Abstract

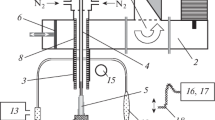

The effects of process parameters on diamond film deposition have been considered in an atmospheric-pressure dc thermal plasma jet reactor. Two different precursor injection systems have been evaluated, counterflow and side injection. The precursor flow rate using ethanol has been found to strongly affect crystal size as well as orientation of crystal growth planes. Further, crystal size on sharp edges has been found to be up to five times larger than on planar surfaces. The effects of substrate geometry on the morphology and area of deposited diamond have been investigated as well. The results of this study show that dc thermal plasma jets can provide high diamond deposition rates, for example on wires and drills, although crystal size and film thickness show substantial variation.

Similar content being viewed by others

REFERENCES

Z. P. Lu, J. Heberlein, and E. Pfender, Plasma Chem. Plasma Process. 12, 35 (1992).

M. Kawarada, K. Kurihara, K. Sasaki, A. Teshima, and K. Koshimo, Proc. Soc. Photo. Opt. Instrum. Eng. 1146, 28 (1989).

E. Pfender, Q. Y. Han, T. W. Or, Z. P. Lu, and J. Heberlein, Diamond Relat. Mater. 1, 127 (1992).

R. L. Woodin, 4th Annual Diamond Technology Workshop, Wisconsin (1993).

M. H. Loh and M. A. Cappeli, Proc. 3rd Int. Symp. on Diamond Materials, (J. P. Dismukes and K. V. Ravi, eds.), The Electrochemical Society, Inc., New Jersey (1993), p. 17.

S. Matsumoto, M. Hino, and T. Kobayashi, Appl. Phys. Lett. 51, 737 (1987).

L. Bardos, S. Berg, T. Nyberg, H. Barankova, and C. Nender, Diamond Relat. Mater. 2, 517 (1993)

K. Suzuki, A. Sawabe, and T. Inuzuka, Jpn. J. Appl. Phys. 29, 153 (1990).

K. R. Stalder and R. L. Sharpless, J. Appl. Phys. 68, 6187 (1990).

M. Asmann, Master Thesis, University of Minnesota (1996).

A. Gicquel, C. Heau, D. Fabre, and J. Perriere, Diamond Related Mater. 1, 776 (1992).

P. Bou, L. Vandenbulcke, and R. Herbin, Diamond Relat. Mater. 1, 933 (1992).

D. G. Goodwin, Appl. Phys. Lett. 59, 277 (1991).

L. K. Bigelow, N. M. Henderson, and R. L. Woodin, Proc. 2nd Int. Conf. New Diamond Sci. Technol. (R. Messier and J. T. Glass, eds.), Materials Research Soc., Pittsburg, (1991), p. 251.

F. M. Creio and W. A. Weimer, Rev. Sci. Instrum. 63, 2065 (1992).

M. E. Coltrin and D. S. Dandy, J. Appl. Phys. 74, 5803 (1993).

B. W. Yu and S. L. Girshick, J. Appl. Phys. 75, 3914 (1994).

D. Kolman, J. Heberlein, E. Pfender, and R. Young, Plasma Chem. Plasma Process. 16, 575 (1996).

F. M. White, Viscous Fluid Flow, McGraw-Hill, New York (1974).

B. S. Massey, Mechanics of Fluids, 5th edition, Van Nostrand Reinhold, England (1983).

P. Bou, J. C. Boettner, and L. Vandelbulcke, Jpn. Appl. Phys. 31, 1505 (1992).

W. L. Hsu, Appl. Phys. Lett. 59, 1427 (1991).

J. A. Mucha, D. L. Flamm, and D. E. Ibbotson, J. Appl. Phys. 65, 3448 (1989).

L. S. Schafer, U. Bringman, C. P. Klages, U. Meier, and K. Kohse-Hoinghaus, Proc. of the NATO Advanced Study Institute on Diamond and Diamond-like Films and Coatings (R. E. Clausing, L. L. Horton, J. C. Angus, and P. Koidl, eds.), NATO ASI Series B: Physics Vol. 266, New York (1991), p. 643.

F. C. Celii, P. Pehrsson, H. T. Wang, and J. E. Butler, Appl. Phys. Lett. 52, 2043 (1988).

Wei Zhu and B. Stoner, Proc. IEE 79, 621 (1991).

S. L. Girshick, C. Li, B. W. Yu, and H. Han, Plasma Chem. Plasma Process. 13, 169 (1993).

A Van der Drift, Philips Res. Rep. 2, 267 (1967).

V. J. Trava-Airoldi, E. J. Corat, A. F. V. Pena, N. F. Leite, V. Baranauskas, and M. C. Salvadori, Diamond Relat. Mater. 4, 1255 (1995).

D. Kolman, J. Heberlein, and E. Pfender, Plasma Chem. Plasma Process., 18, 73 (1998).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Borges, C.F.M., Asmann, M., Pfender, E. et al. Diamond Deposition on Substrates with Different Geometries in a Thermal Plasma Reactor. Plasma Chemistry and Plasma Processing 18, 305–324 (1998). https://doi.org/10.1023/A:1021610801931

Issue Date:

DOI: https://doi.org/10.1023/A:1021610801931