239–252.

Sheu, J. B., Chou, Y. H. and Hu, C. C. (2005) ‘An integrated logistics operational model for green-supply chain management’, Transportation Research Part E, 41, 4, 287–313.

Schrady, D. A. (1967) ‘A deterministic inventory model for repairable items’, Naval Research Logistics Quarterly, 14, 3, 391–398.

Shih, L. -H. (2001) ‘Reverse logistics system planning for recycling electrical appliances and computers in Taiwan’, Resources, Conservation and Recycling, 32, 1, 55–72.

Tang, O. and Grubbström, R. W. (2005) ‘Considering stochastic lead times in a manufacturing/remanufacturing system with deterministic demands and returns’, International Journal of Production Economics, 93–94, 1, 285–300.

Van der Laan, E. A. and Salomon, M. (1997) ‘Production planning and inventory control with remanufacturing and disposal’, European Journal of Operational Research, 102, 2, 264–278.

Van der Laan, E. A., Salomon, M. and Dekker, R. (1999a) ‘Lead-time effects in PUSH and PULL controlled manufacturing/remanufacturing systems’, European Journal of Operational Research, 115, 1, 195–214.

Van der Laan, E. A., Salomon, M., Dekker, R. and van Wassenhove, L. N. (1999b) ‘Inventory control in hybrid systems with remanufacturing’, Management Science, 45, 5, 733–747.

White, C. D., Masanet, E., Rosen, C. M. and Beckman, S. L. (2003) ‘Product recovery with some byte: an overview of management challenges and environmental consequences in reverse manufacturing for the computer industry’, Journal of Cleaner Production, 11, 4, 445–458.

Acknowledgements

The authors would like to thank the referees for the constructive suggestions, which have led the authors to consider more deeply the motivation, modelling and implications of the model. This work was supported by the Ministry of Education Project of Humanities and Social Sciences of China under Grant No. 02JAZ790007 and China Postdoctoral Science Foundation under Grant No. 20060390626.

Author information

Authors and Affiliations

Corresponding author

Additional information

1 Gu Qiaolun is a postdoctor at Antai College of Economics & Management, Shanghai Jiaotong University. She received the BE degree in Mathematics and Applied Mathematics from Hebei Teacher's University in 1989, the ME degree in Mathemuties and Applied Mathematics from Hebei University of Technology in 1992, and the PhD degree in Control Theory and Control Engineering from Nankai University in 2005, China. Since November 2006, she has been a Professor at Computer Department, Tianjin University of Technology and Education, China. Her research interests are in the areas of operations management, logistics and supply chain management.

2 Ji Jianhua is professor, Doctorate supervisor, Secretary of Chinese Communist Party and Director of Logistics Research Introduction of Shanghai Jiaotong University, Professor JI also serve as China logistics expert granted by CFLP, logistics planning expert of China 11th five-year technology plan, member of operation management committee of China management modern research institute, journal reviewer of some important academic journals such as ‘Systems Engineering — Theory & Practice’, ‘Journal of Tianjin University’, etc, and professional expert of Council of Supply Chain Management Professionals (CSCMP). Her research interests are in the areas of operations management, logistics and supply chain management, and mass customisation.

3 Gao Tiegang born in 1966, received BE and ME degrees in Mathematics and Applied Mathematics from Hebei Teacher's University and Huazhong University of Science and Technology, Chjian, in 1988 and 1990, respectively, and the PhD degree in Control Theory and Control Engineering from Nankai University, China, in 2005. Since July 2004, he has been working in College of Software, Nankai University, China. He is currently a professor, whose main research interests are nonlinear system, chaos theory and information security. He has authored/coauthored more than 40 journal papers in these areas.

Appendix

Appendix

Proof of Proposition 5

-

We divide the proof into two parts:

(i) To prove that ω*CMRC<ω*CTMRC

Note that,

ω*CTMRC is an increasing function of b when b>[k(cm−crm)+c]/k+1, which is true by ∂ω*CTMRC/∂b>0, ω*CTMRC is an decreasing function of b when b<k(cm−crm)+c/k+1, which is true by ∂ω*CTMRC/∂b<0, and ω*CTMRC takes its minimum value (we note that Minω*CTMRC) at the point of b=[k(cm−crm)+c]/(k+1) and Minω*CTMRC=(φ+βcm)/(2β)−[γkk(cm−crm−c)k+1/(2(k+1)k+1)]× (k/(k+1))k.

To prove that ω*CMRC<ω*CTMRC, we have to show

which holds by 0<k<1. Hence, ω*CMRC<ω*CTMRC.

(ii) To prove that ω*CTMRC<ω*CRMRC

The proof of ω*CTMRC<ω*CRMRC can be easily observed from Table 1.

Proof of Proposition 6

-

We divide the proof into two parts:

(i) To prove that p*CMRC⩽p*CRMRC, we have to show that

We note,

In order to prove γkk(cm−crm−c)k+1/(4(k+1)k+1) ⩾[(cm−crm−b)/4+(b−c)/(4(k+1))]×γkk(b−c)k/(k+1)k, we have to show that Δ(b) is an increasing function of b and the max value of Δ(b) is γkk(cm−crm−c)k+1/(4(k+1)k+1). The former holds by ∂Δ(b)/∂b=[γkk(b−c)k+1/(4(k+1)k+1)(k+1)(cm−crm−b)>0, and the latter is true by 0<b<(cm−crm) and Δ(cm−crm)=γkk(cm−crm−c)k+1/4(k+1)k+1. Hence, p*CMRC⩽p*CRMRC.

(ii) To prove that p*CRMRC<p*CTMRC

The proof of p*CRMRC<p*CTMRC can be easily observed from Table 1.

Because the ordering for the retail price p* holds, the ordering for the demands of the channels follows trivially.

Proof of Proposition 7

-

We divide the proof into three parts:

(i) The proof of ΠM*CMRC⩾ΠM*CRMRC>ΠM*CTMRC

From the proof of p*CMRC⩽p*CRMRC<p*CTMRC, we can obtain

Note that β>0; we can show

and

Hence, ΠM*CMRC⩾ΠM*CRMRC>ΠM*CTMRC.

(ii) The proof of ΠR*CMRC⩾ΠR*CRMRC>ΠR*CTMRC

In a manner similar to that in the proof of ΠM*CMRC⩾ΠM*CRMRC>ΠM*CTMRC, we can easily prove that ΠR*CMRC⩾ΠR*CRMRC>ΠR*CTMRC.

(iii) The proof of Π*CMRC⩾Π*CRMRC>Π*CTMRC

Obviously, Π*CMRC⩾Π*CRMRC holds by ΠM*CMRC⩾ΠM*CRMRC, ΠR*CMRC⩾ΠR*CRMRC, Π*CMRC=ΠM*CMRC+ΠR*CMRC, and Π*CRMRC=ΠM*CRMRC+ΠR*CRMRC.

Easily, Π*CRMRC>ΠR*CTMRC is true by

Hence, ΠM*CMRC⩾ΠM*CRMRC>ΠM*CTMRC.

Rights and permissions

About this article

Cite this article

Qiaolun, G., Jianhua, J. & Tiegang, G. Pricing management for a closed-loop supply chain. J Revenue Pricing Manag 7, 45–60 (2008). https://doi.org/10.1057/palgrave.rpm.5160122

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1057/palgrave.rpm.5160122